| [1] |

Karim H, Ancian L. Experimental analysis of discontinuities in single phase flow-vibration and pressure fluctuation measurements // SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition. Jakarta, 2017: SPE-186336-MS

|

| [2] |

Ortiz-Vidal L E, Mureithi N W, Rodriguez O M H. Vibration response of a pipe subjected to two-phase flow: analytical formulations and experiments. Nucl Eng Des, 2017, 313: 214

|

| [3] |

Hara F. Two-phase-flow-induced vibrations in a horizontal pulping system. Bull JSME, 1977, 20(142): 419

|

| [4] |

Cargnelutti M F, Belfroid S P C, Schiferli W. Two-phase flow-induced forces on bends in small scale tubes // Proceedings of the ASME 2009 Pressure Vessels and Piping Conference. Volume 4: Fluid-Structure Interaction. Prague, 2009: 369

|

| [5] |

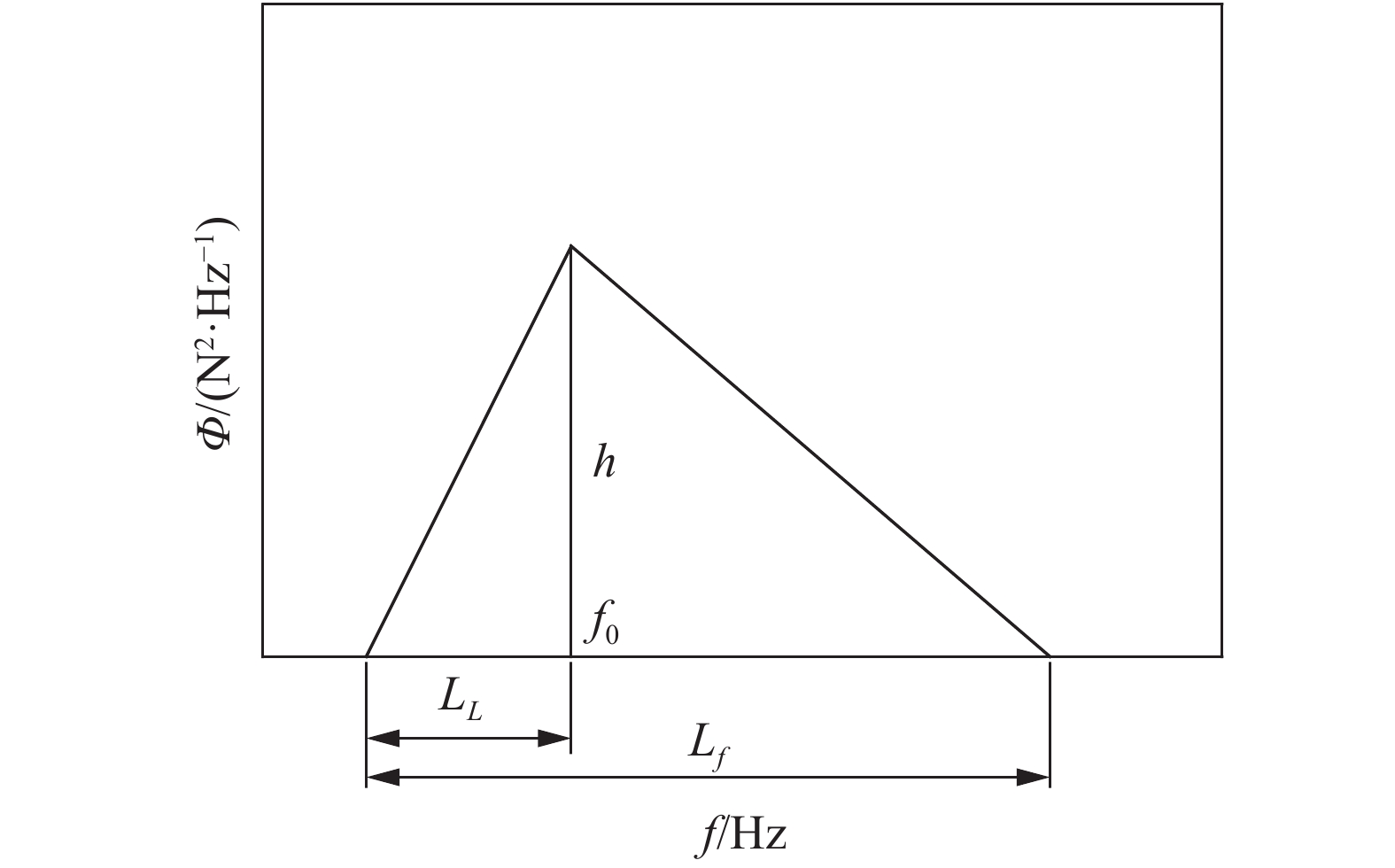

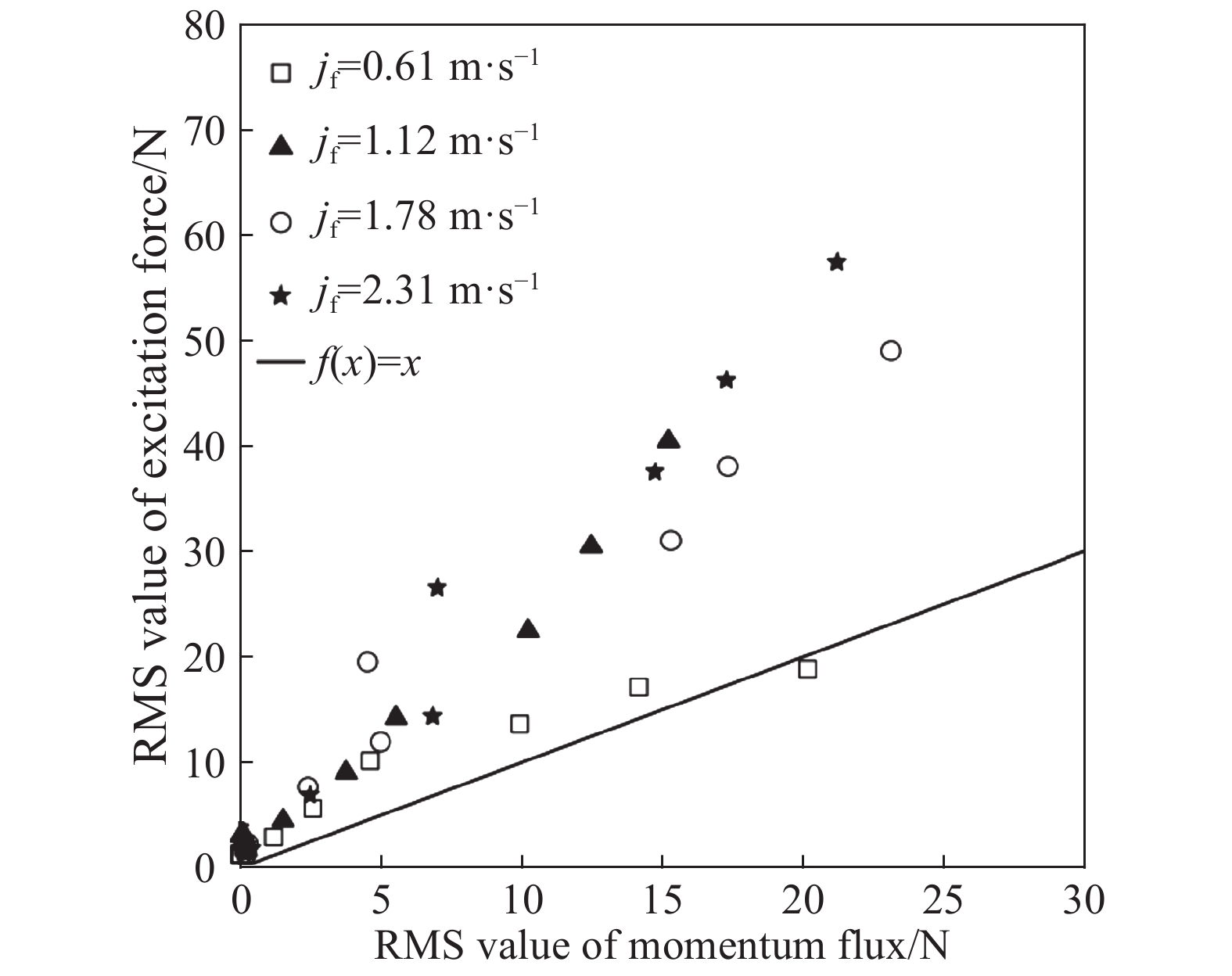

Riverin J L, de Langre E, Pettigrew M J. Fluctuating forces caused by internal two-phase flow on bends and tees. J Sound Vib, 2006, 298(4-5): 1088

|

| [6] |

Riverin J L, Pettigrew M J. Fluctuating forces in U-tubes subjected to internal two-phase flow // Proceedings of the ASME 2005 Pressure Vessels and Piping Conference. Volume 4: Fluid Structure Interaction. Denver, 2005: 547

|

| [7] |

Parsi M, Nair A, Kara M, et al. Condition based assessment of subsea rigid jumpers using advanced analytical model // 10th North American Conference on Multiphase Technology. Banff, 2016: BHR-2016-245

|

| [8] |

Smeulers J P M, Diez N G, Slot H. Flow induced vibration in subsea production systems // SPE Russian Oil and Gas Exploration and Production Technical Conference and Exhibition. Moscow, 2012: SPE-160727-MS

|

| [9] |

Wang L, Yang Y R, Li Y X, et al. Resonance analyses of a pipeline-riser system conveying gas-liquid two-phase flow with flow-pattern evolution. Int J Press Vessels Pip, 2018, 161: 22

|

| [10] |

Liu H G, Kong J Y, Li G F, et al. Inquiry into vibration analysis and control of fluid filled pipe system. J Hubei Univ Technol, 2005, 20(3): 78 doi: 10.3969/j.issn.1003-4684.2005.03.030劉懷廣, 孔建益, 李公法, 等. 充液管道系統振動分析與控制的探討. 湖北工業大學學報, 2005, 20(3):78 doi: 10.3969/j.issn.1003-4684.2005.03.030

|

| [11] |

Jia D. Slug flow induced vibration in a pipeline span, a jumper and a riser section // Offshore Technology Conference. Houston, 2012: OTC-22935-MS

|

| [12] |

Tay B L, Thorpe R B. Statistical analysis of the hydrodynamic forces acting on pipe bends in gas–liquid slug flow and their relation to fatigue. Chem Eng Res Des, 2015, 104: 457

|

| [13] |

Pettigrew M J, Taylor C E, Fisher N J, et al. Flow-induced vibration: recent findings and open questions. Nucl Eng Des, 1998, 185(2-3): 249

|

| [14] |

Swindell R. Hidden integrity threat looms in subsea pipework vibrations. Offshore, 2011, 71(9): 78

|

| [15] |

de Langre E, Villard B. An upper bound on random buffeting forces caused by two-phase flows across tubes. J Fluids Struct, 1998, 12(8): 1005

|

| [16] |

Sakaguchi T, Ozawa M, Hamaguchi H, et al. Analysis of the impact force by a transient liquid slug flowing out of a horizontal pipe. Nucl Eng Des, 1987, 99: 63

|

| [17] |

Mulcahy T M, Lawrence W, Wambsganss M W. Dynamic surface-pressure instrumentation for rods in parallel flow. Exp Mech, 1982, 22(1): 31

|

| [18] |

Chu I C, Chung H J, Lee S. Flow-induced vibration of nuclear steam generator U-tubes in two-phase flow. Nucl Eng Des, 2011, 241(5): 1508

|

| [19] |

Sasakawa T, Serizawa A, Kawara Z. Fluid-elastic vibration in two-phase cross flow. Exp Therm Fluid Sci, 2005, 29(3): 403

|

| [20] |

Pettigrew M J, Zhang C, Mureithi N W, et al. Detailed flow and force measurements in a rotated triangular tube bundle subjected to two-phase cross-flow. J Fluids Struct, 2005, 20(4): 567

|

| [21] |

Miwa S, Mori M, Hibiki T. Two-phase flow induced vibration in piping systems. Prog Nucl Energy, 2015, 78: 270

|

| [22] |

Yih T S, Griffith P. Unsteady Momentum Fluxes in Two-phase Flow and The Vibration of Nuclear Reactor Components [Dissertation]. Massachusetts: Massachusetts Institute of Technology, 1968

|

| [23] |

Cargnelutti M F, Belfroid S P C, Schiferli W, et al. Multiphase fluid structure interaction in bends and T-joints // Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference. ASME 2010 Pressure Vessels and Piping Conference: Volume 4. Bellevue, 2010: 75

|

| [24] |

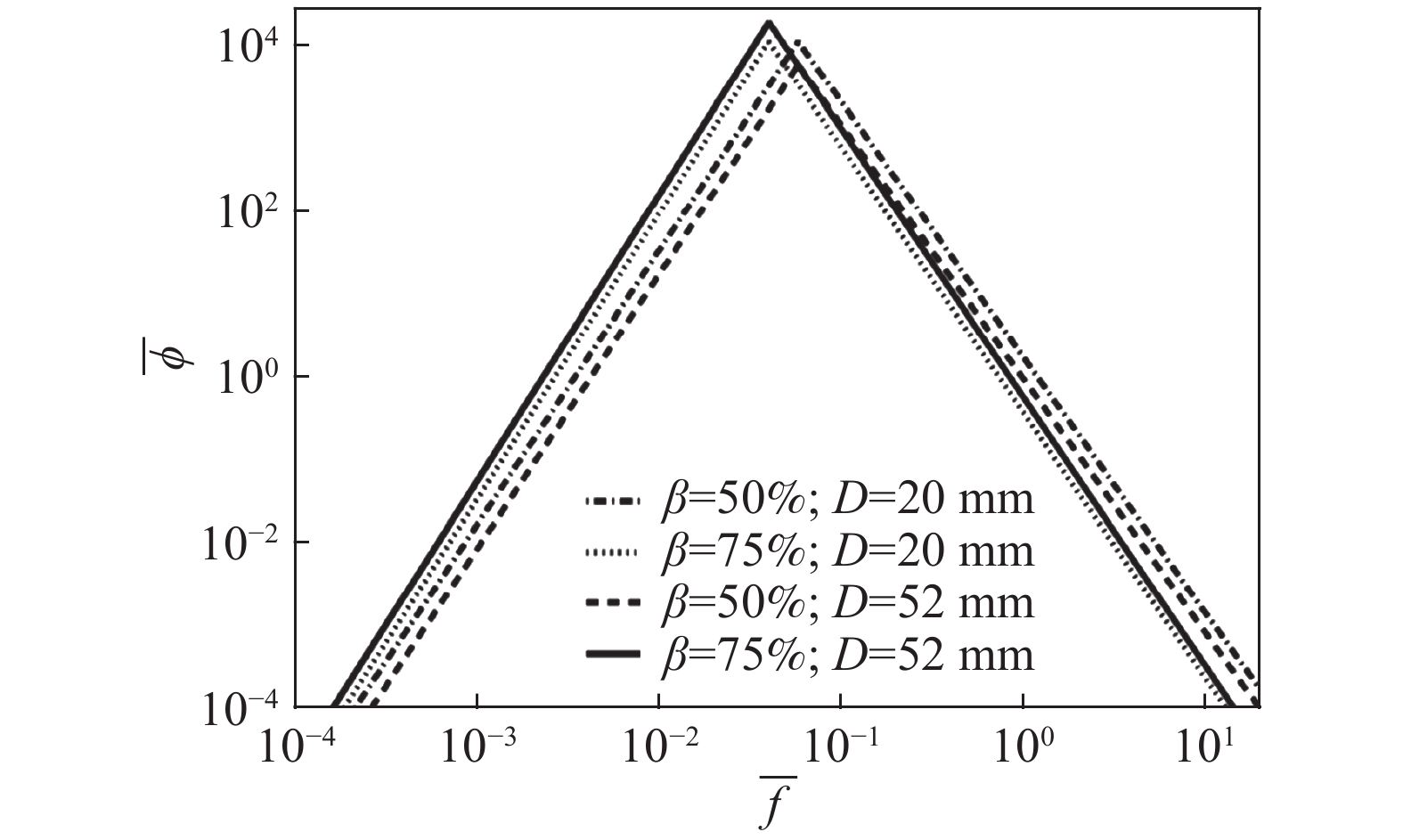

Giraudeau M, Mureithi N W, Pettigrew M J. Two-phase flow-induced forces on piping in vertical upward flow: excitation mechanisms and correlation models. J Pressure Vessel Technol, 2013, 135(3): 030907

|

| [25] |

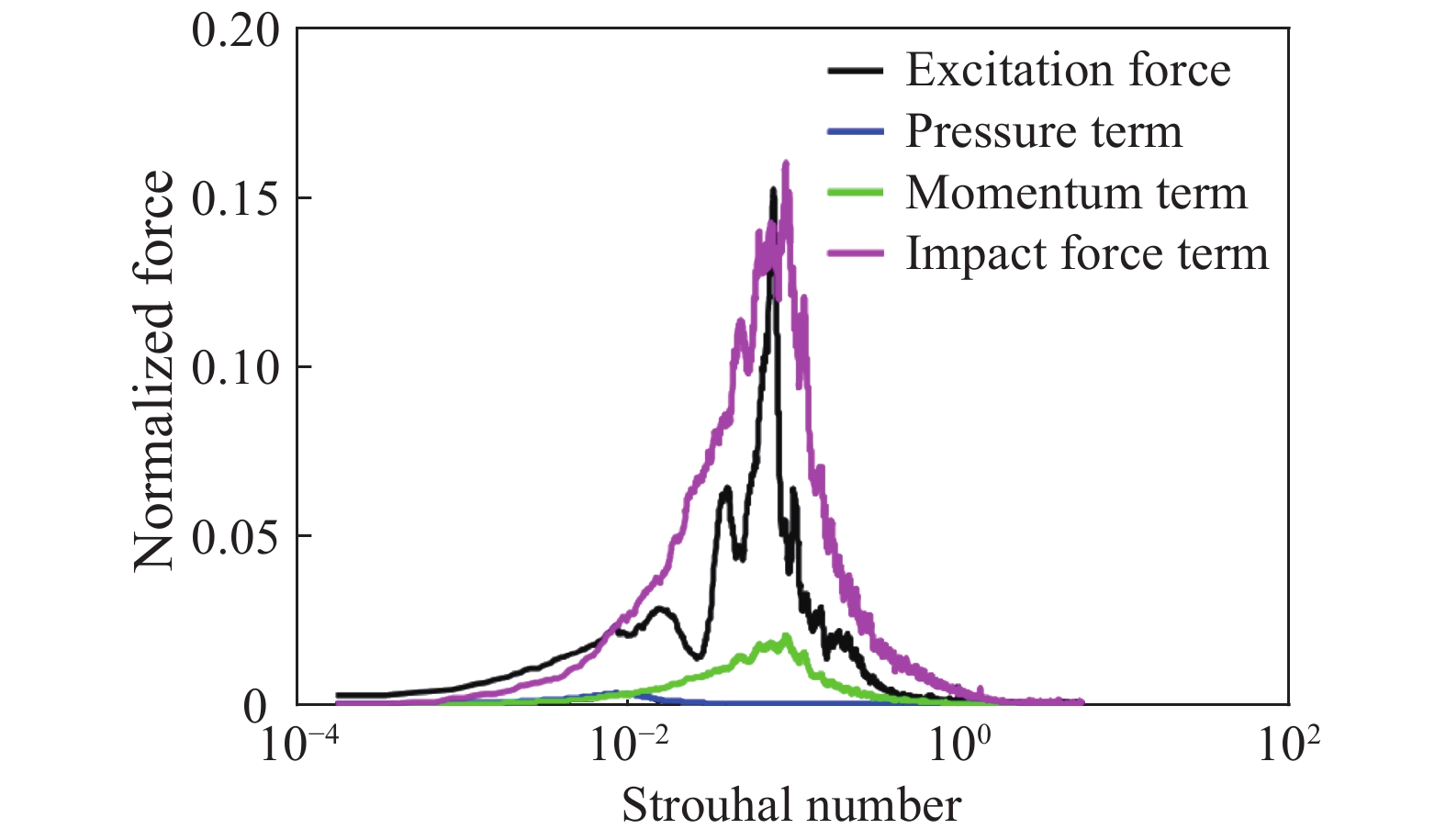

Liu Y, Miwa S, Hibiki T, et al. Experimental study of internal two-phase flow induced fluctuating force on a 90° elbow. Chem Eng Sci, 2012, 76: 173

|

| [26] |

Miwa S, Liu Y, Hibiki T, et al. Two-phase flow induced force fluctuations on pipe bend // Proceedings of the 2014 22nd International Conference on Nuclear Engineering. Volume 2B: Thermal Hydraulics. Prague, Czech Republic, 2014: V02BT09A007

|

| [27] |

Miwa S, Hibiki T, Mori M. Analysis of flow-induced vibration due to stratified wavy two-phase flow. J Fluids Eng, 2016, 138(9): 091302

|

| [28] |

de Henau V, Raithby G D. A study of terrain-induced slugging in two-phase flow pipelines. Int J Multiphase Flow, 1995, 21(3): 365

|

| [29] |

Al-Safran E. Investigation and prediction of slug frequency in gas/liquid horizontal pipe flow. J Petrol Sci Eng, 2009, 69(1-2): 143

|

| [30] |

Peddu A, Chakraborty S, Das P K. Visualization and flow regime identification of downward air–water flow through a 12 mm diameter vertical tube using image analysis. Int J Multiphase Flow, 2018, 100: 1

|

| [31] |

Barnea D, Shoham O, Taitel Y. Flow pattern characterization in two phase flow by electrical conductance probe. Int J Multiphase Flow, 1980, 6(5): 387

|

| [32] |

Taitel Y, Lee N, Dukler A E. Transient gas-liquid flow in horizontal pipes: Modeling the flow pattern transitions. AIChE J, 1978, 24(5): 920

|

| [33] |

Hewitt G F. Measurement of Two-Phase Flow Parameters. London and New York: Academic Press, 1978

|

| [34] |

Chen Z Y, He L M. Experimental study on measuring characteristics of slug flow in horizontal pipe. J Univ Petrol China Nat Sci, 2003, 27(1): 67陳振瑜, 何利民. 水平管段塞流特征參數測量方法的試驗研究. 石油大學學報: 自然科學版, 2003, 27(1):67

|

| [35] |

Barnea D, Brauner N. Holdup of the liquid slug in two phase intermittent flow. Int J Multiphase Flow, 1985, 11(1): 43

|

| [36] |

Dukler A E, Hubbard M G. A model for gas-liquid slug flow in horizontal and near horizontal tubes. Ind Eng Chem Fundamen, 1975, 14(4): 337

|

| [37] |

Zhu H J, Gao Y, Zhao H L. Experimental investigation on the flow-induced vibration of a free-hanging flexible riser by internal unstable hydrodynamic slug flow. Ocean Eng, 2018, 164: 488

|

| [38] |

Wang L, Yang Y R, Li Y X, et al. Dynamic behaviours of horizontal gas-liquid pipes subjected to hydrodynamic slug flow: modelling and experiments. Int J Press Vessels Pip, 2018, 161: 50

|

| [39] |

Al-Hashimy Z, Al-Kayiem H, Time R W. Experimental investigation on the vibration induced by slug flow in horizontal pipe. J Eng Appl Sci, 2016, 11(20): 12134

|

| [40] |

Xing L, Yeung H, Lo S. Investigation of slug flow induced forces on pipe bends applying STAR-OLGA coupling // 15th International Conference on Multiphase Production Technology. Cannes, 2011: BHR-2011-H2

|

| [41] |

Chen B C M. A marine riser with internal flow-induced vibration // Offshore Technology Conference. Houston, Texas, 1992: OTC-6893-MS

|

| [42] |

Ortega A, Rivera A, Larsen C M. Flexible riser response induced by combined slug flow and wave loads // Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering. Volume 4B: Pipeline and Riser Technology. Nantes, 2013: V04BT04A008

|

| [43] |

Swindell R, Belfroid S. Internal flow induced pulsation of flexible risers // Offshore Technology Conference. Houston, Texas, 2007: OTC-18895-MS

|

| [44] |

Zhou X J, Gong J, Chen J. Analysis on the static/dynamic load at the elbow in riser system of subsea pipeline. China Offshore Oil Gas, 2005, 17(4): 268 doi: 10.3969/j.issn.1673-1506.2005.04.012周曉軍, 宮敬, 陳杰. 海底管道立管系統彎頭部位靜、動荷載分析. 中國海上油氣, 2005, 17(4):268 doi: 10.3969/j.issn.1673-1506.2005.04.012

|

| [45] |

Liu C, Li Y X, Wang L, et al. Experimental study on two-phase flow and vibration characteristics of marine riser. China Petrol Mach, 2016, 44(4): 46劉昶, 李玉星, 王琳, 等. 海洋立管兩相流動及管道振動特性試驗研究. 石油機械, 2016, 44(4):46

|

| [46] |

Lu Y J, Liang C, Manzano-Ruiz J J, et al. FSI analysis of flow-Induced vibration in subsea jumper subject to downstream slug and ocean current // Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering. Volume 2: CFD and VIV. San Francisco, 2014: V002T08A062

|

| [47] |

Locharla H, Al Awadhi I, Narayana S, et al. Flow induced vibration in multi phase piping systems - successful mitigation // Abu Dhabi International Petroleum Exhibition & Conference. Abu Dhabi, 2017: SPE-188386-MS

|

| [48] |

Giraudeau M, Pettigrew M J, Mureithi N W. Two-phase flow excitation forces on a vertical U-bend tube // Proceedings of the ASME 2011 Pressure Vessels and Piping Conference. Volume 4: Fluid-Structure Interaction. Baltimore, Maryland, 2011: 103

|

| [49] |

Li W S, Guo L J, Xie X D. Effects of a long pipeline on severe slugging in an S-shaped riser. Chem Eng Sci, 2017, 171: 379

|

| [50] |

Malekzadeh R, Henkes R A W M, Mudde R F. Severe slugging in a long pipeline–riser system: experiments and predictions. Int J Multiphase Flow, 2012, 46: 9

|

| [51] |

Mokhatab S. Severe slugging in a catenary-shaped riser: Experimental and simulation studies. Petrol Sci Technol, 2007, 25(6): 719

|

| [52] |

Montgomery J A, Yeung H C. The stability of fluid production from a flexible riser. J Energy Resour Technol, 2002, 124(2): 83

|

| [53] |

Xie C, Guo L J, Li W S, et al. The influence of backpressure on severe slugging in multiphase flow pipeline-riser systems. Chem Eng Sci, 2017, 163: 68

|

| [54] |

Massey B S, Wardsmith J. Mechanics of Fluids. 9nd Ed. Boca Raton: CRC Press, 2012

|

| [55] |

Beggs D H, Brill J P. A study of two-phase flow in inclined pipes. J Petrol Technol, 1973, 25(5): 607

|

| [56] |

Tay B L, Thorpe R B. Hydrodynamic forces acting on pipe bends in gas–liquid slug flow. Chem Eng Res Des, 2014, 92(5): 812

|

| [57] |

Tay B L, Thorpe R B. Effects of liquid physical properties on the forces acting on a pipe bend in gas–liquid slug flow. Chem Eng Res Des, 2004, 82(3): 344

|

| [58] |

Pontaza J P, Abuali B, Brown G W, et al. Flow-induced vibrations of subsea piping: A screening approach based on numerical simulation // SPE Offshore Europe Oil and Gas Conference and Exhibition. Aberdeen, 2013: SPE-166661-MS

|

| [59] |

Li F Q, Cao J, Duan M L, et al. Two-phase flow induced vibration of subsea span pipeline // The 26th International Ocean and Polar Engineering Conference. Rhodes, 2016: ISOPE-I-16-333

|

| [60] |

Tian H J, Xing Y, Song C Y, et al. Numerical simulation of flue gas desulfurization by horizontal spray tower. Chin J Eng, 2018, 40(1): 17田海軍, 邢奕, 宋存義, 等. 臥式噴淋塔煙氣脫硫的數值模擬. 工程科學學報, 2018, 40(1):17

|

| [61] |

Yuan F, Yang G, Xu A J, et al. Thermal state simulation analysis of molten iron ladle based on different insulation measures. Chin J Eng, 2018, 40(1): 31袁飛, 楊光, 徐安軍, 等. 基于不同保溫措施下的鐵水包熱狀態模擬分析. 工程科學學報, 2018, 40(1):31

|

下載:

下載: