Research progress in encapsulation and application of shape-stabilized composite phase-change materials

-

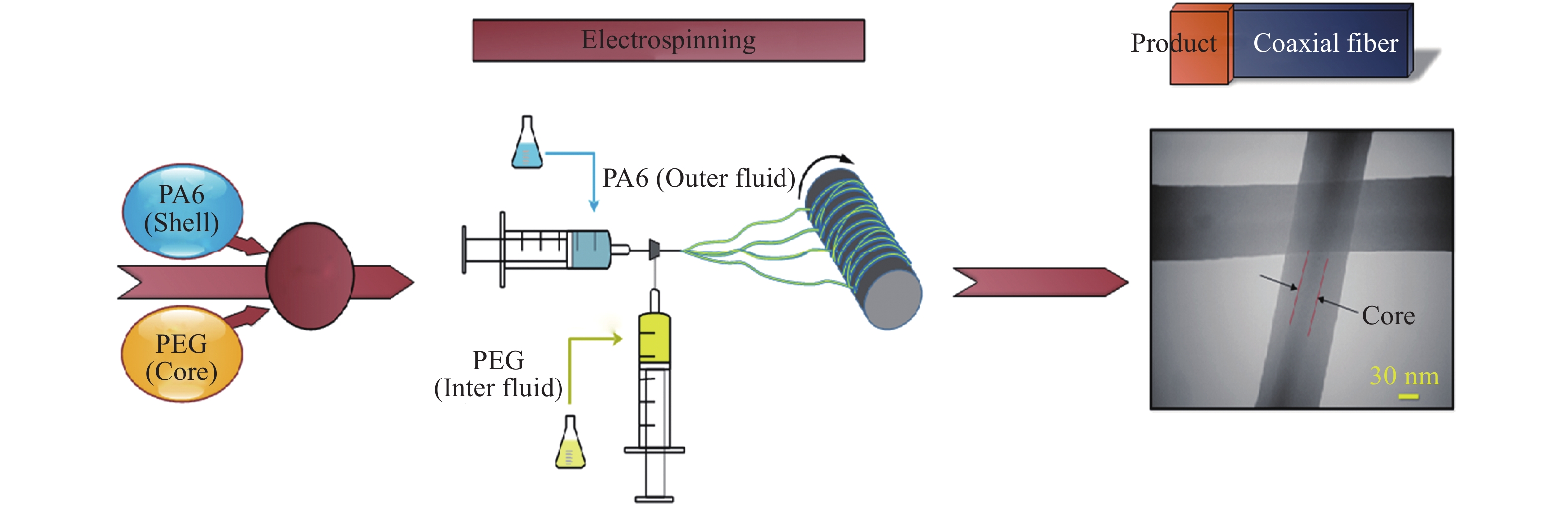

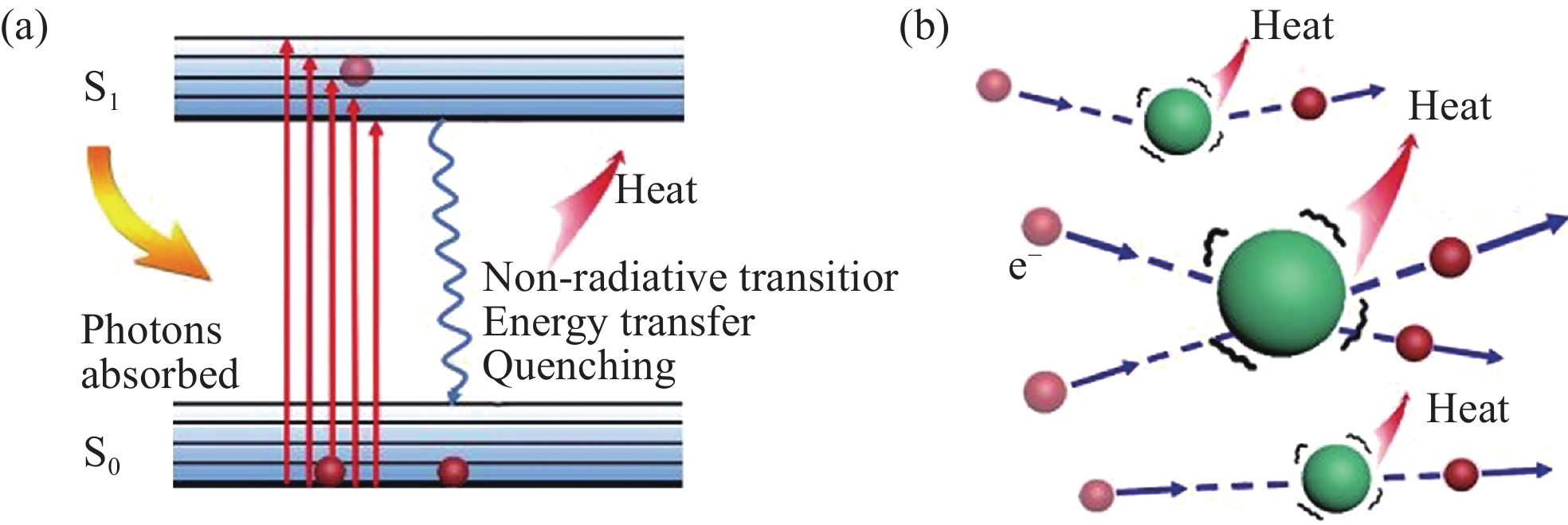

摘要: 有機相變材料具有熱存儲密度高、自身溫度和體積變化小、腐蝕性小和化學性質穩定等優點,能有效提升不可再生能源的利用率,是一種綠色節能環保材料,在新能源開發和熱能儲存領域起著至關重要的作用。然而,有機相變儲能材料普遍存在相變過程中熔融泄漏和熱導率低的問題,嚴重制約了相變材料的實際應用。因此,相變材料的封裝定形和導熱強化成為近年來的研究熱點。本文針對有機相變材料普遍存在的泄漏和熱導率低問題,綜述了有機相變材料的封裝技術和導熱強化技術的基本方法及最新研究成果,并總結了復合相變儲能材料的能量轉換機理,淺談了復合定形相變儲能材料在建筑節能、太陽能和電子設備等領域的應用情況。最后,對未來復合定形相變儲能材料發展的研究重點和方向進行了展望。Abstract: Currently, energy demand and consumption problems have become a focus issue due to rapid economic growth, environmental pollution, and energy shortages. Hence, new technologies must be explored and developed for the recovery of wasted energy or to harness solar energy. Thermal energy storage will not only improve energy utilization efficiency and store wasted heat; it will also ease the problem of energy supply and demand. Thermal energy storage is considered to be one of the most efficient approaches for the sustainable control and utilization of energy. Organic phase-change energy storage as a strategy for thermal energy storage has attracted widespread attention in recent years by virtues of its high latent storage capacity, suitable phase-change temperature, chemical and thermal stability, non-toxicity, and nearly absent supercooling properties. However, the leakage problem and low conductivity of organic phase-change materials during the phase-change process hinder their practical application. Leakage can cause serious environmental damage and reduce thermal energy storage. Low thermal conductivity can result in a large temperature gradient and insensitivity to temperature changes, thereby reducing the heat transfer efficiency of phase-change materials. To solve the above issues, various encapsulation techniques have been developed and substances with high thermal conductivity have become a research hotspot. In this work, we summarized three main approaches—porous absorption, microencapsulation, and electrospinning—to prepare shape-stabilized phase-change materials. For porous absorption, we identified some widely available, low-cost renewable materials that can be used as support material for fabricating composite phase-change materials, such as biomass-derived wood, winter melon, potatoes, and cotton. In addition, the energy conversion mechanism of composite phase-change materials was discussed. The applications of phase-change materials in solar absorption refrigeration systems, solar energy systems, energy storage systems for buildings, passive thermal management of batteries, cold storage, and photovoltaic electricity generation were summarized. Lastly, future research directions on composite phase-change energy storage materials were also proposed.

-

Key words:

- thermal energy storage /

- phase-change materials /

- encapsulation /

- thermal conductivity /

- applications

-

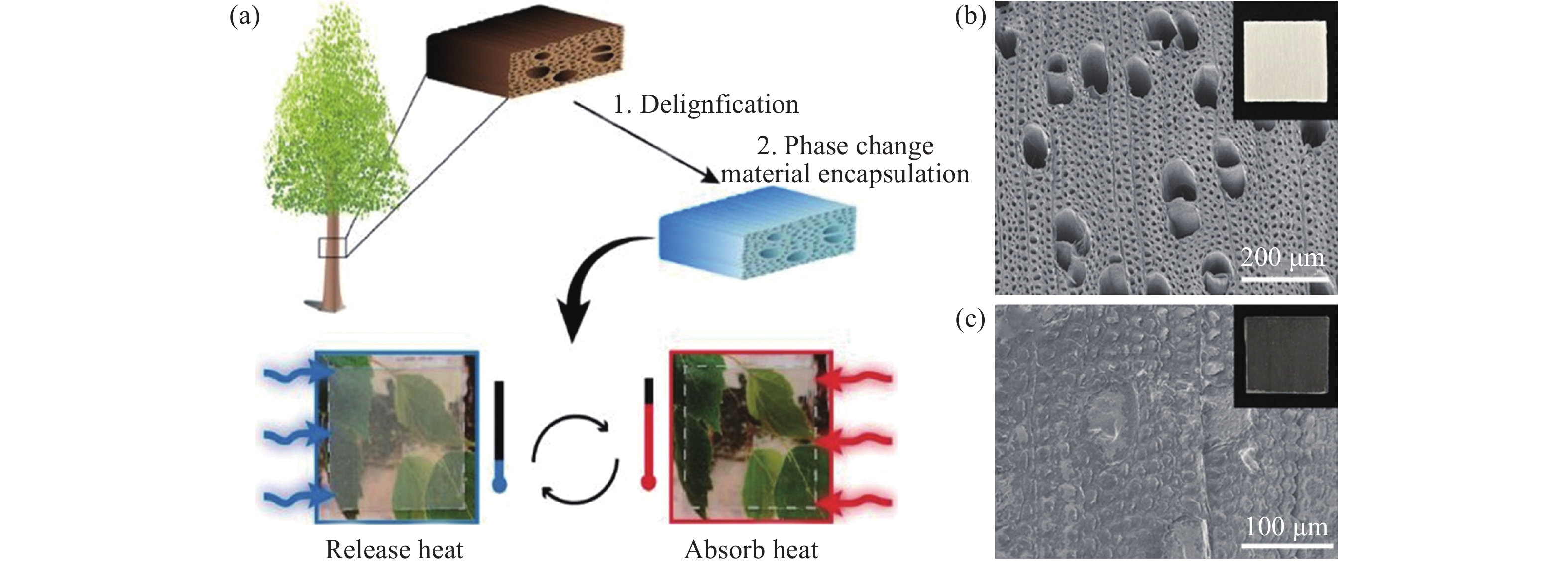

圖 1 木基復合相變材料的制備及性能表征[14]。(a)木基復合相變材料的制備熱儲存示意圖;(b)相變材料浸漬前木材的微觀結構;(c)相變材料浸漬后木材的微觀結構

Figure 1. Preparation and performance of wood-based composite phase-change materials[14]: (a) schematic representation of the preparation of transparent wood for thermal energy storage; (b) SEM images of microstructure of wood before impregnation with phase-change material; (c) SEM images of microstructure of wood after impregnation with phase-change material

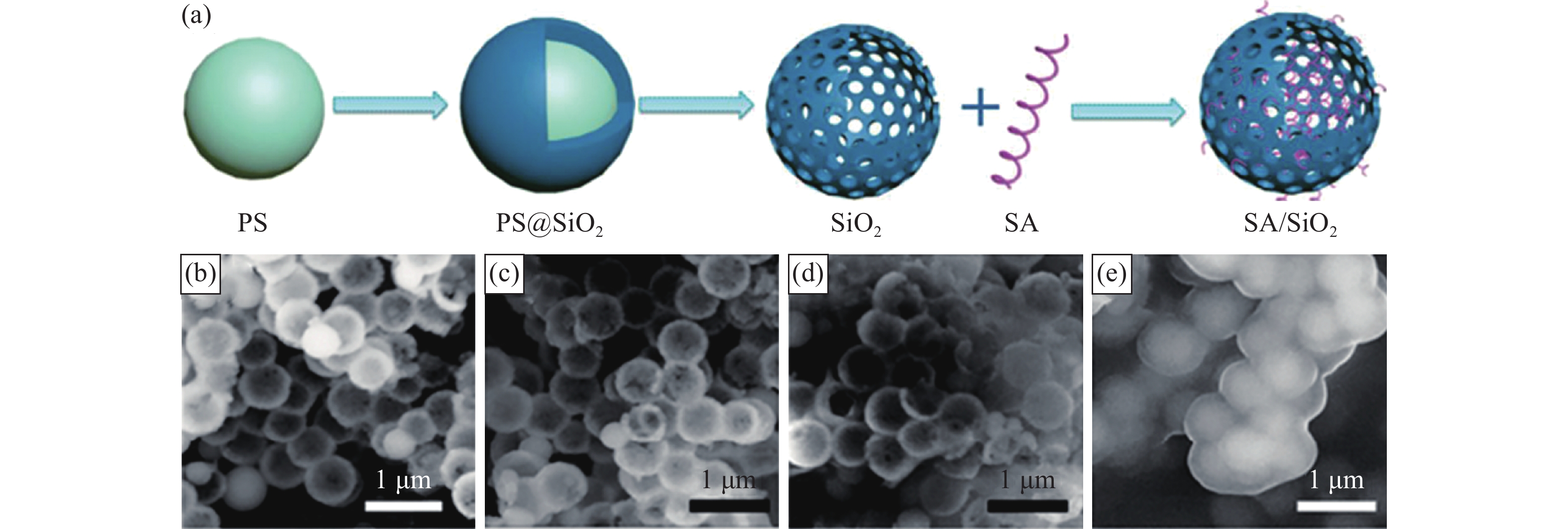

圖 2 二氧化硅微膠囊的制備及微觀形貌[27]。(a)二氧化硅微膠囊的制備流程示意圖;(b) 50%質量分數SA的微膠囊形貌;(c) 60%質量分數SA的微膠囊形貌;(d) 70%質量分數SA的微膠囊形貌;(e) 80%質量分數SA的微膠囊形貌

Figure 2. Preparation process and micromorphology of silica microcapsule[27]: (a) schematic of the synthesis of shape stabilized phase change materials based on stearic acid and mesoporous hollow SiO2 microspheres; (b) SEM images of SA/SiO2 with 50% mass fractions of SA; (c) SEM images of SA/SiO2 with 60% mass fractions of SA; (d) SEM images of SA/SiO2 with 70% mass fractions of SA; (e) SEM images of SA/SiO2 with 80% mass fractions of SA

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Ma L M, Shi D, Pei Q B. Low-carbon transformation of China’s energy in 2015—2050: renewable energy development and feasible path. China Popul Resour Environ, 2018, 28(2): 8馬麗梅, 史丹, 裴慶冰. 中國能源低碳轉型(2015—2050): 可再生能源發展與可行路徑. 中國人口·資源與環境, 2018, 28(2):8 [2] Kasaeian A, Bahrami L, Pourfayaz F, et al. Experimental studies on the applications of PCMs and nano-PCMs in buildings: a critical review. Energy Build, 2017, 154: 96 doi: 10.1016/j.enbuild.2017.08.037 [3] Wang X, Fang J H, Wu J, et al. Development of packaging technology for phase change material. New Chem Mater, 2019, 47(9): 58王鑫, 方建華, 吳江, 等. 相變材料的封裝定型技術研究進展. 化工新型材料, 2019, 47(9):58 [4] Liu H, Wang X D, Wu D Z, et al. Morphology-controlled synthesis of microencapsulated phase change materials with TiO2 shell for thermal energy harvesting and temperature regulation. Energy, 2019, 172: 599 doi: 10.1016/j.energy.2019.01.151 [5] Li C E, Yu H, Song Y, et al. Novel hybrid microencapsulated phase change materials incorporated wallboard for year-long year energy storage in buildings. Energy Convers Manage, 2019, 183: 791 doi: 10.1016/j.enconman.2019.01.036 [6] Zhang T C, Yu H Y, Mao A Q, et al. Research advances in organic phase change materials for technology of thermal enhancement. Chin J Process Eng, 2017, 17(1): 201 doi: 10.12034/j.issn.1009-606X.216225張天馳, 俞海云, 冒愛琴, 等. 有機相變儲能材料導熱增強方法研究進展. 過程工程學報, 2017, 17(1):201 doi: 10.12034/j.issn.1009-606X.216225 [7] Wei Y H. Study on the Structure and Properties of Multi-functional Carbon Aerogels[Dissertation]. Chengdu: Sichuan Normal University, 2018魏燕紅. 多功能碳氣凝膠的結構與性能研究[學位論文]. 成都: 四川師范大學, 2018 [8] Yang H Y, Wang Y Z, Yu Q Q, et al. Composite phase change materials with good reversible thermochromic ability in delignified wood substrate for thermal energy storage. Appl Energy, 2018, 212: 455 doi: 10.1016/j.apenergy.2017.12.006 [9] Yang H Y, Chao W X, Di X, et al. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage. Energy Convers Manage, 2019, 200: 112029 doi: 10.1016/j.enconman.2019.112029 [10] Yang H Y, Wang S Y, Wang X, et al. Wood-based composite phase change materials with self-cleaning superhydrophobic surface for thermal energy storage. Appl Energy, 2020, 261: 114481 doi: 10.1016/j.apenergy.2019.114481 [11] Yang H Y, Wang Y Z, Yu Q Q, et al. Low-cost, three-dimension, high thermal conductivity, carbonized wood-based composite phase change materials for thermal energy storage. Energy, 2018, 159: 929 doi: 10.1016/j.energy.2018.06.207 [12] Ma L Y, Wang Q W, Li L P. Delignified wood/capric acid-palmitic acid mixture stable-form phase change material for thermal storage. Sol Energy Mater Sol Cells, 2019, 194: 215 doi: 10.1016/j.solmat.2019.02.026 [13] Yang Z W, Deng Y, Li J H. Preparation of porous carbonized woods impregnated with lauric acid as shape-stable composite phase change materials. Appl Therm Eng, 2019, 150: 967 doi: 10.1016/j.applthermaleng.2019.01.063 [14] Montanari C, Li Y Y, Chen H, et al. Transparent wood for thermal energy storage and reversible optical transmittance. ACS Appl Mater Interfaces, 2019, 11(22): 20465 doi: 10.1021/acsami.9b05525 [15] Li Y Q, Samad Y A, Polychronopoulou K, et al. From biomass to high performance solar-thermal and electric-thermal energy conversion and storage materials. J Mater Chem A, 2014, 2(21): 7759 doi: 10.1039/C4TA00839A [16] Wei Y H, Li J J, Sun F R, et al. Leakage-proof phase change composites supported by biomass carbon aerogels from succulents. Green Chem, 2018, 20(8): 1858 doi: 10.1039/C7GC03595K [17] Yang J, Zhang E W, Li X F, et al. Cellulose/graphene aerogel supported phase change composites with high thermal conductivity and good shape stability for thermal energy storage. Carbon, 2016, 98: 50 doi: 10.1016/j.carbon.2015.10.082 [18] Shen T W, Lu S F, Xin C, et al. Progress in the research of microcapsule phase-change materials. China Textile Leader, 2017(1): 69申天偉, 陸少鋒, 辛成, 等. 微膠囊相變材料的研究進展. 紡織導報, 2017(1):69 [19] Aftab W, Huang X Y, Wu W H, et al. Nanoconfined phase change materials for thermal energy applications. Energy Environ Sci, 2018, 11(6): 1392 doi: 10.1039/C7EE03587J [20] Wang J X, Wang J, Huang C X, et al. Preparation and characterization of MWCNTs/stearic acid-octadecyl alcohol@urea formaldehyde resin phase change microencasules. Acta Mater Compos Sin, 2019, 36(3): 730王俊霞, 王軍, 黃崇杏, 等. 多壁碳納米管/硬脂酸?十八醇@脲醛樹脂微膠囊的制備及表征. 復合材料學報, 2019, 36(3):730 [21] Lian Q S, Li K, Sayyed A A S, et al. Study on a reliable epoxy-based phase change material: facile preparation, tunable properties, and phase/microphase separation behavior. J Mater Chem A, 2017, 5(28): 14562 doi: 10.1039/C7TA02816D [22] Lian Q S, Li Y, Sayyed A A S, et al. Facile strategy in designing epoxy/paraffin multiple phase change materials for thermal energy storage applications. ACS Sustainable Chem Eng, 2018, 6(3): 3375 doi: 10.1021/acssuschemeng.7b03558 [23] Zhang G H, Bon S A F, Zhao C Y. Synthesis, characterization and thermal properties of novel nanoencapsulated phase change materials for thermal energy storage. Sol Energy, 2012, 86(5): 1149 doi: 10.1016/j.solener.2012.01.003 [24] Wang Y, Wang J P, Nan G H, et al. A novel method for the preparation of narrow-disperse nanoencapsulated phase change materials by phase inversion emulsification and suspension polymerization. Ind Eng Chem Res, 2015, 54(38): 9307 doi: 10.1021/acs.iecr.5b01026 [25] Wang H, Luo J, Yang Y Y, et al. Fabrication and characterization of microcapsulated phase change materials with an additional function of thermochromic performance. Sol Energy, 2016, 139: 591 doi: 10.1016/j.solener.2016.10.011 [26] Zhu Y L, Liang S E, Wang H, et al. Morphological control and thermal properties of nanoencapsulated n-octadecane phase change material with organosilica shell materials. Energy Convers Manage, 2016, 119: 151 doi: 10.1016/j.enconman.2016.04.049 [27] Fan S, Gao H Y, Dong W J, et al. Shape-stabilized phase change materials based on stearic acid and mesoporous hollow SiO2 microspheres (SA/SiO2) for thermal energy storage. Eur J Inorg Chem, 2017, 2017(14): 2138 doi: 10.1002/ejic.201601380 [28] Yin D Z, Liu H, Ma L, et al. Fabrication and performance of microencapsulated phase change materials with hybrid shell by in situ polymerization in pickering emulsion. Polym Adv Technol, 2015, 26(6): 613 doi: 10.1002/pat.3495 [29] Chen C Z, Zhao Y Y, Liu W M. Electrospun polyethylene glycol/cellulose acetate phase change fibers with core-sheath structure for thermal energy storage. Renewable Energy, 2013, 60: 222 doi: 10.1016/j.renene.2013.05.020 [30] Babapoor A, Karimi G, Golestaneh S I, et al. Coaxial electro-spun PEG/PA6 composite fibers: fabrication and characterization. Appl Therm Eng, 2017, 118: 398 doi: 10.1016/j.applthermaleng.2017.02.119 [31] Xi P, Zhao T X, Xia L, et al. Fabrication and characterization of dual-functional ultrafine composite fibers with phase-change energy storage and luminescence properties. Sci Rep, 2017, 7: 40390 doi: 10.1038/srep40390 [32] Chen Y, Ding H, Gao J K, et al. A novel strategy for enhancing the thermal conductivity of shape-stable phase change materials via carbon-based in situ reduction of metal ions. J Clean Prod, 2020, 243: 118627 doi: 10.1016/j.jclepro.2019.118627 [33] Xiao X, Zhang P, Li M. Preparation and thermal characterization of paraffin/metal foam composite phase change material. Appl Energy, 2013, 112: 1357 doi: 10.1016/j.apenergy.2013.04.050 [34] Qian T T, Zhu S K, Wang H L, et al. Comparative study of single-walled carbon nanotubes and graphene nanoplatelets for improving the thermal conductivity and solar-to-light conversion of PEG-infiltrated phase-change material composites. ACS Sustainable Chem Eng, 2019, 7(2): 2446 doi: 10.1021/acssuschemeng.8b05335 [35] Ling Z Y, Chen J J, Xu T, et al. Thermal conductivity of an organic phase change material/expanded graphite composite across the phase change temperature range and a novel thermal conductivity model. Energy Convers Manage, 2015, 102: 202 doi: 10.1016/j.enconman.2014.11.040 [36] Yu S Y, Wang X D, Wu D Z. Microencapsulation of n-octadecane phase change material with calcium carbonate shell for enhancement of thermal conductivity and serving durability: Synthesis, microstructure, and performance evaluation. Appl Energy, 2014, 114: 632 doi: 10.1016/j.apenergy.2013.10.029 [37] Jiang X, Luo R L, Peng F F, et al. Synthesis, characterization and thermal properties of paraffin microcapsules modified with nano-Al2O3. Appl Energy, 2015, 137: 731 doi: 10.1016/j.apenergy.2014.09.028 [38] Zhou Y, Liu X D, Sheng D K, et al. Polyurethane-based solid-solid phase change materials with in situ reduced graphene oxide for light-thermal energy conversion and storage. Chem Eng J, 2018, 338: 117 doi: 10.1016/j.cej.2018.01.021 [39] Li G Y, Zhang X T, Wang J, et al. From anisotropic graphene aerogels to electron-and photo-driven phase change composites. J Mater Chem A, 2016, 4(43): 17042 doi: 10.1039/C6TA07587H [40] Zhang Y A, Wang J S, Qiu J J, et al. Ag-graphene/PEG composite phase change materials for enhancing solar-thermal energy conversion and storage capacity. Appl Energy, 2019, 237: 83 doi: 10.1016/j.apenergy.2018.12.075 [41] Aftab W, Mahmood A, Guo W H, et al. Polyurethane-based flexible and conductive phase change composites for energy conversion and storage. Energy Storage Mater, 2019, 20: 401 doi: 10.1016/j.ensm.2018.10.014 [42] Guo X F, Liu C, Li N, et al. Electrothermal conversion phase change composites: the case of polyethylene glycol infiltrated graphene oxide/carbon nanotube networks. Ind Eng Chem Res, 2018, 57(46): 15697 doi: 10.1021/acs.iecr.8b03093 [43] Tian G H. Study on Heat Transfer Characteristics and Energy Consumption Influence of Phase Change Energy Storage Building Walls[Dissertation]. Xuzhou: China University of Mining and Technology, 2018田國華. 相變儲能建筑墻體傳熱特性及能耗影響研究[學位論文]. 徐州: 中國礦業大學, 2018 [44] Wang S M, Matia?ovsky P, Mihálka P, et al. Experimental investigation of the daily thermal performance of a mPCM honeycomb wallboard. Energy Build, 2018, 159: 419 doi: 10.1016/j.enbuild.2017.10.080 [45] Barzin R, Chen J J J, Young B R, et al. Application of PCM underfloor heating in combination with PCM wallboards for space heating using price based control system. Appl Energy, 2015, 148: 39 doi: 10.1016/j.apenergy.2015.03.027 [46] Silva T, Vicente R, Amaral C, et al. Thermal performance of a window shutter containing PCM: numerical validation and experimental analysis. Appl Energy, 2016, 179: 64 doi: 10.1016/j.apenergy.2016.06.126 [47] Xie J C, Wang W, Liu J P, et al. Experiment and numerical simulation of the thermal performance of phase change wood-plastic envelopes. J Beijing Univ Technol, 2014, 40(8): 1174謝靜超, 王未, 劉加平, 等. 相變木塑圍護結構熱工性能實驗與數值模擬. 北京工業大學學報, 2014, 40(8):1174 [48] Papadimitratos A, Sobhansarbandi S, Pozdin V, et al. Evacuated tube solar collectors integrated with phase change materials. Sol Energy, 2016, 129: 10 doi: 10.1016/j.solener.2015.12.040 [49] Kabeel A E, Khalil A, Shalaby S M, et al. Experimental investigation of thermal performance of flat and v-corrugated plate solar air heaters with and without PCM as thermal energy storage. Energy Convers Manage, 2016, 113: 264 doi: 10.1016/j.enconman.2016.01.068 [50] Diao Y H, Wang S, Zhao Y H, et al. Charging/discharging performance of flat micro-heat pipe array thermal storage device. J Beijing Univ Technol, 2016, 42(10): 1552刁彥華, 汪順, 趙耀華, 等. 平板微熱管陣列相變蓄熱裝置蓄/放熱性能. 北京工業大學學報, 2016, 42(10):1552 [51] Lopez J M, Caceres G, Barrio E P D, et al. Confined melting in deformable porous media: a first attempt to explain the graphite/salt composites behaviour. Int J Heat Mass Transfer, 2010, 53(5-6): 1195 doi: 10.1016/j.ijheatmasstransfer.2009.10.025 [52] Muratore C, Aouadi S M, Voevodin A A. Embedded phase change material microinclusions for thermal control of surfaces. Surf Coat Technol, 2012, 206(23): 4828 doi: 10.1016/j.surfcoat.2012.05.030 [53] Tomizawa Y, Sasaki K, Kuroda A, et al. Experimental and numerical study on phase change material (PCM) for thermal management of mobile devices. Appl Therm Eng, 2016, 98: 320 doi: 10.1016/j.applthermaleng.2015.12.056 [54] Wu W H, Huang X Y, Li K, et al. A functional form-stable phase change composite with high efficiency electro-to-thermal energy conversion. Appl Energy, 2017, 190: 474 doi: 10.1016/j.apenergy.2016.12.159 [55] Shen C F, Li X, Yang G Q, et al. Shape-stabilized hydrated salt/paraffin composite phase change materials for advanced thermal energy storage and management. Chem Eng J, 2020, 385: 123958 doi: 10.1016/j.cej.2019.123958 -

下載:

下載: