A simulation of the effect of Nb-rich carbonitride on the structure and properties of weld HAZ of 22Cr15Ni3.5CuNbN austenitic steel

-

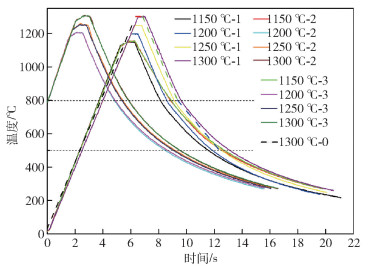

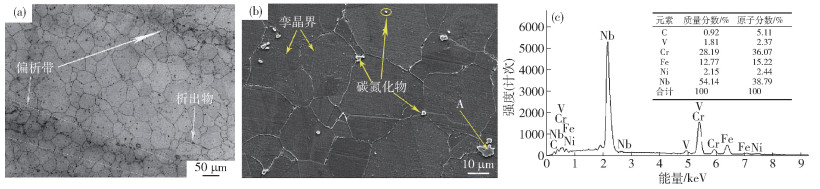

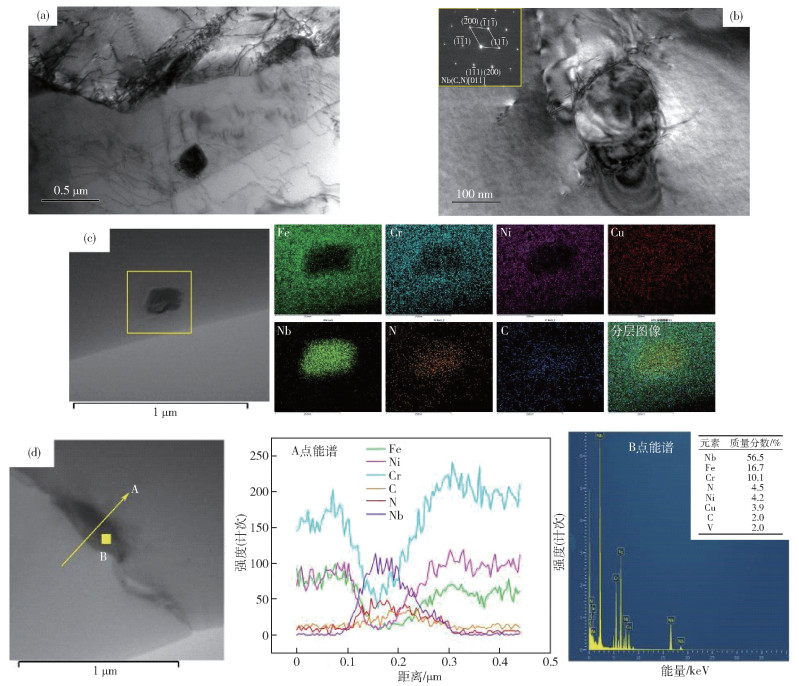

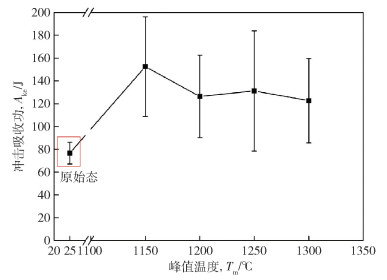

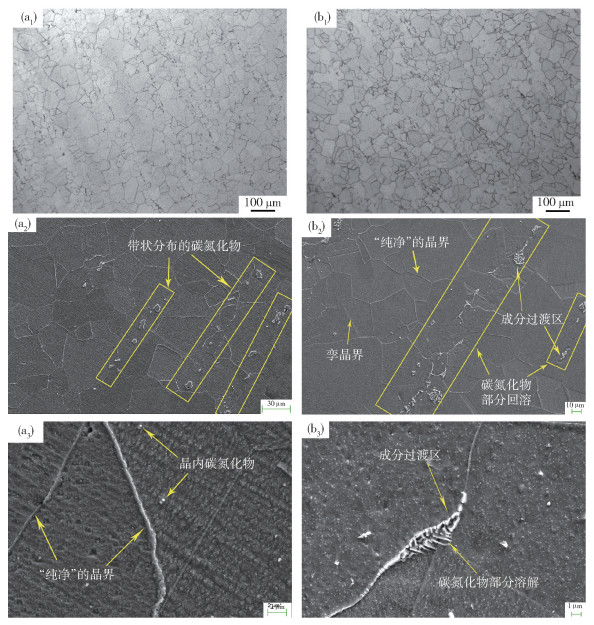

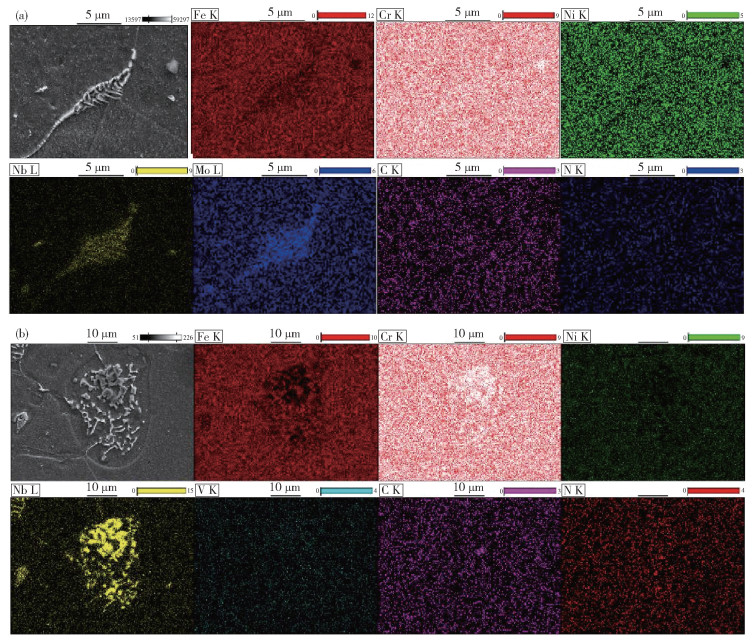

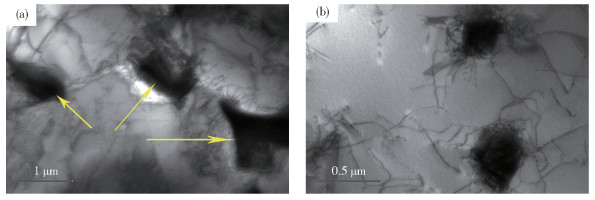

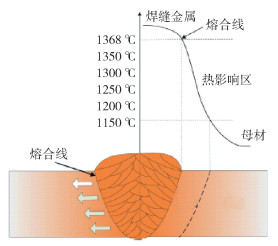

摘要: 采用Gleeble熱模擬的方法, 通過模擬焊接過程中快速加熱和冷卻的熱循環過程, 得到1150~1300 ℃不同峰值溫度下22Cr15Ni3.5CuNbN奧氏體鋼擴大的熱影響區組織, 并對其進行沖擊性能分析. 對熱影響區組織的研究表明, 實驗鋼的母材中存在一定量富Nb復合碳氮化物, 有效釘扎晶界, 且與大量位錯纏結. 在焊接過程中, 該富Nb復合碳氮化物經歷溶解與重新析出的復雜過程: 當峰值溫度為1150 ℃時, 僅小顆粒的富Nb碳氮化物發生了溶解, 而峰值溫度為1300 ℃時, 富Nb復合碳氮化物經歷溶解與重新析出, 呈現網狀的組織形貌, 且其整體尺寸增加. 富Nb復合碳氮化物的演化導致了沖擊功的變化, 經歷焊接熱循環條件的實驗鋼較母材具有更高的沖擊韌性, 隨著峰值溫度的升高, 沖擊韌性呈現先升后降的趨勢, 其中在峰值溫度為1150 ℃時實驗鋼的沖擊韌性最高.Abstract: Niobium is a strong carbonitride-forming element. The evolution of Nb-rich carbonitride in austenitic steels during welding has an important effect on the ductility of the heat-affected zone (HAZ). The new austenitic heat-resistant steel of 22Cr15Ni3.5CuNbN, a candidate material for ultra-super critical boiler superheater and reheater serviced at 620-650 ℃, contains 0.5% Nb, which will significantly affect the steel's weldability; therefore, it is necessary to study the microstructure and properties of the weld HAZ of the steel and provide a reference for the further applications of this new material. Because of the narrow weld HAZ of this material, the extended HAZ structure of 22Cr15Ni3.5CuNbN austenitic steel at different peak temperatures from 1150 ℃ to 1300 ℃ was obtained by Gleeble thermal physical simulation method in this study, aiming to simulate the thermal cycling process of the welding process, and impact performance tests were carried out. The results show that a certain amount of Nb-rich composite carbonitrides is present in the base metal of the experimental steel, which effectively pins the grain boundaries and entangl with a large number of dislocations. The Nb-rich composite carbonitride underwent a complex process of dissolution and re-precipitation during the simulated welding process. When the peak temperature was at 1150 ℃, only small particles of Nb-rich carbonitrides were dissolved, while when the peak temperature reached 1300 ℃, the Nb-rich composite carbonitride underwent dissolution and re-precipitation, showing a "mesh" structure, and its overall size increased. The evolution of Nb-rich composite carbonitrides led to changes in the impact energy of this steel. The impact toughness of the experimental steel subjected to welding thermal cycling condition was higher than that of the base metal. With the increase in the peak temperature, the impact toughness first increased and then decreased. The impact toughness of the steel reached the highest when the peak temperature was at 1150 ℃.

-

圖 4 母材的透射電鏡分析結果. (a)晶界及晶內析出物; (b)晶內析出物與位錯的關系; (c)晶內析出物成分分布; (d)晶界析出物成分分布

Figure 4. TEM analysis results of the base metal: (a) precipitates distributed in grain boundaries and crystals; (b) relationship between dislocations and precipitates distributed in crystals; (c) composition of precipitates distributed in the crystal; (d) composition of precipitates distributed at grain boundaries

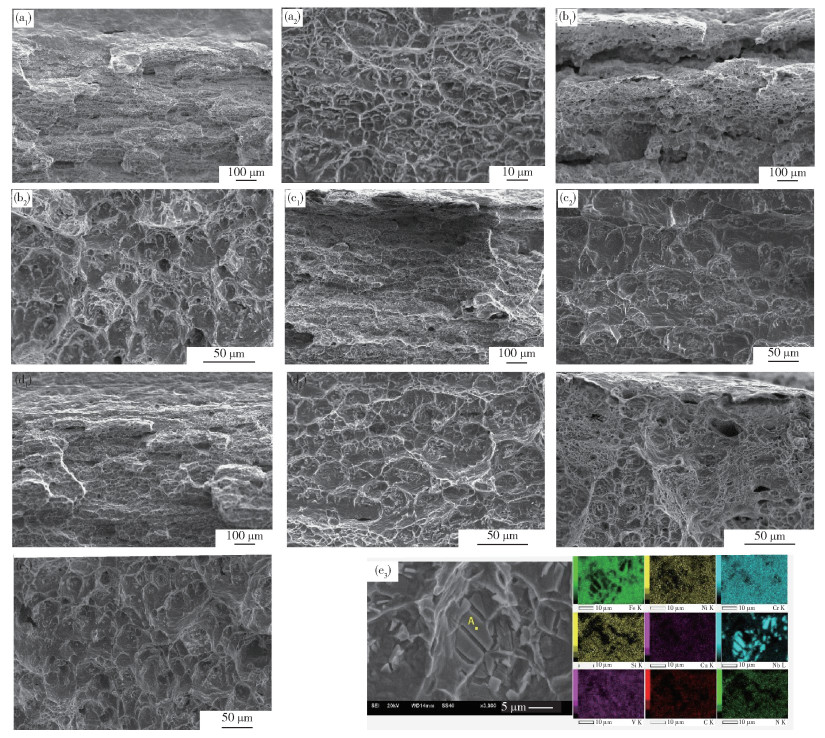

圖 6 沖擊實驗斷口微觀形貌. (a1)母材,缺口近端纖維區; (a2)母材,缺口遠處放射區; (b1)Tm=1150 ℃,缺口近端纖維區; (b2)Tm=1150 ℃,缺口遠處放射區; (c1)Tm=1200 ℃,缺口近端纖維區; (c2) Tm=1200 ℃,缺口遠處放射區; (d1) Tm=1250 ℃, 缺口近端纖維區; (d2)Tm=1250 ℃,缺口遠處放射區; (e1) Tm=1300 ℃,缺口近端纖維區; (e2)Tm=1300 ℃,缺口遠處放射區; (e3) Tm=1300 ℃,斷口處析出物

Figure 6. Fracture morphology of impact test: (a1) base metal, proximal fiber zone close to the notch; (a2) base metal, radiation zone far from the notch; (b1) proximal fiber zone close to the notch at peak temperature of 1150 ℃; (b2) radiation zone far from the notch at peak temperature of 1150 ℃; (c1) proximal fiber zone close to the notch at peak temperature of 1200 ℃; (c2) radiation zone far from the notch at peak temperature of 1200 ℃; (d1) proximal fiber zone close to the notch at peak temperature of 1250 ℃; (d2) radiation zone far from the notch at peak temperature of 1250 ℃; (e1) proximal fiber zone close to the notch at peak temperature of 1300 ℃; (e2) radiation zone far from the notch at peak temperature of 1300 ℃; (e3) precipitate from fracture at peak temperature of 1300 ℃

表 1 實驗用奧氏體耐熱鋼22Cr15Ni3.5CuNbN的化學成分(質量分數)

Table 1. Chemical composition of austenitic heat-resistant steel 22Cr15Ni3.5CuNbN?

% C Si Mn P S Cr Cu Co Ni Nb N B Fe 0.07 0.38 0.64 0.016 0.002 22.6 3.5 0.06 15.7 0.53 0.34 0.003 余量 表 2 析出相在奧氏體中的形成自由能ΔG

Table 2. Free energy of precipitates formation in austenite

析出相 在γ-Fe中的ΔG/(J·mol-1) VC -81208+92.97T VN -155439+97.95T NbC -14400+60.28T NbN -196323+75.56T TiC -202602+83.76T TiN -298600+80.37T 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Xie X S, Ai Z Q, Chi C Y, et al. R & D of the new type SP2215 austenitic heat-resistant steel for servicing 620~650 ℃ boiler super heater/reheater. Steel Pipe, 2018, 47(1): 23 doi: 10.3969/j.issn.1001-2311.2018.01.005謝錫善, 艾卓群, 遲成宇, 等. 620~650 ℃鍋爐過熱器/再熱器用新型奧氏體耐熱鋼SP2215的研發. 鋼管, 2018, 47(1): 23 doi: 10.3969/j.issn.1001-2311.2018.01.005 [2] Brauer G, Jander J. Die nitride des niobs. Z Anorg Allg Chem, 1952, 270(1-4): 160 doi: 10.1002/zaac.19522700114 [3] Yong Q L, Pei H Z, Tian J G, et al. Physico-metallurgical data of niobium in steel. J Iron Steel Res, 1998, 10(2): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON802.015.htm雍岐龍, 裴和中, 田建國, 等. 鈮在鋼中的物理冶金學基礎數據. 鋼鐵研究學報, 1998, 10(2): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON802.015.htm [4] Li H M, Cao J C, Sun L J, et al. Current situation and development of Nb microalloyed steel carbonitride precipitation behavior. Mater Rev, 2010, 24(9): 84 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201017021.htm李鴻美, 曹建春, 孫力軍, 等. 含鈮微合金鋼碳氮化物析出行為研究的現狀及發展. 材料導報, 2010, 24(9): 84 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201017021.htm [5] Irvine K J, Pickering F B, Gladman T. Grain-refined C-Mn steels. Iron Steel Inst J, 1967, 205(2): 161 [6] Tan J. The Effect of Niobium Carbonitride on Austenite Static Recrystallization [Dissertation]. Wuhan: Wuhan University of Science and Technology, 2006譚靜. 鈮的碳氮化物對奧氏體靜態再結晶的影響[學位論文]. 武漢: 武漢科技大學, 2006 [7] Brooks J A, Thompson A W. Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds. Int Mater Rev, 1991, 36(1): 16 doi: 10.1179/imr.1991.36.1.16 [8] Robinson J L, Scott M H. Liquation cracking during the welding of austenitic stainless steels and nickel alloys. Philos Trans R Soc London Ser A, 1980, 295(1413): 105 doi: 10.1098/rsta.1980.0079 [9] Bhaduri A K, Srinivasan G, Klenk A, et al. Study of hot cracking behaviour of 14Cr-15Ni-2.5Mo Ti-modified fully austenitic stainless steels using varestraint and hot ductility tests. Weld World, 2009, 53(1-2): 17 doi: 10.1007/BF03266688 [10] Li L J, Messler R W. Dissolution kinetics of NbC particles in the heat-affected zone of type 347 austenitic stainless steel. Metall Mater Trans A, 2002, 33(7): 2031 doi: 10.1007/s11661-002-0035-3 [11] Xie X S, Yu H Y, Chi C Y, et al. Method for Reinforcing Chromium-Nickel Type Austenitic Heat-Resistant Steel by Using Multiple Nano-Precipitation Phases: China Patent, 201310718590.7, 2014-03-19謝錫善, 于鴻垚, 遲成宇, 等. 用多種納米析出相復合強化鉻鎳型奧氏體耐熱鋼的方法: 中國專利, 201310718590.7, 2014-03-19 [12] Liu W, Lu F G, Yang R J, et al. Gleeble simulation of the HAZ in Inconel 617 welding. J Mater Process Technol, 2015, 225: 221 doi: 10.1016/j.jmatprotec.2015.06.001 [13] Peng Z F, Ren W, Yang C, et al. Relationship between the evolution of phase parameters of grain boundary M23C6 and embrittlement of HR3C super-heater tubes in service. Acta Metall Sin, 2015, 51(11): 1325 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201511004.htm彭志方, 任文, 楊超, 等. HR3C鋼運行過熱器管的脆化與晶界M23C6相參量演化的關系. 金屬學報, 2015, 51(11): 1325 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201511004.htm [14] Zhang Z Y, Li Z D, Yong Q L, et al. Precipitation behavior of carbide during heating process in Nb and Nb-Mo micro-alloyed steels. Acta Metall Sin, 2015, 51(3): 315 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201503007.htm張正延, 李昭東, 雍岐龍, 等. 升溫過程中Nb和Nb-Mo微合金化鋼中碳化物的析出行為研究. 金屬學報, 2015, 51(3): 315 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201503007.htm [15] Huang Z W. Behavior of carbonitrides in micro-alloyed steels in austenite. Sichuan Metall, 1988(2): 51 https://www.cnki.com.cn/Article/CJFDTOTAL-SCYJ198802011.htm黃澤文. 微合金化鋼的碳氮化物在奧氏體中的行為. 四川冶金, 1988(2): 51 https://www.cnki.com.cn/Article/CJFDTOTAL-SCYJ198802011.htm -

下載:

下載: