-

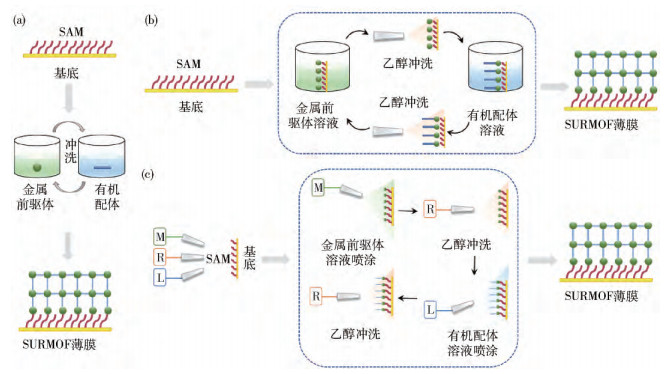

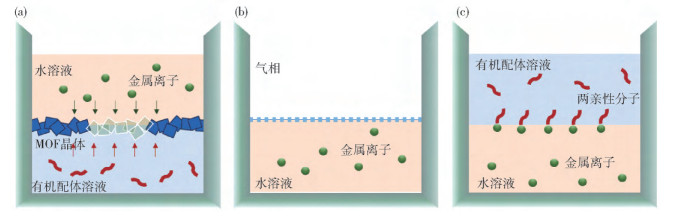

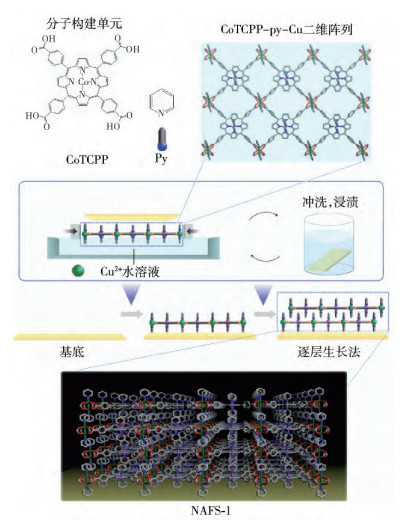

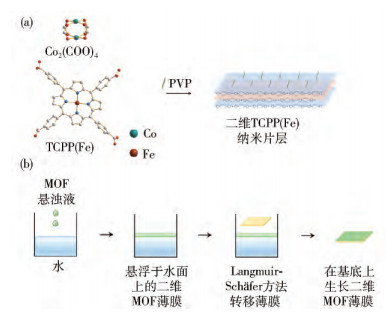

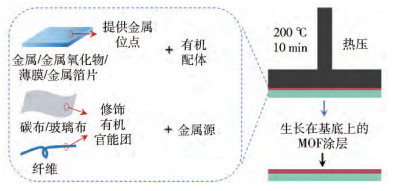

摘要: 作為納米技術領域的一種新材料, 金屬-有機骨架(metal-organic framework, MOF)薄膜材料(也稱為SURMOFs)獲得了越來越多研究者的關注.多種合成方法的不斷提出, 為大量合成膜厚度、均勻性、形態、甚至維度均可控的MOF薄膜材料提供了可能性, 并為薄膜材料在更多領域中的應用提供了機會.本文首先介紹了MOF薄膜材料基于液相或真空的各種合成方法及其適用范圍, 其中, 獲得高質量薄膜的最有效方法之一是在基底材料上沉積自組裝單層(SAMs), 進而誘導MOF薄膜的成核及生長.其次, 總結了近年來MOF薄膜材料在分離、催化、傳感等領域的研究進展, 以及為滿足環境可持續發展和對清潔能源的需求, 新發展起來的在光催化、儲能、光伏以及制備各種電子器件領域的應用.在此基礎上, 討論了限制MOF薄膜實際應用的因素(例如薄膜生長機制需要更深入的研究、薄膜質量及薄膜熱電性能等有待進一步提高等), 對相關領域未來的研究方向進行了展望, 以期為MOF薄膜材料進一步的研究發展提供理論參考.Abstract: As one of the most promising nanomaterials, metal-organic framework (MOF) thin films (also known as surfacesupported MOF thin films, SURMOFs) have attracted much attention in recent years. The development of various synthetic methods makes it possible to obtain MOF thin films with controlled thickness, uniformity, morphology, and even dimensions, providing tremendous opportunities for more applications. Different synthesis methods of MOF thin films based on liquid phase or vacuum range were first introduced, and one of the most effective ways to fabricate quality thin films was depositing self-assembled monolayers (SAMs) on the primary substrate to further induce the nucleation and growth of MOF thin films. Furthermore, some traditional applications of MOF thin films (e. g. separation, catalysis, sensing) were summarized, as well as some newly-developed applications in photocatalysis, energy storage, photovoltaics, and electronic devices, which meet the demands for environmental sustainability and cleaner energy. Although the future is promising, MOF thin films still face some challenges. Therefore, some key factors those limit the MOF films' practical application were discussed, for example, the unclear growth mechanism of thin films, the poor quality and low film thermoe lectric performance. Based on the review of recent developments, this article will provide references for the future research of MOF thin films.

-

Key words:

- metal-organic framework films /

- liquid-phase epitaxy /

- catalysis /

- sensing /

- energy storage

-

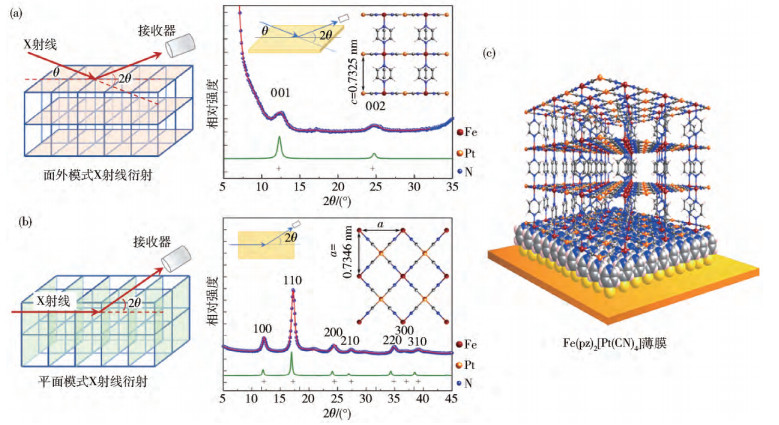

圖 8 X射線衍射方法表征二維薄膜材料的示意圖[60]. (a) 面外模式(out-of-plane) X射線衍射方法獲得的晶面衍射圖譜; (b) 平面模式(in-plane) X射線衍射方法獲得的晶面衍射圖譜; (c) Fe (pz) 2[Pt (CN) 4]薄膜

Figure 8. X-ray diffraction characterization of 2D thin films[60]: (a) patterns obtained by out-of-plane XRD; (b) patterns obtained by in-plane XRD; (c) Fe (pz) 2[Pt (CN) 4] (pz: pyrazine) thin films

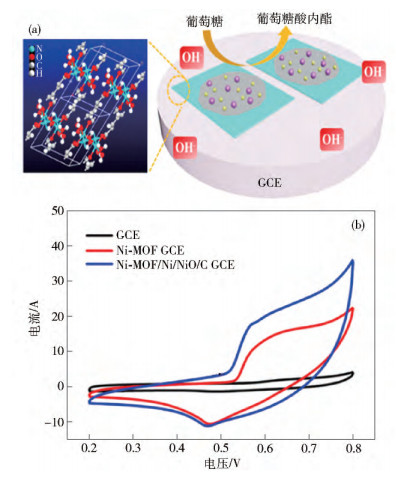

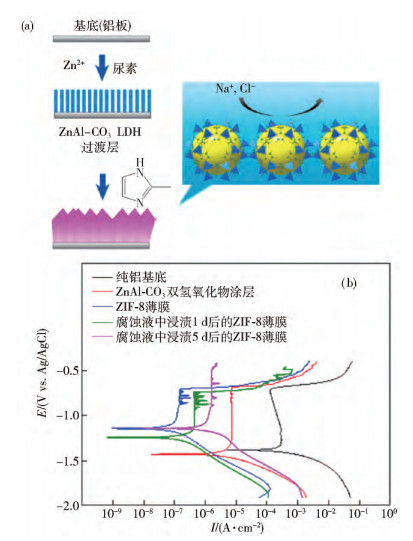

圖 9 Ni-MOF/Ni/Ni O/C納米復合膜用于人血清葡萄糖檢測[87]. (a) 檢測過程示意圖; (b) 不同材料固載的GCE在Na OH (0.1 mol·L-1) 和葡萄糖(0.4 mmol·L-1) 混合溶液中的循環伏安(CV) 曲線

Figure 9. Ni-MOF/Ni/Ni O/C nanocomposite-modified GCE applied for glucose detection in human serum sample[87]: (a) schematic of de-tection process; (b) cyclic voltammetry curves of GCEs immobilized with different materials in Na OH (0.1 mol·L-1) with 0.4 mmol·L-1glucose

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Li B, Wen H M, Cui Y J, et al. Emerging multifunctional metalorganic framework materials. Adv Mater, 2016, 28(40): 8819 doi: 10.1002/adma.201601133 [2] Kaneti Y V, Dutta S, Hossain M S A, et al. Strategies for improving the functionality of zeolitic imidazolate frameworks: tailoring nanoarchitectures for functional applications. Adv Mater, 2017, 29(38): ArtNo. 1700213-1 doi: 10.1002/adma.201700213 [3] Loiseau T, Volkringer C, Haouas M, et al. Crystal chemistry of aluminium carboxylates: from molecular species towards porous infinite three-dimensional networks. C R Chim, 2015, 18(12): 1350 doi: 10.1016/j.crci.2015.08.006 [4] Fu J R. Fabrication and Gas Separation Properties of MOF Membrane and COF Membrane and the COF/MOF Composite Membrane.[Dissertation]. Changchun: Jilin University, 2016付靜茹. MOF膜和COF膜以及COF/MOF復合膜的制備以及氣體分離性質的研究[學位論文]. 長春: 吉林大學, 2016 [5] Li Y S, Yang W S. Molecular sieve membranes: from 3D zeolites to 2D MOFs. Chin J Catal, 2015, 36(5): 692 doi: 10.1016/S1872-2067(15)60838-5 [6] Andres M A, Benzaqui M, Serre C, et al. Fabrication of ultrathin MIL-96(Al) films and study of CO2 adsorption/desorption processes using quartz crystal microbalance. J Colloid Interface Sci, 2018, 519: 88 doi: 10.1016/j.jcis.2018.02.058 [7] Zhang J, Xia T F, Zhao D, et al. In situ secondary growth of Eu (Ⅲ)-organic framework film for fluorescence sensing of sulfur dioxide. Sens Actuators B, 2018, 260: 63 doi: 10.1016/j.snb.2017.12.187 [8] Rubio-Gimenez V, Galbiati M, Castells-Gil J, et al. Bottom-up fabrication of semiconductive metal-organic framework ultrathin films. Adv Mater, 2018, 30(10): 1704291 doi: 10.1002/adma.201704291 [9] Shete M, Kumar P, Bachman J E, et al. On the direct synthesis of Cu(BDC) MOF nanosheets and their performance in mixed matrix membranes. J Membr Sci, 2018, 549: 312 doi: 10.1016/j.memsci.2017.12.002 [10] Bétard A, Fischer R A. Metal-organic framework thin films: from fundamentals to applications. Chem Rev, 2012, 112(2): 1055 doi: 10.1021/cr200167v [11] Sakaida S, Otsubo K, Sakata O, et al. Crystalline coordination framework endowed with dynamic gate-opening behaviour by being downsized to a thin film. Nat Chem, 2016, 8(4): 377 doi: 10.1038/nchem.2469 [12] Edler K J, Yang B. Formation of mesostructured thin films at the air-liquid interface. Chem Soc Rev, 2013, 42(9): 3765 doi: 10.1039/C2CS35300H [13] Genesio G, Maynadie J, Carboni M, et al. Recent status on MOF thin films on transparent conductive oxides substrates (ITO or FTO). New J Chem, 2018, 42(4): 2351 doi: 10.1039/C7NJ03171H [14] He Y R, Tang Y P, Ma D C, et al. UiO-66 incorporated thinfilm nanocomposite membranes for efficient selenium and arsenic removal. J Membr Sci, 2017, 541: 262 doi: 10.1016/j.memsci.2017.06.061 [15] Chernikova V, Shekhah O, Eddaoudi M. Advanced fabrication method for the preparation of MOF thin films: liquid-phase epitaxy approach meets spin coating method. ACS Appl Mater Interfaces, 2016, 8(31): 20459 doi: 10.1021/acsami.6b04701 [16] Chen Y F, Li S Q, Pei X K, et al. A solvent-free hot-pressing method for preparing metal-organic-framework coatings. Angew Chem Int Ed, 2016, 55(10): 3419 doi: 10.1002/anie.201511063 [17] Li W J, Gao S Y, Liu T F, et al. In situ growth of metal-organic framework thin films with gas sensing and molecule storage properties. Langmuir, 2013, 29(27): 8657 doi: 10.1021/la402012d [18] Shekhah O, Fu L L, Sougrat R, et al. Successful implementation of the stepwise layer-by-layer growth of MOF thin films on confined surfaces: mesoporous silica foam as a first case study. Chem Commun, 2012, 48(93): 11434 doi: 10.1039/c2cc36233c [19] Sun Y X, Yang F, Wei Q, et al. Oriented nano-microstructureassisted controllable fabrication of metal-organic framework membranes on nickel foam. Adv Mater, 2016, 28(12): 2374 doi: 10.1002/adma.201505437 [20] Yao M S, Tang W X, Wang G E, et al. MOF thin film-coated metal oxide nanowire array: significantly improved chemiresistor sensor performance. Adv Mater, 2016, 28(26): 5229 doi: 10.1002/adma.201506457 [21] Bao T, Zhang J, Zhang W P, et al. Growth of metal-organic framework HKUST-1 in capillary using liquid-phase epitaxy for open-tubular capillary electrochromatography and capillary liquid chromatography. J Chromatogr A, 2015, 1381: 239 doi: 10.1016/j.chroma.2015.01.005 [22] Dou Z S, Cai J F, Cui Y J, et al. Preparation and gas separation properties of metal organic framework membranes. Z Anorg Allg Chem, 2015, 641(5): 792 doi: 10.1002/zaac.201400574 [23] Hromadka J, Tokay B, Correia R, et al. Highly sensitive volatile organic compounds vapour measurements using a long period grating optical fibre sensor coated with metal organic framework ZIF-8. Sens Actuators B, 2018, 260: 685 doi: 10.1016/j.snb.2018.01.015 [24] Toyao T, Styles M J, Yago T, et al. Fe3O4@HKUST-1 and Pd/Fe3O4@HKUST-1 as magnetically recyclable catalysts prepared via conversion from a Cu-based ceramic. CrystEngComm, 2017, 19(29): 4201 doi: 10.1039/C7CE00390K [25] Lee D T, Zhao J J, Oldham C J, et al. UiO-66-NH2 metal-organic framework (MOF) nucleation on TiO2, ZnO, and Al2O3 atomic layer deposition-treated polymer fibers: role of metal oxide on MOF growth and catalytic hydrolysis of chemical warfare agent simulants. ACS Appl Mater Interfaces, 2017, 9(51): 44847 doi: 10.1021/acsami.7b15397 [26] Qin X, Sun Y X, Wang N X, et al. Surface modifications for preparation of MOF thin films. Chem Ind Eng Prog, 2017, 36(4): 1306 https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201704021.htm秦茜, 孫玉繡, 王乃鑫, 等. 表面修飾在MOF薄膜制備中的應用. 化工進展, 2017, 36(4): 1306 https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201704021.htm [27] Janghouri M, Hosseini H. Water-soluble metal-organic framework hybrid electron injection layer for organic light-emitting devices. J Inorg Organomet Polym Mater, 2017, 27(6): 1800 doi: 10.1007/s10904-017-0644-3 [28] Hou J W, Sutrisna P D, Zhang Y T, et al. Formation of ultrathin, continuous metal-organic framework membranes on flexible polymer substrates. Angew Chem Int Ed, 2016, 55(12): 3947 doi: 10.1002/anie.201511340 [29] Wang N Y, Liu Y, Qiao Z W, et al. Polydopamine-based synthesis of a zeolite imidazolate framework ZIF-100 membrane with high H2/CO2 selectivity. J Mater Chem A, 2015, 3(8): 4722 doi: 10.1039/C4TA06763K [30] Liu J X, Shekhah O, Stammer X, et al. Deposition of metal-organic frameworks by liquid-phase epitaxy: the influence of substrate functional group density on film orientation. Materials, 2012, 5(9): 1581 doi: 10.3390/ma5091581 [31] Virmani E, Rotter J M, Mahringer A, et al. On-surface synthesis of highly oriented thin metal-organic framework films through vapor-assisted conversion. J Am Chem Soc, 2018, 140(14): 4812 doi: 10.1021/jacs.7b08174 [32] Zhuang J L, Terfort A, W?ll C. Formation of oriented and patterned films of metal-organic frameworks by liquid phase epitaxy: a review. Coord Chem Rev, 2016, 307: 391 doi: 10.1016/j.ccr.2015.09.013 [33] Guo Y, Mao Y Y, Hu P, et al. Self-confined synthesis of HKUST-1 membranes from CuO nanosheets at room temperature. Chemistry Select, 2016, 1(1): 108 doi: 10.1002/slct.201500010 [34] Liu Y, Pan J H, Wang N Y, et al. Remarkably enhanced gas separation by partial self-conversion of a laminated membrane to metal-organic frameworks. Angew Chem Int Ed, 2015, 127(10): 3071 doi: 10.1002/ange.201411550 [35] Brower L J, Gentry L K, Napier A L, et al. Tailoring the nanoscale morphology of HKUST-1 thin films via codeposition and seeded growth. Beilstein J Nanotechnol, 2017, 8: 2307 doi: 10.3762/bjnano.8.230 [36] Ismail F M, Abdellah A M, Ali P A, et al. Bilayer sandwichlike membranes of metal organic frameworks-electrospun polymeric nanofibers via SiO 2 nanoparticles seeding. Mater Today Commun, 2017, 12: 119 doi: 10.1016/j.mtcomm.2017.08.001 [37] Liu J X, W?ll C. Surface-supported metal-organic framework thin films: fabrication methods, applications, and challenges. Chem Soc Rev, 2017, 46(19): 5730 doi: 10.1039/C7CS00315C [38] Horiuchi Y, Toyao T, Miyahara K, et al. Visible-light-driven photocatalytic water oxidation catalysed by iron-based metal-organic frameworks. Chem Commun, 2016, 52(29): 5190 doi: 10.1039/C6CC00730A [39] Fan L L, Xue M, Kang Z X, et al. Electrospinning technology applied in zeolitic imidazolate framework membrane synthesis. J Mater Chem, 2012, 22(48): 25272 doi: 10.1039/c2jm35401b [40] Shekhah O, Wang H, Kowarik S, et al. Step-by-step route for the synthesis of metal-organic frameworks. J Am Chem Soc, 2007, 129(49): 15118 doi: 10.1021/ja076210u [41] Hurrle S, Friebe S, Wohlgemuth J, et al. Sprayable, large-area metal-organic framework films and membranes of varying thickness. Chem Eur J, 2017, 23(10): 2294 doi: 10.1002/chem.201606056 [42] Gliemann H, W?ll C. Epitaxially grown metal-organic frameworks. Mater Today, 2012, 15(3): 110 doi: 10.1016/S1369-7021(12)70046-9 [43] Ameloot R, Vermoortele F, Vanhove W, et al. Interfacial synthesis of hollow metal-organic framework capsules demonstrating selective permeability. Nat Chem, 2011, 3(5): 382 doi: 10.1038/nchem.1026 [44] Makiura R, Konovalov O. Interfacial growth of large-area singlelayer metal-organic framework nanosheets. Sci Rep, 2013, 3: ArtNo. 2506-1 doi: 10.1038/srep02506 [45] Gu P, Qian L N, Yan Z D, et al. Fabrication and infrared-transmission properties of a free-standing monolayer of hexagonalclose-packed dielectric microspheres. Opt Commun, 2018, 419: 103 doi: 10.1016/j.optcom.2018.03.016 [46] Otsubo K, Kitagawa H. Metal-organic framework thin films with well-controlled growth directions confirmed by x-ray study. APL Mater, 2014, 2(12): 124105 doi: 10.1063/1.4899295 [47] Makiura R, Motoyama S, Umemura Y, et al. Surface nano-architecture of a metal-organic framework. Nat Mater, 2010, 9(7): 565 doi: 10.1038/nmat2769 [48] Wang Y X, Zhao M T, Ping J F, et al. Bioinspired design of ultrathin 2D bimetallic metal-organic-framework nanosheets used as biomimetic enzymes. Adv Mater, 2016, 28(21): 4149 doi: 10.1002/adma.201600108 [49] Zhao Y B, Kornienko N, Liu Z, et al. Mesoscopic constructs of ordered and oriented metal-organic frameworks on plasmonic silver nanocrystals. J Am Chem Soc, 2015, 137(6): 2199 doi: 10.1021/ja512951e [50] Müller U, Puetter H, Hesse M, et al. Method for Electrochemical Production of A Crystalline Porous Metal Organic Skeleton Material: US Patent, 7968739B2.2011-6-28 [51] Li W J, Liu J, Sun Z H, et al. Integration of metal-organic frameworks into an electrochemical dielectric thin film for electronic applications. Nat Commun, 2016, 7: 11830 doi: 10.1038/ncomms11830 [52] Feng J F, Yang X, Gao S Y, et al. Facile and rapid growth of nanostructured Ln-BTC metal-organic framework films by electrophoretic deposition for explosives sensing in gas and Cr3+ detection in solution. Langmuir, 2017, 33(50): 14238 doi: 10.1021/acs.langmuir.7b03170 [53] Li M Y, Dinca M. Reductive electrosynthesis of crystalline metal-organic frameworks. J Am Chem Soc, 2011, 133(33): 12926 doi: 10.1021/ja2041546 [54] Stassen I, Styles M, Grenci G, et al. Chemical vapour deposition of zeolitic imidazolate framework thin films. Nat Mater, 2016, 15(3): 304 doi: 10.1038/nmat4509 [55] Ahvenniemi E, Karppinen M. In situ atomic/molecular layer-bylayer deposition of inorganic-organic coordination network thin films from gaseous precursors. Chem Mater, 2016, 28(17): 6260 doi: 10.1021/acs.chemmater.6b02496 [56] Lemaire P C, Zhao J J, Williams P S, et al. Copper benzenetricarboxylate metal-organic framework nucleation mechanisms on metal oxide powders and thin films formed by atomic layer deposition. ACS Appl Mater Interfaces, 2016, 8(14): 9514 doi: 10.1021/acsami.6b01195 [57] Delen G, Ristanovi? Z, Mandemaker L D B, et al. Mechanistic insights into growth of surface-mounted metal-organic framework films resolved by infrared (nano-) spectroscopy. Chem Eur J, 2018, 24(1): 187 doi: 10.1002/chem.201704190 [58] Worrall S D, Bissett M A, Hill P I, et al. Metal-organic framework templated electrodeposition of functional gold nanostructures. Electrochim Acta, 2016, 222: 361 doi: 10.1016/j.electacta.2016.10.187 [59] Liu J X, Redel E, Walheim S, et al. Monolithic high performance surface anchored metal-organic framework Bragg reflector for optical sensing. Chem Mater, 2015, 27(6): 1991 doi: 10.1021/cm503908g [60] Otsubo K, Haraguchi T, Sakata O, et al. Step-by-step fabrication of a highly oriented crystalline three-dimensional pillared-layer-type metal-organic framework thin film confirmed by synchrotron X-ray diffraction. J Am Chem Soc, 2012, 134(23): 9605 doi: 10.1021/ja304361v [61] Haraguchi T, Otsubo K, Sakata O, et al. Remarkable lattice shrinkage in highly oriented crystalline three-dimensional metalorganic framework thin films. Inorg Chem, 2015, 54(24): 11593 doi: 10.1021/acs.inorgchem.5b02207 [62] Zhu Y H, Ciston J, Zheng B, et al. Unravelling surface and interfacial structures of a metal-organic framework by transmission electron microscopy. Nat Mater, 2017, 16(5): 532 doi: 10.1038/nmat4852 [63] Cliffe M J, Wan W, Zou X D, et al. Correlated defect nanoregions in a metal-organic framework. Nat Commun, 2014, 5: 4176 doi: 10.1038/ncomms5176 [64] Kozachuk O, Meilikhov M, Yusenko K, et al. A solid-solution approach to mixed-metal metal-organic frameworks-detailed characterization of local structures, defects and breathing behaviour of Al/V frameworks. Eur J Inorg Chem, 2013, 2013(26): 4546 doi: 10.1002/ejic.201300591 [65] St Petkov P, Vayssilov G N, Liu J X, et al. Defects in MOFs: a thorough characterization. Chem Phys Chem, 2012, 13(8): 2025 doi: 10.1002/cphc.201200222 [66] Bennett T D, Todorova T K, Baxter E F, et al. Connecting defects and amorphization in UiO-66 and MIL-140 metal-organic frameworks: a combined experimental and computational study. Phys Chem Chem Phys, 2016, 18(3): 2192 doi: 10.1039/C5CP06798G [67] Feyand M, Mugnaioli E, Vermoortele F, et al. Automated diffraction tomography for the structure elucidation of twinned, submicrometer crystals of a highly porous, catalytically active bismuth metal-organic framework. Angew Chem Int Ed, 2012, 124(41): 10519 doi: 10.1002/ange.201204963 [68] Vermoortele F, Bueken B, Le Bars G, et al. Synthesis modulation as a tool to increase the catalytic activity of metal-organic frameworks: the unique case of UiO-66(Zr). J Am Chem Soc, 2013, 135(31): 11465 doi: 10.1021/ja405078u [69] Adatoz E, Avci A K, Keskin S. Opportunities and challenges of MOF-based membranes in gas separations. Sep Purif Technol, 2015, 152: 207 doi: 10.1016/j.seppur.2015.08.020 [70] Huang K, Liu S N, Li Q Q, et al. Preparation of novel metalcarboxylate system MOF membrane for gas separation. Sep Purif Technol, 2013, 119: 94 doi: 10.1016/j.seppur.2013.09.008 [71] Hu Y X, Dong X L, Nan J P, et al. Metal-organic framework membranes fabricated via reactive seeding. Chem Commun, 2011, 47(2): 737 doi: 10.1039/C0CC03927F [72] Münch A S, Seidel J, Obst A, et al. High-separation performance of chromatographic capillaries coated with MOF-5 by the controlled SBU approach. Chem Eur J, 2011, 17(39): 10958 doi: 10.1002/chem.201100642 [73] Ramos-Fernandez E V, Garcia-Domingos M, Juan-Alcaniz J, et al. MOFs meet monoliths: Hierarchical structuring metal organic framework catalysts. Appl Catal A, 2011, 391(1-2): 261 doi: 10.1016/j.apcata.2010.05.019 [74] Zhang T Y, Liu W X, Meng G, et al. Construction of hierarchical copper-based metal-organic framework nanoarrays as functional structured catalysts. Chem Cat Chem, 2017, 9(10): 1771 doi: 10.1002/cctc.201700060 [75] Maina J W, Schutz J A, Grundy L, et al. Inorganic nanoparticles/metal organic framework hybrid membrane reactors for efficient photocatalytic conversion of CO2. ACS Appl Mater Interfaces, 2017, 9(40): 35010 doi: 10.1021/acsami.7b11150 [76] Lin S Y, Pineda-Galvan Y, Maza W A, et al. Electrochemical water oxidation by a catalyst-modified metal-organic framework thin film. Chem Sus Chem, 2017, 10(3): 514 doi: 10.1002/cssc.201601181 [77] Gong Y N, Ouyang T, He C T, et al. Photoinduced water oxidation by an organic ligand incorporated into the framework of a stable metal-organic framework. Chem Sci, 2016, 7(2): 1070 doi: 10.1039/C5SC02679B [78] Usov P M, Ahrenholtz S R, Maza W A, et al. Cooperative electrochemical water oxidation by Zr nodes and Ni-porphyrin linkers of a PCN-224 MOF thin film. J Mater Chem A, 2016, 4(43): 16818 doi: 10.1039/C6TA05877A [79] Johnson B A, Bhunia A, Ott S. Electrocatalytic water oxidation by a molecular catalyst incorporated into a metal-organic framework thin film. Dalton Trans, 2017, 46(5): 1382 doi: 10.1039/C6DT03718F [80] Vaddipalli S R, Sanivarapu S R, Vengatesan S, et al. Heterostructured Au NPs/CdS/LaBTC MOFs photoanode for efficient photoelectrochemical water splitting: Stability enhancement via CdSe QDs to 2D-CdS nanosheets transformation. ACS Appl Mater Interfaces, 2016, 8(35): 23049 doi: 10.1021/acsami.6b06851 [81] Zhao S L, Wang Y, Dong J C, et al. Ultrathin metal-organic framework nanosheets for electrocatalytic oxygen evolution. Nature Energy, 2016, 1: 16184 doi: 10.1038/nenergy.2016.184 [82] Fan L L. Preparation and Application of Zeolite and Metal-Organic Framework Membranes[Dissertation]. Changchun: Jilin University, 2014范黎黎. 沸石分子篩膜和金屬-有機骨架膜的制備和應用[學位論文]. 長春: 吉林大學, 2014 [83] Ye L, Liu J X, Gao Y, et al. Highly oriented MOF thin filmbased electrocatalytic device for the reduction of CO2 to CO exhibiting high faradaic efficiency. J Mater Chem A, 2016, 4(40): 15320 doi: 10.1039/C6TA04801C [84] Kornienko N, Zhao Y B, Kley C S, et al. Metal-organic frameworks for electrocatalytic reduction of carbon dioxide. J Am Chem Soc, 2015, 137(44): 14129 doi: 10.1021/jacs.5b08212 [85] Allendorf M D, Houk R J, Andruszkiewicz L, et al. Stress-induced chemical detection using flexible metal-organic frameworks. J Am Chem Soc, 2008, 130(44): 14404 doi: 10.1021/ja805235k [86] Hromadka J, Tokay B, Correia R, et al. Carbon dioxide measurements using long period grating optical fibre sensor coated with metal organic framework HKUST-1. Sens Actuators B, 2018, 255: 2483 doi: 10.1016/j.snb.2017.09.041 [87] Shu Y, Yan Y, Chen J Y, et al. Ni and NiO nanoparticles decorated metal-organic framework nanosheets: Facile synthesis and high-performance nonenzymatic glucose detection in human serum. ACS Appl Mater Interfaces, 2017, 9(27): 22342 doi: 10.1021/acsami.7b07501 [88] Liu J, Sun F X, Zhang F, et al. In situ growth of continuous thin metal-organic framework film for capacitive humidity sensing. J Mater Chem, 2011, 21(11): 3775 doi: 10.1039/c0jm03123b [89] Aubrey M L, Long J R. A dual-ion battery cathode via oxidative insertion of anions in a metal-organic framework. J Am Chem Soc, 2015, 137(42): 13594 doi: 10.1021/jacs.5b08022 [90] Jiao Y, Pei J, Yan C S, et al. Layered nickel metal-organic framework for high performance alkaline battery-supercapacitor hybrid devices. J Mater Chem A, 2016, 4(34): 13344 doi: 10.1039/C6TA05384J [91] Li B, Liu J, Nie Z M, et al. Metal-organic frameworks as highly active electrocatalysts for high-energy density, aqueous zinc-polyiodide redox flow batteries. Nano Lett, 2016, 16(7): 4335 doi: 10.1021/acs.nanolett.6b01426 [92] Lee D Y, Kim E K, Shin C Y, et al. Layer-by-layer deposition and photovoltaic property of Ru-based metal-organic frameworks. RSC Adv, 2014, 4(23): 12037 doi: 10.1039/c4ra00397g [93] Lopez H A, Dhakshinamoorthy A, Ferrer B, et al. Photochemical response of commercial MOFs: Al2(BDC)3 and its use as active material in photovoltaic devices. J Phys Chem C, 2011, 115(45): 22200 doi: 10.1021/jp206919m [94] Chi W S, Roh D K, Lee C S, et al. A shape-and morphologycontrolled metal organic framework template for high-efficiency solid-state dye-sensitized solar cells. J Mater Chem A, 2015, 3(43): 21599 doi: 10.1039/C5TA06731F [95] Liu J X, Zhou W C, Liu J X, et al. A new class of epitaxial porphyrin metal-organic framework thin films with extremely high photocarrier generation efficiency: promising materials for all-solid-state solar cells. J Mater Chem A, 2016, 4(33): 12739 doi: 10.1039/C6TA04898F [96] Deng H X, Grunder S, Cordova K E, et al. Large-pore apertures in a series of metal-organic frameworks. Science, 2012, 336(6084): 1018 doi: 10.1126/science.1220131 [97] Park H J, So M C, Gosztola D, et al. Layer-by-layer assembled films of perylene diimide-and squaraine-containing metal-organic framework-like materials: Solar energy capture and directional energy transfer. ACS Appl Mater Interfaces, 2016, 8(38): 24983 doi: 10.1021/acsami.6b03307 [98] Sheberla D, Bachman J C, Elias J S, et al. Conductive MOF electrodes for stable supercapacitors with high areal capacitance. Nat Mater, 2017, 16(2): 220 doi: 10.1038/nmat4766 [99] Zhang M, Ma L, Wang L L, et al. Insights into the use of metalorganic framework as high-performance anticorrosion coatings. ACS Appl Mater Interfaces, 2018, 10(3): 2259 doi: 10.1021/acsami.7b18713 [100] Talin A A, Centrone A, Ford A C, et al. Tunable electrical conductivity in metal-organic framework thin-film devices. Science, 2013: 1246738 http://smartsearch.nstl.gov.cn/paper_detail.html?id=dfa1ad916706aed7fe1d8d58485e2667 [101] Erickson K J, Leonard F, Stavila V, et al. Thin film thermoelectric metal-organic framework with high seebeck coefficient and low thermal conductivity. Adv Mater, 2015, 27(22): 3453 doi: 10.1002/adma.201501078 [102] Jain P, Stroppa A, Nabok D, et al. Switchable electric polarization and ferroelectric domains in a metal-organic-framework. Npj Quantum Mater, 2016, 1(1): 16012 doi: 10.1038/npjquantmats.2016.12 [103] Wang Z B, Nminibapiel D, Shrestha P, et al. Resistive switching nanodevices based on metal-organic frameworks. Chem Nano Mat, 2016, 2(1): 67 doi: 10.1002/cnma.201500143 [104] Gu Z G, Chen S C, Fu W Q, et al. Epitaxial growth of MOF thin film for modifying the dielectric layer in organic field-effect transistors. ACS Appl Mater Interfaces, 2017, 9(8): 7259 doi: 10.1021/acsami.6b14541 [105] Shekhah O, Wang H, Zacher D, et al. Growth mechanism of metal-organic frameworks: insights into the nucleation by employing a step-by-step route. Angew Chem Int Ed, 2009, 48(27): 5038 doi: 10.1002/anie.200900378 [106] Xu G, Yamada T, Otsubo K, et al. Facile "modular assembly" for fast construction of a highly oriented crystalline MOF nanofilm. J Am Chem Soc, 2012, 134(40): 16524 doi: 10.1021/ja307953m [107] Ohnsorg M L, Beaudoin C K, Anderson M E. Fundamentals of MOF thin film growth via liquid-phase epitaxy: investigating the initiation of deposition and the influence of temperature. Langmuir, 2015, 31(22): 6114 doi: 10.1021/acs.langmuir.5b01333 [108] Yu X J, Zhuang J L, Scherr J, et al. Minimization of surface energies and ripening outcompete template effects in the surface growth of metal-organic frameworks. Angew Chem Int Ed, 2016, 55(29): 8348 doi: 10.1002/anie.201602907 [109] Hod I, Sampson M D, Deria P, et al. Fe-porphyrin-based metal-organic framework films as high-surface concentration, heterogeneous catalysts for electrochemical reduction of CO2. ACS Catal, 2015, 5(11): 6302 doi: 10.1021/acscatal.5b01767 [110] Dragasser A, Shekhah O, Zybaylo O, et al. Redox mediation enabled by immobilised centres in the pores of a metal-organic framework grown by liquid phase epitaxy. Chem Commun, 2012, 48(5): 663 doi: 10.1039/C1CC16580A [111] Yaghi O M, O'Keeffe M, Ockwig N W, et al. Reticular synthesis and the design of new materials. Nature, 2003, 423(6941): 705 doi: 10.1038/nature01650 -

下載:

下載: