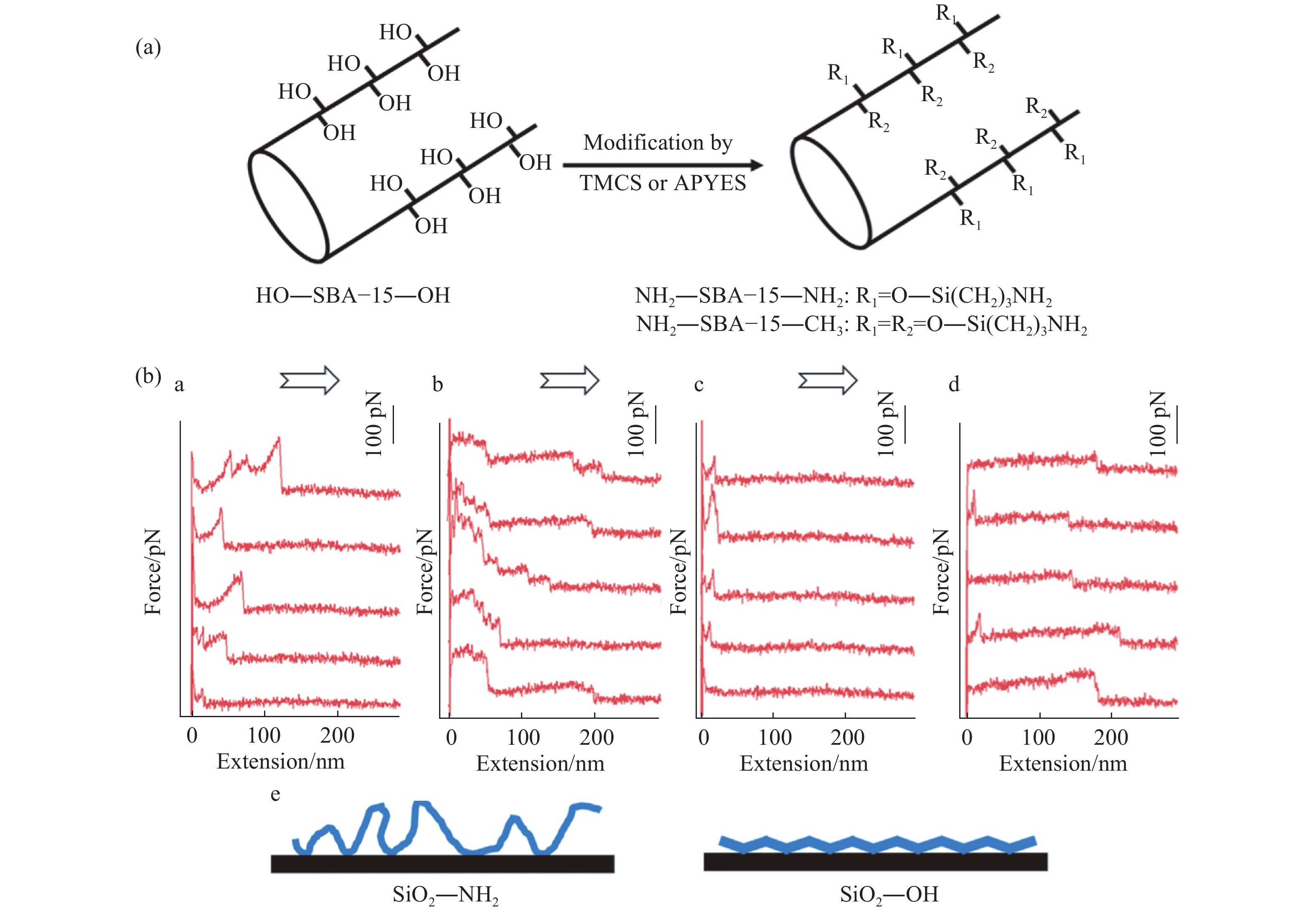

-

摘要: 相變儲能技術的發展對于促進新能源開發和提高能源利用效率具有非常重要的意義。相變材料由于具有高儲能密度和小體積變化等優勢引起了人們的廣泛關注。然而,相變材料在固–液相轉變過程中易發生液體泄漏而限制了其應用。因此,人們選擇用多孔支撐材料來解決相變材料的泄露問題。介孔二氧化硅材料由于具有良好的物理化學穩定性、生物相容性、阻燃性能、低毒性、耐腐蝕性、尺寸可控、表面形貌可調和高比表面積等優點,其作為載體材料能綜合提高相變復合物的各方面性能并拓寬相變儲能材料的應用空間。對近年來國內外關于介孔二氧化硅載體的孔尺寸、孔結構和孔表面性質對相變材料結晶行為的影響等方面進行了綜合分析,并對今后提高介孔二氧化硅相變材料儲能效率的研究方法的前景做了展望。Abstract: Increasing concerns surrounding the rising global energy demand has forced humans to look for alternative energy sources such as the development and utilization of natural gas and nuclear energy, or to increase the efficiency of energy use, thereby optimizing the use of energy. Improving energy efficiency is an effective method that can quickly and efficiently reduce the energy demand and supply gap. Furthermore, developing new technologies for energy storage and energy saving is an effective way to solve the energy crisis, which is of great significance for the sustainable development of energy. Latent heat storage has become a popular research topic owing to its large energy storage density and small temperature changes during energy storage and its excellent thermal stability and high safety. Currently, phase-change materials have been widely used in solar heating systems, air conditioning systems, thermally regulated textiles, energy-efficient building construction, temperature-controlled greenhouses and other fields. The development of phase-change energy storage technology is significant for promoting the development of alternative energy sources and improving energy efficiency. However, phase change materials are prone to liquid leakage during the solid-liquid phase transition, which limits their application. To solve this problem, researchers have started introducing porous support materials to phase-change materials. Porous support materials have attracted extensive research attention in recent years owing to their outstanding properties such as high specific surface area, large pore volume, and low density. Porous support materials can absorb phase-change materials in their pores through the physical adsorption phenomena such as capillary action and interfacial tension, and thereby gradually develop into important substrates for phase-change material encapsulation. Inorganic materials are used as carriers for phase change energy storage materials. Compared with organic carrier materials, inorganic carrier materials have higher mechanical strength, flame retardancy and thermal conductivity, which can reduce the production cost of phase-change energy storage materials, and have a high research value. Mesoporous silica materials have good physical and chemical stability, biocompatibility, flame retardancy, low toxicity, corrosion resistance, controllable size, adjustable surface morphology and high specific surface area. They can comprehensively improve the performance of various aspects of phase change composites and broaden the application space of phase change energy storage materials. In this review, the effects of pore size, pore structure, and pore surface properties on the crystallization behavior of phase change materials in mesoporous silica carriers developed in recent years were comprehensively analyzed, and prospects of research methods for heat storage efficiency were explored.

-

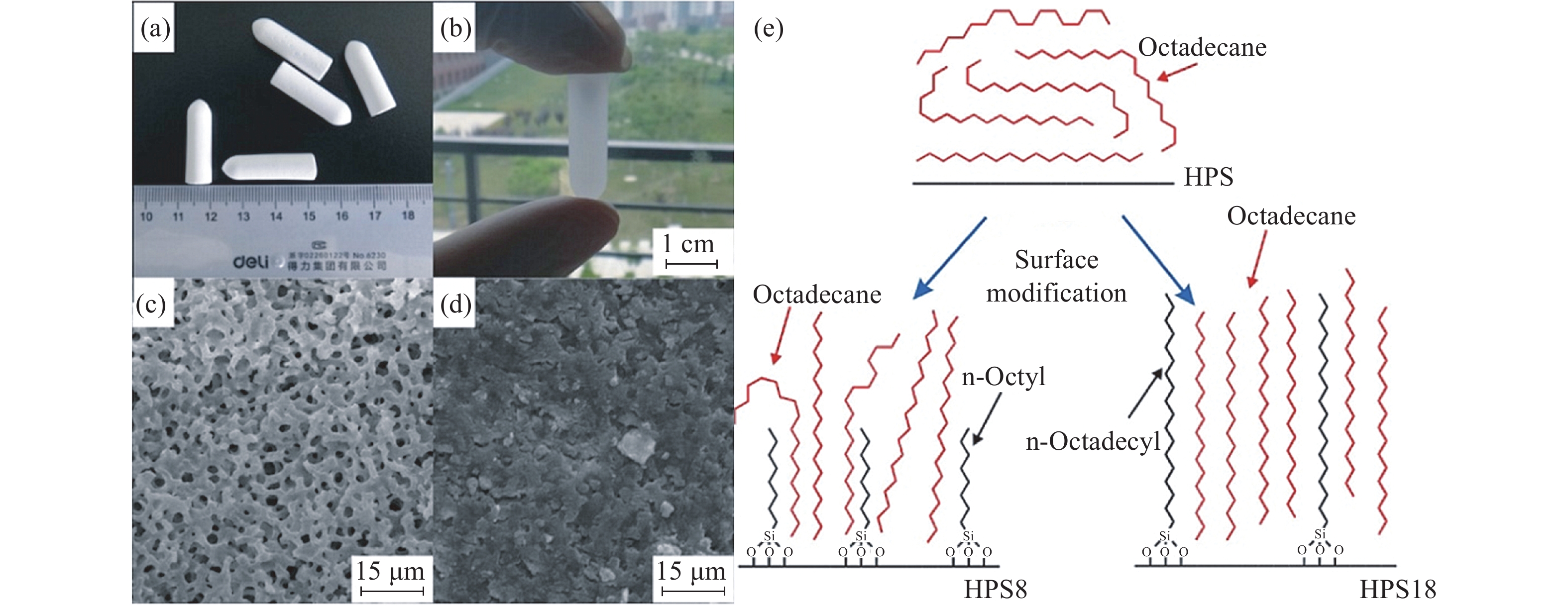

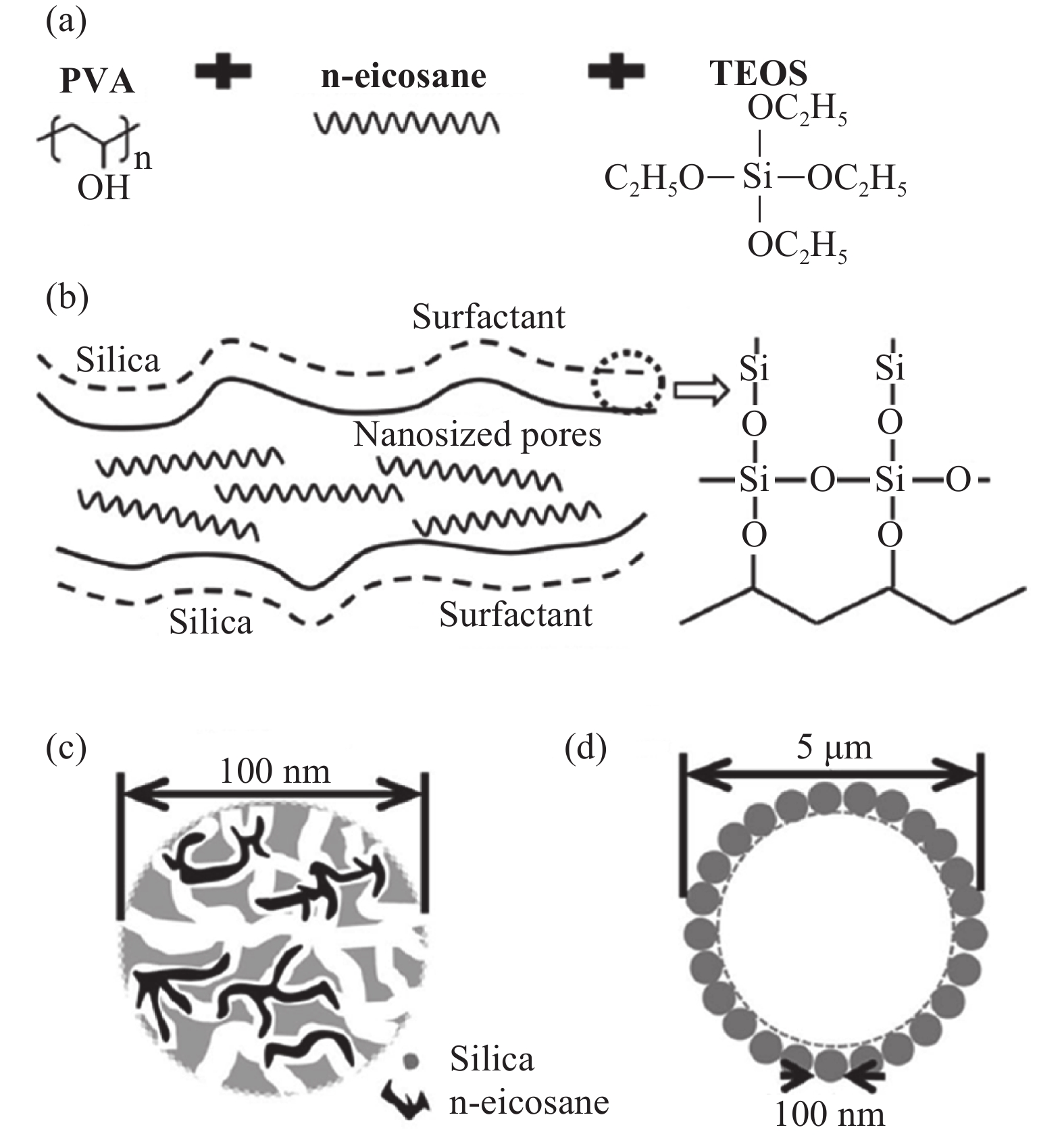

圖 1 正二十烷@二氧化硅復合物的制備示意圖。(a)起始物料;(b)納米二氧化硅孔中的正二十烷分子(右側圖為孔隙內壁可能的結構圖);(c)孔隙中含有正二十烷的硅顆粒的結構(顆粒直徑約為100 nm);(d)正二十烷@二氧化硅顆粒自組裝成微米大小的空心球體[24]

Figure 1. Schematic diagram of the preparation of n-eicosane@silica composite: (a) starting materials; (b) n-eicosane molecules in the pores of nano-silica (the figure on the right is a possible structural diagram of the inner wall of the pore); (c) structure of silicon particles containing n-eicosane in the pores (approximately 100 nm); (d) self-assembly of n-eicosane@silica particles into micrometer-sized hollow spheres[24]

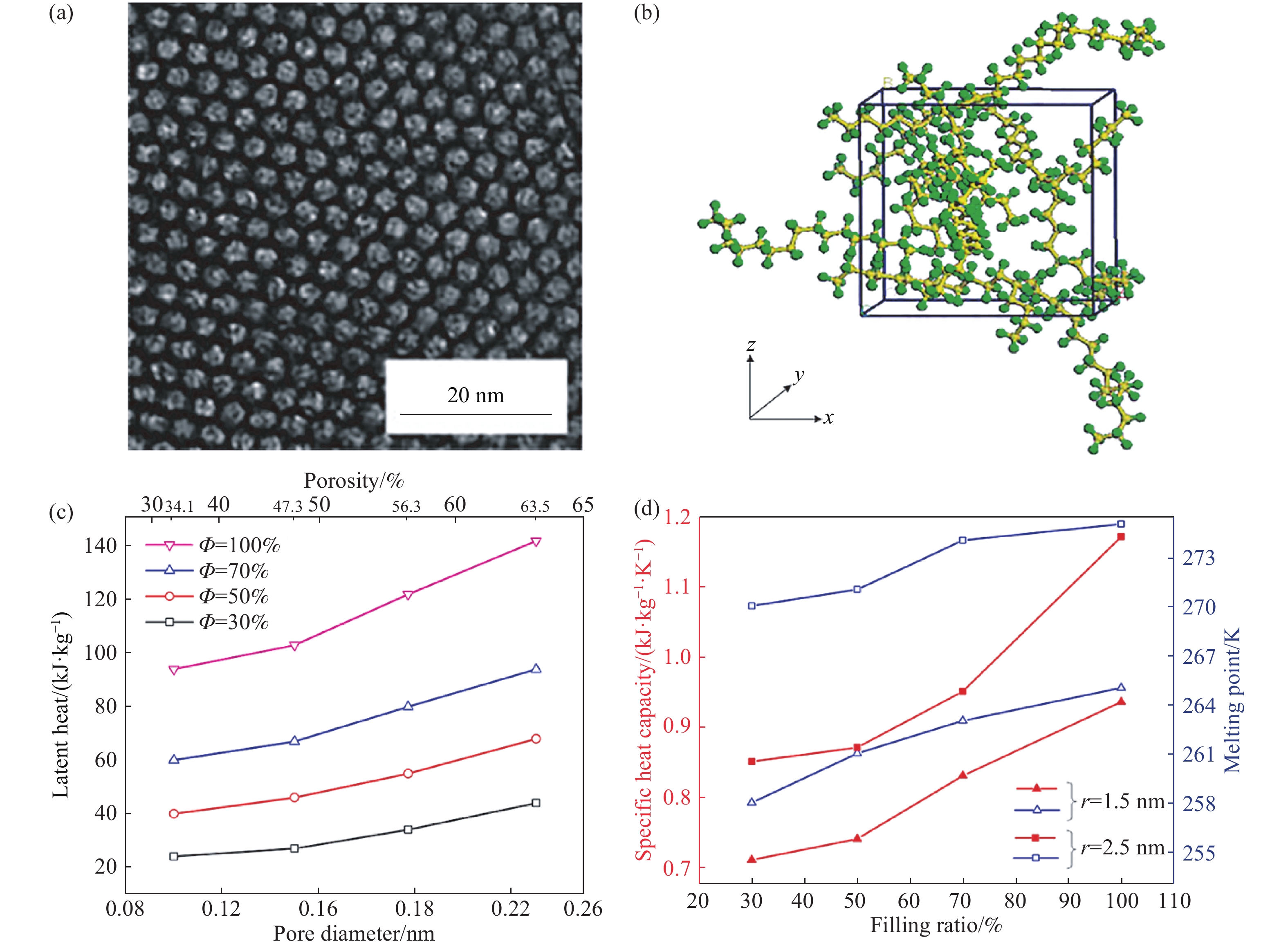

圖 2 C17H36/MCM–41復合材料的影響因素對比。(a)MCM–41的SEM圖;(b)優化的C17H36晶體結構(黃色代表碳,綠色代表氫);(c)不同填充率的C17H36/MCM–41復合材料的潛熱隨孔徑或孔隙率的變化(Φ為填充率);(d)C17H36/MCM–41復合材料的潛熱和熔點隨填充率的變化(r為孔直徑)[41]

Figure 2. Comparison of influencing factors of C17H36/MCM-41 composite: (a) SEM image of MCM–41; (b) optimized C17H36 crystal structure (yellow represents carbon, green represents hydrogen); (c) latent heat of C17H36/MCM–41 composites with different filling rates varies with pore size or porosity (Φ is filling rate); (d) latent heat and melting point of C17H36/MCM–41 composite materials change with filling rates (r is pore diameter)[41]

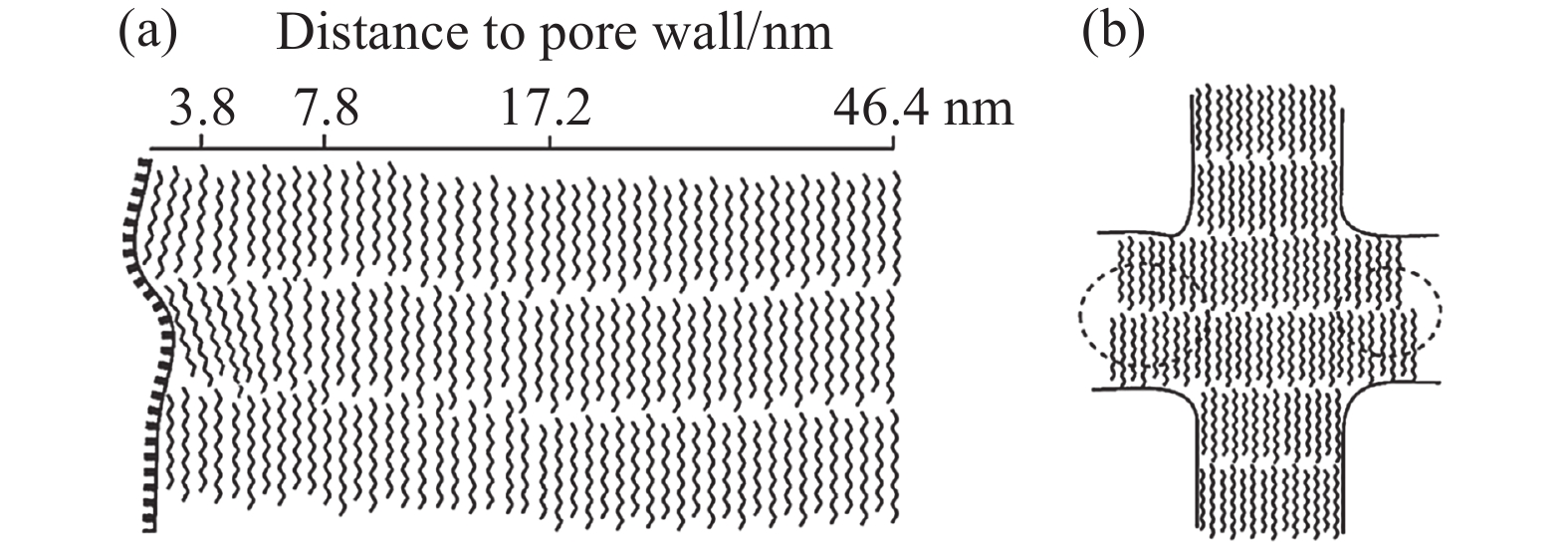

圖 4 C16被吸附于SBA–15(7.8和17.2 nm),CPG(8.1和300 nm),C–SBA–15(15.6 nm)和KIT–6(8.6 nm)的示意圖(C—冷卻;H—加熱;D—維度;T16—分子在載體中的排列)[52]

Figure 4. Schematic diagram of C16 being adsorbed on SBA–15 (7.8 and 17.2 nm), CPG (8.1 and 300 nm), C–SBA–15 (15.6 nm) and KIT–6 (8.6 nm) (C: cooling; H: heating; D: dimension; T16: the molecular arrangements in the bulk)[52]

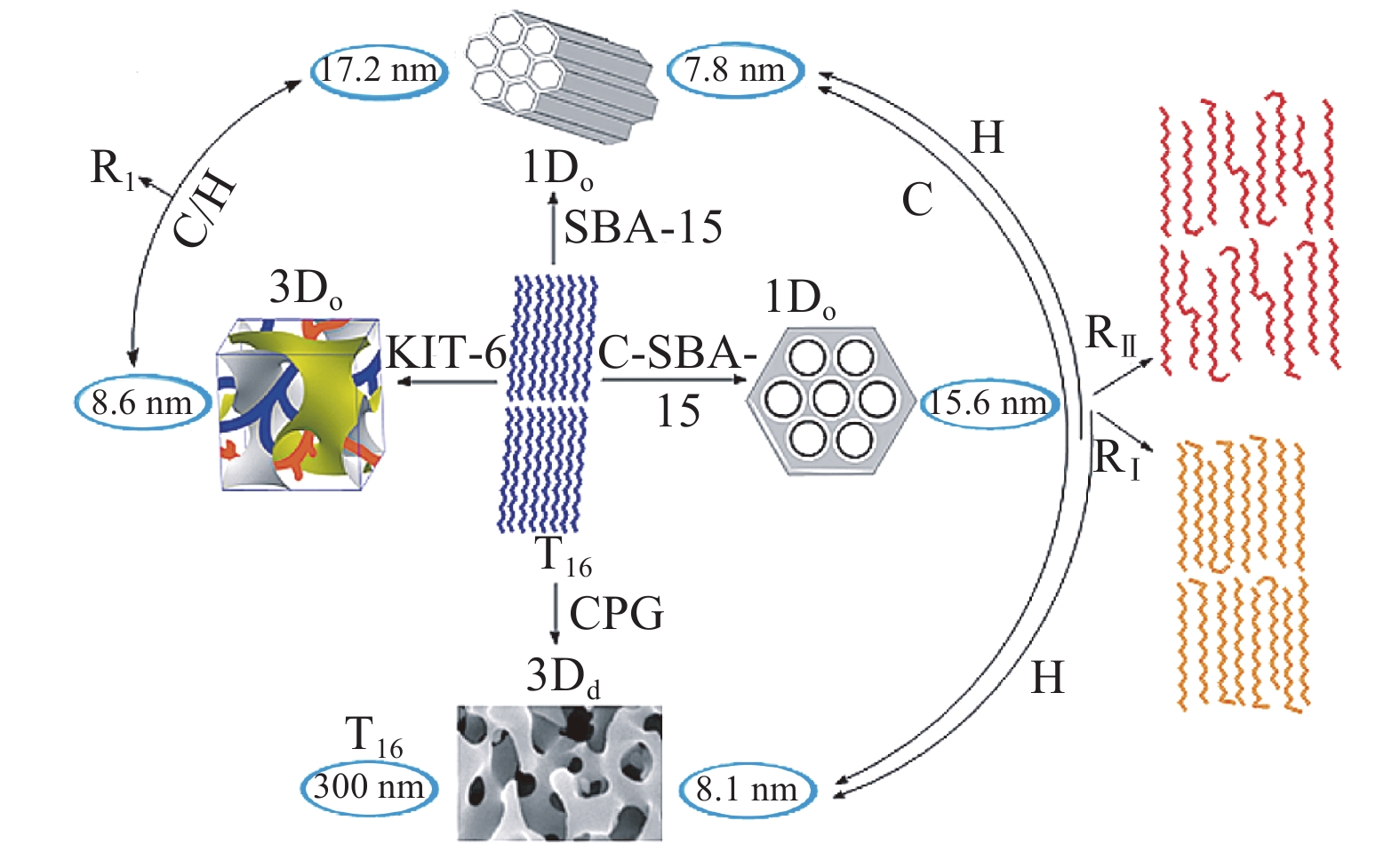

圖 5 PEG/RMS復合物的制備及性能示意圖。(a1)RMS合成過程示意圖;(a2)真空浸漬法制備相變復合物;(a3)PEG/RMS復合物形成機理示意圖;(b)DSC曲線;(c)理論焓值和實際焓值的對比圖[55]

Figure 5. Schematic diagram of preparation and performance of PEG/RMS complexes: (a1) schematic diagram of the synthesis process of RMS: (a2) vacuum impregnation method to prepare the phase change composites; (a3) schematic diagram of the formation mechanism of the PEG/RMS composites; (b) DSC curve; (c) comparison of theoretical and actual enthalpies[55]

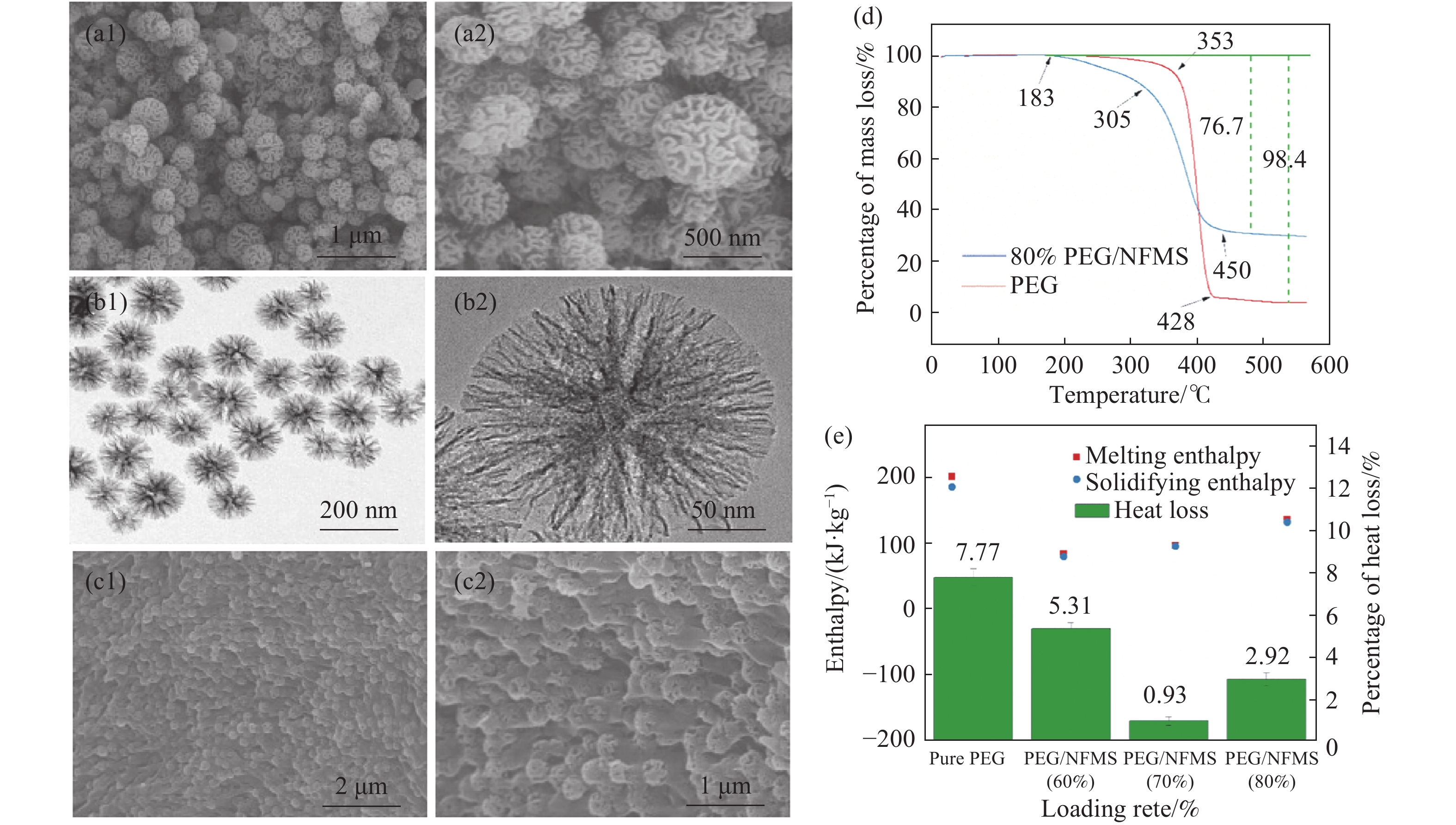

圖 6 PEG/NFMS復合物的制備及性能示意圖。(a)NFMS的SEM圖;(b)NFMS的TEM圖;(c)PEG/NFMS的SEM圖;(d)80% PEG/NFMS和純PEG的TG圖;(e)復合物的焓值和熱損失率的對比圖[56]

Figure 6. Schematic diagram of the preparation and performance of PEG/NFMS complexes: (a) SEM images of NFMS; (b) TEM images of NFMS; (c) SEM images of PEG/NFMS; (d) TG image of 80% PEG/NFMS and pure PEG; (e) comparison of the enthalpy and heat loss rate of PEG/NFMS[56]

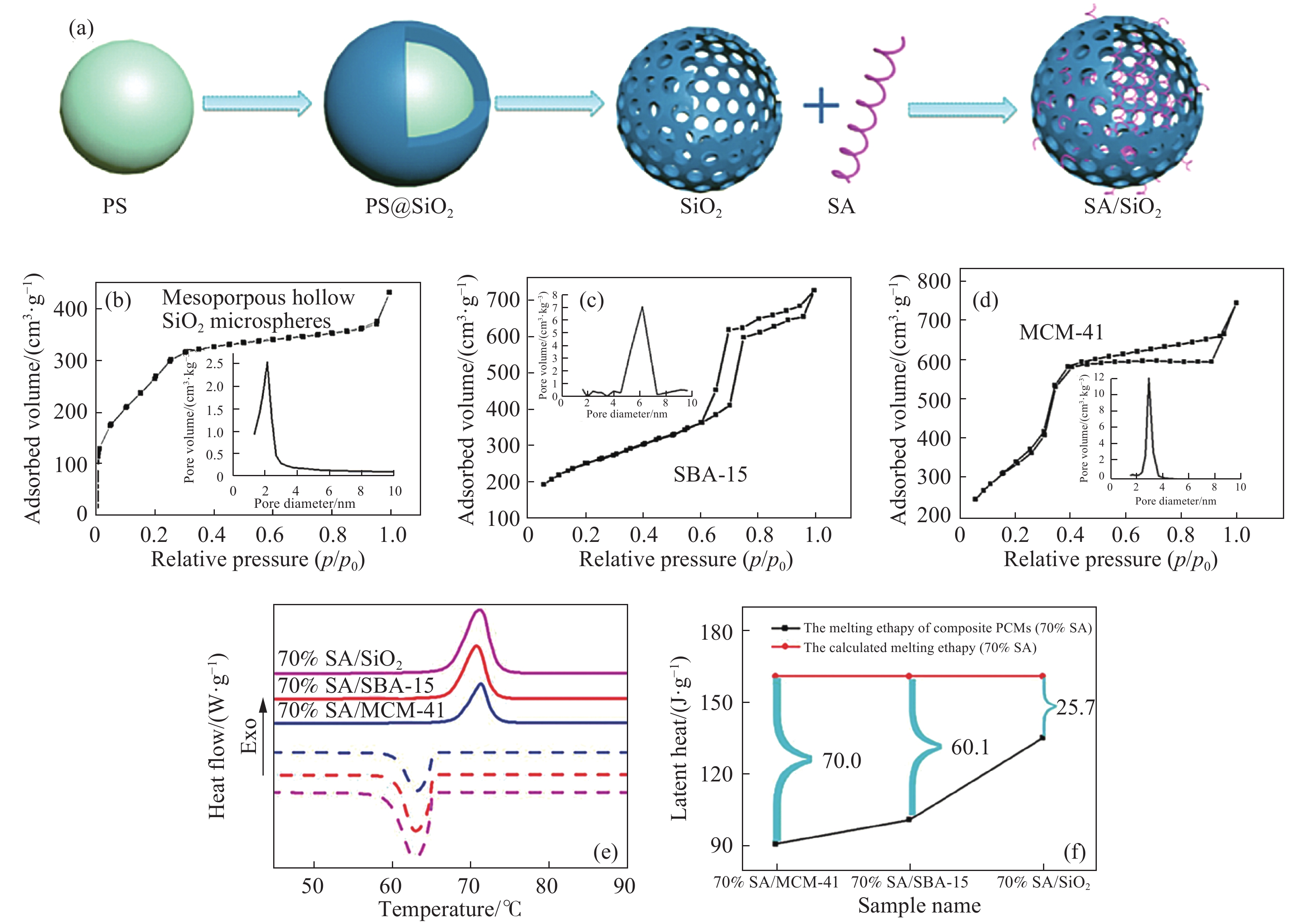

圖 7 SA/SiO2復合材料的制備及性能示意圖。(a)SA/SiO2復合物的制備示意圖;(b)SiO2微球BET圖;(c)SBA–15的BET圖;(d)MCM–41的BET圖;(e)復合物的DSC圖;(f)復合PCMs的實際熔融焓與理論熔融焓對比[67]

Figure 7. Schematic diagram of preparation and performance of SA/SiO2 composites: (a) schematic diagram of preparation of SA/SiO2 composites; (b) BET of SiO2 microspheres; (c) BET of SBA–15; (d) BET of MCM–41; (e) DSC of composites; (f) comparison of actual melting enthalpy and theoretical melting enthalpy of composite PCMs[67]

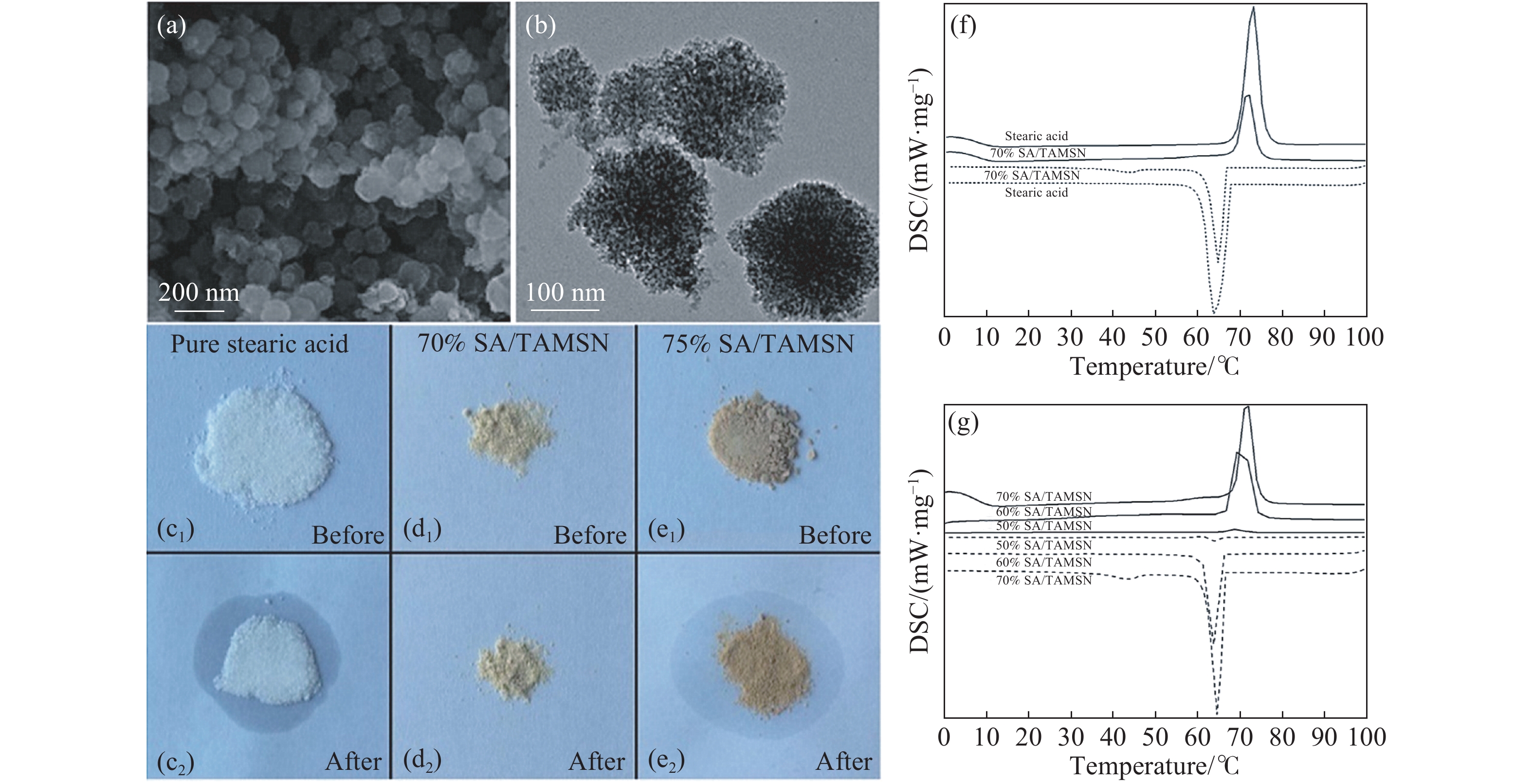

圖 8 SA/TAMSNs相變復合材料形貌及性能。(a)TAMSNs的SEM圖;(b)TAMSNs的TEM圖;(c1,d1和e1)泄漏測試前的SA和復合物;(c2,d2和e2)泄漏測試后的SA和復合物;(f和g)不同負載量的復合物DSC圖[71]

Figure 8. Morphology and properties of SA/TAMSNs phase change composites: (a) SEM image of TAMSNs; (b) TEM image of TAMSNs; (c1, d1 and e1) SA and compound before leakage test; (c2, d2 and e2) SA and compound after leakage test; (f and g) DSC of the compounds with different loadings[71]

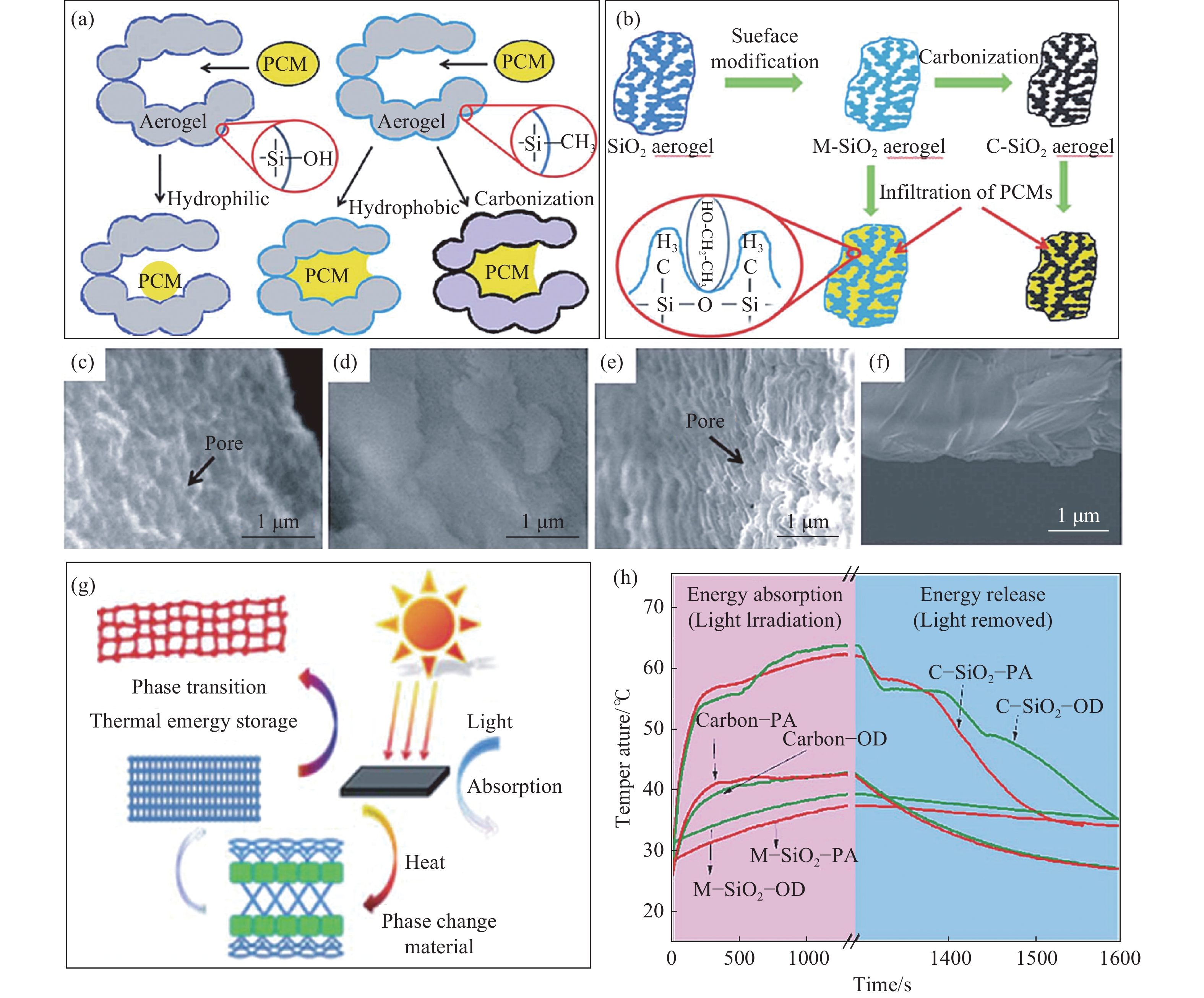

圖 10 十八烷/HPS復合物的形貌及負載機理。(a)HPS和(b)十八烷/HPS復合物的照片;(c)HPS和(d)十八烷/HPS復合物的TEM圖;(e)表面修飾前后的HPS載體與十八烷分子的示意圖[80]

Figure 10. Morphology and loading mechanism of octadecane/HPS composites: the optical image of the HPS (a) and composited with octadecane (b); the SEM images of HPS (c) and composited with octadecane (d); (e) the hypothetical image of the arrangement of octadecane molecules on the composite PCM surfaces[80]

圖 11 氣凝膠基相變復合材料。(a)表面修飾前后氣凝膠中浸漬PCM的對比示意圖;(b)親水性至疏水性的表面改性和碳化過程示意圖;(c)M–SiO2,(d)M–SiO2–PA,(e)C–SiO2和(f)C–SiO2–OD復合材料的顯微結構的SEM圖像;(g)光熱轉換的機理和(h)不同樣品的光熱轉換曲線[81]

Figure 11. Aerogel-based composite PCMs: (a) schematic comparison of the PCM penetration in the untreated and treated aerogels; (b) illustration of the hydrophilic-to-hydrophobic surface modification and carbonization process; the SEM images of the microstructures (c) M–SiO2, (d) M–SiO2–PA, (e) C–SiO2 and (f) C–SiO2–OD composites; (g) the mechanism of light-to-heat conversion and (h) the curves of light-to-heat conversion by the different samples[81]

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Faraj K, Khaled M, Faraj J, et al. Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renewable Sustainable Energy Rev, 2020, 119: 109579 [2] Johar D K, Sharma D, Soni S L, et al. Experimental investigation on latent heat thermal energy storage system for stationary CI engine exhaust. Appl Therm Eng, 2016, 104: 64 [3] Alva G, Liu L K, Huang X, et al. Thermal energy storage materials and systems for solar energy applications. Renewable Sustainable Energy Rev, 2017, 68: 693 [4] Czaun M, Kothandaraman J, Goeppert A, et al. Iridium-catalyzed continuous hydrogen generation from formic acid and its subsequent utilization in a fuel cell: Toward a carbon neutral chemical energy storage. ACS Catal, 2016, 6(11): 7475 [5] Wang T Y, Diao Y H, Zhu T T, et al. Thermal performance of solar air collection-storage system with phase change material based on flat micro-heat pipe arrays. Energy Convers Manage, 2017, 142: 230 [6] Veerakumar C, Sreekumar A. Phase change material based cold thermal energy storage: Materials, techniques and applications–A review. Int J Refrig, 2016, 67: 271 [7] Sánchez P, Sánchez-Fernandez M V, Romero A, et al. Development of thermo-regulating textiles using paraffin wax microcapsules. Thermochim Acta, 2010, 498(1-2): 16 [8] Nejman A, Cie?lak M, Gajdzicki B, et al. Methods of PCM microcapsules application and the thermal properties of modified knitted fabric. Thermochim Acta, 2014, 589: 158 [9] Beyhan B, Paksoy H, Da?gan Y. Root zone temperature control with thermal energy storage in phase change materials for soilless greenhouse applications. Energy Convers Manage, 2013, 74: 446 [10] Liu P P, Liu S Q, Gao H Y, et al. Preparation and properties of hydroxyapatite aerogel composite phase change materials. Chin J Eng, 2020, 42(1): 120劉盼盼, 劉斯奇, 高鴻毅, 等. 羥基磷灰石氣凝膠復合相變材料的制備及其性能. 工程科學學報, 2020, 42(1):120 [11] Tao Z, Wu L M, Zhang Y F, et al. Preparation and properties of biomass porous carbon-based composite phase change materials. Chin J Eng, 2020, 42(1): 113陶璋, 伍玲梅, 張亞飛, 等. 生物質多孔碳基復合相變材料制備及性能. 工程科學學報, 2020, 42(1):113 [12] Hai G T, Xue X D, Su T Q, et al. Molecular dynamics study on the interaction between metal-organic frameworks and phase change core materials. Chin J Eng, 2020, 42(1): 99海廣通, 薛祥東, 蘇天琪, 等. 金屬有機骨架與相變芯材相互作用的分子動力學. 工程科學學報, 2020, 42(1):99 [13] Li Y Q, Li Y, Xi Z S, et al. Eggplant-derived porous carbon encapsulating polyethylene glycol as phase change materials. Chin J Eng, 2020, 42(1): 106李亞瓊, 李洋, 席作帥, 等. 茄子衍生多孔碳負載聚乙二醇相變復合材料. 工程科學學報, 2020, 42(1):106 [14] Ramakrishnan S, Sanjayan J, Wang X M, et al. A novel paraffin/expanded perlite composite phase change material for prevention of PCM leakage in cementitious composites. Appl Energy, 2015, 157: 85 [15] Wang C Y, Feng L L, Li W, et al. Shape-stabilized phase change materials based on polyethylene glycol/porous carbon composite: the influence of the pore structure of the carbon materials. Solar Energy Mater Sol Cells, 2012, 105: 21 [16] Zhou D, Zhao C Y. Experimental investigations on heat transfer in phase change materials (PCMs) embedded in porous materials. Appl Therm Eng, 2011, 31(5): 970 [17] Huang X B, Chen X, Li A, et al. Shape-stabilized phase change materials based on porous supports for thermal energy storage applications. Chem Eng J, 2019, 356: 641 [18] Zhang L J, Shi H F, Li W W, et al. Structure and thermal performance of poly (ethylene glycol) alkyl ether (Brij)/porous silica (MCM-41) composites as shape-stabilized phase change materials. Thermochim Acta, 2013, 570: 1 [19] Gao H Y, Bo L J, Liu P P, et al. Ambient pressure dried flexible silica aerogel for construction of monolithic shape-stabilized phase change materials. Sol Energy Mater Sol Cells, 2019, 201: 110122 [20] Feng D L, Feng Y H, Qiu L, et al. Review on nanoporous composite phase change materials: Fabrication, characterization, enhancement and molecular simulation. Renewable Sustainable Energy Rev, 2019, 109: 578 [21] Wang J J, Xu X L, Liang K Y, et al. Thermal conductivity enhancement of porous shape-stabilized composite phase change materials for thermal energy storage applications: a review. Chin J Eng, 2020, 42(1): 26王靜靜, 徐小亮, 梁凱彥, 等. 多孔基定形復合相變材料傳熱性能提升研究進展. 工程科學學報, 2020, 42(1):26 [22] Li M, Shi J B. Review on micropore grade inorganic porous medium based form stable composite phase change materials: Preparation, performance improvement and effects on the properties of cement mortar. Constr Build Mater, 2019, 194: 287 [23] Zhang J, Wang S S, Zhang S D, et al. In situ synthesis and phase change properties of Na2SO4·10H2O@SiO2 solid nanobowls toward smart heat storage. J Phys Chem C, 2011, 115(41): 20061 [24] Wang W, Wang C Y, Li W, et al. Novel phase change behavior of n-eicosane in nanoporous silica: emulsion template preparation and structure characterization using small angle X-ray scattering. Phys Chem Chem Phys, 2013, 15(34): 14390 [25] Xie Z Y, Bai L, Huang S W, et al. New strategy for surface functionalization of periodic mesoporous silica based on meso-HSiO1.5. J Am Chem Soc, 2014, 136(4): 1178 [26] Mitran R A, Berger D, Munteanu C, et al. Evaluation of different mesoporous silica supports for energy storage in shape-stabilized phase change materials with dual thermal responses. J Phys Chem C, 2015, 119(27): 15177 [27] Li M, Wang W, Zhang Z G, et al. Monodisperse Na2SO4·10H2O@SiO2 microparticles against supercooling and phase separation during phase change for efficient energy storage. Ind Eng Chem Res, 2017, 56(12): 3297 [28] Rashidi S, Esfahani J A, Karimi N. Porous materials in building energy technologies—A review of the applications, modelling and experiments. Renewable Sustainable Energy Rev, 2018, 91: 229 [29] Sar? A, Bicer A, Al-Ahmed A, et al. Silica fume/capric acid-palmitic acid composite phase change material doped with CNTs for thermal energy storage. Sol Energy Mater Sol Cells, 2018, 179: 353 [30] Zhang L, Zhang P, Wang F, et al. Phase change materials based on polyethylene glycol supported by graphene-based mesoporous silica sheets. Appl Therm Eng, 2016, 101: 217 [31] Li H Q, Chen H S, Li X Y, et al. Development of thermal energy storage composites and prevention of PCM leakage. Appl Energy, 2014, 135: 225 [32] Matei C, Buhǎl?eanu L, Berger D, et al. Functionalized mesoporous silica as matrix for shape-stabilized phase change materials. Int J Heat Mass Transfer, 2019, 144: 118699 [33] Liu P P, Gao H Y, Chen X, et al. In situ one-step construction of monolithic silica aerogel-based composite phase change materials for thermal protection. Compos Part B-Eng, 2020, 195: 108072 [34] Feng L L, Zhao W, Zheng J, et al. The shape-stabilized phase change materials composed of polyethylene glycol and various mesoporous matrices (AC, SBA-15 and MCM-41). Sol Energy Mater Sol Cells, 2011, 95(12): 3550 [35] Mitran R A, Berger D, Matei C. Phase change materials based on mesoporous silica. Curr Org Chem, 2018, 22(27): 2644 [36] Aftab W, Huang X Y, Wu W H, et al. Nanoconfined phase change materials for thermal energy applications. Energy Environ Sci, 2018, 11(6): 1392 [37] Su W G, Darkwa J, Kokogiannakis G. Review of solid–liquid phase change materials and their encapsulation technologies. Renewable Sustainable Energy Rev, 2015, 48: 373 [38] Pan L, Tao Q H, Zhang S D, et al. Preparation, characterization and thermal properties of micro-encapsulated phase change materials. Sol Energy Mater Sol Cells, 2012, 98: 66 [39] Dutil Y, Rousse D R, Salah N B, et al. A review on phase-change materials: mathematical modeling and simulations. Renewable Sustainable Energy Rev, 2011, 15(1): 112 [40] Zhang Z J, Wang J X, Tang X, et al. Comparison study between mesoporous silica nanoscale microsphere and active carbon used as the matrix of shape-stabilized phase change material. Sci Rep, 2019, 9: 16056 [41] Zhang J R, Feng Y H, Yuan H B, et al. Thermal properties of C17H36/MCM-41 composite phase change materials. Comput Mater Sci, 2015, 109: 300 [42] Sundarram S S, Li W. The effect of pore size and porosity on thermal management performance of phase change material infiltrated microcellular metal foams. Appl Therm Eng, 2014, 64(1-2): 147 [43] Liu S, Ma G X, Xie S L, et al. Diverting the phase transition behaviour of adipic acid via mesoporous silica confinement. RSC Adv, 2016, 6(113): 111787 [44] Lazarenko M M, Alekseev A N, Alekseev S A, et al. Nanocrystallite–liquid phase transition in porous matrices with chemically functionalized surfaces. Phys Chem Chem Phys, 2019, 21(44): 24674 [45] Wang X, Wei Y T, Zhang D X, et al. Phase behaviors of n-octacosane in nanopores: Role of pore size and morphology. Thermochim Acta, 2020, 690: 178687 [46] Mehryan S A M, Vaezi M, Sheremet M, et al. Melting heat transfer of power-law non-Newtonian phase change nano-enhanced n-octadecane-mesoporous silica (MPSiO2). Int J Heat Mass Transfer, 2020, 151: 119385 [47] Qian T T, Li J H, Min X, et al. Integration of pore confinement and hydrogen-bond influence on the crystallization behavior of C18 PCMs in mesoporous silica for form-stable phase change materials. ACS Sustainable Chem Eng, 2018, 6(1): 897 [48] Han L P, Ma G X, Xie S L, et al. Preparation and characterization of the shape-stabilized phase change material based on sebacic acid and mesoporous MCM-41. J Therm Anal Calorim, 2017, 130(2): 935 [49] Mitran R A, Berger D, Matei C. Improving thermal properties of shape-stabilized phase change materials containing lauric acid and mesocellular foam silica by assessing thermodynamic properties of the non-melting layer. Thermochim Acta, 2018, 660: 70 [50] Sui J, Zhang S Q, Zhai M, et al. Polymorphism of a hexadecane–heptadecane binary system in nanopores. RSC Adv, 2017, 7(18): 10737 [51] Yan X, Gao C F, Wang T B, et al. New phase behavior of n-undecane–tridecane mixtures confined in porous materials with pore sizes in a wide mesoscopic range. RSC Adv, 2013, 3(39): 18028 [52] Wang L P, Sui J, Zhai M, et al. Physical control of phase behavior of hexadecane in nanopores. J Phys Chem C, 2015, 119(32): 18697 [53] Zhang D, Wu K R. Tuning effect of porous structure on phase changing behavior of organic phase changing matters. J Tongji Univ Nat Sci Ed, 2004, 32(9): 1163張東, 吳科如. 孔結構對有機相變物質相變行為的調節作用. 同濟大學學報:自然科學版, 2004, 32(9):1163 [54] Yang C C, Li J C, Jiang Q. Temperature–pressure phase diagram of silicon determined by Clapeyron equation. Solid State Commun, 2004, 129(7): 437 [55] Min X, Fang M H, Huang Z H, et al. Enhanced thermal properties of novel shape-stabilized PEG composite phase change materials with radial mesoporous silica sphere for thermal energy storage. Sci Rep, 2015, 5: 12964 [56] Gao J K, Tao W W, Chen D, et al. High performance shape-stabilized phase change material with nanoflower-like wrinkled mesoporous silica encapsulating polyethylene glycol: preparation and thermal properties. Nanomaterials, 2018, 8(6): 385 [57] Kadoono T, Ogura M. Heat storage properties of organic phase-change materials confined in the nanospace of mesoporous SBA-15 and CMK-3. Phys Chem Chem Phys, 2014, 16(12): 5495 [58] Chen D, Chen Y, Guo X W, et al. Mesoporous silica nanoparticles with wrinkled structure as the matrix of myristic acid for the preparation of a promising new shape-stabilized phase change material via simple method. RSC Adv, 2018, 8(60): 34224 [59] Serrano A, del Campo J M, Peco N, et al. Influence of gelation step for preparing PEG–SiO2 shape-stabilized phase change materials by sol–gel method. J Sol-Gel Sci Technol, 2019, 89(3): 731 [60] Zhu Y L, Qin Y S, Liang S E, et al. Graphene/SiO2/n-octadecane nanoencapsulated phase change material with flower like morphology, high thermal conductivity, and suppressed supercooling. Appl Energy, 2019, 250: 98 [61] Qian T T, Li J H, Min X, et al. Radial-like mesoporous silica sphere: A promising new candidate of supporting material for storage of low-, middle-, and high-temperature heat. Energy, 2016, 112: 1074 [62] Wang L Y, Tsai P S, Yang Y M. Preparation of silica microspheres encapsulating phase-change material by sol-gel method in O/W emulsion. J Microencapsul, 2006, 23(1): 3 [63] Zhang H Z, Sun S Y, Wang X D, et al. Fabrication of microencapsulated phase change materials based on n-octadecane core and silica shell through interfacial polycondensation. Colloids Surf A, 2011, 389(1-3): 104 [64] Zhang X Y, Wang X D, Wu D Z. Design and synthesis of multifunctional microencapsulated phase change materials with silver/silica double-layered shell for thermal energy storage, electrical conduction and antimicrobial effectiveness. Energy, 2016, 111: 498 [65] Wei J, Wang T, Li H, et al. Design and synthesis of organo-silica shell based dual-functional microencapsulated phase change material for thermal regulating systems. Chem Pap, 2018, 72(4): 1055 [66] Liu H, Niu J F, Wang X D, et al. Design and construction of mesoporous silica/n-eicosane phase-change nanocomposites for supercooling depression and heat transfer enhancement. Energy, 2019, 188: 116075 [67] Fan S, Gao H Y, Dong W J, et al. Shape-stabilized phase change materials based on stearic acid and mesoporous hollow SiO2 microspheres (SA/SiO2) for thermal energy storage. Eur J Inorg Chem, 2017, 2017(14): 2138 [68] He L H, Li J R, Zhou C, et al. Phase change characteristics of shape-stabilized PEG/SiO2 composites using calcium chloride-assisted and temperature-assisted sol gel methods. Sol Energy, 2014, 103: 448 [69] Tang B T, Cui J S, Wang Y M, et al. Facile synthesis and performances of PEG/SiO2 composite form-stable phase change materials. Sol Energy, 2013, 97: 484 [70] Tang B T, Wang Y M, Qiu M G, et al. A full-band sunlight-driven carbon nanotube/PEG/SiO2 composites for solar energy storage. Sol Energy Mater Sol Cells, 2014, 123: 7 [71] Chen Y, Zhang X J, Wang B F, et al. Fabrication and characterization of novel shape-stabilized stearic acid composite phase change materials with tannic-acid-templated mesoporous silica nanoparticles for thermal energy storage. RSC Adv, 2017, 7(26): 15625 [72] Chen Y, Zhu Y Y, Wang J B, et al. Novel shape-stabilized phase change materials composed of polyethylene glycol/nonsurfactant-templated mesoporous silica: Preparation and thermal properties. JOM, 2017, 69(12): 2774 [73] Zhang Y Z, Zheng S L, Zhu S Q, et al. Evaluation of paraffin infiltrated in various porous silica matrices as shape-stabilized phase change materials for thermal energy storage. Energy Convers Manage, 2018, 171: 361 [74] Jal P K, Patel S, Mishra B K. Chemical modification of silica surface by immobilization of functional groups for extractive concentration of metal ions. Talanta, 2004, 62(5): 1005 [75] Li L Y, Li N K, Tu Q, et al. Functional modification of silica through enhanced adsorption of elastin-like polypeptide block copolymers. Biomacromolecules, 2018, 19(2): 298 [76] Bagwe R P, Hilliard L R, Tan W H. Surface modification of silica nanoparticles to reduce aggregation and nonspecific binding. Langmuir, 2006, 22(9): 4357 [77] Feng D L, Feng Y H, Li P, et al. Modified mesoporous silica filled with PEG as a shape-stabilized phase change materials for improved thermal energy storage performance. Microporous Mesoporous Mater, 2020, 292: 109756 [78] Gao J K, Zhou J, Zhang X J, et al. Facile functionalized mesoporous silica using biomimetic method as new matrix for preparation of shape-stabilized phase-change material with improved enthalpy. Int J Energy Res, 2019, 43(14): 8649 [79] Wang J J, Yang M, Lu Y F, et al. Surface functionalization engineering driven crystallization behavior of polyethylene glycol confined in mesoporous silica for shape-stabilized phase change materials. Nano Energy, 2016, 19: 78 [80] Wang Y C, Zhang L Y, Tao S Y, et al. Phase change in modified hierarchically porous monolith: An extra energy increase. Microporous Mesoporous Mater, 2014, 193: 69 [81] Huang X Y, Liu Z P, Xia W, et al. Alkylated phase change composites for thermal energy storage based on surface-modified silica aerogels. J Mater Chem A, 2015, 3(5): 1935 -

下載:

下載: