Numerical simulation and optimization of the flow in the sintering flue gas circulating hot air hood

-

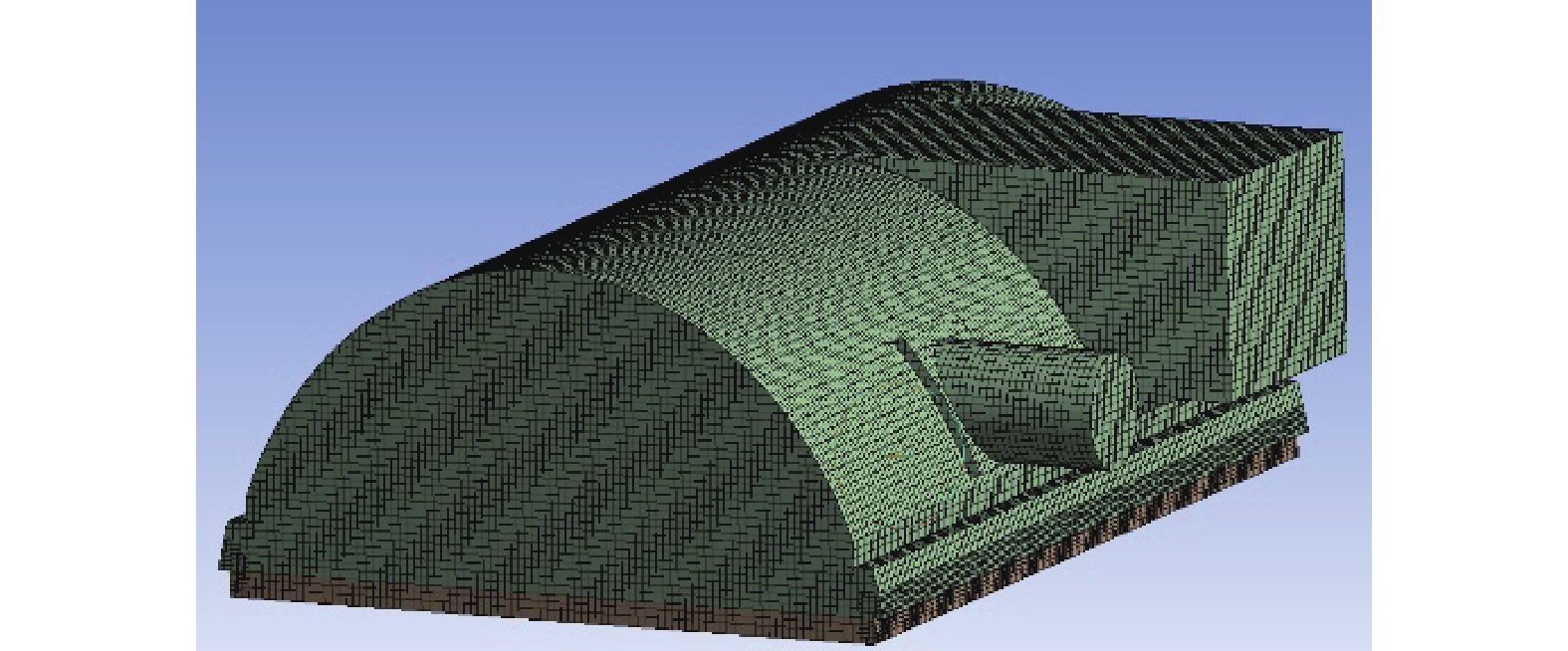

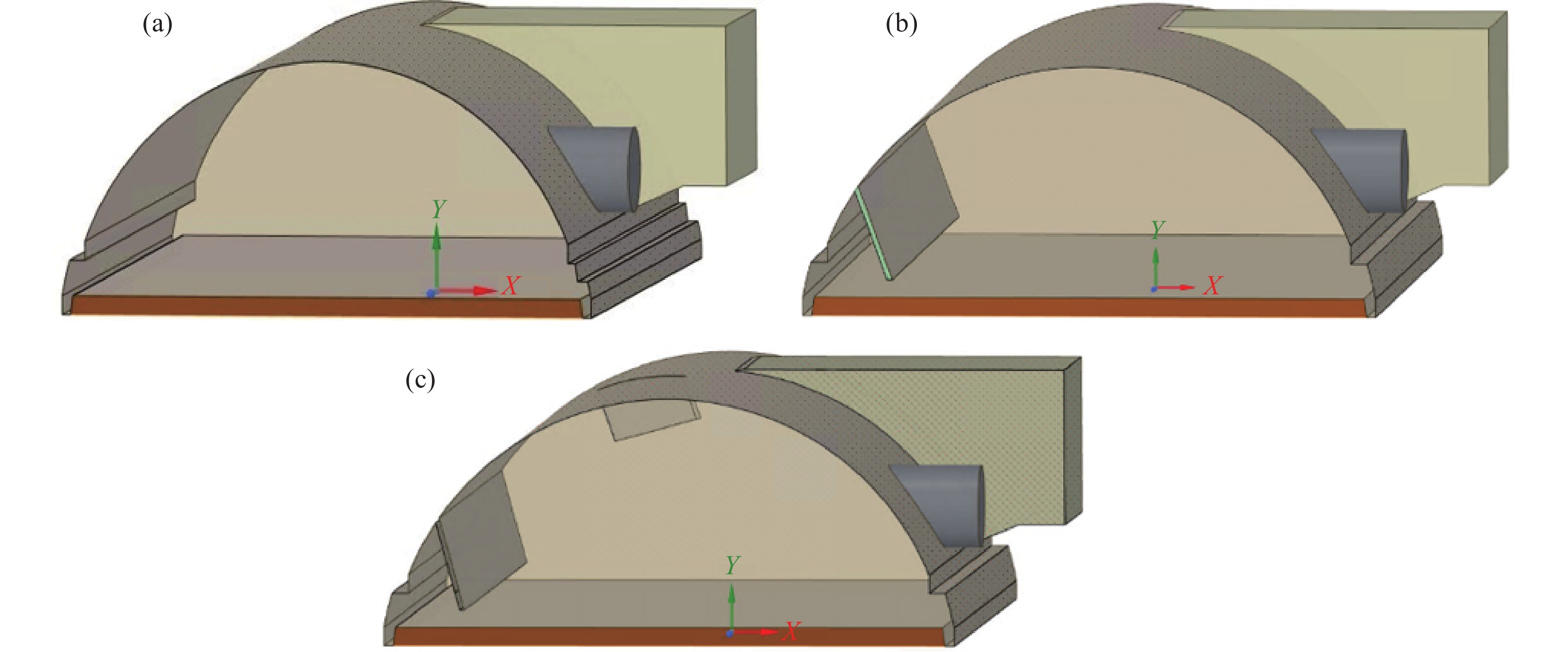

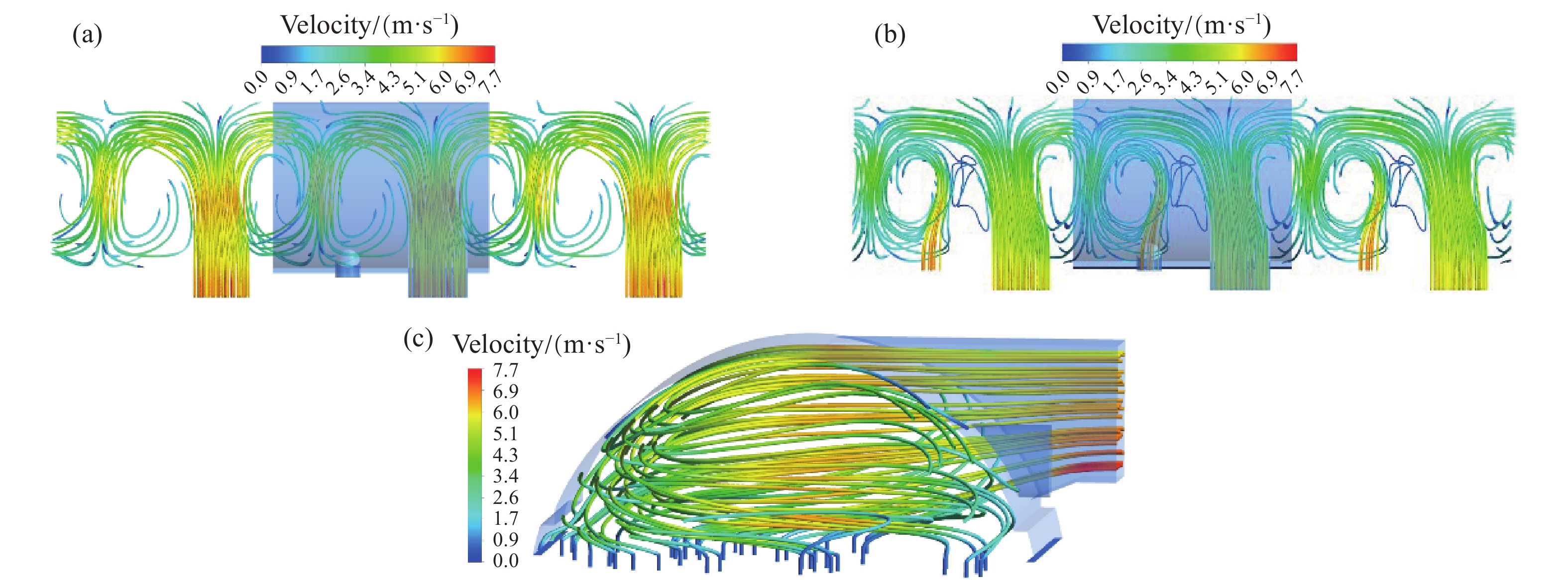

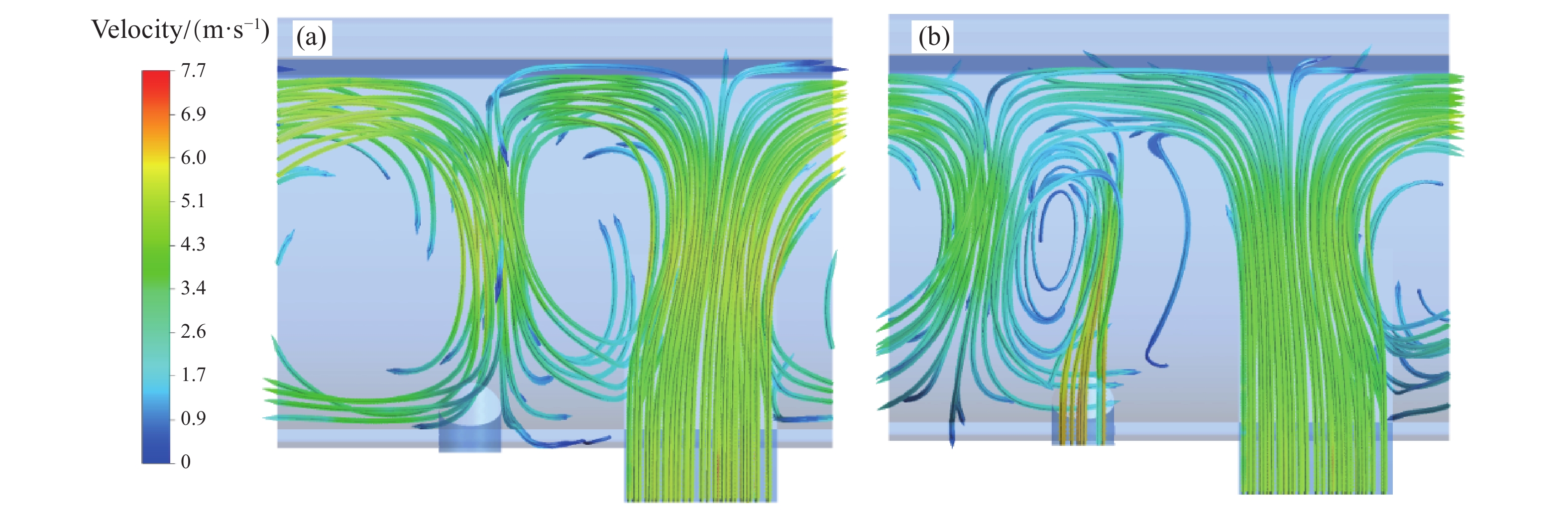

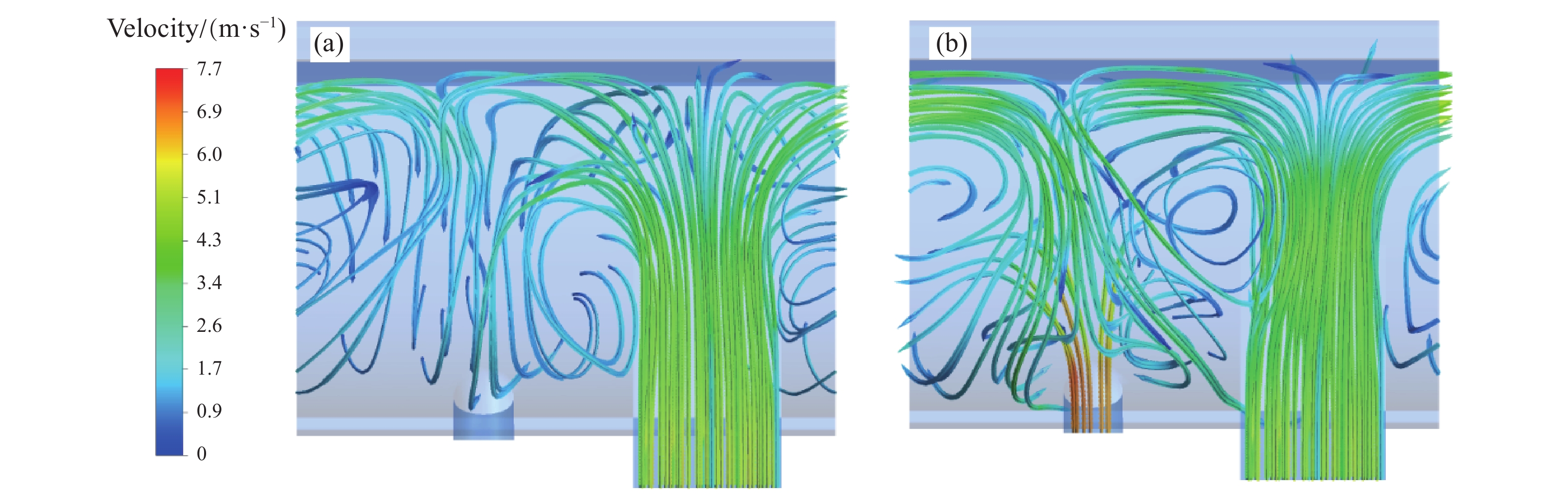

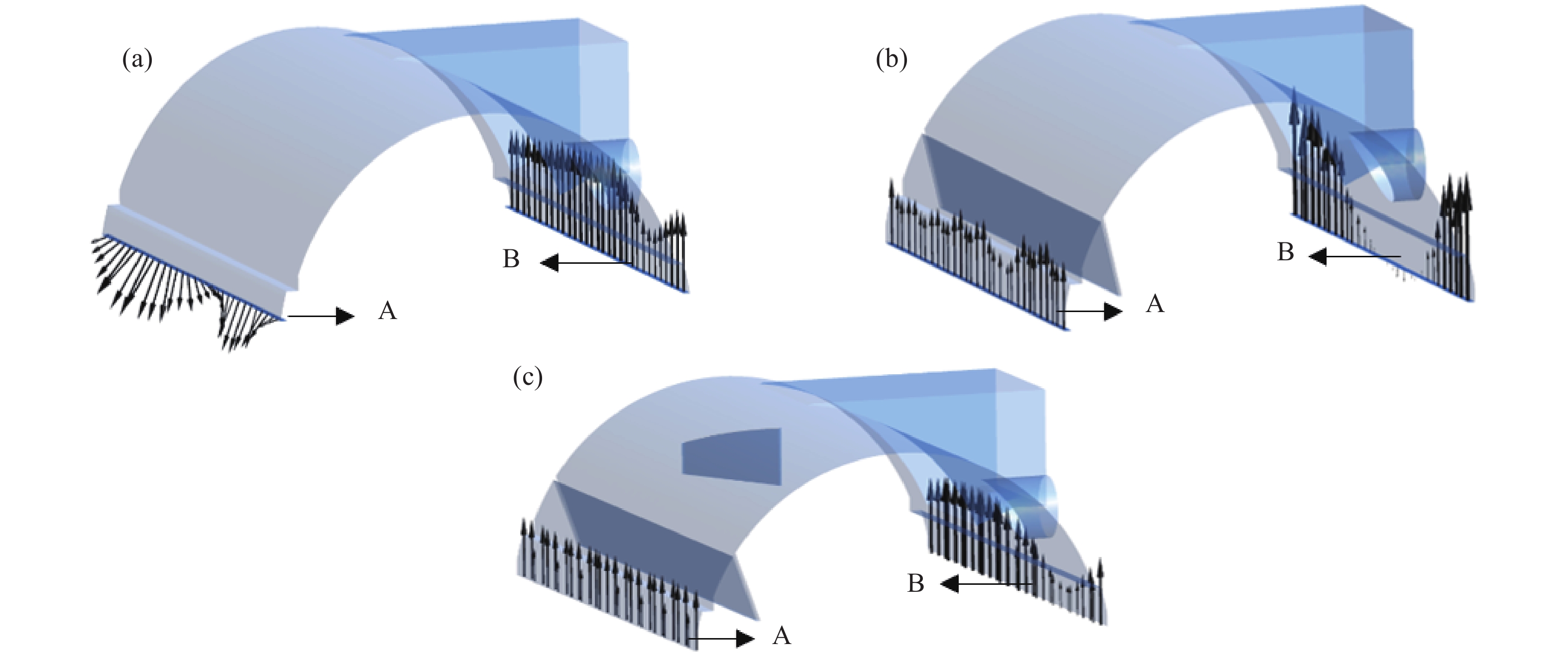

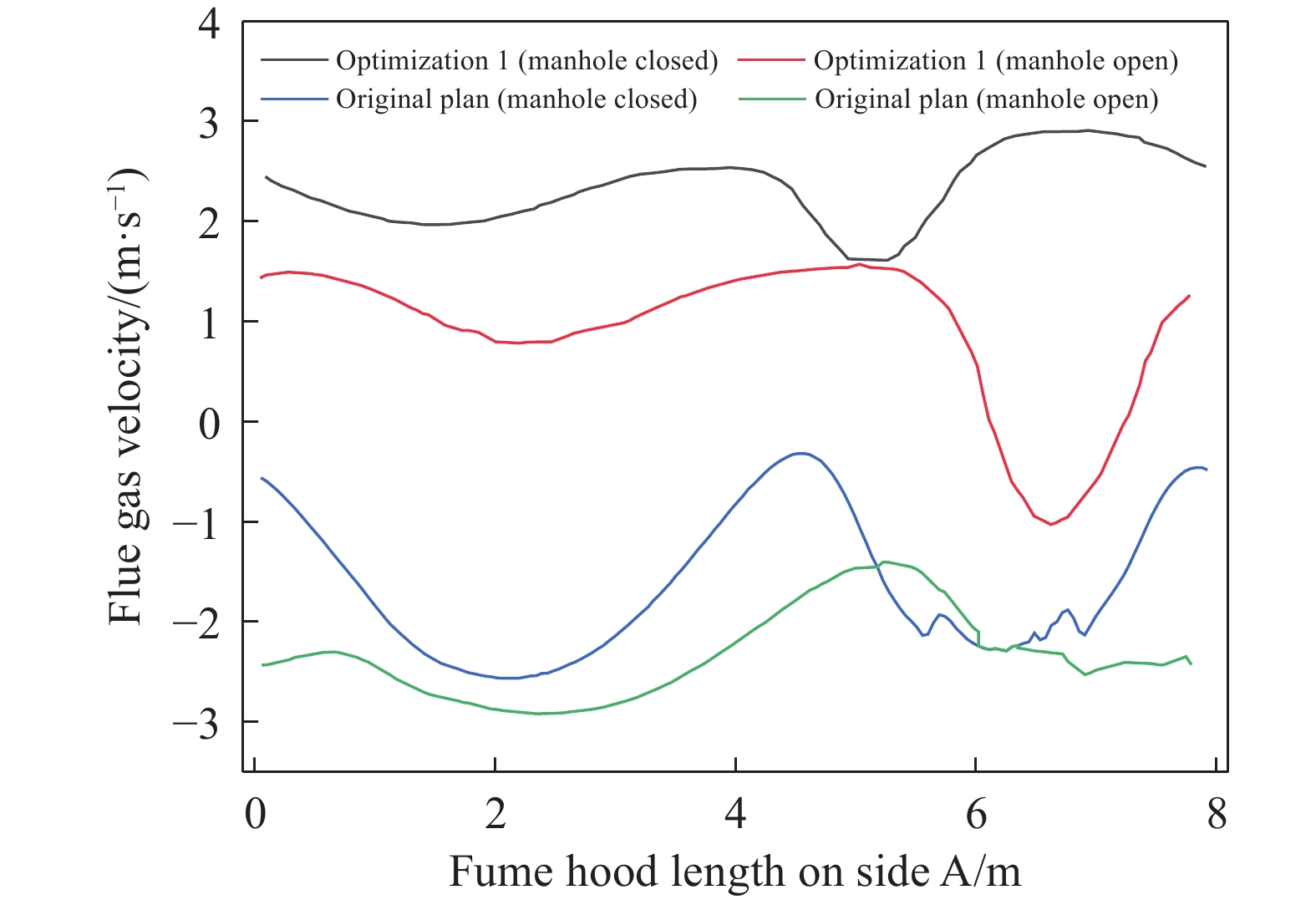

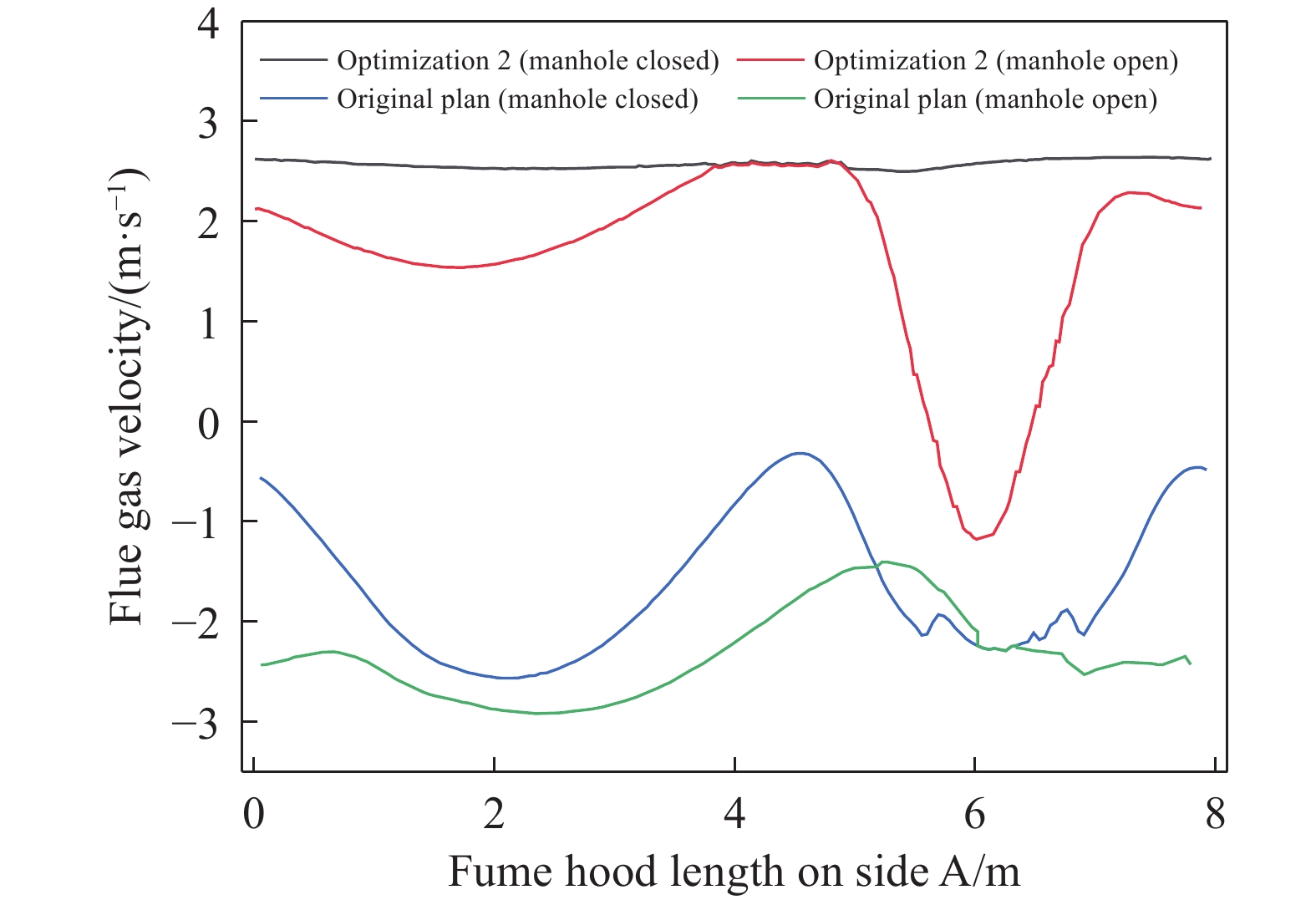

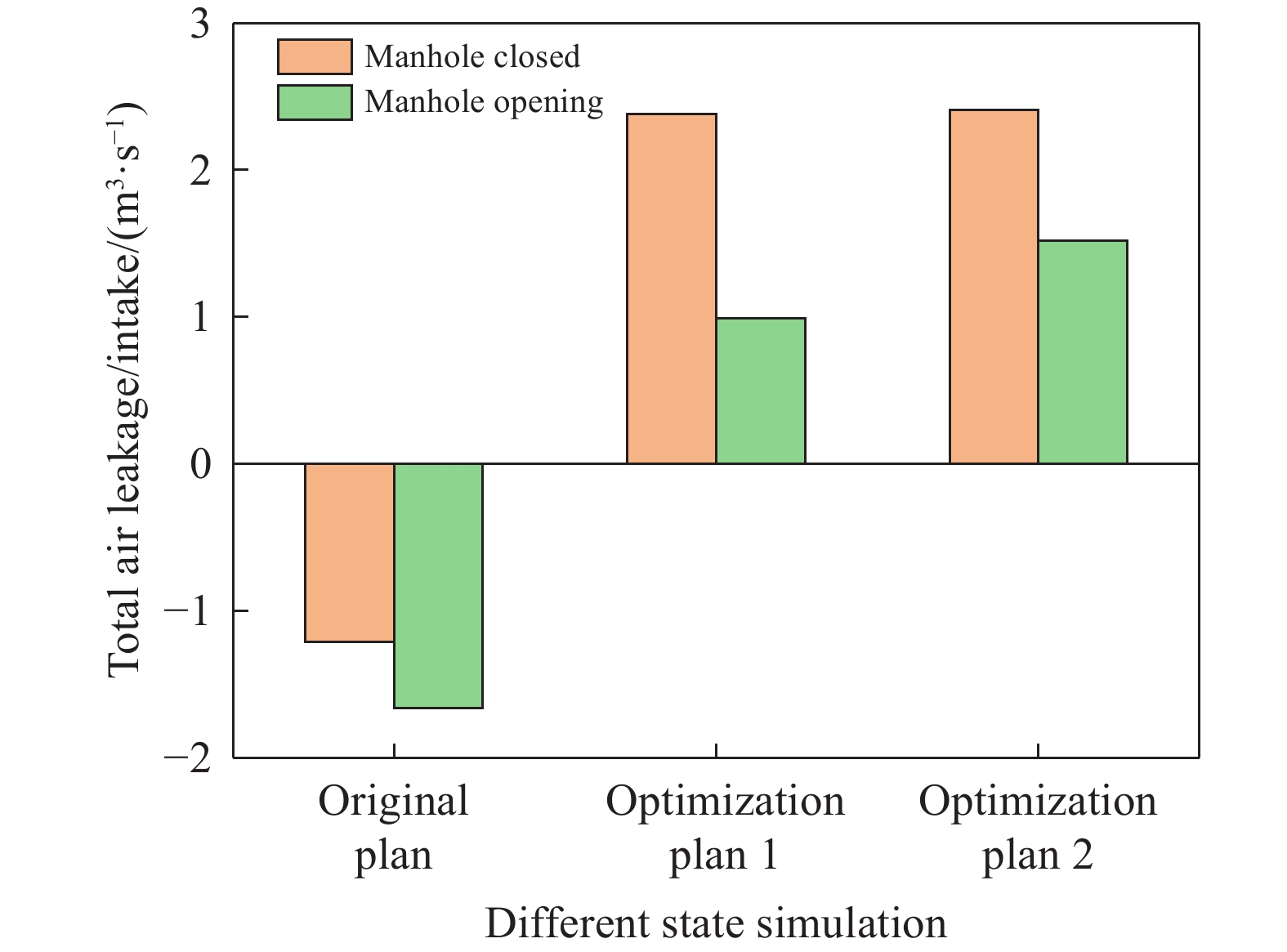

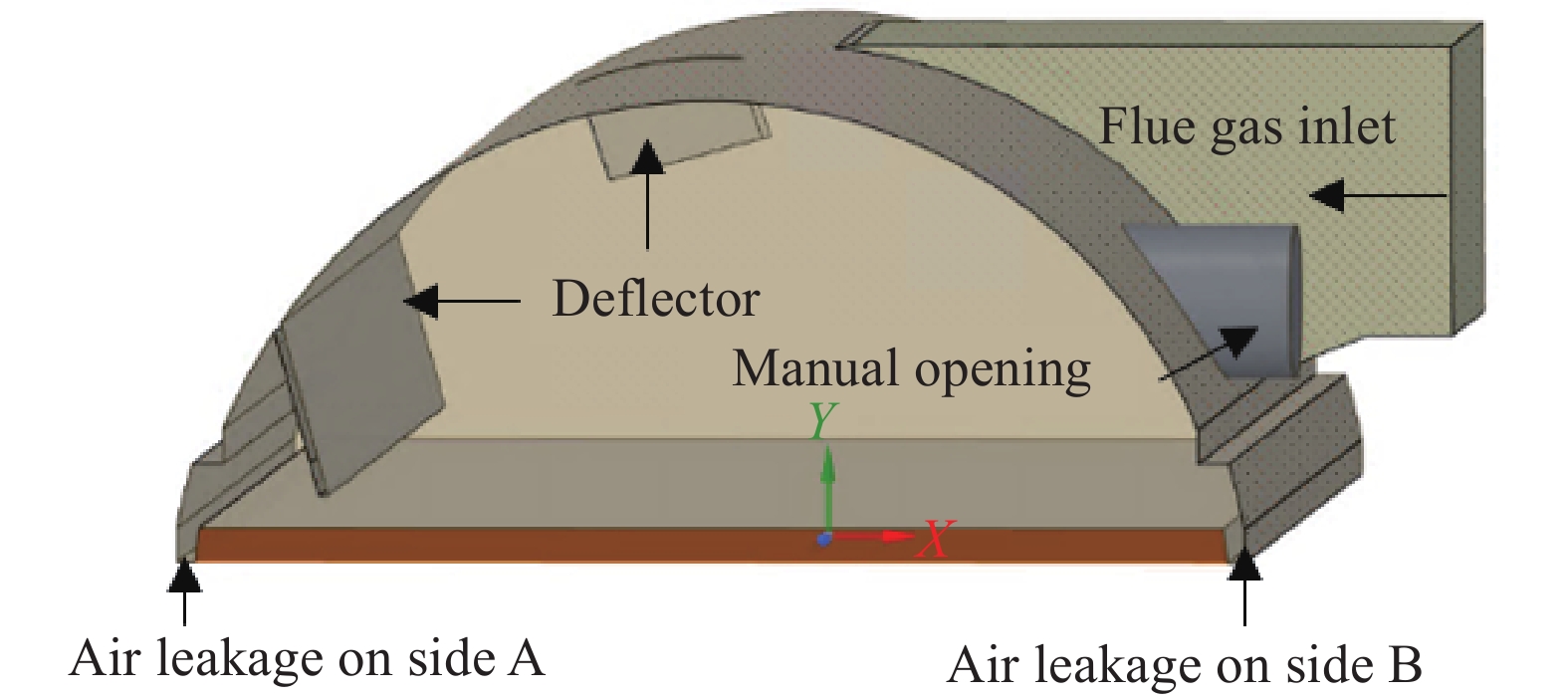

摘要: 煙氣循環技術是基于部分熱廢氣被再次引入燒結過程的原理而開發的一種新型燒結模式,對提高燒結余熱利用率、降低污染物排放和燒結能耗具有顯著效果。但循環煙氣在煙氣罩內流動狀態、煙氣罩漏風狀況等對煙氣循環的效果及穩定性至關重要。為此,對某鋼廠循環煙氣罩內煙氣流動狀態及漏風狀況進行模擬,結果表明:現有煙氣罩人孔打開時雖然在一定程度上削弱了煙氣進入形成漩渦的強度,但并未改善煙氣旋轉流動,導致料面上煙氣流速不均;通過優化煙氣罩內導流板結構和數量,削弱了煙氣罩內煙氣旋轉流動,明顯改善了循環煙氣的流動,使煙氣分布更均勻;同時煙氣罩漏風狀況大大改善,優化后使A側漏風口由漏風1.2 m3?s?1變為吸風2.4 m3?s?1,有利于燒結生產的順行。Abstract: The flue gas circulation technology is a new type of sintering mode developed based on the principle of the reintroduction of part of the hot exhaust gas into the sintering process. It has considerable effects on improving the utilization rate of the sintering waste heat and reducing pollutant emissions and sintering energy consumption. However, the circulating flue gas flow state in the flue gas hood and air leakage of the flue gas hood are critical to the effect and stability of the flue gas circulation. Simultaneously, they have a considerable impact on the quality indicators of the sintered ore. To optimize the circulating flue gas flow state in the flue gas hood, improve the air leakage of the flue gas hood, and maximize the advantages of low pollution and low emission of the flue gas circulation sintering technology, this study simulated the flue gas flow status in the circulating flue gas hood of a steel plant and the air leakage situation. Results show that although the strength of the smoke entering to form the vortex is weakened to a certain extent when the existing smoke hood manhole is opened, the swirling flow of the smoke is not improved, resulting in the uneven flow velocity of the smoke on the material surface. Moreover, evident air leakage of the flue gas hood is observed. By optimizing the structure and number of baffles in the flue gas hood, the rotating flow of the flue gas in the flue gas hood is weakened, the circulation of the flue gas flow considerably improved, and the flue gas distribution is more uniform. Simultaneously, the air leakage of the gas hood greatly improved. After optimization, the air leakage on the side changes from a leakage of 1.2 m3·s?1 to a suction of 2.4 m3·s?1, which is conducive to the smooth movement of the sintering production.

-

Key words:

- sintering /

- flue gas hood /

- flue gas circulation /

- air leakage /

- flow state

-

表 1 數學模型計算邊界條件

Table 1. Mathematical model to calculate boundary conditions

Boundary conditions Parameter Ventilation negative pressure/kPa ?18 Inlet pressure/kPa 0 Manhole pressure/kPa 0.1 Leakage pressure/kPa 0 Bed thickness/mm 850 Width of air leakage gap/mm 10 Bed width/mm 6200 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Xing Y, Zhang W B, Su W, et al. Research of ultra-low emission technologies of the iron and steel industry in China. Chin J Eng, 2021, 43(1): 1邢奕, 張文伯, 蘇偉, 等. 中國鋼鐵行業超低排放之路. 工程科學學報, 2021, 43(1):1 [2] He K B. Winning the defense of the blue sky needs to acceleratethe ultra-low emission transformation of the steel industry. China Environ News, 2019-05-06賀克斌. 打贏藍天保衛戰需要加快鋼鐵行業超低排放改造. 中國環境報, 2019-05-06 [3] Li X C. Road map to high-quality development of iron and steel industry in new age. Iron Steel, 2019, 54(1): 1 doi: 10.13228/j.boyuan.issn0449-749x.20180264李新創. 新時代鋼鐵工業高質量發展之路. 鋼鐵, 2019, 54(1):1 doi: 10.13228/j.boyuan.issn0449-749x.20180264 [4] Zhou J C, Zhang C X, Li X P, et al. Status of energy consumption and review and prospect of energy saving technologies of blast furnace procedure in China. J Iron Steel Res, 2010, 22(9): 1 doi: 10.13228/j.boyuan.issn1001-0963.2010.09.011周繼程, 張春霞, 酈秀萍, 等. 中國高爐工序能耗現狀及節能技術的回顧與展望. 鋼鐵研究學報, 2010, 22(9):1 doi: 10.13228/j.boyuan.issn1001-0963.2010.09.011 [5] Gao X. Development situation and trend analysis of sintering industry in China. Iron Steel, 2008, 43(1): 85 doi: 10.3321/j.issn:0449-749X.2008.01.021郜學. 中國燒結行業的發展現狀和趨勢分析. 鋼鐵, 2008, 43(1):85 doi: 10.3321/j.issn:0449-749X.2008.01.021 [6] Yan B J, Xing Y, Lu P, et al. A critical review on the research progress of multi-pollutant collaborative control technologies of sintering flue gas in the iron and steel industry. Chin J Eng, 2018, 40(7): 767閆伯駿, 邢奕, 路培, 等. 鋼鐵行業燒結煙氣多污染物協同凈化技術研究進展. 工程科學學報, 2018, 40(7):767 [7] Que Z G, Wu S L, Ai X B. To reduce NOx emission based on optimizing the existing states of coarse coke breeze during iron ore sintering process. Chin J Eng, 2020, 42(2): 163闕志剛, 吳勝利, 艾仙斌. 基于優化粗粒級固體燃料賦存形態的鐵礦燒結過程NOx減排. 工程科學學報, 2020, 42(2):163 [8] Xia J F, Yu Y J, Wang X J, et al. Research on operation parameters optimization of sinter cooler waste heat recovery system based on exergy efficiency optimization. J Iron Steel Res, 2019, 31(7): 637 doi: 10.13228/j.boyuan.issn1001-0963.20180311夏建芳, 余媛君, 王瀟杰, 等. 基于?效率目標的環冷機余熱回收系統操作參數優化. 鋼鐵研究學報, 2019, 31(7):637 doi: 10.13228/j.boyuan.issn1001-0963.20180311 [9] Wang G, Wen Z, Lou G F, et al. Mathematical modeling of and parametric studies on flue gas recirculation iron ore sintering. Appl Therm Eng, 2016, 102: 648 doi: 10.1016/j.applthermaleng.2016.04.018 [10] Long H M, Zhang X Y, Li J X, et al. Study on emission characteristics of SO2 and feasibility of desulfurization in iron ore sintering process. Chin J Process Eng, 2015, 15(2): 230龍紅明, 張向陽, 李家新, 等. 鐵礦燒結過程SO2的排放特性及過程脫硫的可行性研究. 過程工程學報, 2015, 15(2):230 [11] Qie J M, Zhang C X, Wang H F, et al. Analysis of emission situation and emission reduction technology of typical sintering flue gas pollutants. Sinter Pelletizing, 2016, 41(6): 59 doi: 10.13403/j.sjqt.2016.06.078郄俊懋, 張春霞, 王海風, 等. 燒結煙氣典型污染物排放形勢及減排技術分析. 燒結球團, 2016, 41(6):59 doi: 10.13403/j.sjqt.2016.06.078 [12] Liu C P, Yang D W, Hui J M, et al. One-stop solution of cascade utilization of waste heat recovery, desulfurization and denitrification in the sintering system. J Iron Steel Res, 2016, 28(10): 50 doi: 10.13228/j.boyuan.issn1001-0963.20150364劉傳鵬, 楊東偉, 惠建明, 等. 燒結余熱梯級利用及脫硫脫硝一站式解決方案. 鋼鐵研究學報, 2016, 28(10):50 doi: 10.13228/j.boyuan.issn1001-0963.20150364 [13] Ding Y, Shi D M. High-efficiency utilization of waste heat at fully integrated steel plant. Iron Steel, 2011, 46(10): 88 doi: 10.13228/j.boyuan.issn0449-749x.2011.10.020丁毅, 史德明. 鋼鐵企業余熱資源高效利用. 鋼鐵, 2011, 46(10):88 doi: 10.13228/j.boyuan.issn0449-749x.2011.10.020 [14] Sun Y J, Dong H, Feng J S, et al. Thermodynamic analysis of waste heat recovery for sinter?cooling system. J Iron Steel Res, 2015, 27(1): 16孫用軍, 董輝, 馮軍勝, 等. 燒結?冷卻?余熱回收系統熱力學分析. 鋼鐵研究學報, 2015, 27(1):16 [15] Wang Z C, Zhou Z A, Hu B, et al. Wind-oxygen balance model of flue gas circulation in sintering. Iron Steel, 2015, 50(12): 53 doi: 10.13228/j.boyuan.issn0449-749x.20150418王兆才, 周志安, 胡兵, 等. 燒結煙氣循環風氧平衡模型. 鋼鐵, 2015, 50(12):53 doi: 10.13228/j.boyuan.issn0449-749x.20150418 [16] Ren W, Gao J, Xu W Q, et al. Numerical simulation of sintering flue gas circulation system equipment?flue gas distributor based on fluent. J North Univ China (Nat Sci Ed) , 2021, 42(1): 56任偉, 高璟, 徐文青, 等. 基于Fluent的燒結煙氣循環系統設備?煙氣分配器數值模擬. 中北大學學報(自然科學版), 2021, 42(1):56 [17] Long H M, Wang Y F, Wu Y, et al. Study on sintering flue gas for recycling of pollutants aimed at emission reduction and progress of applications. Angang Technol, 2020(1): 9龍紅明, 王毅璠, 伍英, 等. 面向污染物減排的燒結煙氣循環研究與應用進展. 鞍鋼技術, 2020(1):9 [18] Qian L X, Wang Y F, Liu M L, et al. Performance evaluation of urea injection on the emission reduction of dioxins and furans in a commercial municipal solid waste incinerator. Process Saf Environ Prot, 2021, 146: 577 doi: 10.1016/j.psep.2020.11.048 [19] Zhang Y D, Long H M, Wu Y, et al. Analysis on reaction in sintering process under hot exhaust gas circulation. Sinter Pelletizing, 2020, 45(5): 63章裕東, 龍紅明, 伍英, 等. 熱廢氣循環條件下的燒結過程反應解析. 燒結球團, 2020, 45(5):63 [20] Long H M, Li J X, Wang P, et al. Reaction mechanism of emission reduction of dioxin by addition of urea in iron ore sintering process. Chin J Process Eng, 2010, 10(5): 944龍紅明, 李家新, 王平, 等. 尿素對減少鐵礦燒結過程二惡英排放的作用機理. 過程工程學報, 2010, 10(5):944 [21] Ahn H, Choi S, Cho B. Process simulation of iron ore sintering bed with flue gas recirculation. Ironmak Steelmak, 2013, 40(2): 120 doi: 10.1179/1743281212Y.0000000071 [22] Ahn H, Choi S, Cho B. Process simulation of iron ore sintering bed with flue gas recirculation. Ironmak Steelmak, 2013, 40(2): 128 doi: 10.1179/1743281212Y.0000000072 [23] Zhang X H, Zhang J Y, Tian W Y, et al. Numerical simulation of flue gas circulation sintering. J Central South Univ (Sci Technol) , 2014, 45(4): 1312張小輝, 張家元, 田萬一, 等. 煙氣循環燒結的數值仿真. 中南大學學報(自然科學版), 2014, 45(4):1312 [24] Fan X H, Yu Z Y, Gan M, et al. Influence of O2 content in circulating flue gas on iron ore sintering. J Iron Steel Res Int, 2013, 20(6): 1 doi: 10.1016/S1006-706X(13)60103-X [25] Fan X H, Yu Z Y, Gan M, et al. Combustion behavior and influence mechanism of CO on iron ore sintering with flue gas recirculation. J Central South Univ, 2014, 21(6): 2391 doi: 10.1007/s11771-014-2192-0 [26] Yang Z W, Wang Z C, Wen R Y, et al. Simulation research of sintering flue gas recirculation system. Sinter Pelletizing, 2018, 43(3): 63楊正偉, 王兆才, 溫榮耀, 等. 燒結煙氣循環系統仿真模擬研究. 燒結球團, 2018, 43(3):63 [27] Xu Y, Mao R, Wang F, et al. Numerical simulation of sintering flue gas circulation system. J Iron Steel Res, 2020, 32(7): 675許源, 毛瑞, 王飛, 等. 燒結煙氣循環系統數值模擬. 鋼鐵研究學報, 2020, 32(7):675 -

下載:

下載: