Research status and prospect of clean and high-value utilization of HyperCoal in China

-

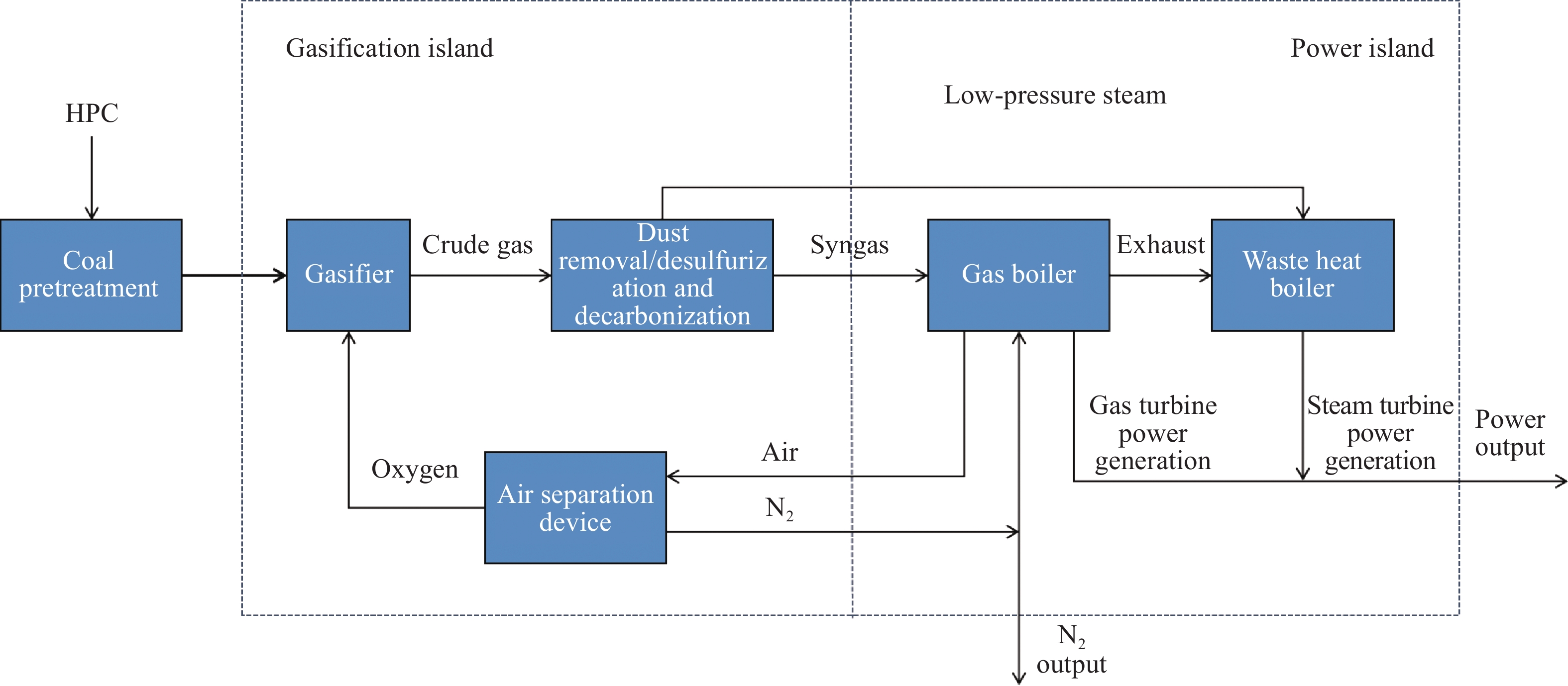

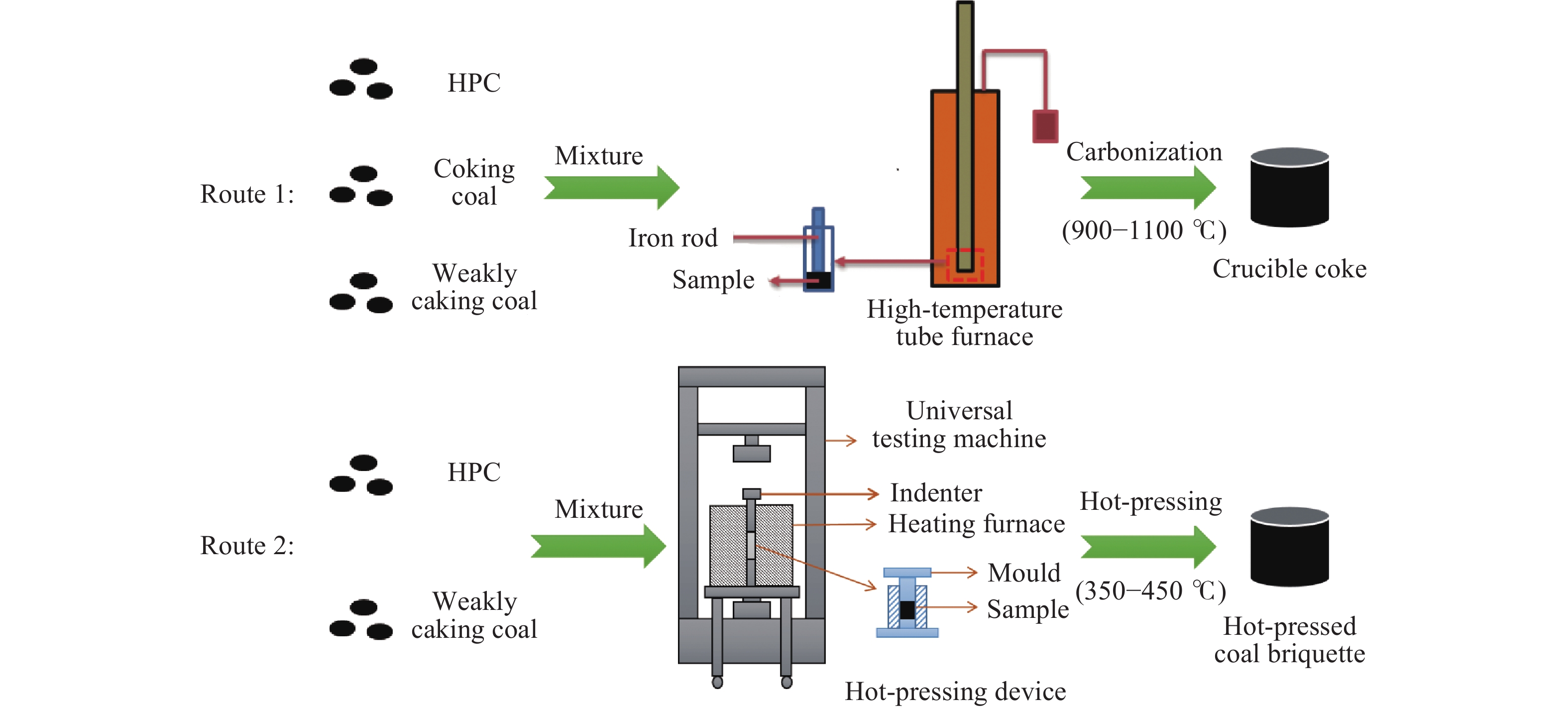

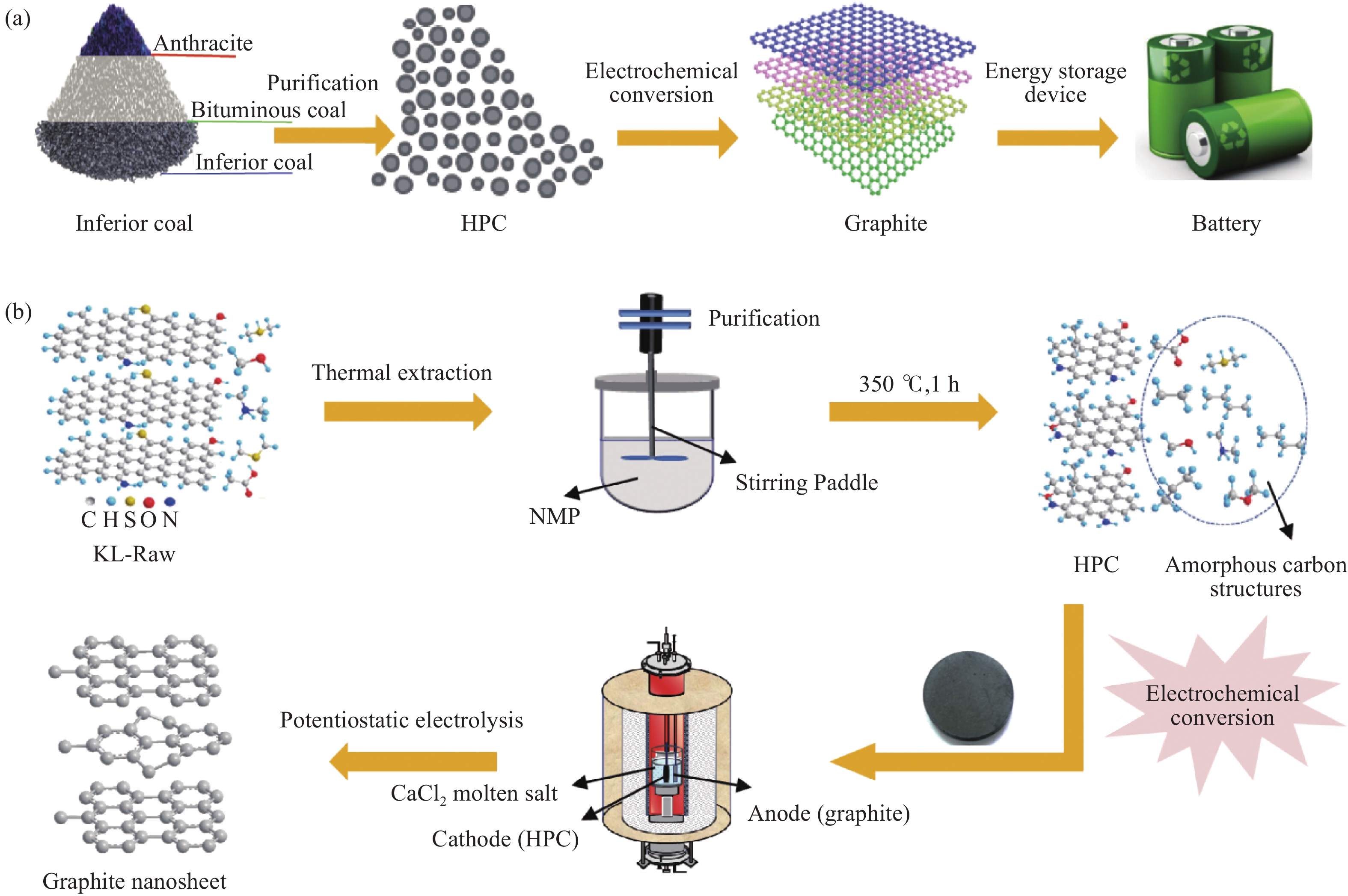

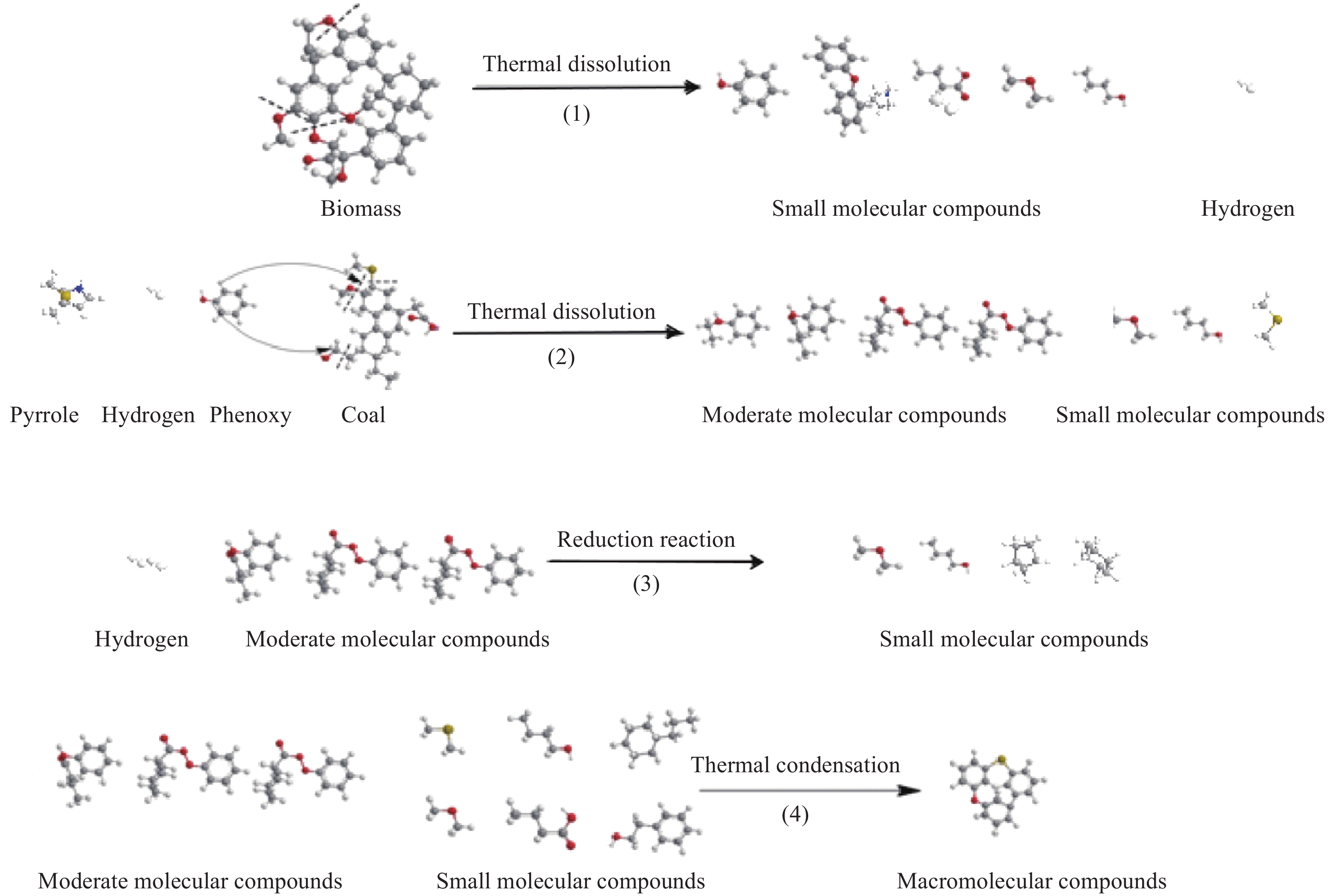

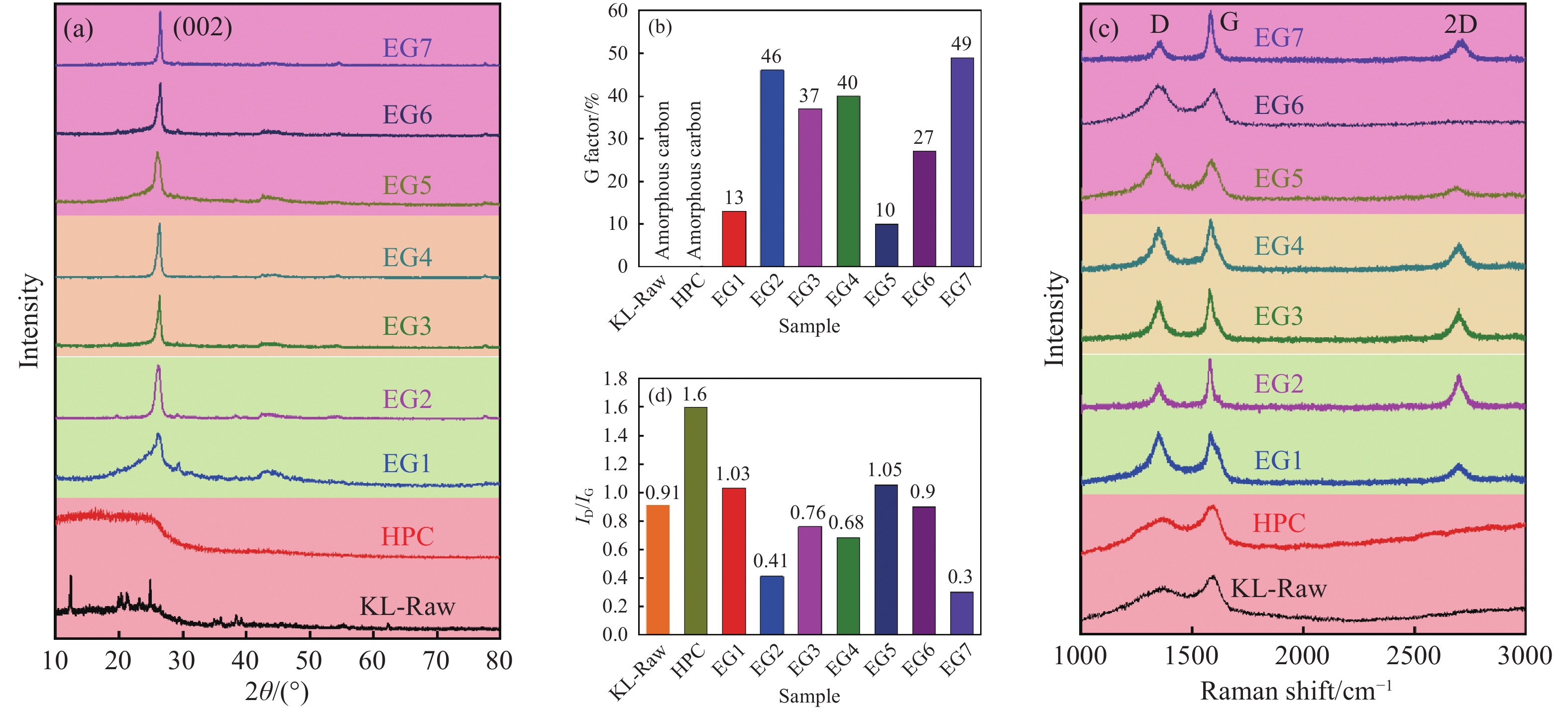

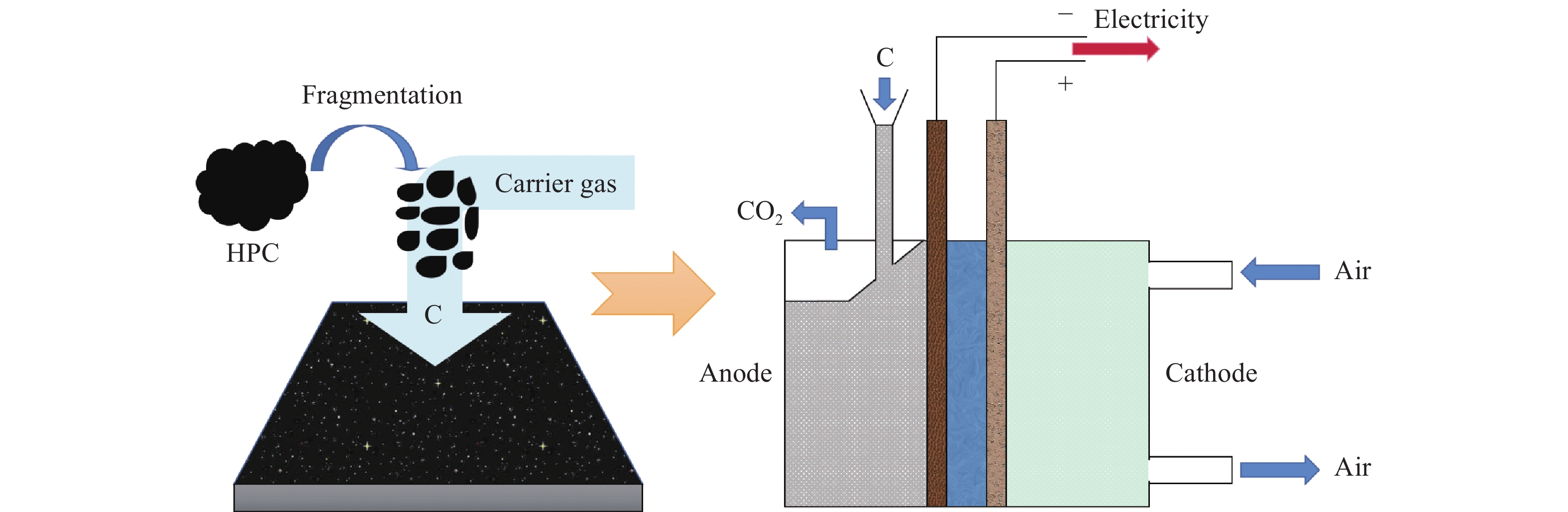

摘要: 作為一個煤炭大國,煤炭在我國的能源結構中占據重要地位。然而,煤炭的過度使用不可避免的造成了環境污染和溫室效應等問題。因此發展潔凈煤技術是解決煤炭利用問題的重要方式,對于我國經濟的可持續發展至關重要。HyperCoal(HPC)是通過溶劑萃取技術得到的一種煤衍生物,由于具有低灰、低水、高熱值、高反應性、良好熱塑性、環境友好等特性,在潔凈煤技術中有著重要的應用。基于此,本文指出了目前我國對HPC的應用研究現狀,并詳細闡述了本研究團隊在配煤煉焦和制備石墨電極領域的突破性研究進展。然而,目前HPC在推廣和應用過程中還存在一些問題。在未來,還亟需解決HPC的規模化生產問題,并對HPC的萃取機理和作用機制開展更加深入的研究。Abstract: China is the world’s largest coal-producing country; coal is very important to Chinese energy structure. However, the excess use of coal has caused serious environmental pollution and the greenhouse effect. Therefore, an indispensable way to solve this coal utilization problem is the development of clean coal technology, which is also essential for the sustainable development of China’s economy. HyperCoal (HPC), a coal derivative obtained by solvent extraction with the properties of low ash content, low moisture, high calorific value, high reactivity, good thermoplasticity, and environmental friendliness, has excellent application in clean coal technology. In terms of combustion, HPC can be used as an advanced fuel for fuel cell and chemical cycle combustion for improving combustion efficiency. Regarding gasification and liquefaction, HPC can be used in the integrated coal gasification combined cycle technology to reduce catalyst loss and equipment damage. In terms of coking coal blending, HPC can be used as an additive in the coking process and a binder for hot-pressed coal briquettes, which can increase the strength of coke and replace scarce coking coal resources such as fat and main coking coals. In the preparation of high-grade carbon materials, HPC can be used to prepare the pitch-based carbon fiber, activated carbon, and graphite electrodes, which considerably improves the performance of carbon materials. Therefore, HPC is valuable in the clean and high-value utilization of coal. On this basis, this paper pointed out the current research status of HPC application in China and elaborated the breakthrough with considerable research results of our team concerning coking coal blending and the preparation of crystalline graphite. However, currently, there are still some problems in the spread and the application of HPC. In the future, large-scale production issues need to be urgently solved, and in-depth research on the extraction mechanism and the action mechanism of HPC should be conducted.

-

Key words:

- HyperCoal /

- clean coal /

- ash /

- solvent extraction /

- coal derivative

-

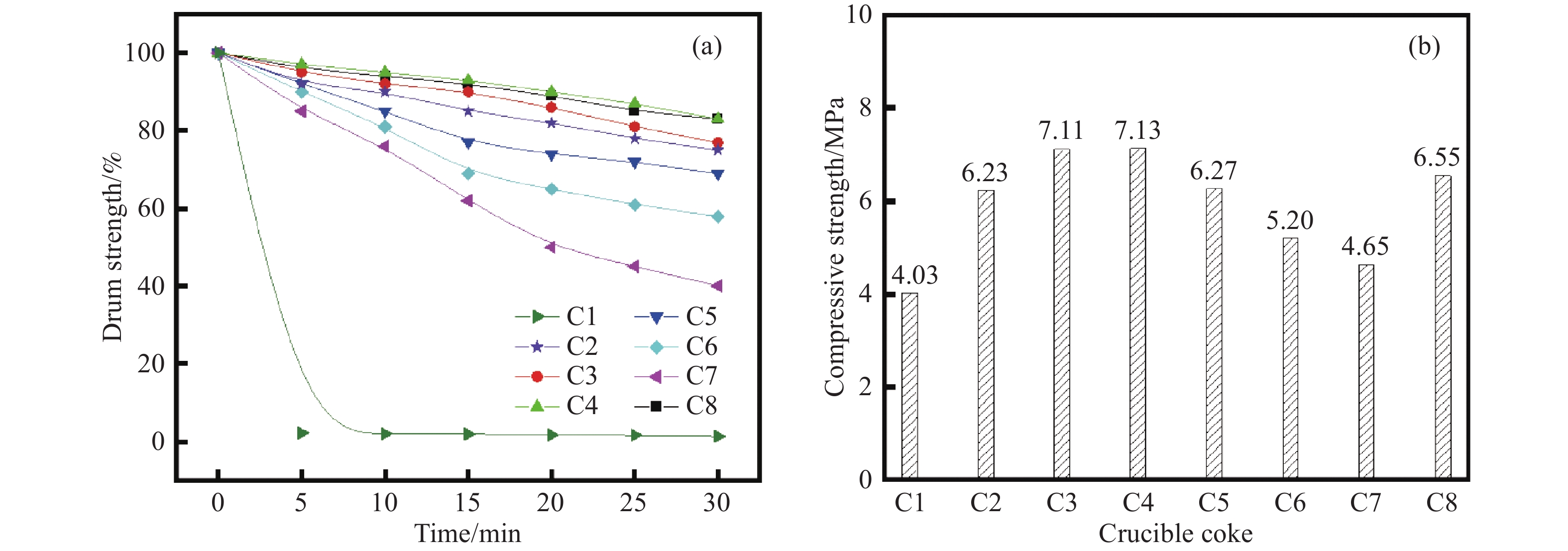

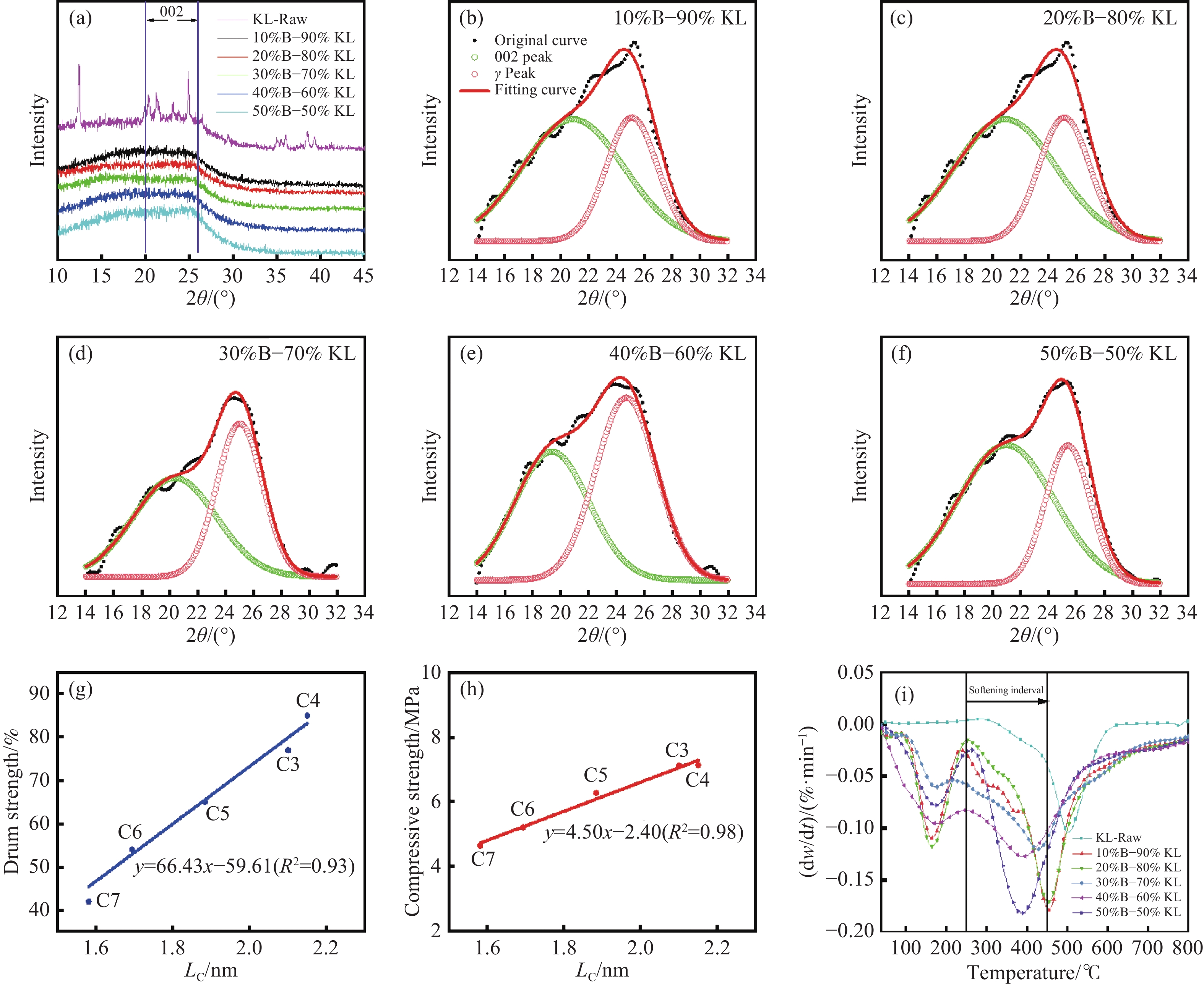

圖 6 Bio-HPC的表征結果[47]. (a~f)X射線衍射圖譜及分峰擬合圖;(g~h)微晶堆疊高度Lc與坩堝焦冷強度的關系圖;(i)KL-Raw和Bio-HPC的熱失重速率曲線圖

Figure 6. Characterization results of Bio-HPC[47]: (a?f) XRD patterns and peak-fitting curves; (g?h) relationship between structural parameters and the cold strength of crucible coke; (i) DTG curves of KL-Raw and Bio-HPC

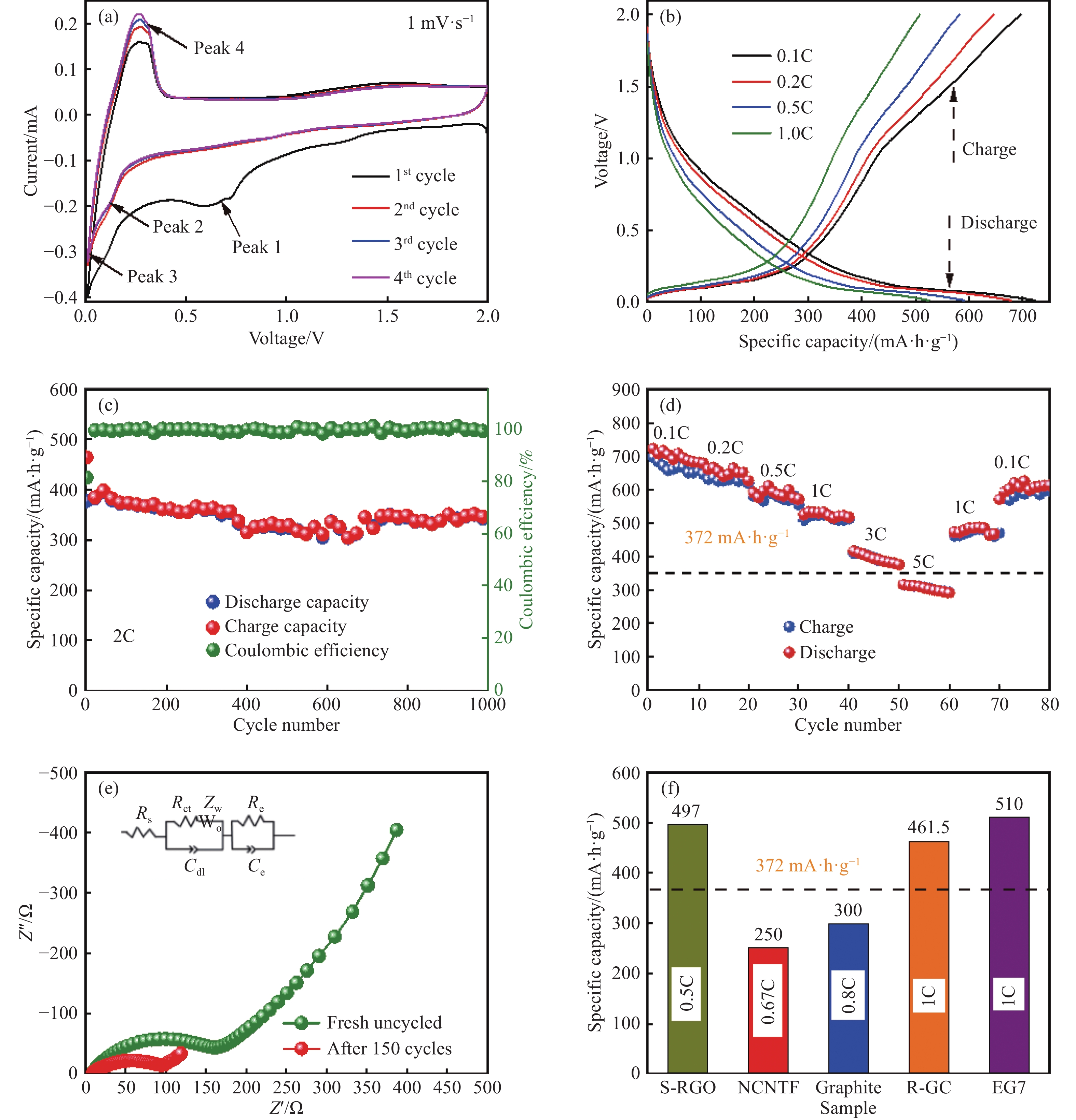

圖 9 EG7的電化學性能[43].(a)循環伏安曲線;(b)不同倍率下的恒電流充放電曲線圖;(c)倍率為2C時的循環性能;(d)倍率性能;(e)電化學阻抗譜;(f)性能對比

Figure 9. Electrochemical performances of EG7[43]: (a) cyclic voltammetry curves; (b) galvanostatic charge-discharge curves of EG7 at different rates; (c) cycling performance and coulombic efficiency at a current rate of 2C; (d) rate capability; (e) electrochemical impedance spectroscopy; (f) comparison of specific capacities reported in the literature and this work

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Wang Y Y. Research on current situation and countermeasures of coal-fired air pollutants control in China. Coal Econ Res, 2019, 39(8): 66王永英. 我國燃煤大氣污染物控制現狀及對策研究. 煤炭經濟研究, 2019, 39(8):66 [2] Zhao L J. Current situation of coal deashing technology and its development in future. Energy Sci Technol, 2021, 19(1): 83趙利軍. 煤炭除灰技術的現狀和發展. 能源科技, 2021, 19(1):83 [3] Zhang S. The Application of Pre-Treatment in Producing Ash-Free Coal by Low Rank Coals [Dissertation]. Tangshan: North China University of Science and Technology, 2016張帥. 預處理在低階煤制備無灰煤中的應用[學位論文]. 唐山: 華北理工大學, 2016 [4] Song X, Peng Y, Gong L S. Research and prospect in coal reprocessing field of chemical deashing in rare coking coal. Coal Technol, 2020, 39(8): 202宋璇, 彭垠, 鞏林盛. 化學脫灰在稀缺煉焦煤中煤再選領域的研究與前景探討. 煤炭技術, 2020, 39(8):202 [5] Rahman M, Pudasainee D, Gupta R. Review on chemical upgrading of coal: Production processes, potential applications and recent developments. Fuel Process Technol, 2017, 158: 35 doi: 10.1016/j.fuproc.2016.12.010 [6] Okuyama N, Komatsu N, Shigehisa T, et al. Hyper-coal process to produce the ash-free coal. Fuel Process Technol, 2004, 85(8-10): 947 doi: 10.1016/j.fuproc.2003.10.019 [7] Yang J X, Wei W J, Qi Y, et al. Research progress on hyper-coal for efficient utilization. J China Coal Soc, 2020, 45(9): 3301楊建校, 魏文杰, 祁勇, 等. 無灰煤高效利用研究進展. 煤炭學報, 2020, 45(9):3301 [8] Fan L H, Liang Y H, Hou C X. Research progress on ash-free coal preparation and application. Coal Sci Technol, 2011, 39(3): 120樊麗華, 梁英華, 侯彩霞. 無灰煤的制備及應用研究進展. 煤炭科學技術, 2011, 39(3):120 [9] Kim J P, Choi H K, Chang Y J, et al. Feasibility of using ash-free coal in a solid-oxide-electrolyte direct carbon fuel cell. Int J Hydrog Energy, 2012, 37(15): 11401 doi: 10.1016/j.ijhydene.2012.04.162 [10] Dudek M, Tomczyk P, Socha R, et al. Use of ash-free “Hyper-coal” as a fuel for a direct carbon fuel cell with solid oxide electrolyte. Int J Hydrog Energy, 2014, 39(23): 12386 doi: 10.1016/j.ijhydene.2014.04.057 [11] Ju H, Eom J, Lee J K, et al. Durable power performance of a direct ash-free coal fuel cell. Electrochimica Acta, 2014, 115: 511 doi: 10.1016/j.electacta.2013.10.124 [12] Wang Q, Cheng Y, Wu C N, et al. A novel energy conservation process for zero emission of carbon dioxide: Chemical looping combustion. Prog Chem, 2008, 20(10): 1612王琦, 程易, 吳昌寧, 等. 新型節能CO2零排放工藝: 化學循環燃燒技術. 化學進展, 2008, 20(10):1612 [13] Shabani A, Rahman M, Pudasainee D, et al. Evaluation of ash-free coal for chemical looping combustion - part I: Thermogravimetric single cycle study and the reaction mechanism. Can J Chem Eng, 2017, 95(4): 623 doi: 10.1002/cjce.22721 [14] Shabani A, Rahman M, Pudasainee D, et al. Evaluation of ash-free coal for chemical looping combustion - part II: Thermogravimetric multi-cycle performance. Can J Chem Eng, 2017, 95(5): 832 doi: 10.1002/cjce.22713 [15] Liu H W, Ni W D, Li Z, et al. Strategic thinking on IGCC development in China. Energy Policy, 2008, 36(1): 1 doi: 10.1016/j.enpol.2007.08.034 [16] Kong Y J, Kim J, Chun D, et al. Comparative studies on steam gasification of ash-free coals and their original raw coals. Int J Hydrog Energy, 2014, 39(17): 9212 doi: 10.1016/j.ijhydene.2014.04.054 [17] Park S H, Chung S W, Lee S K, et al. Thermo-economic evaluation of 300 MW class integrated gasification combined cycle with ash free coal (AFC) process. Appl Therm Eng, 2015, 89: 843 doi: 10.1016/j.applthermaleng.2015.06.066 [18] Sharma A, Kawashima H, Saito I, et al. Structural characteristics and gasification reactivity of chars prepared from K2CO3 mixed HyperCoals and coals. Energy Fuels, 2009, 23(4): 1888 doi: 10.1021/ef800817h [19] Sharma A, Saito I, Takanohashi T. Effect of steam partial pressure on gasification rate and gas composition of product gas from catalytic steam gasification of HyperCoal. Energy Fuels, 2009, 23(10): 4887 doi: 10.1021/ef900461w [20] Sharma A, Takanohashi T, Morishita K, et al. Low temperature catalytic steam gasification of HyperCoal to produce H2 and synthesis gas. Fuel, 2008, 87(4-5): 491 doi: 10.1016/j.fuel.2007.04.015 [21] Sharma A, Takanohashi T, Saito I. Effect of catalyst addition on gasification reactivity of HyperCoal and coal with steam at 775-700 ℃. Fuel, 2008, 87(12): 2686 doi: 10.1016/j.fuel.2008.03.010 [22] Sharma A, Takanohashi T. Controlling the H2/CO ratio of the synthesis gas in a single step by catalytically gasifying coal in a steam and carbon dioxide mixed environment at low temperatures. Energy Fuels, 2010, 24(3): 1745 doi: 10.1021/ef901178d [23] Koyano K, Takanohashi T, Saito I. Catalytic hydrogenation of HyperCoal (ashless coal) and reusability of catalyst. Energy Fuels, 2009, 23(7): 3652 doi: 10.1021/ef900135r [24] Zou D H, Yang X, Shui H F, et al. Liquefaction of thermal extracts from co-thermal dissolution of a sub-bituminous coal with lignin and reusability of Ni?Mo?S/Al2O3 catalyst. J Fuel Chem Technol, 2019, 47(1): 23 doi: 10.1016/S1872-5813(19)30004-0 [25] Takanohashi T, Shishido T, Saito I. Effects of HyperCoal addition on coke strength and thermoplasticity of coal blends. Energy Fuels, 2008, 22(3): 1779 doi: 10.1021/ef7007375 [26] Sekine Y, Fujimoto H. Evaluation of the structure and strength of coke with HPC binder under various preparation conditions. ISIJ Int, 2019, 59(8): 1437 doi: 10.2355/isijinternational.ISIJINT-2018-772 [27] Sekine Y, Sumomozawa F, Shishido T. Coking technology using heavy oil residue and hyper coal. ISIJ Int, 2014, 54(11): 2446 doi: 10.2355/isijinternational.54.2446 [28] Hao L F, Feng P, Song W L, et al. Modification performance of Hypercoal as an additive on co-carbonization of coal. J Fuel Chem Technol, 2012, 40(9): 1025 doi: 10.1016/S1872-5813(12)60037-1 [29] Sharma A, Sakimoto N, Anraku D, et al. Physical and chemical characteristics of coal-binder interface and carbon microstructure near interface. ISIJ Int, 2014, 54(11): 2470 doi: 10.2355/isijinternational.54.2470 [30] Zhao J, Zuo H B, Wang G W, et al. Improving the coke property through adding HPC extracted from the mixture of low-rank coal and biomass. Energy Fuels, 2020, 34(2): 1802 doi: 10.1021/acs.energyfuels.9b03459 [31] Wang Y J, Zuo H B, Zhao J, et al. Using HyperCoal to prepare metallurgical coal briquettes via hot-pressing. Int J Miner Metall Mater, 2019, 26(5): 547 doi: 10.1007/s12613-019-1763-3 [32] Baker D A, Rials T G. Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci, 2013, 130(2): 713 doi: 10.1002/app.39273 [33] Yang J X, Nakabayashi K, Miyawaki J, et al. Preparation of isotropic pitch-based carbon fiber using hyper coal through co-carbonation with ethylene bottom oil. J Ind Eng Chem, 2016, 34: 397 doi: 10.1016/j.jiec.2015.11.026 [34] Yang J X, Nakabayashi K, Miyawaki J, et al. Preparation of pitch based carbon fibers using Hyper-coal as a raw material. Carbon, 2016, 106: 28 doi: 10.1016/j.carbon.2016.05.019 [35] Shimanoe H, Mashio T, Nakabayashi K, et al. Manufacturing spinnable mesophase pitch using direct coal extracted fraction and its derived mesophase pitch based carbon fiber. Carbon, 2020, 158: 922 doi: 10.1016/j.carbon.2019.11.082 [36] Li X, Zhu X Q, Okuda K, et al. Preparation of carbon fibers from low-molecular-weight compounds obtained from low-rank coal and biomass by solvent extraction. New Carbon Mater, 2017, 32(1): 41 doi: 10.1016/S1872-5805(17)60106-9 [37] Watanabe H, Tsumura T, Toyoda M. EDLC characteristics of carbon materials prepared from coal extract. Electrochemistry, 2020, 88(3): 119 doi: 10.5796/electrochemistry.20-63011 [38] Zhao X Y, Huang S S, Cao J P, et al. HyperCoal-derived porous carbons with alkaline hydroxides and carbonate activation for electric double-layer capacitors. Fuel Process Technol, 2014, 125: 251 doi: 10.1016/j.fuproc.2014.04.012 [39] Zhao X Y, Huang S S, Cao J P, et al. KOH activation of a HyperCoal to develop activated carbons for electric double-layer capacitors. J Anal Appl Pyrolysis, 2014, 105: 116 doi: 10.1016/j.jaap.2013.10.010 [40] Fan L H, Wang X L, Hou C X, et al. Research on performance comparison of lignite-activated carbon and hypercoal-activated carbon. J Funct Mater, 2017, 48(1): 1244 doi: 10.3969/j.issn.1001-9731.2017.01.044樊麗華, 王曉柳, 侯彩霞, 等. 褐煤基活性炭和無灰煤基活性炭性能對比研究. 功能材料, 2017, 48(1):1244 doi: 10.3969/j.issn.1001-9731.2017.01.044 [41] Xu L J, Fan L H, Hou C X, et al. Effect of adding microwave absorber on structures and properties of hypercoal-based activated carbons. J Wuhan Univ Technol Mater Sci Ed, 2020, 35(3): 488 doi: 10.1007/s11595-020-2283-8 [42] An F Q, Zhao H L, Cheng Z, et al. Development status and research progress of power battery for pure electric vehicles. Chin J Eng, 2019, 41(1): 22安富強, 趙洪量, 程志, 等. 純電動車用鋰離子電池發展現狀與研究進展. 工程科學學報, 2019, 41(1):22 [43] Zhu Z L, Zuo H B, Li S J, et al. A green electrochemical transformation of inferior coals to crystalline graphite for stable Li-ion storage. J Mater Chem A, 2019, 7(13): 7533 doi: 10.1039/C8TA12412D [44] Guo B L, Hou C X, Fan L H, et al. Effect of extraction temperature on hyper-coal structure and electrochemistry of coal-based activated carbon. Chin J Inorg Chem, 2018, 34(9): 1615 doi: 10.11862/CJIC.2018.201郭秉霖, 侯彩霞, 樊麗華, 等. 萃取溫度對無灰煤結構及煤基活性炭電化學性能的影響. 無機化學學報, 2018, 34(9):1615 doi: 10.11862/CJIC.2018.201 [45] Fan L H, Du J W, Liang Y H, et al. Pyrolysis behavior of hypercoal and its adding effect in blending coal. Coal Sci Technol, 2017, 45(3): 185樊麗華, 杜敬文, 梁英華, 等. 無灰煤的熱解行為及其在配煤中的添加效果. 煤炭科學技術, 2017, 45(3):185 [46] Shui H F, He F, Wu Y, et al. Study on the use of the thermal dissolution soluble fraction from shenfu sub-bituminous coal in coke-making coal blends. Energy Fuels, 2015, 29(3): 1558 doi: 10.1021/ef502736a [47] Zhao J, Zuo H B, Wang J S, et al. The mechanism and products for co-thermal extraction of biomass and low-rank coal with NMP. Int J Miner Metall Mater, 2019, 26(12): 1512 doi: 10.1007/s12613-019-1872-z [48] Ma Z, Zhuang Y C, Deng Y M, et al. From spent graphite to amorphous sp2+sp3 carbon-coated sp2 graphite for high-performance lithium ion batteries. J Power Sources, 2018, 376: 91 -

下載:

下載: