Crack propagation and coalescence mechanism of double-hole cumulative blasting in coal seam

-

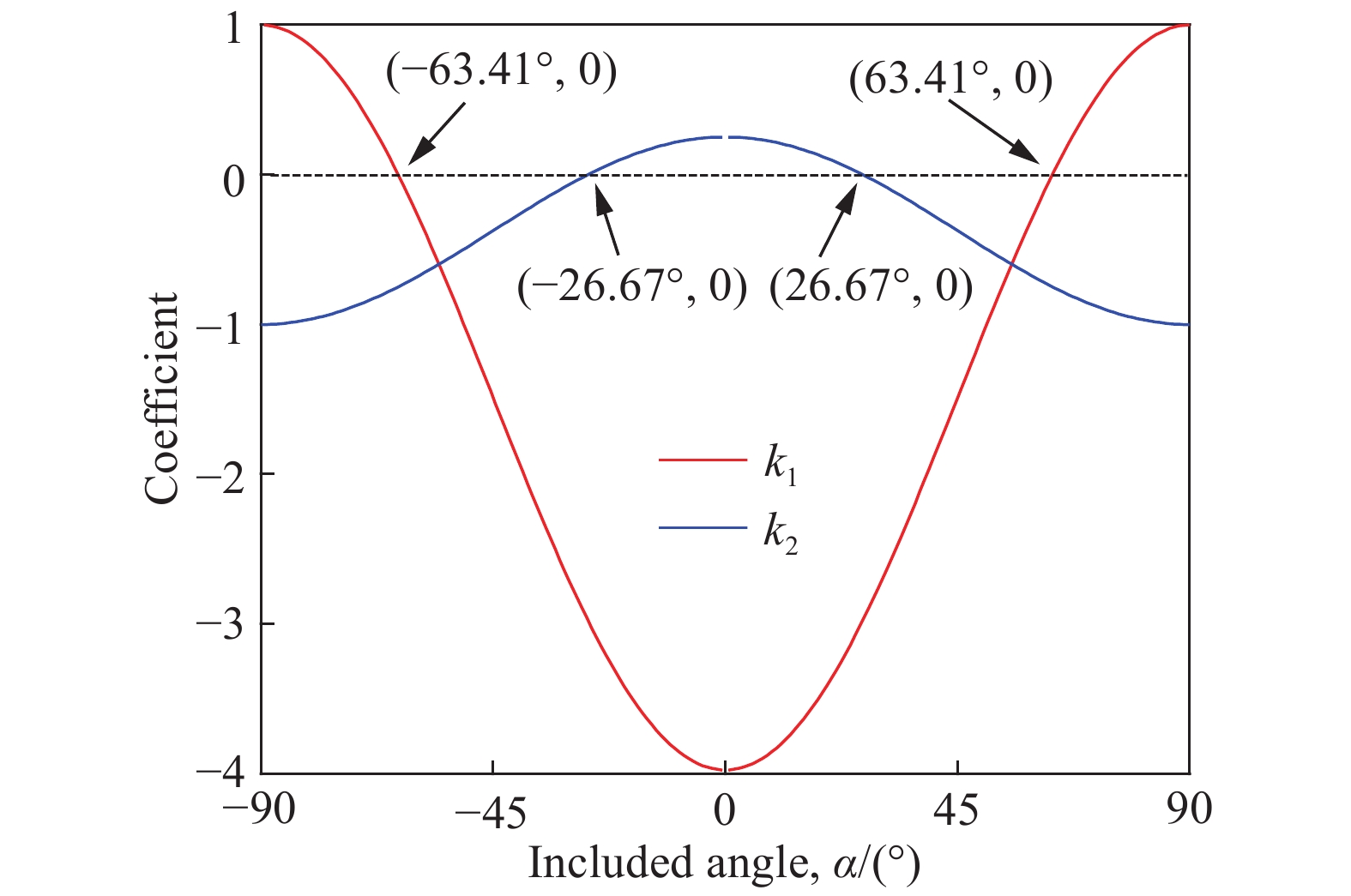

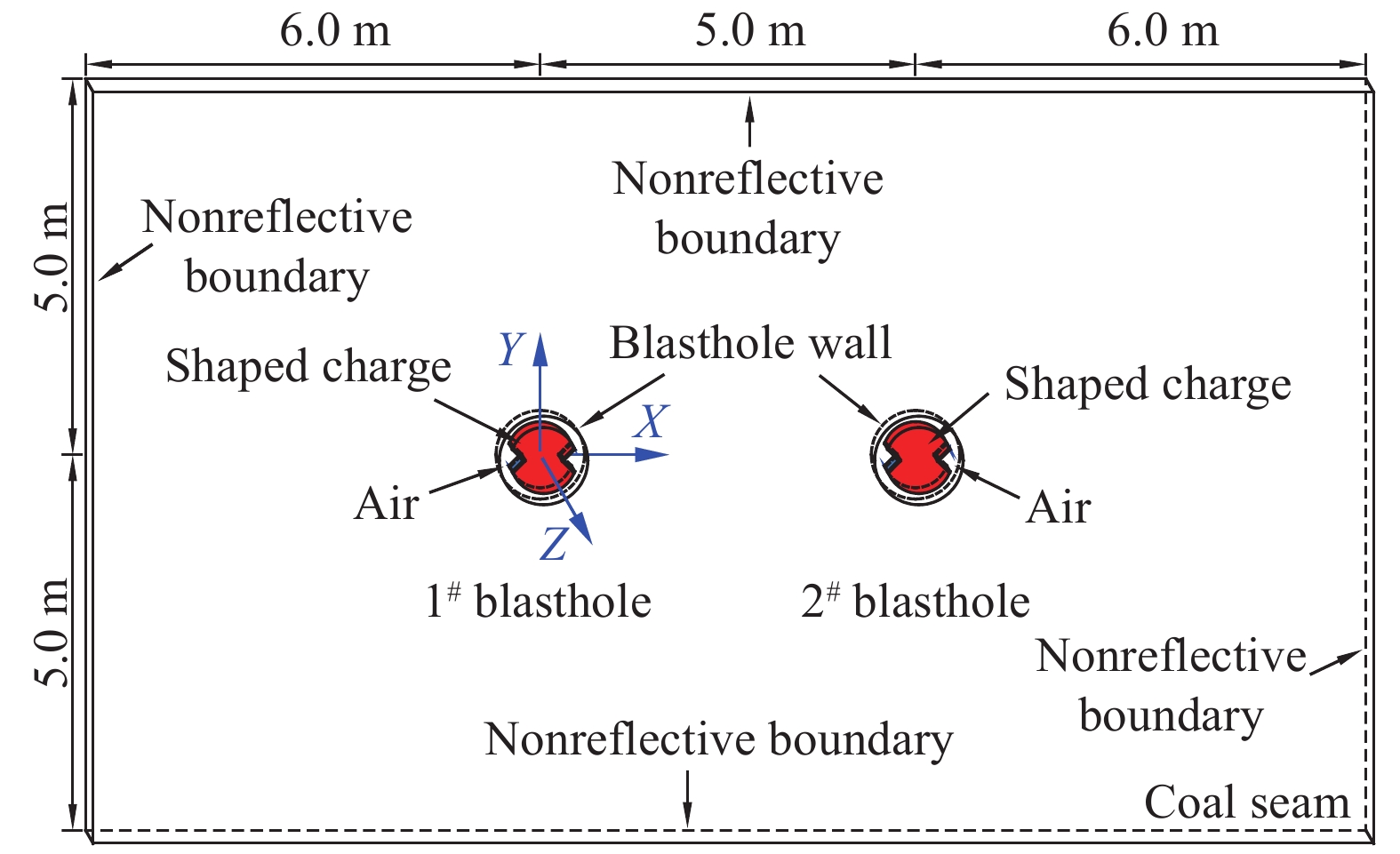

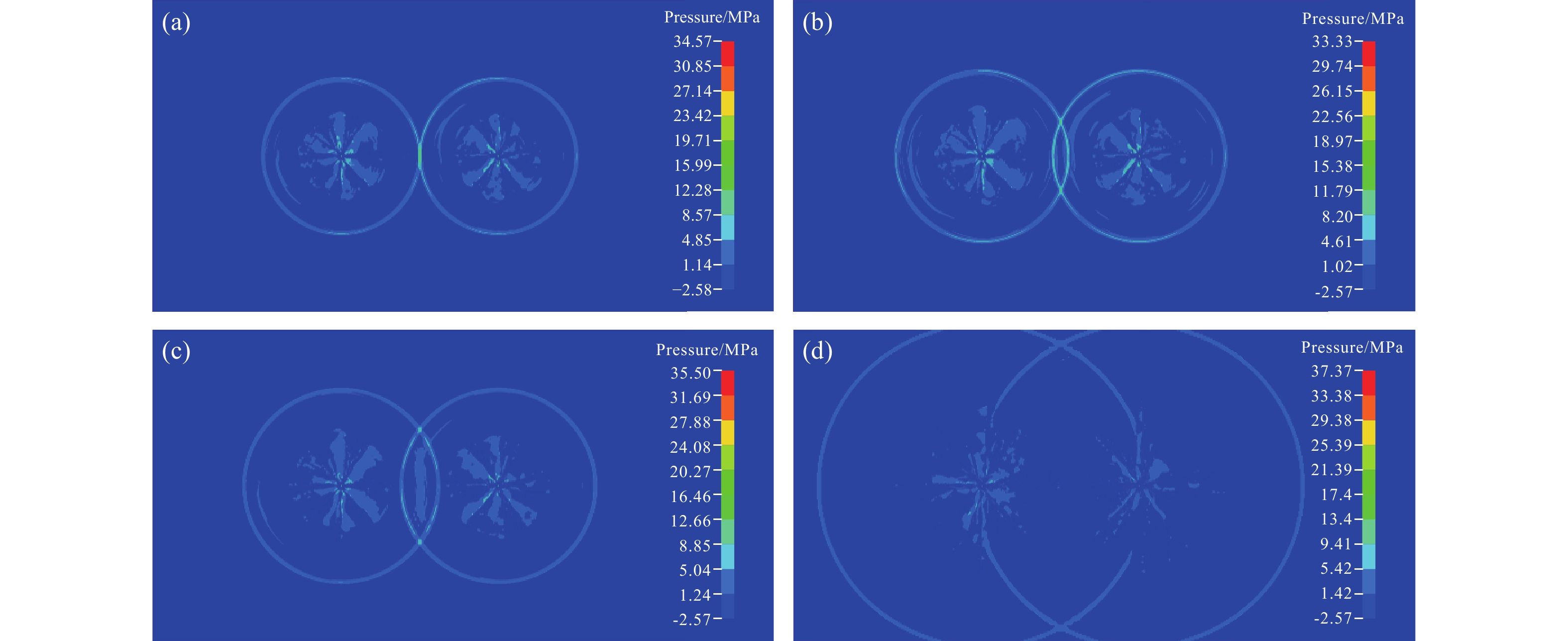

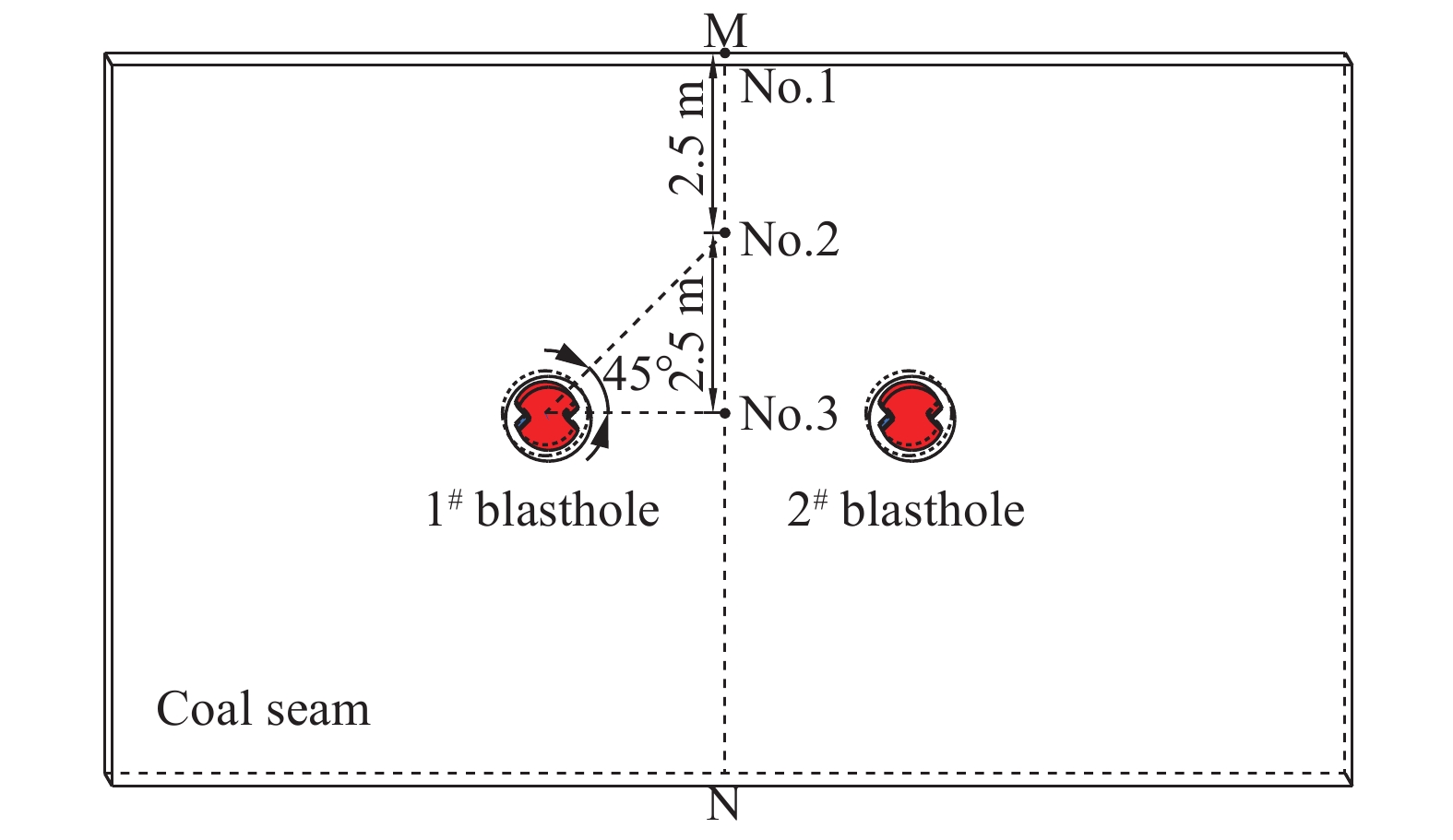

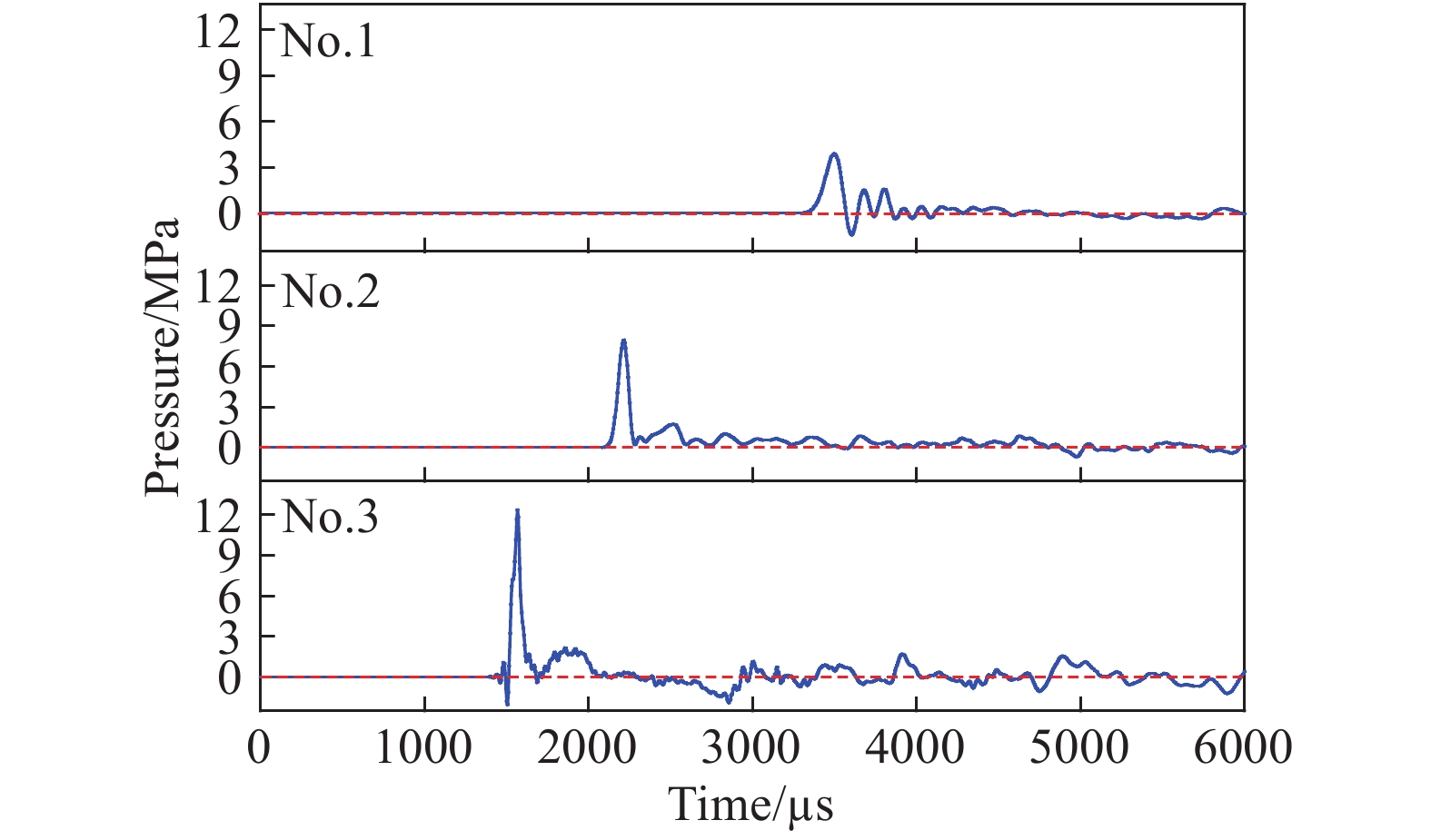

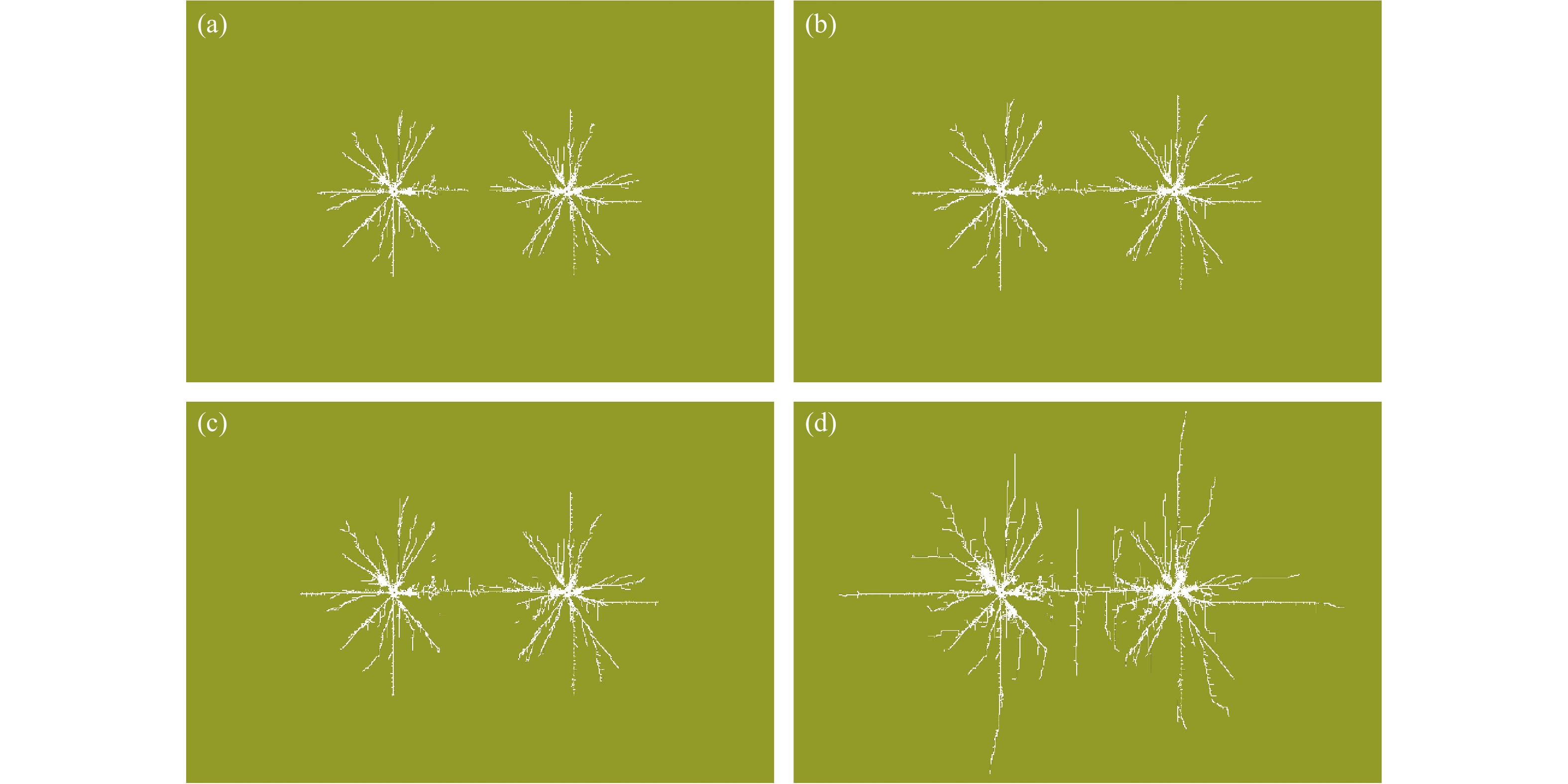

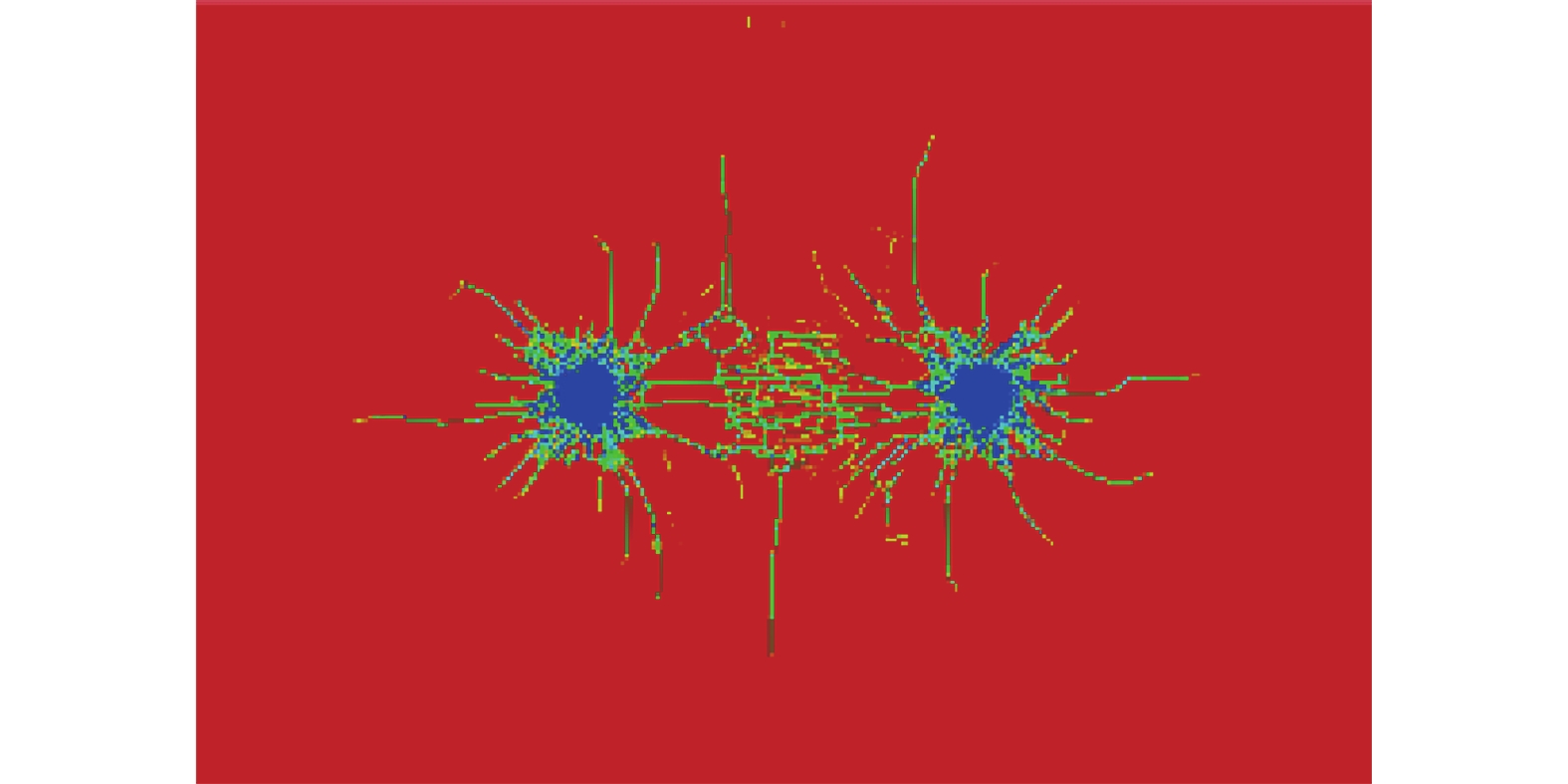

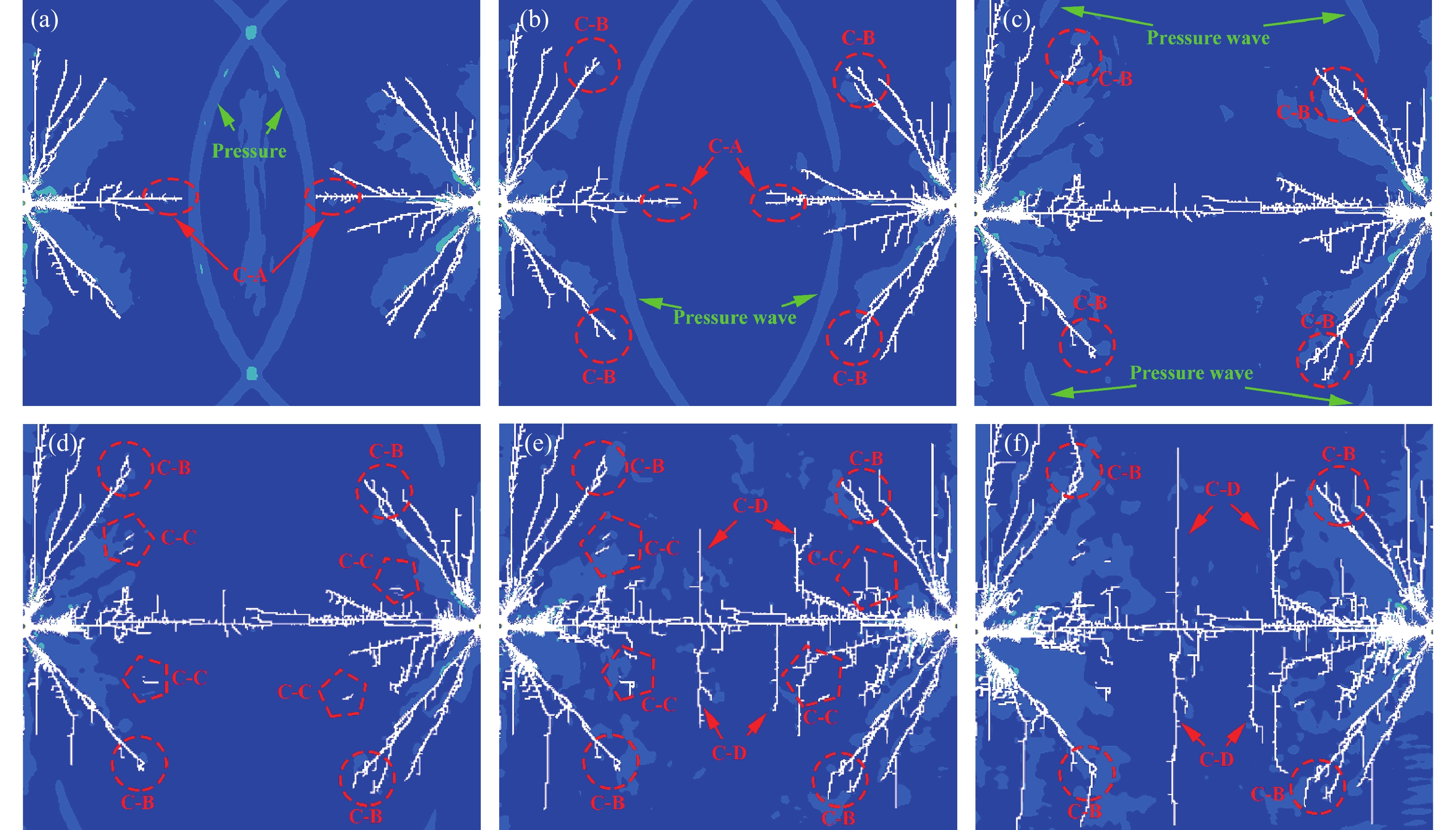

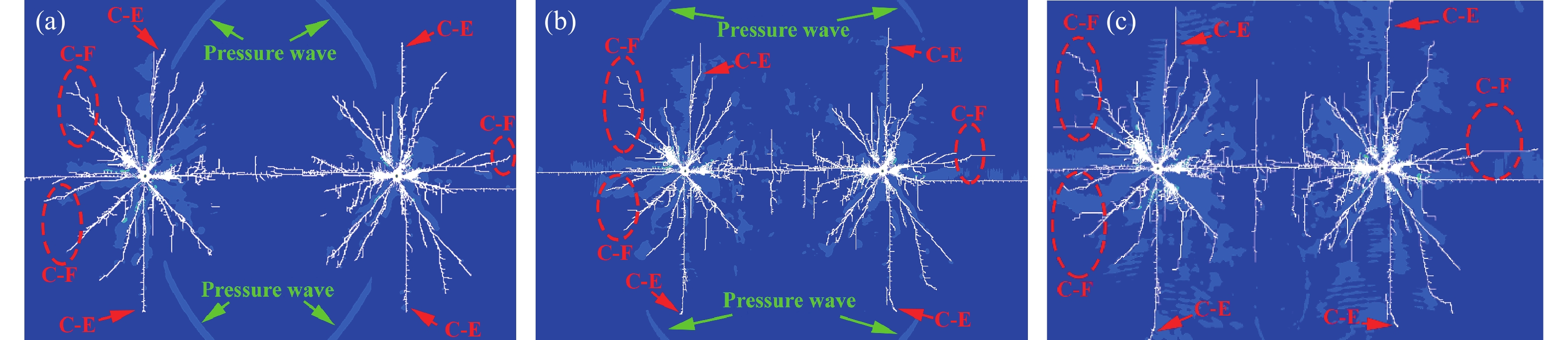

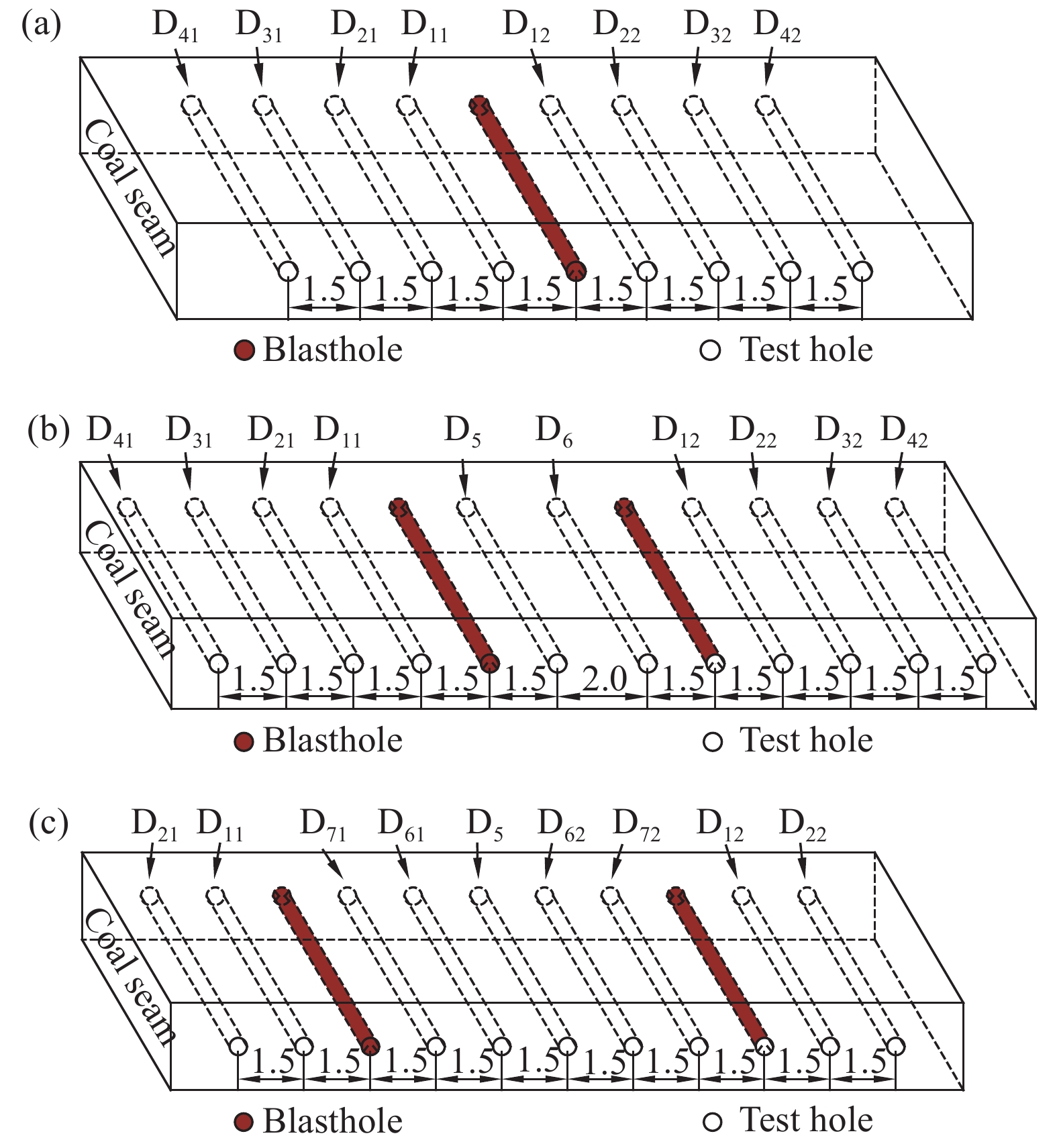

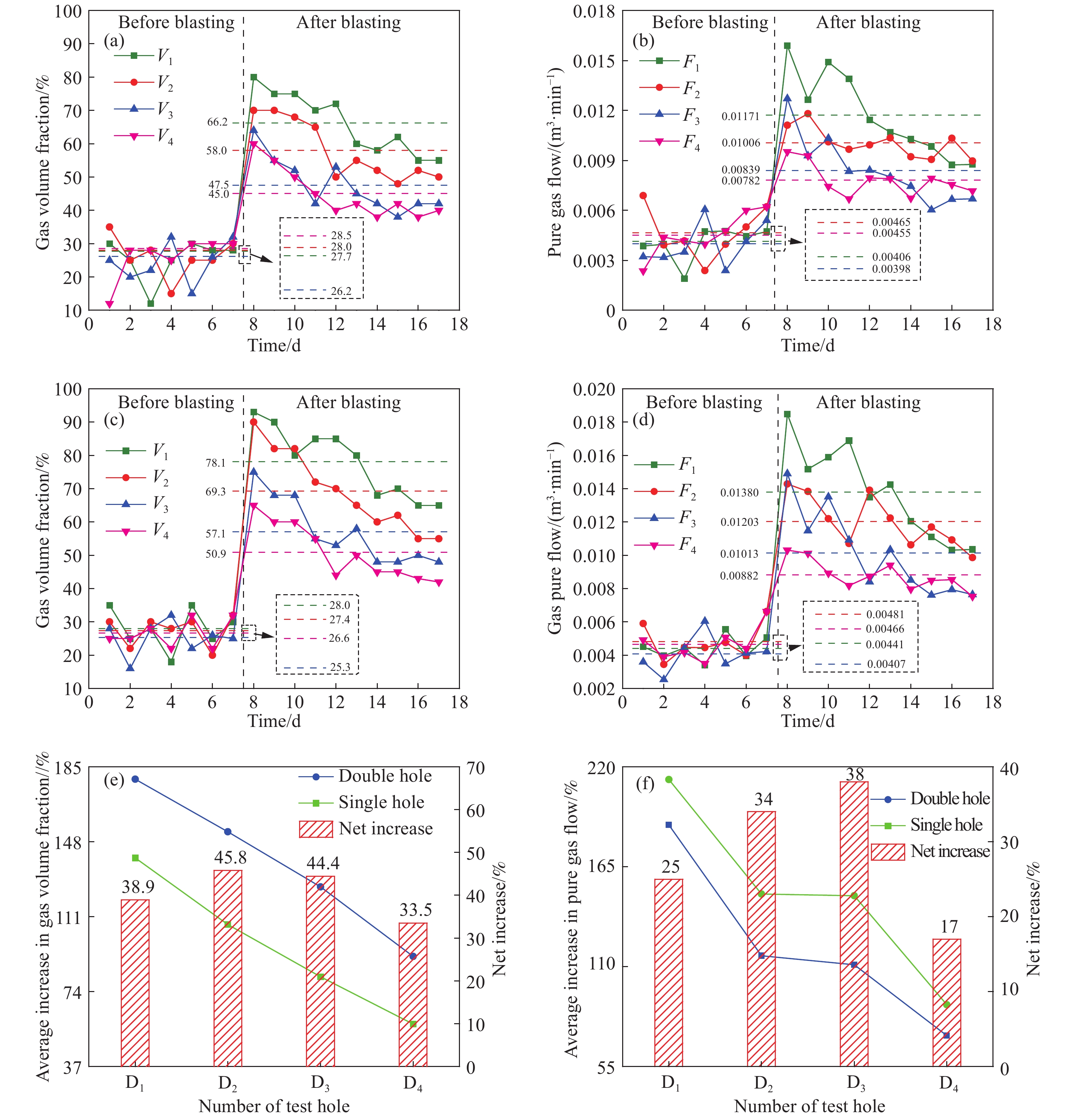

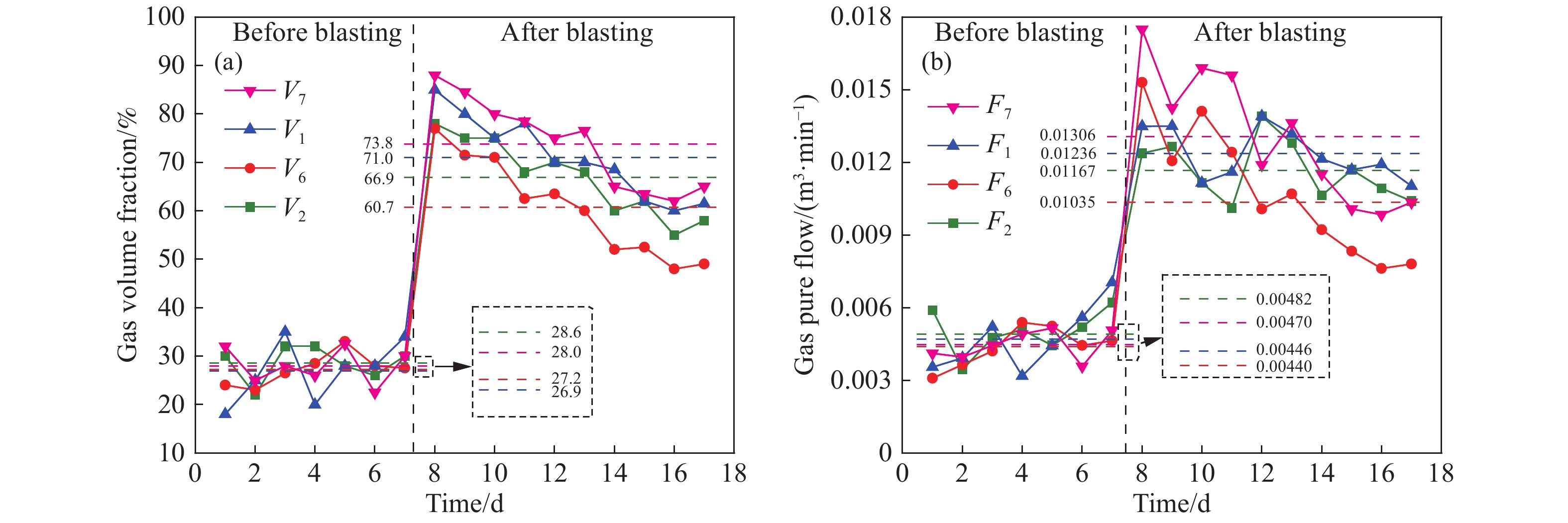

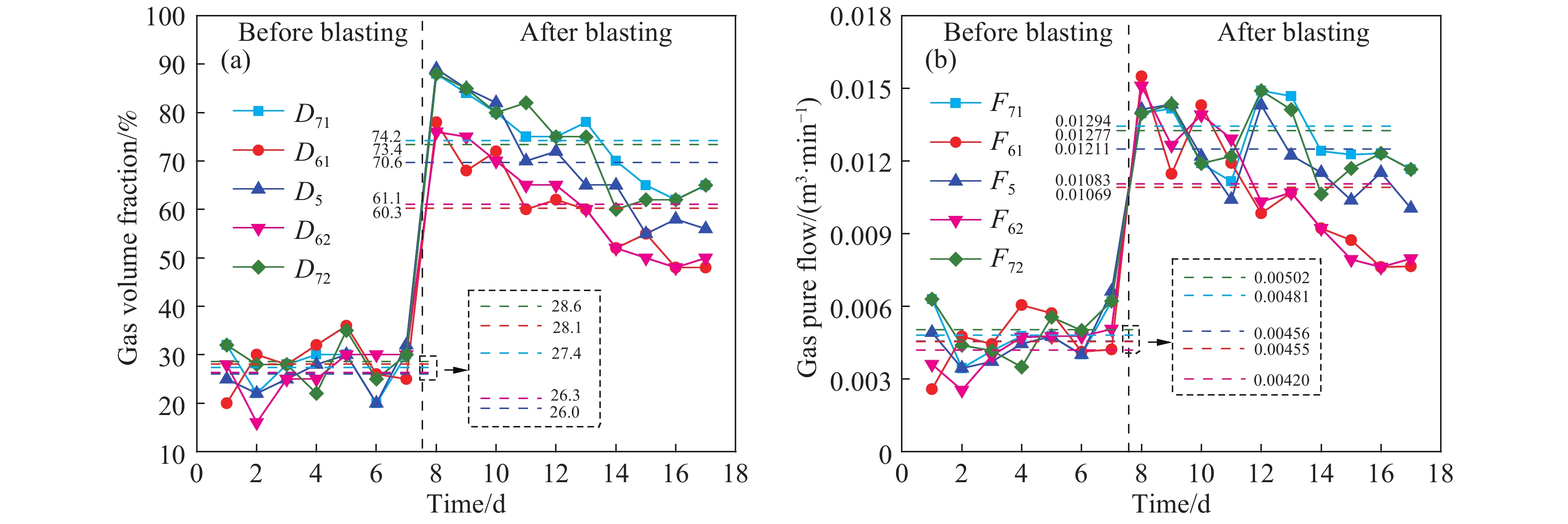

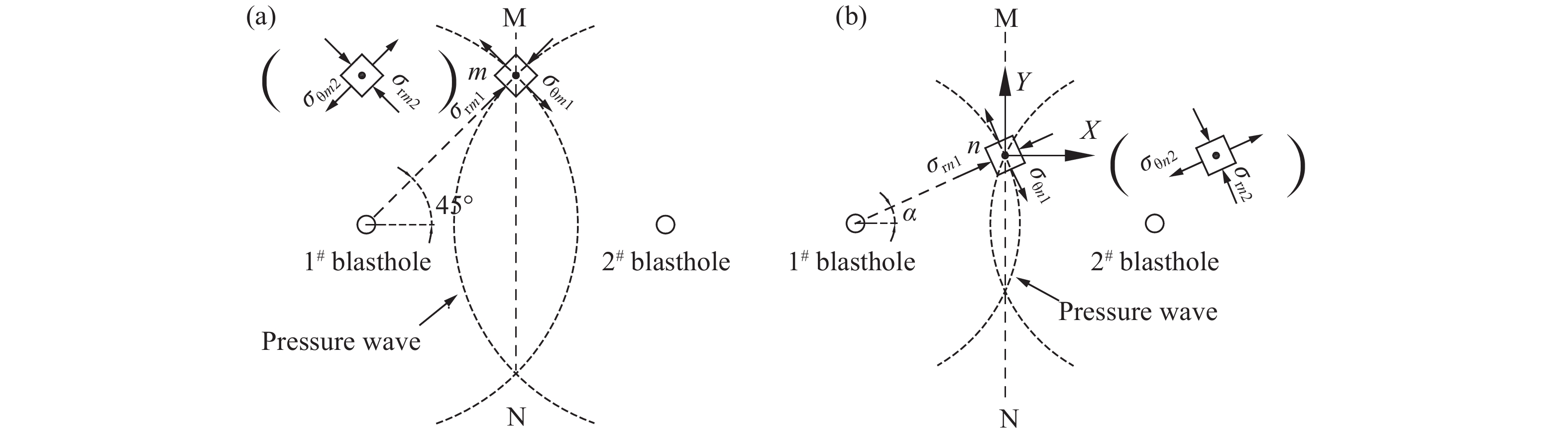

摘要: 針對雙孔聚能爆破孔間煤層裂隙擴展貫通問題,基于對雙孔爆破應力波疊加效應的分析,建立雙孔聚能爆破數值分析模型,研究雙孔同時起爆時應力波的傳播特征、煤體的應力狀態、煤體裂隙擴展貫通規律以及應力波疊加效應對裂隙擴展的影響。結果表明,應力波疊加效應致使兩爆破孔中間截面上部分區域及其鄰域內形成均壓區,迫使部分徑向裂隙轉向,主導爆生裂隙空白帶的形成;兩爆破孔間的定向裂隙相互貫通后,爆生氣體相互作用促進貫通區裂隙的擴展并貫穿空白帶。同時,結合煤層深孔聚能爆破現場試驗發現,在兩爆破孔外側,應力波疊加效應促進裂隙的擴展,該作用隨著遠離爆破孔呈先增加后減小之勢;在兩爆破孔之間,應力波疊加效應抑制部分區域裂隙的擴展,致使兩爆破孔之間不同位置處煤層增透效果有起伏變化。Abstract: This paper focuses on the radius of coal failure zones under cumulative blasting with shaped charge. Based on the analysis of the mutual superposition effect of the explosion stress waves during the simultaneous detonation of two blastholes, a numerical analysis model of the double-hole cumulative blasting with linear shaped charge was established. Additionally, the propagation characteristics of the stress wave during the simultaneous detonation of two blastholes, stress state of the coal body, mechanism of coal crack propagation and coalescence, and influence of the stress wave superposition effect on crack propagation were evaluated. Results show that the stress wave superposition effect induces the formation of a pressure equalization zone in the partial region of the middle section of the two blastholes and its adjacent regions. This occurrence forces the radial cracks of the two blastholes to turn, and they cannot connect with each other, leading to the formation of a gap blank zone between the two blastholes. After the directional cracks generated under cumulative blasting load coalesce, the collision of the explosive gases produced from the two blastholes further promotes the expansion of the cracks in the directional crack coalescence zone and eventually penetrates the gap blank zone. Field test results of deep-hole cumulative blasting in coal seams show that the explosion stress waves from the blastholes in the opposite side promotes the propagation of the blasting-induced crack on the left or right side of the two blastholes. This propagation first increases and then decreases as it moves away from the blasthole. Between the two blastholes, the stress wave superposition effect from the two blastholes inhibits the propagation of the cracks in some areas, resulting in a W-like fluctuation in the degree of improvement of the gas drainage effect at different positions in the area between the two blastholes.

-

圖 9 煤層深孔聚能爆破相鄰兩孔同時起爆過程中應力波對兩爆破孔之間裂隙擴展的影響。(a)t=1955 μs;(b)t=2320 μs;(c)t=2965 μs;(d)t=3085 μs;(e)t=4355 μs;(f)t=5630 μs

Figure 9. Effect of the stress wave on crack propagation between two blastholes during the simultaneous detonation of two blastholes: (a) t=1955 μs;(b) t=2320 μs;(c) t=2965 μs;(d) t=3085 μs;(e) t=4355 μs;(f) t=5630 μs

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Guo D Y, Zhao J C, Zhang C, et al. Mechanism of control hole on coal crack initiation and propagation under deep-hole cumulative blasting in coal seam. Chin J Rock Mech Eng, 2018, 37(4): 919郭德勇, 趙杰超, 張超, 等. 煤層深孔聚能爆破控制孔作用機制研究. 巖石力學與工程學報, 2018, 37(4):919 [2] Chu H B, Ye H Y, Yang X L, et al. Experiments on propagation of blasting vibration based on damage accumulation. J Vib Shock, 2016, 35(2): 173褚懷保, 葉紅宇, 楊小林, 等. 基于損傷累積的爆破振動傳播規律試驗研究. 振動與沖擊, 2016, 35(2):173 [3] Singh P K, Roy M P, Paswan R K. Controlled blasting for long term stability of pit-walls. Int J Rock Mech Min Sci, 2014, 70: 388 doi: 10.1016/j.ijrmms.2014.05.006 [4] Lu W B, Li H B, Chen M, et al. Safety criteria of blasting vibration in hydropower engineering and several key problems in their application. Chin J Rock Mech Eng, 2009, 28(8): 1513 doi: 10.3321/j.issn:1000-6915.2009.08.001盧文波, 李海波, 陳明, 等. 水電工程爆破振動安全判據及應用中的幾個關鍵問題. 巖石力學與工程學報, 2009, 28(8):1513 doi: 10.3321/j.issn:1000-6915.2009.08.001 [5] Li Q Y, Li X B, Fan Z P, et al. One time deep hole raise blasting technology and case study. Chin J Rock Mech Eng, 2013, 32(4): 664 doi: 10.3969/j.issn.1000-6915.2013.04.003李啟月, 李夕兵, 范作鵬, 等. 深孔爆破一次成井技術與應用實例分析. 巖石力學與工程學報, 2013, 32(4):664 doi: 10.3969/j.issn.1000-6915.2013.04.003 [6] Liang B, Ding X C, Sun W J, et al. Numerical simulation of increasing permeability by double hole presplitting blasting in low permeability coal seam. Blasting, 2014, 31(2): 84 doi: 10.3963/j.issn.1001-487X.2014.02.018梁冰, 丁學丞, 孫維吉, 等. 低透氣性煤層雙孔預裂爆破增透數值模擬. 爆破, 2014, 31(2):84 doi: 10.3963/j.issn.1001-487X.2014.02.018 [7] Miao Y S, Li X J, Yan H H, et al. Research and application of a symmetric bilinear initiation system in rock blasting. Int J Rock Mech Min Sci, 2018, 102: 52 doi: 10.1016/j.ijrmms.2018.01.017 [8] Zhao J J, Zhang Y, Ranjith P G. Numerical simulation of blasting-induced fracture expansion in coal masses. Int J Rock Mech Min Sci, 2017, 100: 28 doi: 10.1016/j.ijrmms.2017.10.015 [9] Hu S B, Wang E Y, Kong X G. Damage and deformation control equation for gas-bearing coal and its numerical calculation method. J Nat Gas Sci Eng, 2015, 25: 166 doi: 10.1016/j.jngse.2015.04.039 [10] Ataei M, Kamali M. Prediction of blast-induced vibration by adaptive neuro-fuzzy inference system in Karoun 3 power plant and dam. J Vib Control, 2013, 19(12): 1906 doi: 10.1177/1077546312444769 [11] Yue Z W, Yang L Y, Wang Y B. Experimental study of crack propagation in polymethyl methacrylate material with double holes under the directional controlled blasting. Fatigue Fract Eng Mater Struct, 2013, 36(8): 827 doi: 10.1111/ffe.12049 [12] Ramulu M, Chakraborty A K, Sitharam T G. Damage assessment of basaltic rock mass due to repeated blasting in a railway tunnelling project – A case study. Tunnell Undergr Space Technol, 2009, 24(2): 208 doi: 10.1016/j.tust.2008.08.002 [13] Yan C B. Analysis of cumulative damage effect of rock mass blasting based on acoustic frequency spectrum characters. Rock Soil Mech, 2017, 38(9): 2721閆長斌. 基于聲波頻譜特征的巖體爆破累積損傷效應分析. 巖土力學, 2017, 38(9):2721 [14] Fei H L, Yuan J H. Study of slope stability based on blasting cumulative damage. Chin J Rock Mech Eng, 2016, 35(Suppl 2): 3868費鴻祿, 苑俊華. 基于爆破累積損傷的邊坡穩定性變化研究. 巖石力學與工程學報, 2016, 35(增刊2): 3868 [15] Zhu Z H, Qu G J, Yang Y Q, et al. Dynamic photoelastic studies in the influence of delay ignition on the penetration of cracks between boreholes. Explos Shock Waves, 1991, 11(4): 346朱振海, 曲廣建, 楊永琦, 等. 起爆時差對孔間裂縫貫穿影響的動光彈研究. 爆炸與沖擊, 1991, 11(4):346 [16] Yang R S, Wang Y B, Yang L Y, et al. Dynamic caustic experimental in two borehole study of crack propagation cut blasting. J China Univ Min Technol, 2012, 41(6): 868楊仁樹, 王雁冰, 楊立云, 等. 雙孔切槽爆破裂紋擴展的動焦散實驗. 中國礦業大學學報, 2012, 41(6):868 [17] Li Q, Yu Q, Zhu G Y, et al. Experimental study of crack propagation under two-hole slotted cartridge blasting with different amounts of charge. Chin J Rock Mech Eng, 2017, 36(9): 2205李清, 于強, 朱各勇, 等. 不同藥量的切縫藥包雙孔爆破裂紋擴展規律試驗. 巖石力學與工程學報, 2017, 36(9):2205 [18] Wei C H, Zhu W C, Bai Y, et al. Numerical simulation on two-hole blasting of rock under different joint angles and in-situ stress conditions. Chin J Theor Appl Mech, 2016, 48(4): 926 doi: 10.6052/0459-1879-15-259魏晨慧, 朱萬成, 白羽, 等. 不同節理角度和地應力條件下巖石雙孔爆破的數值模擬. 力學學報, 2016, 48(4):926 doi: 10.6052/0459-1879-15-259 [19] Guo D Y, Zhao J C, Lü P F, et al. Effective fracture zone under deep-hole cumulative blasting in coal seam. Chin J Eng, 2019, 41(5): 582郭德勇, 趙杰超, 呂鵬飛, 等. 煤層深孔聚能爆破有效致裂范圍探討. 工程科學學報, 2019, 41(5):582 [20] Zhao Y S, Feng Z C, Wan Z J. Least energy priciple of dynamical failure of rock mass. Chin J Rock Mech Eng, 2003, 22(11): 1781 doi: 10.3321/j.issn:1000-6915.2003.11.005趙陽升, 馮增朝, 萬志軍. 巖體動力破壞的最小能量原理. 巖石力學與工程學報, 2003, 22(11):1781 doi: 10.3321/j.issn:1000-6915.2003.11.005 [21] Zhao Y S, Yang D, Hu Y Q, et al. Study on the effective technology way for mining methane in low permeability coal seam. J China Coal Soc, 2001, 26(5): 455 doi: 10.3321/j.issn:0253-9993.2001.05.002趙陽升, 楊棟, 胡耀青, 等. 低滲透煤儲層煤層氣開采有效技術途徑的研究. 煤炭學報, 2001, 26(5):455 doi: 10.3321/j.issn:0253-9993.2001.05.002 [22] Hallquist J O. LS-DYNA Keyword User’s Manual. California: Livermore Software Technology Corporation, 2007 [23] Guo D Y, Zhao J C, Lü P F, et al. Dynamic effects of deep-hole cumulative blasting in coal seam and its application. Chin J Eng, 2016, 38(12): 1681郭德勇, 趙杰超, 呂鵬飛, 等. 煤層深孔聚能爆破動力效應分析與應用. 工程科學學報, 2016, 38(12):1681 [24] Liu J, Liu Z G, Gao K, et al. Experimental study and application of directional focused energy blasting in deep boreholes. Chin J Rock Mech Eng, 2014, 33(12): 2490劉健, 劉澤功, 高魁, 等. 深孔定向聚能爆破增透機制模擬試驗研究及現場應用. 巖石力學與工程學報, 2014, 33(12):2490 [25] Mu C M, Wang H L, Huang W Y, et al. Increasing permeability mechanism using directional cumulative blasting in coal seams with high concentration of gas and low permeability. Rock Soil Mech, 2013, 34(9): 2496穆朝民, 王海露, 黃文堯, 等. 高瓦斯低透氣性煤體定向聚能爆破增透機制. 巖土力學, 2013, 34(9):2496 [26] Zhao J J. Failure Mechanism of Hard Thick Coal under Various Types of Disturbance at the Front of Mining Face[Dissertation]. Beijing: China University of Mining & Technology (Beijing), 2018趙健健. 堅硬厚煤層分區域擾動破壞機理及弱化方法[學位論文]. 北京: 中國礦業大學(北京), 2018 -

下載:

下載: