Influence of nanosized precipitate on the corrosion behavior of high-strength low-alloy steels: a review

-

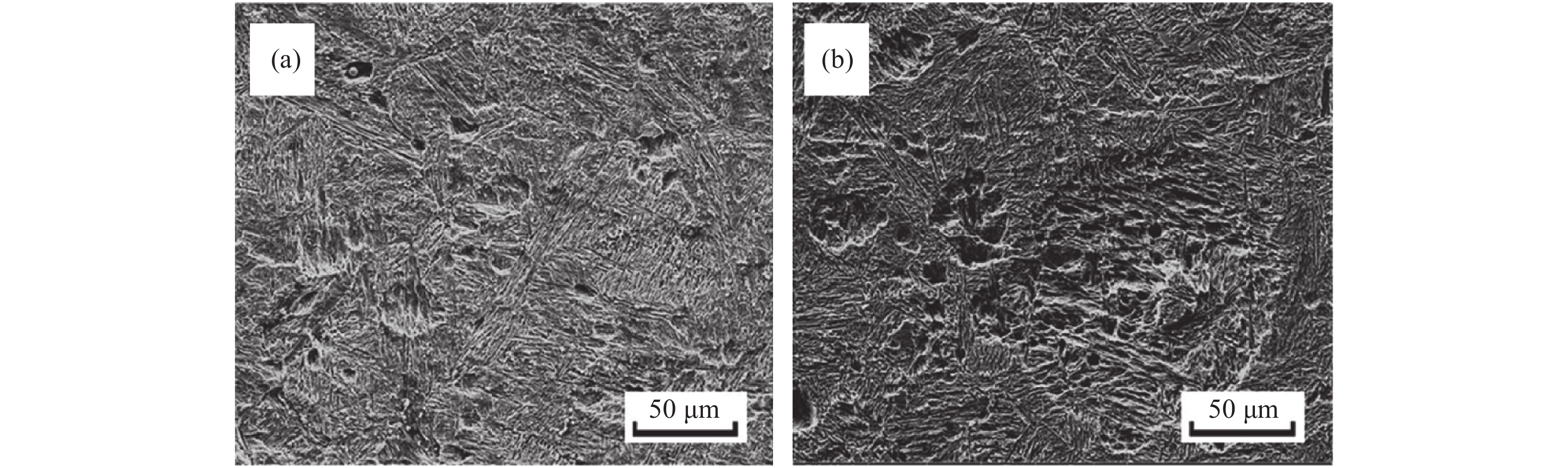

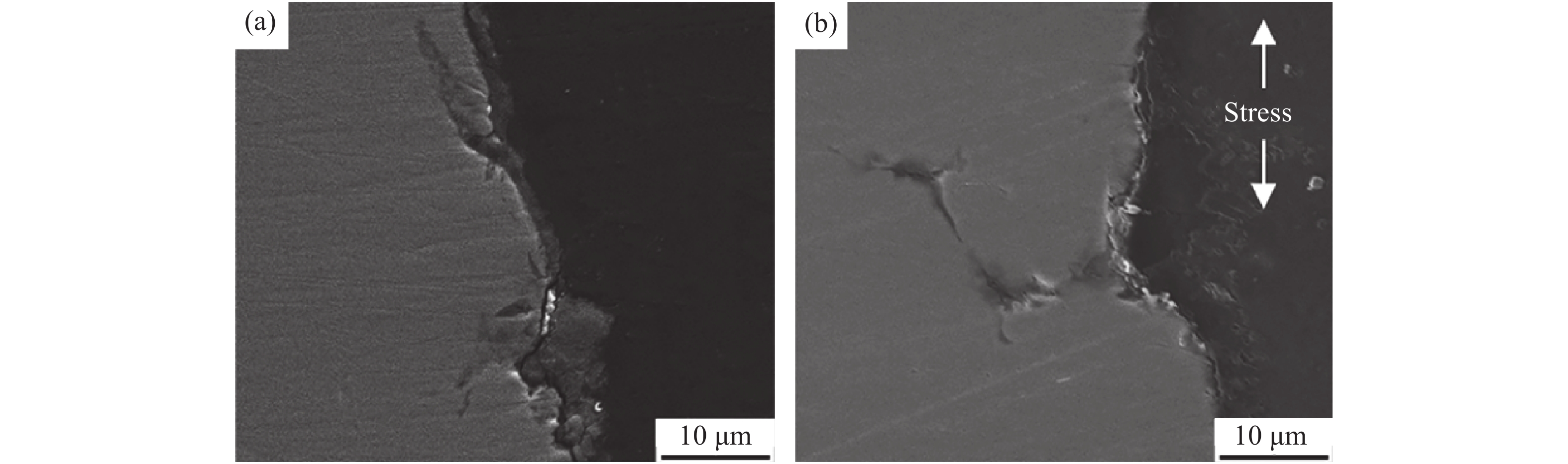

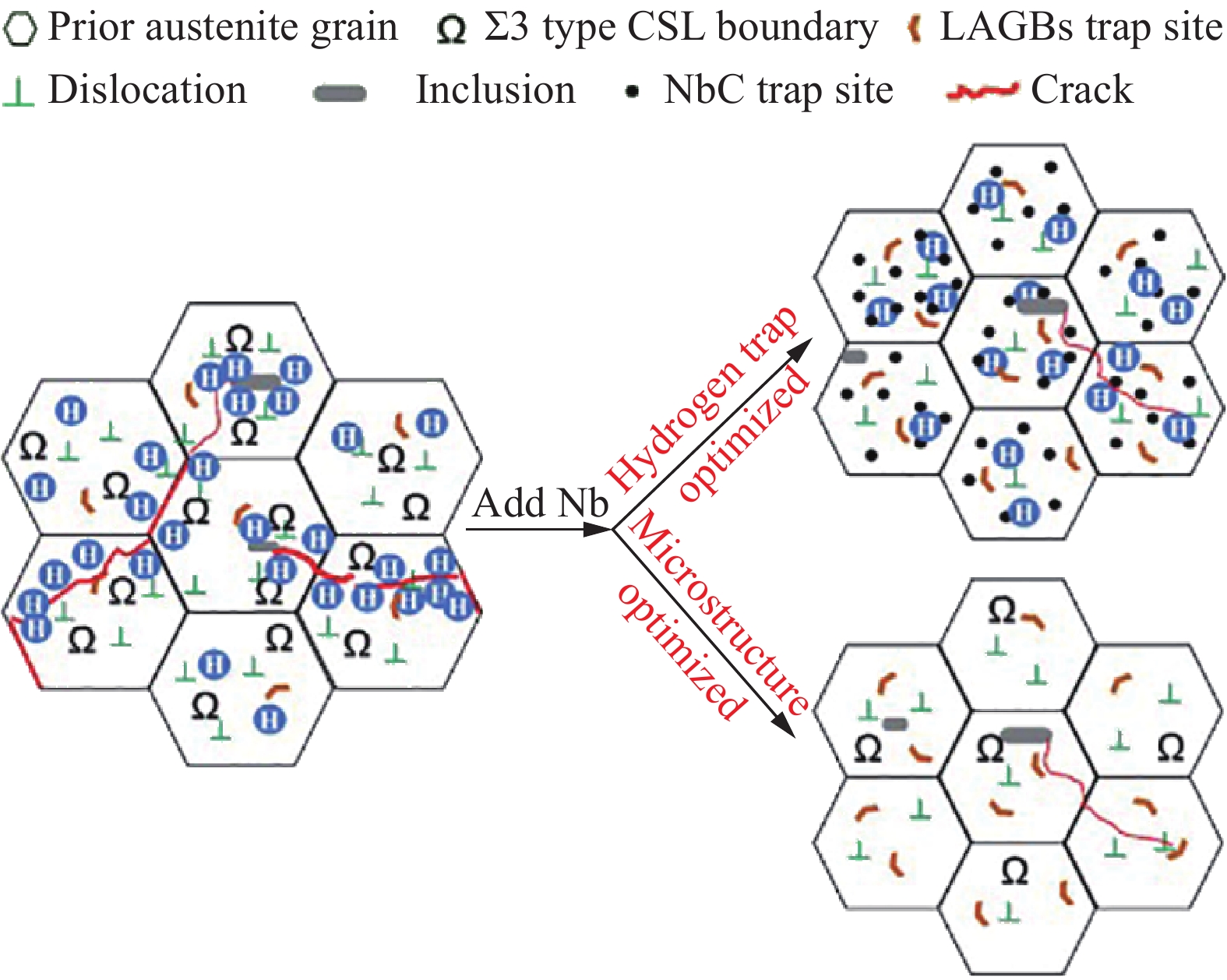

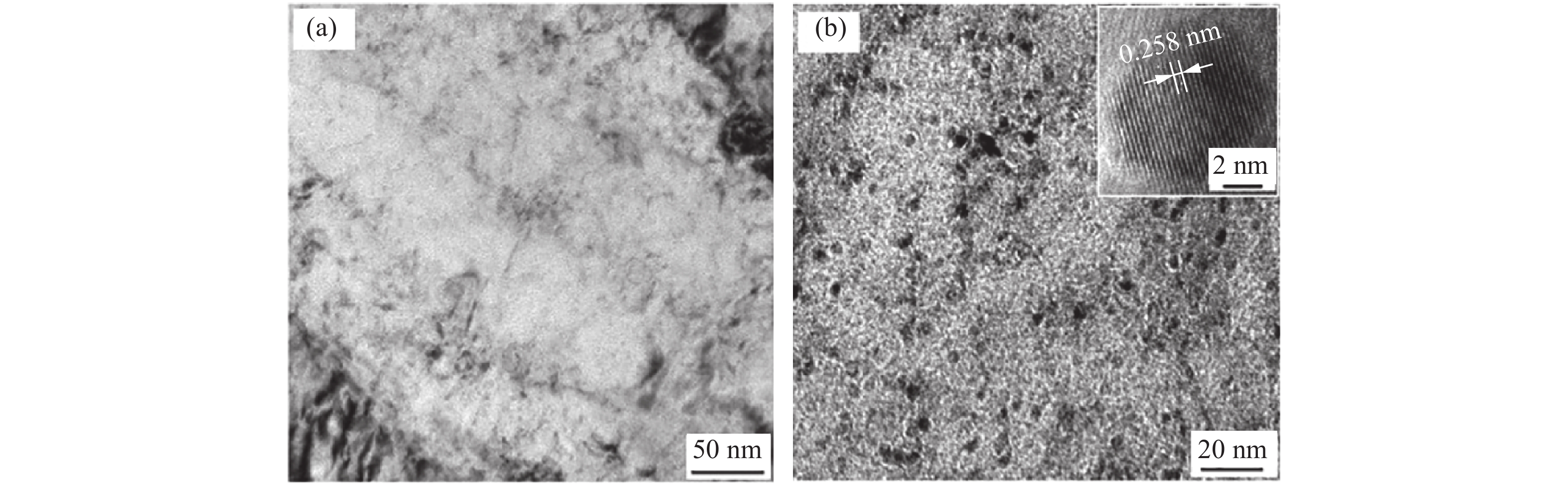

摘要: 高強度低合金鋼中Nb、V和Ti等微合金化元素的納米析出相對于調控鋼的組織和性能具有重要作用,它可以確保鋼基體同時擁有較高的力學性能和較強的耐蝕性能。本文基于國內外最新研究現狀,系統闡述了納米析出相在高強度低合金鋼中的存在形態以及其對鋼中氫擴散、均勻腐蝕、應力腐蝕開裂以及各類氫損傷等腐蝕行為的影響規律和機制。研究表明,納米析出相對鋼基體腐蝕行為的影響受其尺寸、數量和分布狀態的控制。細小且與基體共格或半共格的納米析出相不僅可以通過改善鋼的微觀組織(包括亞結構)提高耐蝕性能,其導致的不可逆氫陷阱及對氫擴散的強烈抑制作用還可以極大提高抗應力腐蝕和各類氫損傷的能力。而大尺寸的非共格析出相則可能惡化鋼基體的耐蝕性能和促進氫損傷。最后展望了目前關注較少的納米析出相對腐蝕疲勞影響的相關研究。明確納米析出相對高強度低合金鋼腐蝕行為的影響規律與機制將有助于更高品質耐蝕鋼的開發和應用。Abstract: Compared with the widely used plain carbon steels, high-strength low-alloy steels exhibit high tensile strength, excellent fatigue performance, good plasticity, and toughness, and have attracted considerable attention in recent years. In the strengthening and toughening of high-strength low-alloy steels, the addition of carbide-forming and nitride-forming elements (i.e., Nb, V, and Ti) promotes the formation of nanosized precipitates. Nanosized precipitate in high-strength low-alloy steels plays a significant role in the microstructure optimization, which could maintain the high mechanical properties and excellent corrosion resistance of the steel matrix. With the advancement of characterization techniques and simulation methods in the atomic scale over the past few decades, the effect of nanosized precipitate on the corrosion behavior of high-strength low-alloy steels has become increasingly clear. Based on the obtained achievements in China and abroad, the existing morphology of nanosized precipitate and its influence on hydrogen diffusion, uniform corrosion, stress corrosion cracking, and hydrogen-induced damage were reviewed systematically in this study. Results show that the influence of nanosized precipitates on the corrosion behavior of high-strength low-alloy steels depends on its size, quantity, and status of crystal deposition. The fine and (semi-)coherent precipitate in the steel matrix can significantly improve not only the corrosion resistance by refining the microstructure (including the substructure) but also the resistance to hydrogen-induced damage by acting as an irreversible hydrogen-trapping site and strongly restraining hydrogen diffusion. However, incoherent precipitates with a large size would deteriorate the corrosion resistance because of the loss of microstructure optimization. Finally, this study forecasts the influence of nanosized precipitate on fatigue corrosion of high-strength low-alloy steels, which has not been investigated in previous studies. The optimization of the corrosion resistance of high-strength low-alloy steels can be achieved by controlling the nanosized precipitates. Clarifying the influence of nanosized precipitate on corrosion behavior would contribute significantly to the development of high-quality high-strength low-alloy steels.

-

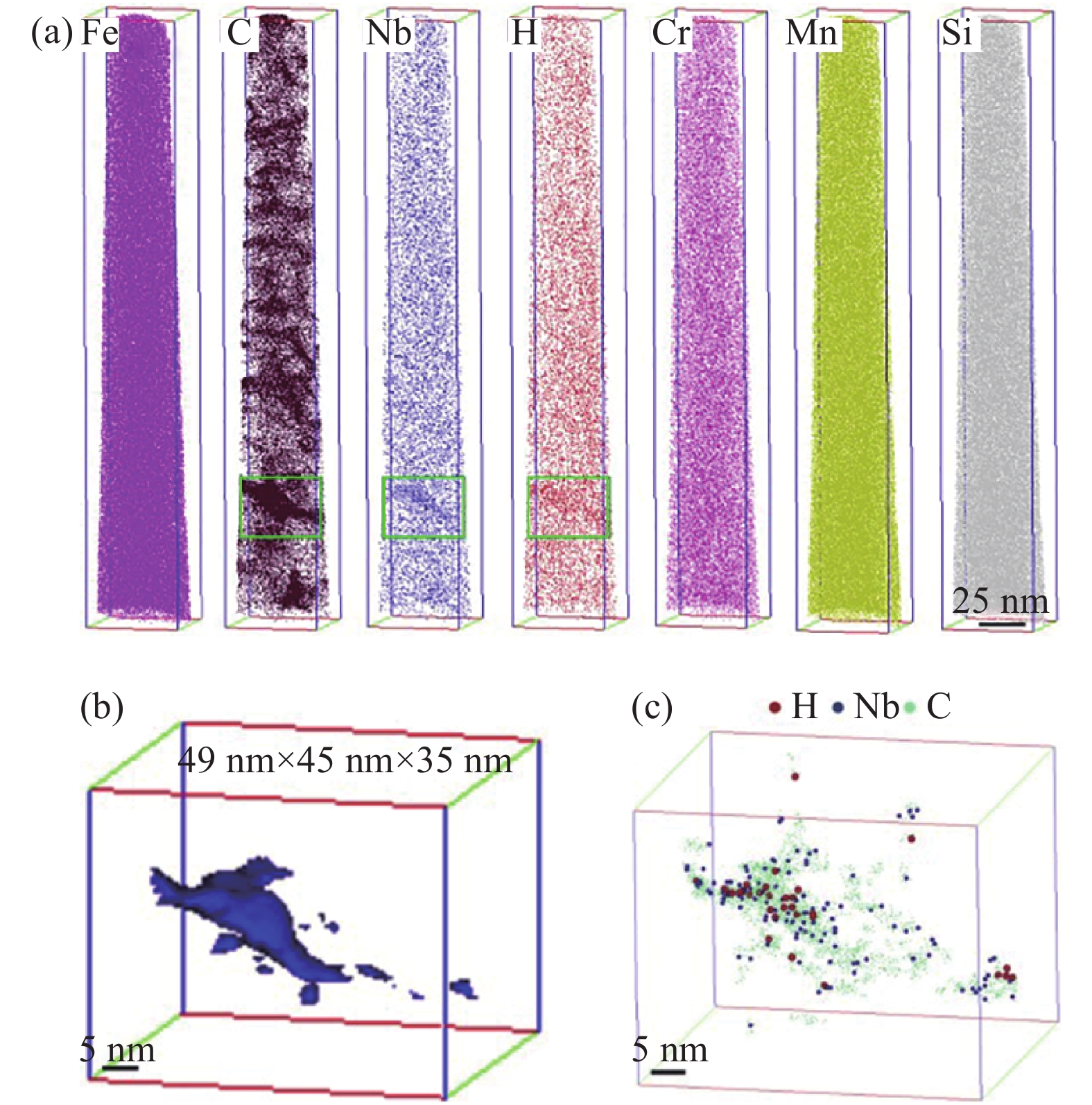

圖 2 高強度低合金鋼中元素三維空間分布[49]。(a)原子分布圖;(b)(a)中綠框內原子分數7.4% (C?+?Nb)等濃度表面;(c)等濃度面內C、Nb和H分布

Figure 2. Element distributions in high-strength low-alloy steel[49]: (a) atom maps; (b) atom fraction of 7.4% (C?+?Nb) isoconcentration surfaces of the region enclosed in a green box; (c) distributions of C, Nb, and H atoms inside the isoconcentration surfaces

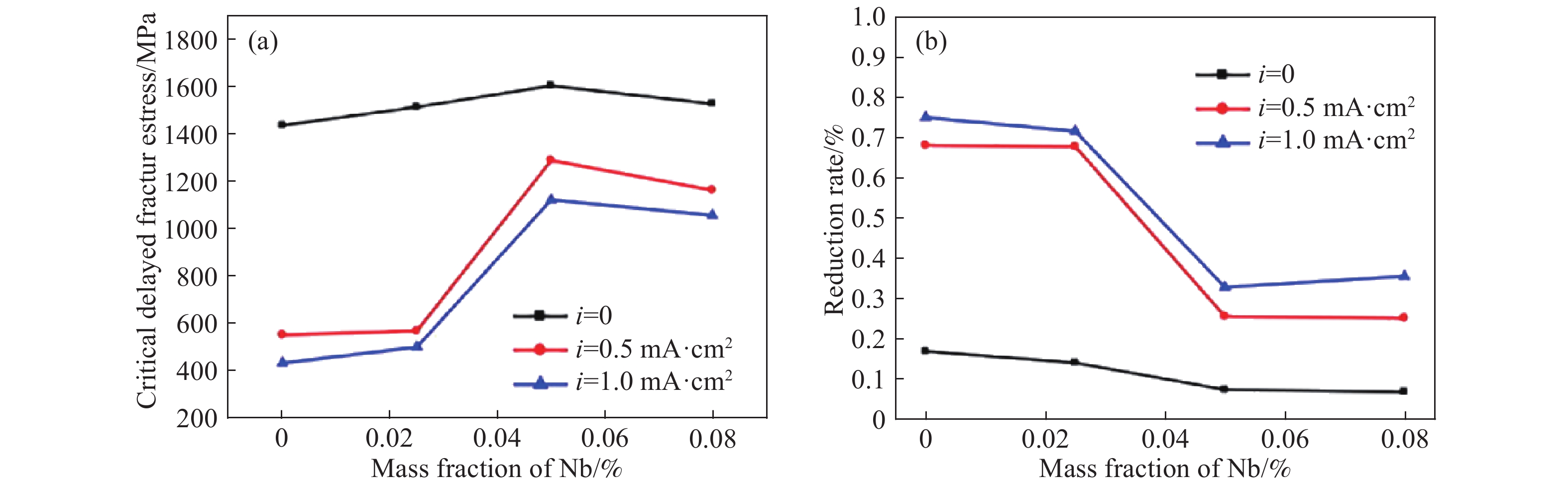

圖 6 Nb含量對高強度低合金鋼氫致滯后斷裂性能影響[87]。(a)臨界延遲斷裂應力;(b)臨界斷裂應力下降率(i為電化學充氫電流密度)

Figure 6. Delayed fracture strength of high-strength low-alloy steel with different Nb contents[87]: (a) critical delayed fracture stress; (b) reduction rate of delayed fracture strength (i is the electrochemical hydrogen-charging current density)

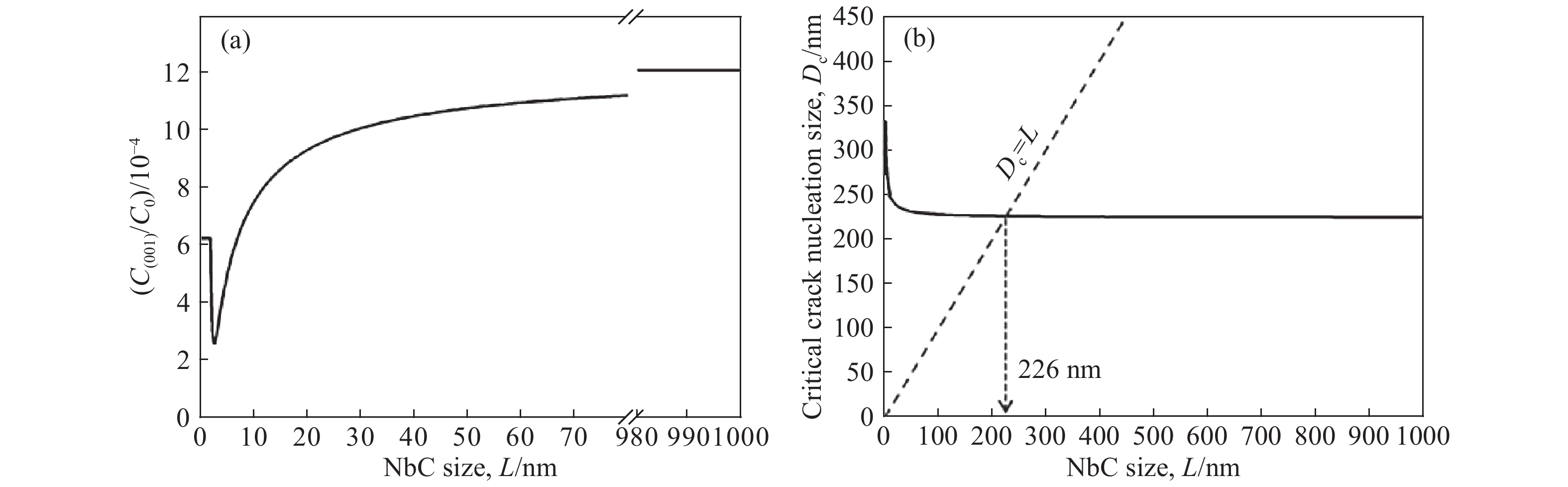

圖 7 NbC納米析出相尺寸對氫鼓泡影響[93]。(a)不同尺寸(L)NbC析出相界面處氫濃度(C(001))與基體內可擴散氫濃度(C0)比值;(b)氫鼓泡裂紋臨界形核尺寸(Dc)與NbC析出相尺寸(L)關系

Figure 7. Influence of NbC size on the hydrogen blistering[93]: (a) ratio of hydrogen concentration at the NbC interfaces (C(001)) to diffusion hydrogen concentration in the matrix (C0) with NbC precipitate size; (b) critical size for blistering nucleation (Dc) with NbC precipitate size (L)

表 1 鋼中常見缺陷與氫的結合能大小

Table 1. Trapping sites and corresponding hydrogen-trapping activation energies in steel

Trapping sites Eb/(kJ·mol?1) Reference Iron lattice 8.64 [30?31] Low-angle grain boundary 17.2?18.6 [32] Austenite/martensite interface 22 [32] Dislocation 26.4?26.8 [32] Microvoid 35.2?40 [32] High-angle grain boundary 59 [33] Ferrite/cementite interface 66.3?66.8 [34?35] MnS interface 72 [32] Al2O3 interface 79?86.2 [32] (Semi-)coherent (Nb, V, Ti)(C, N) interface 42.6?98 [32, 36?40] 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Xu X X, You G Q, Ding Y H, et al. Microstructure and mechanical properties of inertia friction welded joints between high-strength low-alloy steel and medium carbon steel. J Mater Process Technol, 2020, 286: 116811 doi: 10.1016/j.jmatprotec.2020.116811 [2] Zhang X G. Development of high strength low alloy steel in recent years. Iron Steel, 2011, 46(11): 1張曉剛. 近年來低合金高強度鋼的進展. 鋼鐵, 2011, 46(11):1 [3] Jiang S H, Wang H, Wu Y, et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature, 2017, 544(7651): 460 doi: 10.1038/nature22032 [4] Kim H J, Jeon S H, Yang W S, et al. Effects of titanium content on hydrogen embrittlement susceptibility of hot-stamped boron steels. J Alloys Compd, 2018, 735: 2067 doi: 10.1016/j.jallcom.2017.12.004 [5] Li L F, Song B, Cheng J, et al. Effects of vanadium precipitates on hydrogen trapping efficiency and hydrogen induced cracking resistance in X80 pipeline steel. Int J Hydrogen Energy, 2018, 43(36): 17353 doi: 10.1016/j.ijhydene.2018.07.110 [6] Yong Q L, Sun X J, Zheng L, et al. Roles of second phases in structural steels. Sci Technol Innov Herald, 2009(8): 2 doi: 10.3969/j.issn.1674-098X.2009.08.002雍岐龍, 孫新軍, 鄭磊, 等. 鋼鐵材料中第二相的作用. 科技創新導報, 2009(8):2 doi: 10.3969/j.issn.1674-098X.2009.08.002 [7] Wei H, Chen Y L, Yu W, et al. Study on corrosion resistance of high-strength medium-carbon spring steel and its hydrogen-induced delayed fracture. Constr Build Mater, 2020, 239: 117815 doi: 10.1016/j.conbuildmat.2019.117815 [8] Huang Y, Zhao A M, Cheng Y F, et al. Interphase precipitation behavior of nano-sized carbides in low carbon steel. Chin J Eng, 2015, 37(7): 896黃耀, 趙愛民, 程永峰, 等. 低碳鋼中納米尺寸碳化物的相間析出行為. 工程科學學報, 2015, 37(7):896 [9] Wang Y Q, Clark S J, Janik V, et al. Investigating nano-precipitation in a V-containing HSLA steel using small angle neutron scattering. Acta Mater, 2018, 145: 84 doi: 10.1016/j.actamat.2017.11.032 [10] Park T M, Kim H J, Um H Y, et al. The possibility of enhanced hydrogen embrittlement resistance of medium-Mn steels by addition of micro-alloying elements. Mater Charact, 2020, 165: 110386 doi: 10.1016/j.matchar.2020.110386 [11] Ma J, Zhang B, Wang J Q, et al. Anisotropic 3D growth of corrosion pits initiated at MnS inclusions for A537 steel during corrosion fatigue. Corros Sci, 2010, 52(9): 2867 doi: 10.1016/j.corsci.2010.04.036 [12] Mohammed S, Hua Y, Barker R, et al. Investigating pitting in X65 carbon steel using potentiostatic polarisation. Appl Surf Sci, 2017, 423: 25 doi: 10.1016/j.apsusc.2017.06.015 [13] Zhang B, Ma X L. A review?Pitting corrosion initiation investigated by TEM. J Mater Sci Technol, 2019, 35(7): 1455 doi: 10.1016/j.jmst.2019.01.013 [14] Hao W K, Liu Z Y, Wu W, et al. Electrochemical characterization and stress corrosion cracking of E690 high strength steel in wet-dry cyclic marine environments. Mater Sci Eng A, 2018, 710: 318 doi: 10.1016/j.msea.2017.10.042 [15] Hur D H, Han J H, Lee U C, et al. Microchemistry of Ti-carbonitrides and their role in the early stage of pit initiation of Alloy 600. Corrosion, 2006, 62(7): 591 doi: 10.5006/1.3280673 [16] Tan J B, Wu X Q, Han E H, et al. Role of TiN inclusion on corrosion fatigue behavior of Alloy 690 steam generator tubes in borated and lithiated high temperature water. Corros Sci, 2014, 88: 349 doi: 10.1016/j.corsci.2014.07.059 [17] Duan X G, Cai Q W, Wu H B. Ti?Mo ferrite matrix micro-alloy steel with nanometer-sized precipitates. Acta Metall Sin, 2011, 47(2): 251段修剛, 蔡慶伍, 武會賓. Ti?Mo全鐵素體基微合金高強鋼納米尺度析出相. 金屬學報, 2011, 47(2):251 [18] Chen C Y, Chen S F, Chen C C, et al. Control of precipitation morphology in the novel HSLA steel. Mater Sci Eng A, 2015, 634: 123 doi: 10.1016/j.msea.2015.03.027 [19] Xie Z J, Ma X P, Shang C J, et al. Nano-sized precipitation and properties of a low carbon niobium micro-alloyed bainitic steel. Mater Sci Eng A, 2015, 641: 37 doi: 10.1016/j.msea.2015.05.101 [20] Meng F J, Wang J Q, Han E H, et al. The role of TiN inclusions in stress corrosion crack initiation for Alloy 690TT in high-temperature and high-pressure water. Corros Sci, 2010, 52(3): 927 doi: 10.1016/j.corsci.2009.11.015 [21] Rahnama A, Clark S, Sridhar S. Machine learning for predicting occurrence of interphase precipitation in HSLA steels. Comput Mater Sci, 2018, 154: 169 doi: 10.1016/j.commatsci.2018.07.055 [22] Chang S H, Yeh P T, Huang K T. Microstructures, mechanical properties and corrosion behaviors of NbC added to Vanadis 4 tool steel via vacuum sintering and heat treatments. Vacuum, 2017, 142: 123 doi: 10.1016/j.vacuum.2017.05.015 [23] Zhang S Q, Fan E D, Wan J F, et al. Effect of Nb on the hydrogen-induced cracking of high-strength low-alloy steel. Corros Sci, 2018, 139: 83 doi: 10.1016/j.corsci.2018.04.041 [24] Zuo L F, Ni R, Wang Z D, et al. Nano-precipitates in low carbon high strength steel during thr tempering process. J Iron Steel Res, 2013, 25(3): 39左龍飛, 倪銳, 王自東, 等. 低碳高強鋼中納米析出相回火過程中的透射分析. 鋼鐵研究學報, 2013, 25(3):39 [25] Yong Q L. Second Phases in Structural Steels. Beijing: Metallurgical Industry Press, 2006雍岐龍. 鋼鐵材料中的第二相. 北京: 冶金工業出版社, 2006 [26] Grabke H J, Riecke E. Absorption and diffusion of hydrogen in steels. Mater Tehnol, 2000, 34(6): 331 [27] Sojka J, Vodárek V, Schindler I, et al. Effect of hydrogen on the properties and fracture characteristics of TRIP 800 steels. Corros Sci, 2011, 53(8): 2575 doi: 10.1016/j.corsci.2011.04.015 [28] Grabke H J, Gehrmann F, Riecke E. Hydrogen in microalloyed steels. Steel Res Int, 2001, 72(5-6): 225 doi: 10.1002/srin.200100110 [29] Ghosh G, Rostron P, Garg R, et al. Hydrogen induced cracking of pipeline and pressure vessel steels: A review. Eng Fract Mech, 2018, 199: 609 doi: 10.1016/j.engfracmech.2018.06.018 [30] Stefano D D, Mrovec M, Els?sser C. First-principles investigation of quantum mechanical effects on the diffusion of hydrogen in iron and nickel. Phys Rev B, 2015, 92: 224301 doi: 10.1103/PhysRevB.92.224301 [31] Lee J Y, Lee S M. Hydrogen trapping phenomena in metals with B. C. C. and F. C. C. crystals structures by the desorption thermal analysis technique. Surf Coat Technol, 1986, 28(3-4): 301 doi: 10.1016/0257-8972(86)90087-3 [32] Dwivedi S K, Vishwakarma M. Effect of hydrogen in advanced high strength steel materials. Int J Hydrogen Energy, 2019, 44(51): 28007 doi: 10.1016/j.ijhydene.2019.08.149 [33] Chu W Y, Qiao L J, Li J X, et al. Hydrogen Embrittle and Stress Corrosion Cracking?Basic Part. Beijing: Science Press, 2013褚武揚, 喬利杰, 李金許, 等. 氫脆和應力腐蝕?基礎部分. 北京: 科學出版社, 2013 [34] Robertson W M, Thompson A W. Permeation measurements of hydrogen trapping in 1045 steel. Metall Trans A, 1980, 11(4): 553 doi: 10.1007/BF02670691 [35] Liu M A, Rivera-Díaz-del-Castillo P E J, Barraza-Fierroa J I, et al. Microstructural influence on hydrogen permeation and trapping in steels. Mater Des, 2019, 167: 107605 doi: 10.1016/j.matdes.2019.107605 [36] Wallaert E, Depover T, Arafin M, et al. Thermal desorption spectroscopy evaluation of the hydrogen-trapping capacity of NbC and NbN precipitates. Metall Mater Trans A, 2014, 45(5): 2412 doi: 10.1007/s11661-013-2181-1 [37] Pressouyre G M, Bernstein I M. A quantitative analysis of hydrogen trapping. Metall Trans A, 1978, 9(11): 1571 doi: 10.1007/BF02661939 [38] Pressouyre G M, Bernstein I M. An example of the effect of hydrogen trapping on hydrogen embrittlement. Metall Trans A, 1981, 12(5): 835 doi: 10.1007/BF02648348 [39] Restrepo S E, Stefano D D, Mrovec M, et al. Density functional theory calculations of iron?vanadium carbide interfaces and the effect of hydrogen. Int J Hydrogen Energy, 2020, 45(3): 2382 doi: 10.1016/j.ijhydene.2019.11.102 [40] Ma Y, Shi Y F, Wang H Y, et al. A first-principles study on the hydrogen trap characteristics of coherent nano-precipitates in α-Fe. Int J Hydrogen Energ, 2020, 45(51): 27941 doi: 10.1016/j.ijhydene.2020.07.123 [41] Wei J, Dong J H, Ke W, et al. Influence of inclusions on early corrosion development of ultra-low carbon bainitic steel in NaCl solution. Corrosion, 2015, 71(12): 1467 doi: 10.5006/1837 [42] Avci R, Davis B H, Wolfenden M L, et al. Mechanism of MnS-mediated pit initiation and propagation in carbon steel in an anaerobic sulfidogenic media. Corros Sci, 2013, 76: 267 doi: 10.1016/j.corsci.2013.06.049 [43] Lee J, Lee T, Mun D J, et al. Comparative study on the effects of Cr, V, and Mo carbides for hydrogen-embrittlement resistance of tempered martensitic steel. Sci Rep, 2019, 9: 5219 doi: 10.1038/s41598-019-41436-2 [44] Wei F G, Tsuzaki K. Quantitative analysis on hydrogen trapping of TiC particles in steel. Metall Mater Trans A, 2006, 37(2): 331 doi: 10.1007/s11661-006-0004-3 [45] Sawada H, Taniguchi S, Kawakami K, et al. Transition of the interface between iron and carbide precipitate from coherent to semi-coherent. Metals, 2017, 7(7): 277 doi: 10.3390/met7070277 [46] Wei F G, Hara T, Tsuzaki K. Nano-preciptates design with hydrogen trapping character in high strength steel//Advanced Steels. Berlin: Springer-Verlag Berlin Heidelberg and Metallurgical Industry Press, 2011 [47] Shi R J, Ma Y, Wang Z D, et al. Atomic-scale investigation of deep hydrogen trapping in NbC/α-Fe semi-coherent interfaces. Acta Mater, 2020, 200: 686 doi: 10.1016/j.actamat.2020.09.031 [48] Lin Y C, McCarroll I E, Lin Y T, et al. Hydrogen trapping and desorption of dual precipitates in tempered low-carbon martensitic steel. Acta Mater, 2020, 196: 516 doi: 10.1016/j.actamat.2020.06.046 [49] Zhang S Q, Wan J F, Zhao Q Y, et al. Dual role of nanosized NbC precipitates in hydrogen embrittlement susceptibility of lath martensitic steel. Corros Sci, 2020, 164: 108345 doi: 10.1016/j.corsci.2019.108345 [50] Chen Y S, Lu H Z, Liang J T, et al. Observation of hydrogen trapping at dislocations, grain boundaries, and precipitates. Science, 2020, 367(6474): 171 [51] Takahashi J, Kawakami K, Kobayashi Y, et al. The first direct observation of hydrogen trapping sites in TiC precipitation-hardening steel through atom probe tomography. Scripta Mater, 2010, 63(3): 261 doi: 10.1016/j.scriptamat.2010.03.012 [52] Weng L, Wu H Y, Du L X. Corrosion behavior of Ti-containing weathering steel in marine environment. Hot Work Technol, https://doi.org/10.14158/j.cnki.1001-3814.20192685翁鐳, 吳紅艷, 杜林秀. 含Ti耐候鋼在海洋環境中的腐蝕行為. 熱加工工藝, https://doi.org/10.14158/j.cnki.1001-3814.20192685 [53] Ghosh S, Singh A K, Mula S, et al. Mechanical properties, formability and corrosion resistance of thermomechanically controlled processed Ti?Nb stabilized IF steel. Mater Sci Eng A, 2017, 684: 22 doi: 10.1016/j.msea.2016.12.034 [54] Zhang X, Wei W Z, Cheng L, et al. Effects of niobium and rare earth elements on microstructure and initial marine corrosion behavior of low-alloy steels. Appl Surf Sci, 2019, 475: 83 doi: 10.1016/j.apsusc.2018.12.243 [55] Wang Z H, Wu J S, Li J, et al. Effects of niobium on the mechanical properties and corrosion behavior of simulated weld HAZ of HSLA steel. Metall Mater Trans A, 2018, 49(1): 187 doi: 10.1007/s11661-017-4391-4 [56] Suter T, B?hni H. A new microelectrochemical method to study pit initiation on stainless steels. Electrochim Acta, 1997, 42(20-22): 3275 doi: 10.1016/S0013-4686(70)01783-8 [57] Chen H, Lu L. Effect of residual stress on localized corrosion behavior of metallic materials. Chin J Eng, 2019, 41(7): 929陳恒, 盧琳. 殘余應力對金屬材料局部腐蝕行為的影響. 工程科學學報, 2019, 41(7):929 [58] Ejaz H, Lu Z P, Chen J J, et al. The effects of hydrogen on anodic dissolution and passivation of iron in alkaline solutions. Corros Sci, 2015, 101: 165 doi: 10.1016/j.corsci.2015.09.013 [59] Zhao Q Y, Wang Z H, Fan E D, et al. Effects of nanosized Nb carbide precipitates on the corrosion behavior of high-strength low-alloy steel in simulated seawater. Int J Electrochem Sci, 2017, 12: 7989 [60] Cui Q Q, Wu J S, Xie D H, et al. Effect of nanosized NbC precipitates on hydrogen diffusion in X80 pipeline steel. Materials, 2017, 10(7): 721 doi: 10.3390/ma10070721 [61] Li J, Wu J S, Wang Z H, et al. The effect of nanosized NbC precipitates on electrochemical corrosion behavior of high strength low-alloy steel in 3.5%NaCl solution. Int J Hydrogen Energy, 2017, 42(34): 22175 doi: 10.1016/j.ijhydene.2017.03.087 [62] Chen C Y, Liao M H. Synergistic effects of carbon content and Ti/Mo ratio on precipitation ehavior of HSLA steel: Insights from experiment and critical patent analysis. Mater Des, 2020, 186: 108361 doi: 10.1016/j.matdes.2019.108361 [63] Bansal G K, Srivastava V C, Chowdhury S G. Role of solute Nb in altering phase transformations during continuous cooling of a low-carbon steel. Mater Sci Eng A, 2019, 767: 138416 doi: 10.1016/j.msea.2019.138416 [64] Zhang X, Mi G Y, Xiong L D, et al. Effects of interlaminar microstructural inhomogeneity on mechanical properties and corrosion resistance of multi-layer fiber laser welded high strength low alloy steel. J Mater Process Technol, 2018, 252: 81 doi: 10.1016/j.jmatprotec.2017.09.012 [65] Wan X L, Li G Q, Wu K M. In-situ observations of grain refinement by TiN particles in the simulated coarse-grained heat-affected zone of a high-strength low-alloy steel. Chin J Eng, 2016, 38(3): 371萬響亮, 李光強, 吳開明. 原位觀察TiN 粒子對低合金高強度鋼模擬焊接熱影響區粗晶區晶粒細化作用. 工程科學學報, 2016, 38(3):371 [66] Moon J, Lee C. Behavior of (Ti, Nb)(C, N) complex particle during thermomechanical cycling in the weld CGHAZ of a microalloyed steel. Acta Mater, 2009, 57(7): 2311 doi: 10.1016/j.actamat.2009.01.042 [67] Qiao Q Q, Lu L, Fan E D, et al. Effects of Nb on stress corrosion cracking of high-strength low-alloy steel in simulated seawater. Int J Hydrogen Energy, 2019, 44(51): 27962 doi: 10.1016/j.ijhydene.2019.08.259 [68] Shanmugam S, Misra R D K, Hartmann J, et al. Microstructure of high strength niobium-containing pipeline steel. Mater Sci Eng A, 2006, 441(1-2): 215 doi: 10.1016/j.msea.2006.08.017 [69] Zhang Y R, Dong C F, Li X G, et al. Hydrogen induced cracking behaviors of X70 pipeline steel and its welds under electrochemical charging. Acta Metall Sin, 2006, 42(5): 521 doi: 10.3321/j.issn:0412-1961.2006.05.015張穎瑞, 董超芳, 李曉剛, 等. 電化學充氫條件下X70管線鋼及其焊縫的氫致開裂行為. 金屬學報, 2006, 42(5):521 doi: 10.3321/j.issn:0412-1961.2006.05.015 [70] Li X D, Liu J H, Sun J B, et al. Effect of microstructural aspects in the heat-affected zone of high strength pipeline steels on the stress corrosion cracking mechanism: Part I. In acidic soil environment. Corros Sci, 2019, 160: 108167 doi: 10.1016/j.corsci.2019.108167 [71] Liu C S, Li Z Z, Chen C F. Stress corrosion cracking of stainless steel. Surf Technol, 2020, 49(3): 1劉傳森, 李壯壯, 陳長風. 不銹鋼應力腐蝕開裂綜述. 表面技術, 2020, 49(3):1 [72] Li X G. Corrosion and Protection of Materials. Changsha: Central South University Press, 2009李曉剛. 材料腐蝕與防護. 長沙: 中南大學出版社, 2009 [73] Wang Y F, Hu S Y, Li Y, et al. Improved hydrogen embrittlement resistance after quenching–tempering treatment for a Cr?Mo?V high strength steel. Int J Hydrogen Energy, 2019, 44(54): 29017 doi: 10.1016/j.ijhydene.2019.09.142 [74] Wu W, Wang Q Y, Yang L, et al. Corrosion and SCC initiation behavior of low-alloy high-strength steels microalloyed with Nb and Sb in a simulated polluted marine atmosphere. J Mater Res Technol, 2020, 9(6): 12976 doi: 10.1016/j.jmrt.2020.09.033 [75] Fan E D, Zhang S Q, Xie D H, et al, Effect of nanosized NbC precipitates on hydrogen induced cracking of high-strength low-alloy steel. Int J Miner Metall Mater, https://doi.org/10.1007/s12613-020-2167-0 [76] Wu W, Liu Z Y, Wang Q Y, et al. Improving the resistance of high-strength steel to SCC in a SO2-polluted marine atmosphere through Nb and Sb microalloying. Corros Sci, 2020, 170: 108693 doi: 10.1016/j.corsci.2020.108693 [77] Zhou C S, Ye B G, Song Y Y, et al. Effects of internal hydrogen and surface-absorbed hydrogen on the hydrogen embrittlement of X80 pipeline steel. Int J Hydrogen Energy, 2019, 44(40): 22547 doi: 10.1016/j.ijhydene.2019.04.239 [78] Ohaeri E, Eduok U, Szpunar J. Hydrogen related degradation in pipeline steel: A review. Int J Hydrogen Energy, 2018, 43(31): 14584 doi: 10.1016/j.ijhydene.2018.06.064 [79] Li J X, Wang W, Zhou Y, et al. A review of research status of hydrogen embrittlement for automotive advanced high-strength steels. Acta Metall Sin, 2020, 56(4): 444 doi: 10.11900/0412.1961.2019.00427李金許, 王偉, 周耀, 等. 汽車用先進高強鋼的氫脆研究進展. 金屬學報, 2020, 56(4):444 doi: 10.11900/0412.1961.2019.00427 [80] Jack T A, Pourazizi R, Ohaeri E, et al. Investigation of the hydrogen induced cracking behaviour of API 5L X65 pipeline steel. Int J Hydrogen Energy, 2020, 45(35): 17671 doi: 10.1016/j.ijhydene.2020.04.211 [81] Thomas A, Szpunar J A. Hydrogen diffusion and trapping in X70 pipeline steel. Int J Hydrogen Energy, 2020, 45(3): 2390 doi: 10.1016/j.ijhydene.2019.11.096 [82] Hojo T, Akiyama E, Saitoh H, et al. Effects of residual stress and plastic strain on hydrogen embrittlement of a stretch-formed TRIP-aided martensitic steel sheet. Corros Sci, 2020, 177: 108957 doi: 10.1016/j.corsci.2020.108957 [83] Cheng X Y, Zhang H X. A new perspective on hydrogen diffusion and hydrogen embrittlement in low-alloy high strength steel. Corros Sci, 2020, 174: 108800 doi: 10.1016/j.corsci.2020.108800 [84] Kalashami A G, Kermanpur A, Ghassemali E, et al. The effect of Nb on texture evolutions of the ultrafine-grained dual-phase steels fabricated by cold rolling and intercritical annealing. J Alloys Compd, 2017, 694: 1026 doi: 10.1016/j.jallcom.2016.10.148 [85] Depover T, Verbeken K. The effect of TiC on the hydrogen induced ductility loss and trappingbehavior of Fe?C?Ti alloys. Corros Sci, 2016, 112: 308 doi: 10.1016/j.corsci.2016.07.013 [86] Chun Y S, Park K T, Lee S C. Delayed static failure of twinning-induced plasticity steels. Scripta Mater, 2012, 66(12): 960 doi: 10.1016/j.scriptamat.2012.02.038 [87] Zhang S Q, Huang Y H, Sun B T, et al. Effect of Nb on hydrogen-induced delayed fracture in high strength hot stamping steels. Mater Sci Eng A, 2015, 626: 136 doi: 10.1016/j.msea.2014.12.051 [88] Kang H J, Yoo J S, Park J T, et al. Effect of nano-carbide formation on hydrogen-delayed fracture for quenching and tempering steels during high-frequency induction heat treatment. Mater Sci Eng A, 2012, 543: 6 doi: 10.1016/j.msea.2012.02.008 [89] Yoo J, Jo M C, Jo M C, et al. Effects of Ti alloying on resistance to hydrogen embrittlement in (Nb+Mo)-alloyed ultra-high-strength hot-stamping steels. Mater Sci Eng A, 2020, 791: 139763 doi: 10.1016/j.msea.2020.139763 [90] Wu M, Chu W Y, Li J X, et al. Effects of stress and incluion on hydrogen blistering in wheel steel. Acta Metall Sin, 2006, 42(8): 815 doi: 10.3321/j.issn:0412-1961.2006.08.007武明, 褚武揚, 李金許, 等. 應力和夾雜對車輪鋼中氫鼓泡的影響. 金屬學報, 2006, 42(8):815 doi: 10.3321/j.issn:0412-1961.2006.08.007 [91] Li Yan, Fu A Q, Han Y. Causes of hydrogen blistering for 20G steel in wet hydrogen sulfide environment. Corros Prot, 2015, 36(7): 687 doi: 10.11973/fsyfh-201507019李巖, 付安慶, 韓燕. 濕硫化氫環境中20G鋼氫鼓泡原因. 腐蝕與防護, 2015, 36(7):687 doi: 10.11973/fsyfh-201507019 [92] Huang W, Gu H R, Liu Q H, et al. Suppression of hydrogen-induced damage in 22MnB5 hot stamping steel by microalloying. Mater Chem Phys, 2020, 256: 123729 doi: 10.1016/j.matchemphys.2020.123729 [93] Zhang S Q, Zhao Q Y, Liu J, et al. Understanding the effect of niobium on hydrogen-induced blistering in pipeline steel: A combined experimental and theoretical study. Corros Sci, 2019, 159: 108142 doi: 10.1016/j.corsci.2019.108142 [94] Giordani E J, Guimar?es V A, Pinto T B, et al. Effect of precipitates on the corrosion-fatigue crack initiation of ISO 5832-9 stainless steel biomaterial. Int J Fatigue, 2004, 26(10): 1129 doi: 10.1016/j.ijfatigue.2004.03.002 -

下載:

下載: