| [1] |

Reith F, Lengke M, Falconer D, et al. The geomicrobiology of gold. ISME J, 2007: 567

|

| [2] |

Yu S M, Yu T T, Song W P, et al. Ultrasound-assisted cyanide extraction of gold from gold concentrate at low temperature. Ultrason Sonochem, 2020, 64: 105039 doi: 10.1016/j.ultsonch.2020.105039

|

| [3] |

Guo X Y, Zhang L, Tian Q H, et al. Stepwise extraction of gold and silver from refractory gold concentrate calcine by thiourea. Hydrometallurgy, 2020, 194: 105330 doi: 10.1016/j.hydromet.2020.105330

|

| [4] |

Han J H, Li X A, Dai S J. Electrochemical influence of quartz on cyanide leaching of gold. Chem Phys Lett, 2020, 739: 136997 doi: 10.1016/j.cplett.2019.136997

|

| [5] |

Wang H J, Feng Y L, Li H R, et al. Simultaneous extraction of gold and zinc from refractory carbonaceous gold ore by chlorination roasting process. Trans Nonferrous Met Soc China, 2020, 30(4): 1111 doi: 10.1016/S1003-6326(20)65282-7

|

| [6] |

Yang T Z, Rao S, Liu W F, et al. A selective process for extracting antimony from refractory gold ore. Hydrometallurgy, 2017, 169: 571 doi: 10.1016/j.hydromet.2017.03.014

|

| [7] |

Jia Y J, Wang X H, Cheng W, et al. Research progress on non-cyanide leaching of refractory gold ores. Chin J Eng, 2019, 41(3): 307賈玉娟, 王曉輝, 程偉, 等. 難處理金礦非氰浸金研究進展. 工程科學學學報, 2019, 41(3):307

|

| [8] |

Cao P, Zhang S H, Zheng Y J. Effects of iron, arsenic and carbon removal from a dust of refractory gold concentrates on cyanide leaching. Chin J Nonferrous Met, 2020, 30(5): 1142 doi: 10.11817/j.ysxb.1004.0609.2020-39533曹攀, 張霜華, 鄭雅杰. 難冶金精礦煙塵中鐵砷碳的脫除對氰化浸金的影響. 中國有色金屬學報, 2020, 30(5):1142 doi: 10.11817/j.ysxb.1004.0609.2020-39533

|

| [9] |

Ren C Y. Study on The Mechanism and Process of Gold Leaching by Thiourea in The Acid System of Biological Pre-Oxidation Residue of Refractory Gold Ore Containing Arsenic [Dissertation]. Beijing: General Research Institute for Nonferrous Metals, 2020任傳裕. 含砷難處理金礦生物預氧化渣酸性體系硫脲浸金機理及工藝研究[學位論文]. 北京: 北京有色金屬研究總院, 2020

|

| [10] |

Wang G H, Liu X X, Wu Y H, et al. Bio-oxidation of a high-sulfur refractory gold concentrate with a two-stage chemical-biological approach. Hydrometallurgy, 2020, 197: 105421 doi: 10.1016/j.hydromet.2020.105421

|

| [11] |

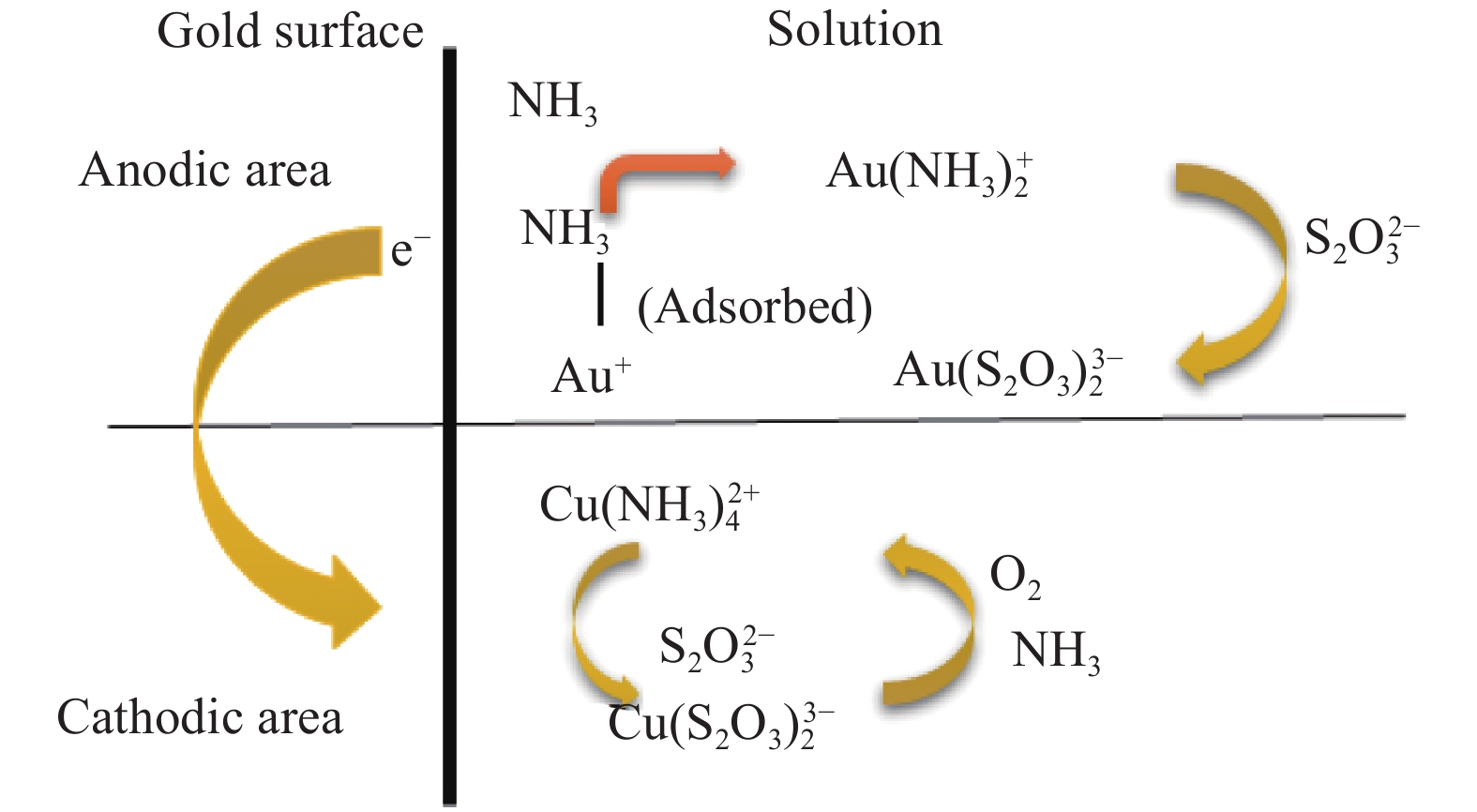

Wang J, Wang W, Dong K W, et al. Research on leaching of carbonaceous gold ore with copper-ammonia-thiosulfate solutions. Miner Eng, 2019, 137: 232 doi: 10.1016/j.mineng.2019.04.013

|

| [12] |

Liu X L, Jiang T, Xu B, et al. Thiosulphate leaching of gold in the Cu?NH3? $ {\rm{S_2O_3^{2-}}} $ ?H2O system: An updated thermodynamic analysis using predominance area and species distribution diagrams. Miner Eng, 2020, 151: 106336 doi: 10.1016/j.mineng.2020.106336 ?H2O system: An updated thermodynamic analysis using predominance area and species distribution diagrams. Miner Eng, 2020, 151: 106336 doi: 10.1016/j.mineng.2020.106336

|

| [13] |

Liu X L, Xu B, Yang Y B, et al. Effect of galena on thiosulfate leaching of gold. Hydrometallurgy, 2017, 171: 157 doi: 10.1016/j.hydromet.2017.05.011

|

| [14] |

Yang Y B, Gao W, Xu B, et al. Study on oxygen pressure thiosulfate leaching of gold without the catalysis of copper and ammonia. Hydrometallurgy, 2019, 187: 71 doi: 10.1016/j.hydromet.2019.05.006

|

| [15] |

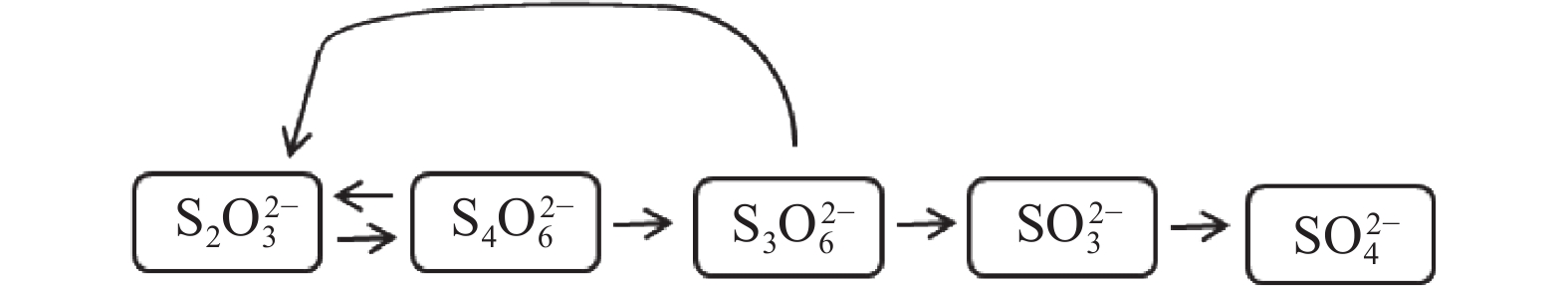

Nie Y H, Yang L, Wang Q, et al. Connection between gold dissolution in thiosulfate leaching and Cu(II) complexes during the cathodic process. Electrochimica Acta, 2019, 328: 135079 doi: 10.1016/j.electacta.2019.135079

|

| [16] |

Xu B, Li K, Zhong Q, et al. Study on the oxygen pressure alkaline leaching of gold with generated thiosulfate from sulfur oxidation. Hydrometallurgy, 2018, 177: 178 doi: 10.1016/j.hydromet.2018.03.006

|

| [17] |

Jeffrey M I, Watling K, Hope G A, et al. Identification of surface species that inhibit and passivate thiosulfate leaching of gold. Miner Eng, 2008, 21(6): 443 doi: 10.1016/j.mineng.2008.01.006

|

| [18] |

Baron J Y, Mirza J, Nicol E A, et al. SERS and electrochemical studies of the gold-electrolyte interface under thiosulfate based leaching conditions. Electrochimica Acta, 2013, 111: 390 doi: 10.1016/j.electacta.2013.07.195

|

| [19] |

Xu B, Yang Y B, Li Q, et al. Effect of common associated sulfide minerals on thiosulfate leaching of gold and the role of humic acid additive. Hydrometallurgy, 2017, 171: 44 doi: 10.1016/j.hydromet.2017.04.006

|

| [20] |

Yu H, Zi F T, Hu X Z, et al. The copper-ethanediamine-thiosulphate leaching of gold ore containing limonite with cetyltrimethyl ammonium bromide as the synergist. Hydrometallurgy, 2014, 150: 178 doi: 10.1016/j.hydromet.2014.10.008

|

| [21] |

Chandra I, Jeffrey M I. A fundamental study of ferric oxalate for dissolving gold in thiosulfate solutions. Hydrometallurgy, 2005, 77(3? 4): 191

|

| [22] |

Heath J A, Jeffrey M I, Zhang H G, et al. Anaerobic thiosulfate leaching: Development of in situ gold leaching systems. Miner Eng, 2008, 21(6): 424 doi: 10.1016/j.mineng.2007.12.006

|

| [23] |

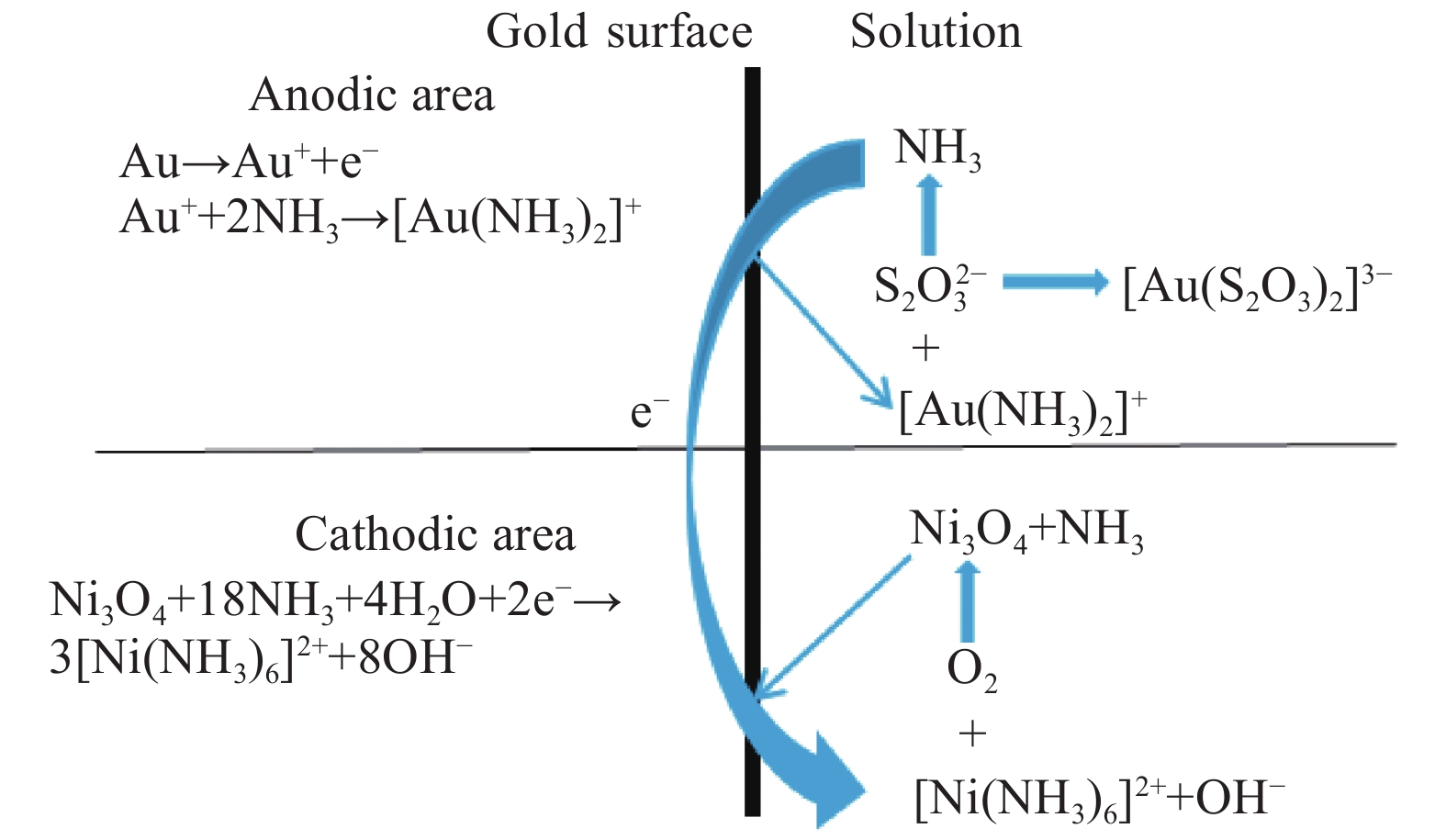

Xu B, Li K, Dong Z L, et al. Eco-friendly and economical gold extraction by nickel catalyzed ammoniacal thiosulfate leaching-resin adsorption recovery. J Cleaner Prod, 2019, 233: 1475 doi: 10.1016/j.jclepro.2019.06.182

|

| [24] |

Xu B, Yang Y B, Li Q, et al. Stage leaching of a complex polymetallic sulfide concentrate: Focus on the extraction of Ag and Au. Hydrometallurgy, 2016, 159: 87 doi: 10.1016/j.hydromet.2015.10.008

|

| [25] |

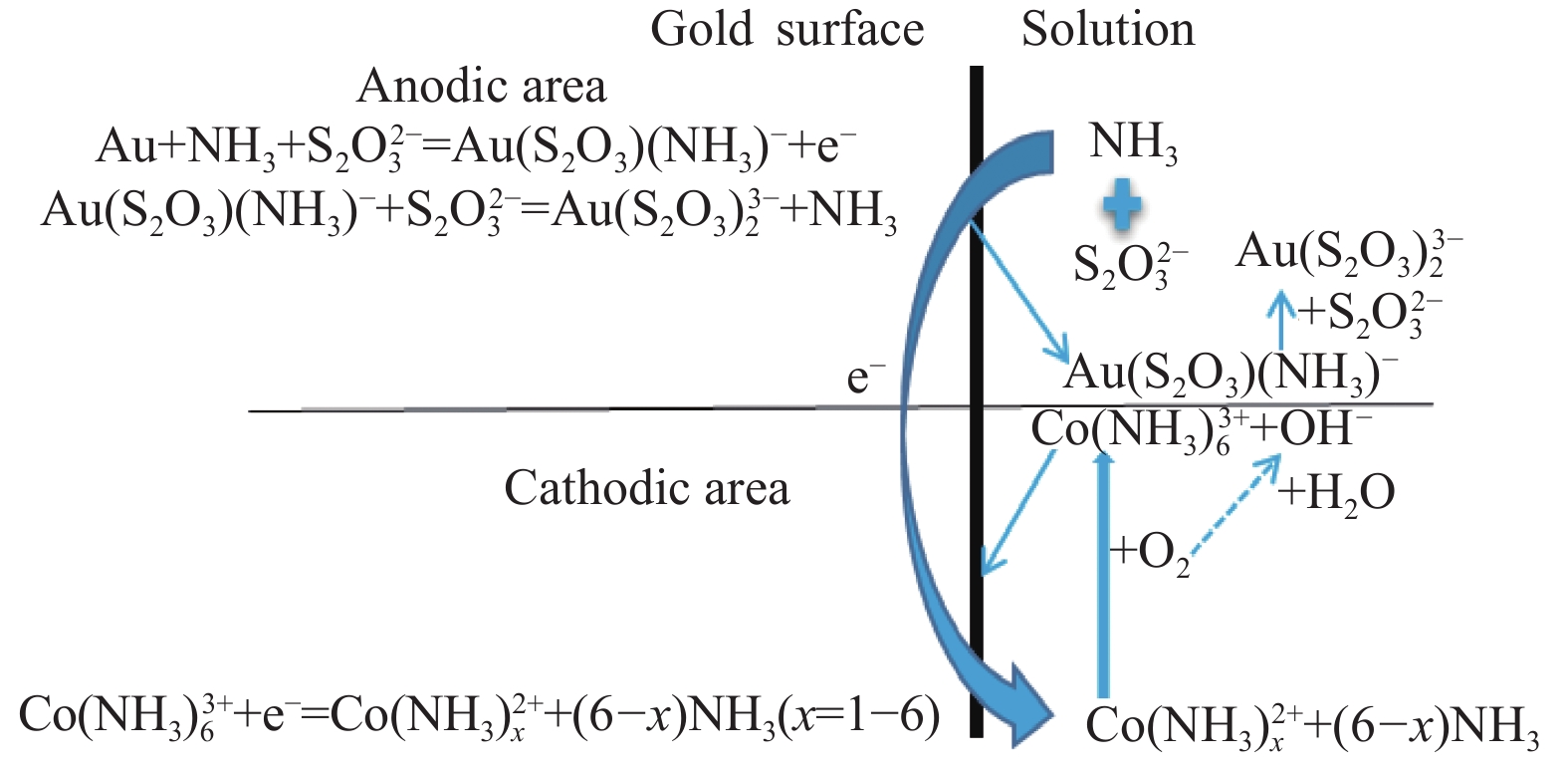

Xu B, Li K, Li Q, et al. Kinetic studies of gold leaching from a gold concentrate calcine by thiosulfate with cobalt-ammonia catalysis and gold recovery by resin adsorption from its pregnant solution. Sep Purif Technol, 2019, 213: 368 doi: 10.1016/j.seppur.2018.12.064

|

| [26] |

Liu X L, Xu B, Yang Y B, et al. Thermodynamic analysis of ammoniacal thiosulphate leaching of gold catalysed by Co(III)/Co(II) using Eh-pH and speciation diagrams. Hydrometallurgy, 2018, 178: 240 doi: 10.1016/j.hydromet.2018.05.014

|

| [27] |

Nie Y H, Yang L, Sun W, et al. Increase in gold dissolution in copper ammonia thiosulfate solution via cobalt surface modification. Hydrometallurgy, 2020, 197: 105473 doi: 10.1016/j.hydromet.2020.105473

|

| [28] |

Altinkaya P, Wang Z L, Korolev I, et al. Leaching and recovery of gold from ore in cyanide-free glycine media. Miner Eng, 2020, 158: 106610 doi: 10.1016/j.mineng.2020.106610

|

| [29] |

Oraby E A, Eksteen J J, Tanda B C. Gold and copper leaching from gold-copper ores and concentrates using a synergistic lixiviant mixture of glycine and cyanide. Hydrometallurgy, 2017, 169: 339 doi: 10.1016/j.hydromet.2017.02.019

|

| [30] |

Tauetsile P J, Oraby E A, Eksteen J J. Activated carbon adsorption of gold from cyanide-starved glycine solutions containing copper. Part 1: Isotherms. Sep Purif Technol, 2019, 211: 594 doi: 10.1016/j.seppur.2018.09.024

|

| [31] |

Feng D, van Deventer J S J. The role of amino acids in the thiosulphate leaching of gold. Miner Eng, 2011, 24(9): 1022 doi: 10.1016/j.mineng.2011.04.017

|

| [32] |

Groudev S N, Ivanov I M, Spasova I I, et al. Pilot scale microbial leaching of gold and silver from an oxide ore in elshitza mine//Minerals Bioprocessing II Conference. Bulgaria, 1995: 135

|

| [33] |

Oraby E A, Eksteen J J. The leaching of gold, silver and their alloys in alkaline glycine-peroxide solutions and their adsorption on carbon. Hydrometallurgy, 2015, 152: 199 doi: 10.1016/j.hydromet.2014.12.015

|

| [34] |

Wu H, Feng Y L, Huang W F, et al. The role of glycine in the ammonium thiocyanate leaching of gold. Hydrometallurgy, 2019, 185: 111 doi: 10.1016/j.hydromet.2019.01.019

|

| [35] |

Perea C G, Restrepo O J. Use of amino acids for gold dissolution. Hydrometallurgy, 2018, 177: 79 doi: 10.1016/j.hydromet.2018.03.002

|

| [36] |

Oraby E A, Eksteen J J, Karrech A, et al. Gold extraction from paleochannel ores using an aerated alkaline glycine lixiviant for consideration in heap and in situ leaching applications. Miner Eng, 2019, 138: 112 doi: 10.1016/j.mineng.2019.04.023

|

| [37] |

Adams M D. Chloride as an alternative lixiviant to cyanide for gold ores. Gold Ore Process, 2016: 525

|

| [38] |

Ahtiainen R, Lundstr?m M. Cyanide-free gold leaching in exceptionally mild chloride solutions. J Cleaner Prod, 2019, 234: 9 doi: 10.1016/j.jclepro.2019.06.197

|

| [39] |

Wang Q. Non-Cyanide Gold Extraction Experiment and Mechanism Study of Fine-Grained Carbonaceous Gold Deposit [Dissertation]. Kunming: Kunming University of Science and Technology, 2019王強. 微細粒包裹型碳質金礦的非氰提金試驗及機理研究[學位論文]. 昆明: 昆明理工大學, 2019

|

| [40] |

Diaz M A, Kelsall G H, Welham N J. Electrowinning coupled to gold leaching by electrogenerated chlorine: I. Au(III)–Au(I)/Au kinetics in aqueous Cl2/Cl? electrolytes. J Electroanal Chem, 1993, 361(1-2): 25 doi: 10.1016/0022-0728(93)87035-T

|

| [41] |

Seisko S, Aromaa J, Lundstr?m M. Effect of redox potential and OCP in ferric and cupric chloride leaching of gold. Hydrometallurgy, 2020, 195: 105374 doi: 10.1016/j.hydromet.2020.105374

|

| [42] |

Seisko S, Aromaa J, Lundstr?m M. Features affecting the cupric chloride leaching of gold. Miner Eng, 2019, 137: 94 doi: 10.1016/j.mineng.2019.03.030

|

| [43] |

Zhang N, Zhou Q B, Yin X, et al. Trace amounts of aqueous copper(II) chloride complexes in hypersaline solutions: Spectrophotometric and thermodynamic studies. J Solution Chem, 2014, 43(2): 326 doi: 10.1007/s10953-014-0129-8

|

| [44] |

Seisko S, Lampinen M, Aromaa J, et al. Kinetics and mechanisms of gold dissolution by ferric chloride leaching. Miner Eng, 2018, 115: 131 doi: 10.1016/j.mineng.2017.10.017

|

| [45] |

Lampinen M, Seisko S, Forsstr?m O, et al. Mechanism and kinetics of gold leaching by cupric chloride. Hydrometallurgy, 2017, 169: 103 doi: 10.1016/j.hydromet.2016.12.008

|

| [46] |

Bonsdorff R V, Aromaa J, O Forsén, et al. The rate of gold dissolution in concentrated cupric chloride solutions//The John E. Dutrizac International Symposium on Copper Hydrometallurgy. Toronto, 2007: 121

|

| [47] |

Baghalha M. Leaching of an oxide gold ore with chloride/hypochlorite solutions. Int J Miner Process, 2007, 82(4): 178 doi: 10.1016/j.minpro.2006.09.001

|

| [48] |

Nam K S, Jung B H, An J W, et al. Use of chloride-hypochlorite leachants to recover gold from tailing. Int J Miner Process, 2008, 86(1-4): 131

|

| [49] |

Hasab M G, Rashchi F, Raygan S. Simultaneous sulfide oxidation and gold leaching of a refractory gold concentrate by chloride-hypochlorite solution. Miner Eng, 2013, 50-51: 140

|

| [50] |

Hasab M G, Rashchi F, Raygan S. Chloride-hypochlorite leaching and hydrochloric acid washing in multi-stages for extraction of gold from a refractory concentrate. Hydrometallurgy, 2014, 142: 56 doi: 10.1016/j.hydromet.2013.11.015

|

| [51] |

Yanuar E, Suprapto. Leaching and adsorption of gold from lape-sumbawa rocks (Indonesia) by hypochlorite-chloride. Procedia Chem, 2015, 17: 59 doi: 10.1016/j.proche.2015.12.134

|

| [52] |

Pak K S, Zhang T A, Kim C S, et al. Research on chlorination leaching of pressure-oxidized refractory gold concentrate. Hydrometallurgy, 2020, 194: 105325 doi: 10.1016/j.hydromet.2020.105325

|

| [53] |

Sousa R, Futuro A, Fiúza A, et al. Bromine leaching as an alternative method for gold dissolution. Miner Eng, 2018, 118: 16 doi: 10.1016/j.mineng.2017.12.019

|

| [54] |

Wang Q, Hu X Z, Zi F T, et al. Extraction of gold from refractory gold ore using bromate and ferric chloride solution. Miner Eng, 2019, 136: 89 doi: 10.1016/j.mineng.2019.02.037

|

| [55] |

Chiu Y T, Lee P Y, Wi-Afedzi T, et al. Elimination of bromate from water using aluminum beverage cans via catalytic reduction and adsorption. J Colloid Interface Sci, 2018, 532: 416 doi: 10.1016/j.jcis.2018.07.112

|

| [56] |

Han P P, Xia Y. Thiol-functionalized metal-organic framework for highly efficient removal of bromate from water. J Environ Chem Eng, 2018, 6(2): 3384 doi: 10.1016/j.jece.2018.03.045

|

| [57] |

Vasudevan S. Studies relating to electrolytic preparation of potassium bromate. Ind Eng Chem Res, 2008, 47(5): 1743 doi: 10.1021/ie071554e

|

| [58] |

Davis A, Tran T. Gold dissolution in iodide electrolytes. Hydrometallurgy, 1991, 26(2): 163 doi: 10.1016/0304-386X(91)90029-L

|

| [59] |

Gong L Y, Li F, Yu Y, et al. Pollution-free iodinated desugarization by gold process conditions and regeneration research. Environ Sci Manag, 2011, 36(5): 64 doi: 10.3969/j.issn.1673-1212.2011.05.016宮麗媛, 李芬, 于洋, 等. 無污染碘化法提金工藝條件及再生研究. 環境科學與管理, 2011, 36(5):64 doi: 10.3969/j.issn.1673-1212.2011.05.016

|

| [60] |

Xu Q, Chen D H, Chen L, et al. Gold leaching from waste printed circuit board by iodine process. Nonferrous Met, 2010, 62(3): 88徐渠, 陳東輝, 陳亮, 等. 碘化法從廢棄印刷線路板中浸取金. 有色金屬, 2010, 62(3):88

|

| [61] |

Konyratbekova S S, Baikonurova A, Ussoltseva G A, et al. Thermodynamic and kinetic of iodine-iodide leaching in gold hydrometallurgy. Trans Nonferrous Met Soc China, 2015, 25(11): 3774 doi: 10.1016/S1003-6326(15)63980-2

|

| [62] |

Baghalha M. The leaching kinetics of an oxide gold ore with iodide/iodine solutions. Hydrometallurgy, 2012, 113-114: 42 doi: 10.1016/j.hydromet.2011.11.013

|

| [63] |

Altansukh B, Haga K, Ariunbolor N, et al. Leaching and adsorption of gold from waste printed circuit boards using iodine-iodide solution and activated carbon. Eng J, 2016, 20(4): 29 doi: 10.4186/ej.2016.20.4.29

|

| [64] |

Zhang X L, Sun C B, Xing Y, et al. Thermal decomposition behavior of pyrite in a microwave field and feasibility of gold leaching with generated elemental sulfur from the decomposition of gold-bearing sulfides. Hydrometallurgy, 2018, 180: 210 doi: 10.1016/j.hydromet.2018.07.012

|

| [65] |

Guo X Y, Qin H, Tian Q H, et al. The efficacy of a new iodination roasting technology to recover gold and silver from refractory gold tailing. J Cleaner Prod, 2020, 261: 121147 doi: 10.1016/j.jclepro.2020.121147

|

| [66] |

Li Q, Shen H, Zhang Y, et al. Research progress of thiourea gold leaching process. Gold, 2018, 39(1): 66 doi: 10.11792/hj20180114李騫, 沈煌, 張雁, 等. 硫脲浸金研究進展. 黃金, 2018, 39(1):66 doi: 10.11792/hj20180114

|

| [67] |

?rgül S, Atalay ü. Reaction chemistry of gold leaching in thiourea solution for a turkish gold ore. Hydrometallurgy, 2002, 67(1-3): 71 doi: 10.1016/S0304-386X(02)00136-6

|

| [68] |

Li J S, Miller J D. Reaction kinetics of gold dissolution in acid thiourea solution using ferric sulfate as oxidant. Hydrometallurgy, 2007, 89(3-4): 279 doi: 10.1016/j.hydromet.2007.07.015

|

| [69] |

Bai A P. Research on Influencing Factors and Mechanism of Gold Leaching with Alkaline Thiourea Solution [Dissertation]. Beijing: Beijing General Research Institute of Nonferrous Metals, 2017白安平. 堿性硫脲浸金影響因素及浸出機理研究[學位論文]. 北京: 北京有色金屬研究總院, 2017

|

| [70] |

Zheng S, Wang Y Y, Chai L Y. Research status and prospect of gold leaching in alkaline thiourea solution. Miner Eng, 2006, 19(13): 1301 doi: 10.1016/j.mineng.2005.12.009

|

| [71] |

Guo Y J, Guo X, Wu H Y, et al. A novel bio-oxidation and two-step thiourea leaching method applied to a refractory gold concentrate. Hydrometallurgy, 2017, 171: 213 doi: 10.1016/j.hydromet.2017.05.023

|

| [72] |

Yoshimura A, Takai M, Matsuno Y. Novel process for recycling gold from secondary sources: Leaching of gold by dimethyl sulfoxide solutions containing copper bromide and precipitation with water. Hydrometallurgy, 2014, 149: 177 doi: 10.1016/j.hydromet.2014.08.003

|

下載:

下載: