Curing performance of alkali-activated cement–phosphorous slag and its compatibility with sulfur tailings

-

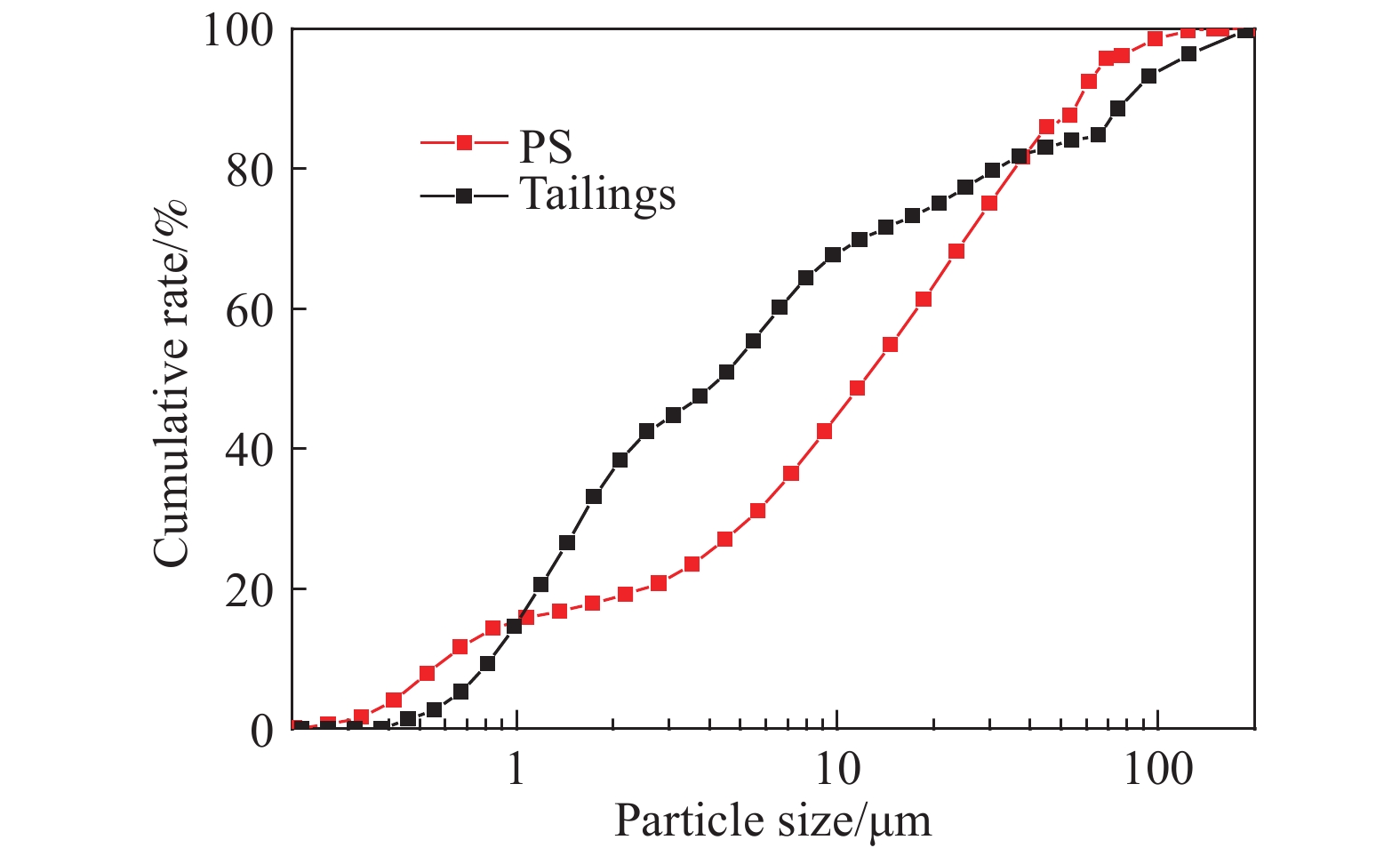

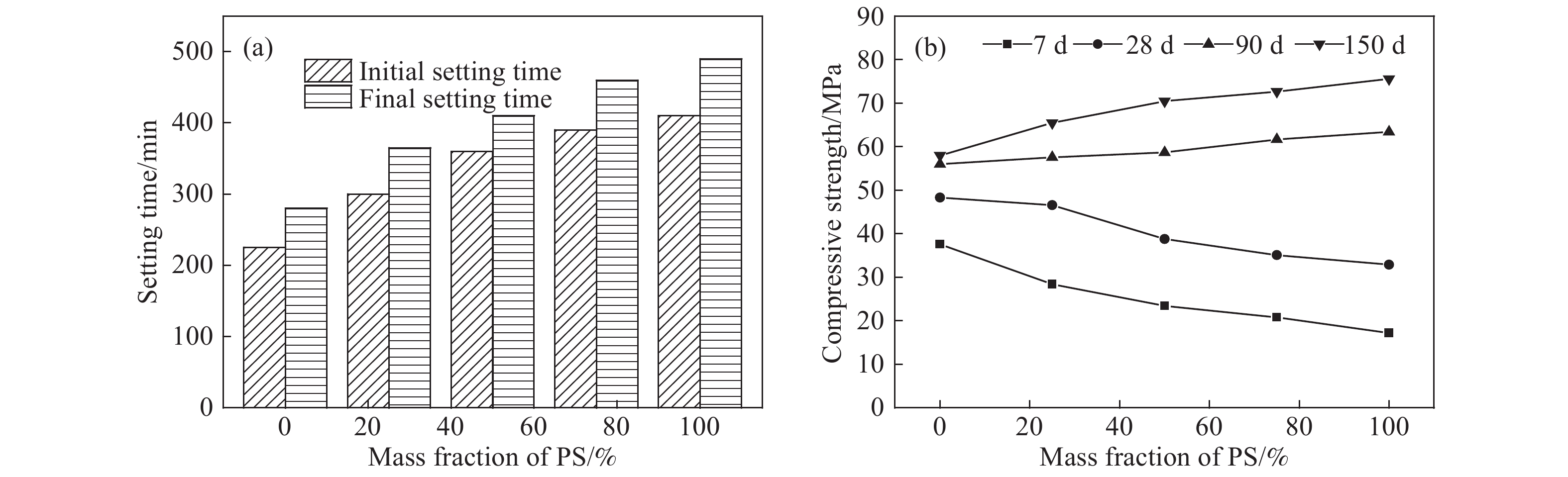

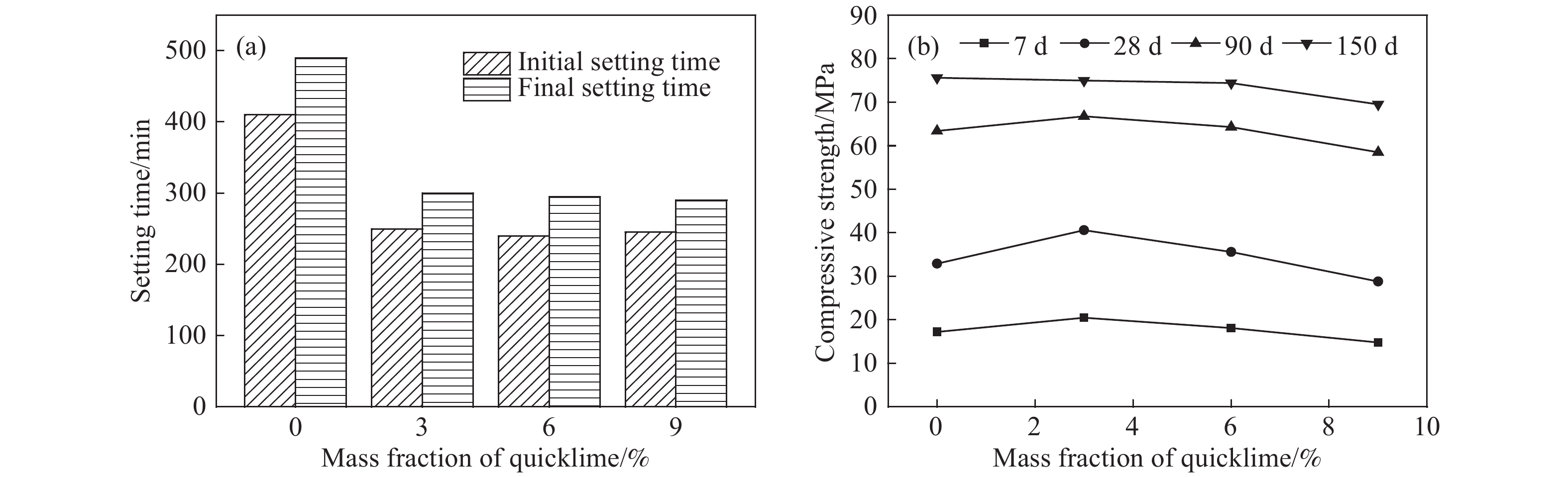

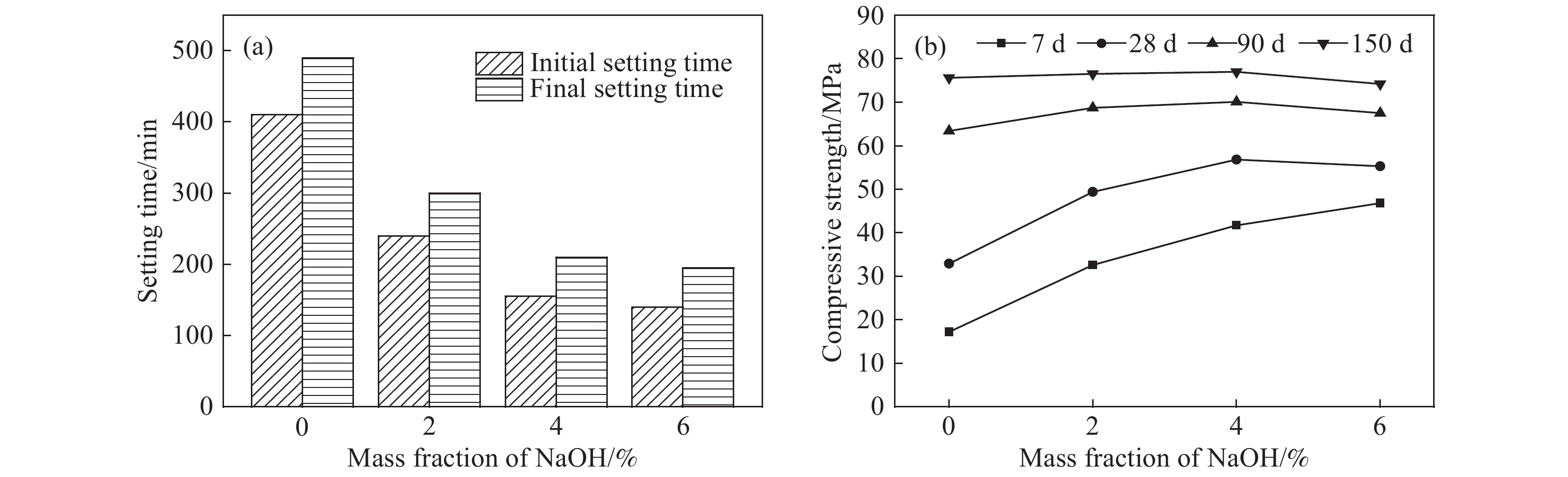

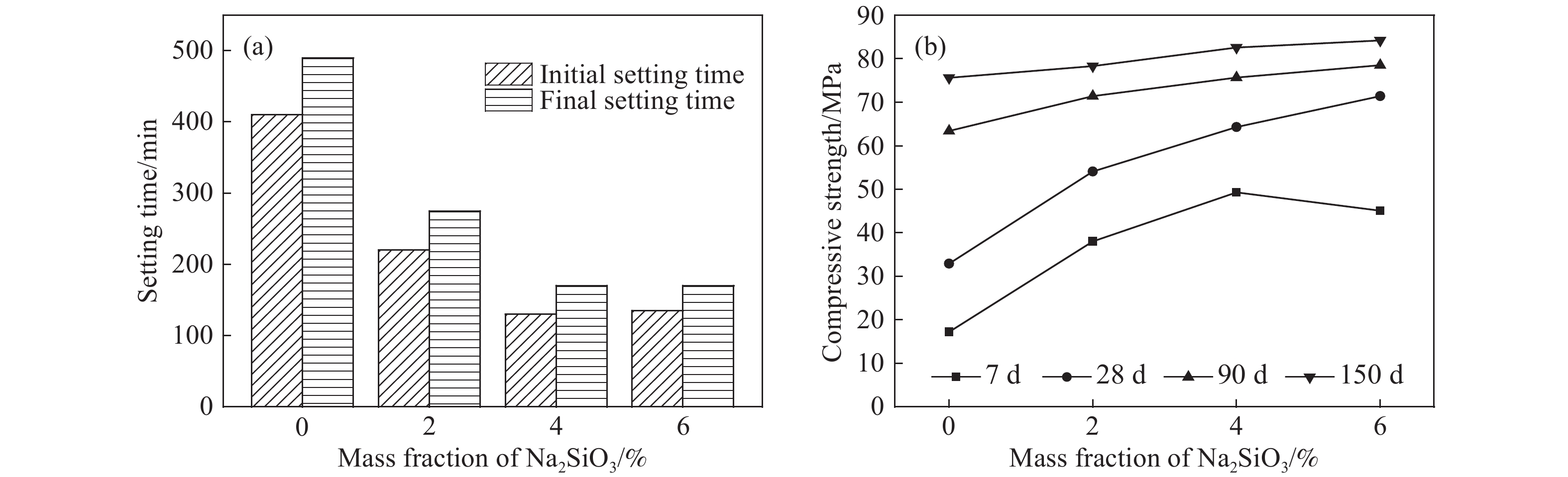

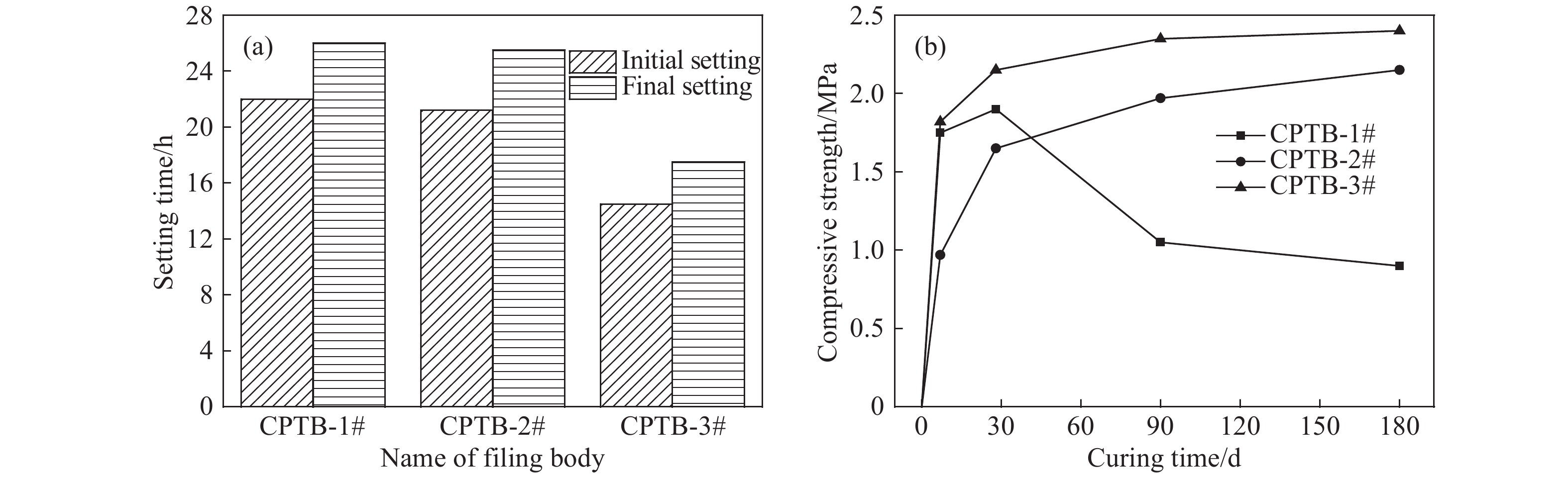

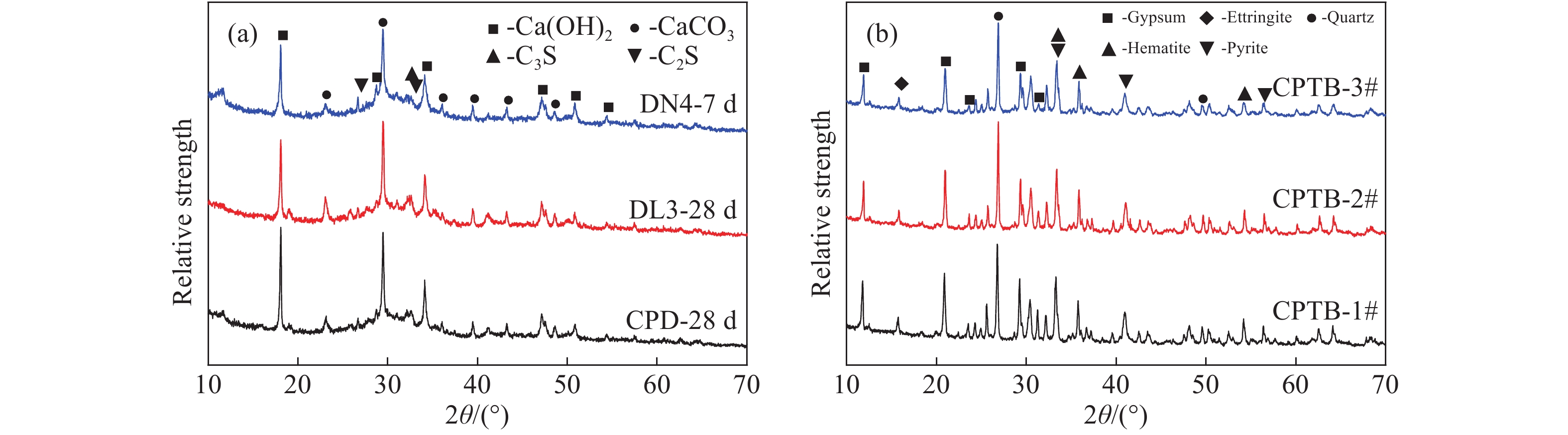

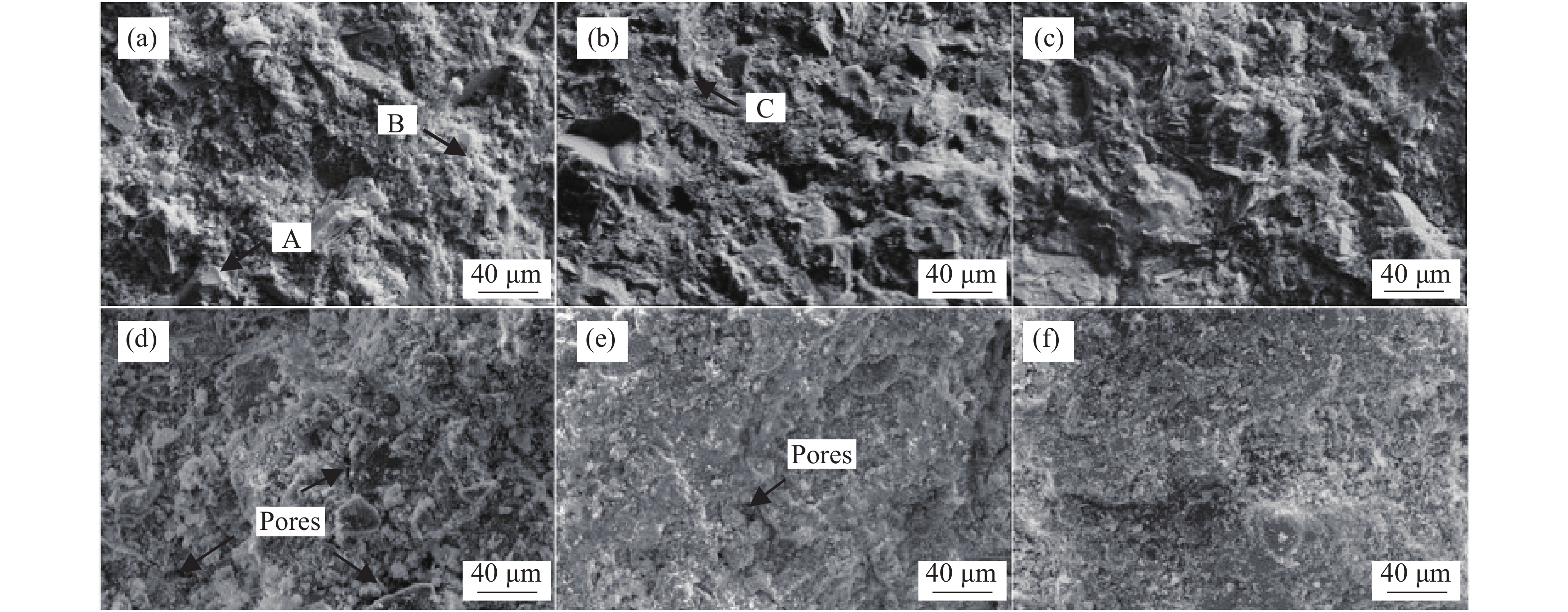

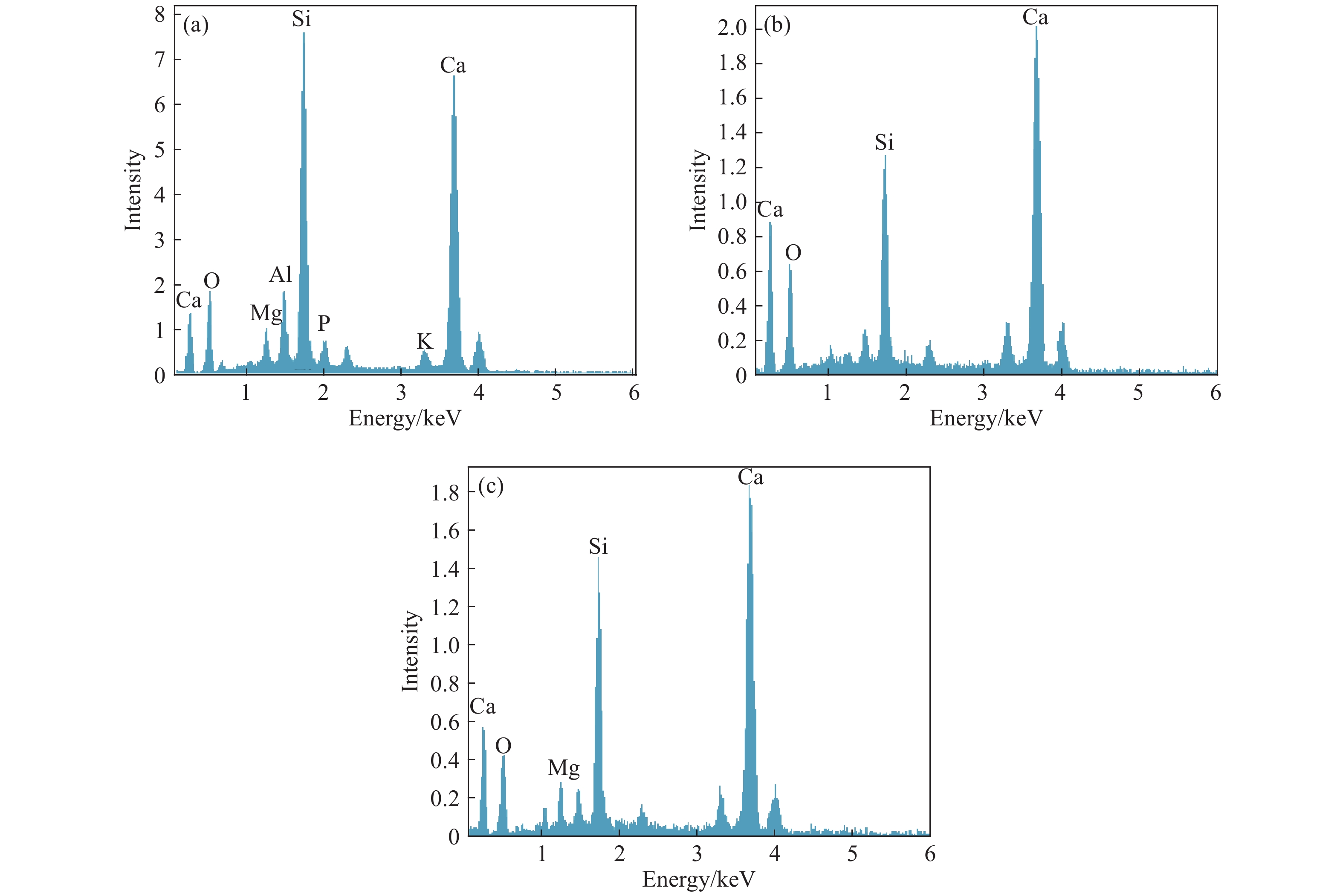

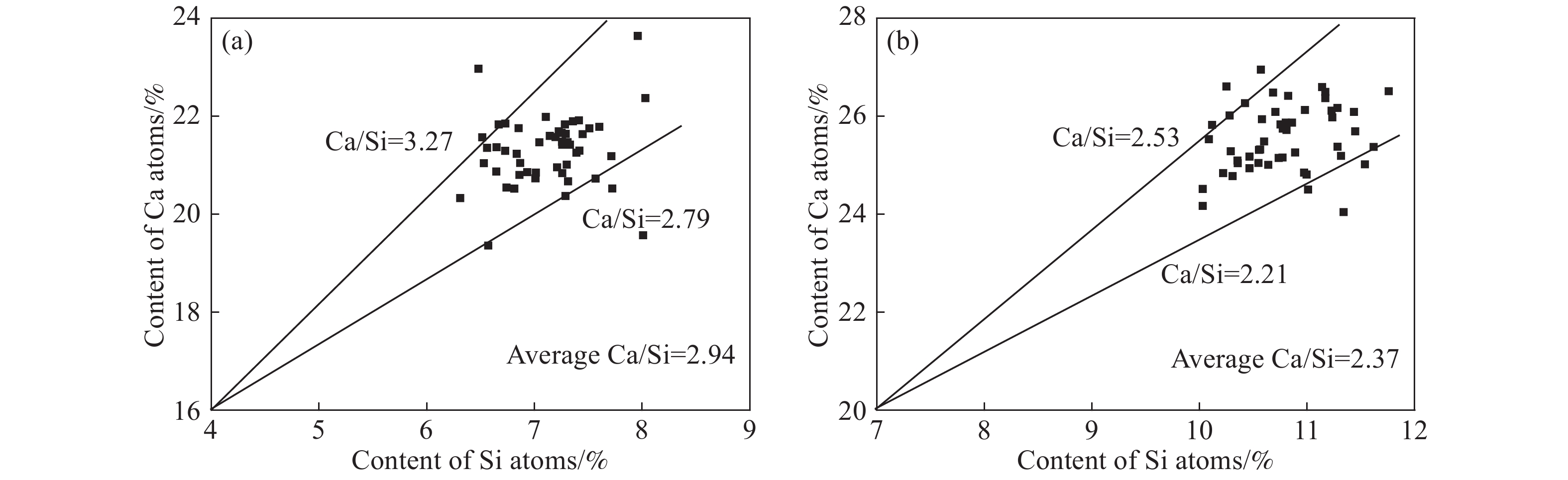

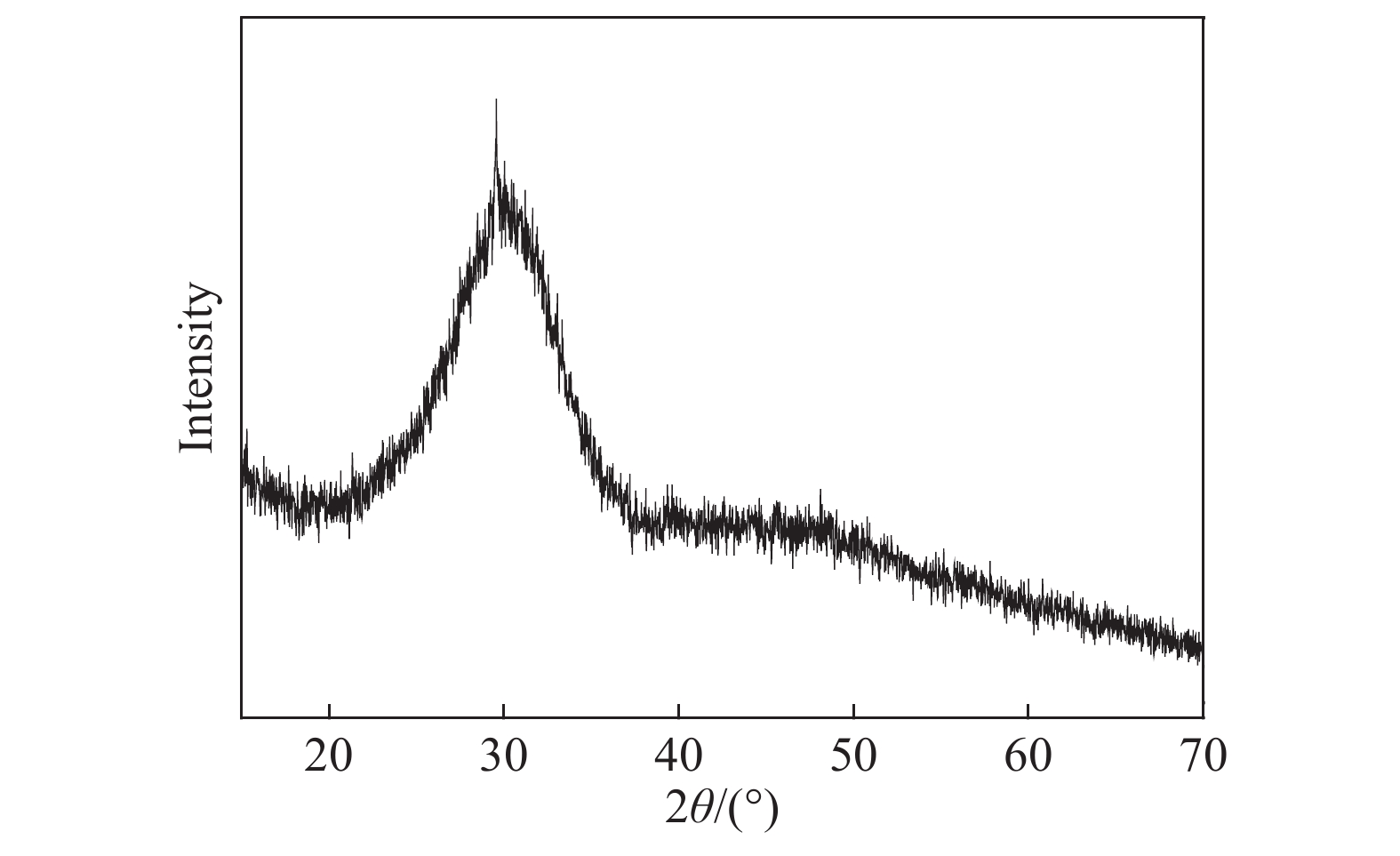

摘要: 基于磷渣材料水化特性和礦山充填應用條件,研究堿激發水泥?磷渣共同作為膠凝材料(CPCM)膠結含硫尾砂的可行性。選取生石灰、NaOH、Na2SiO3作為激發劑,開展CPCM固化性能試驗,并評價CPCM與含硫尾砂相容性。研究結果表明:磷渣摻量為水泥的100%、生石灰為3%時,CPCM終凝時間300 min,28 d抗壓強度40.6 MPa,基本可等量替代P.O 42.5水泥應用于礦山嗣后充填。Na2SiO3摻量4%時,CPCM終凝時間比水泥縮短39.3%,7 d強度提高31.1%。與水泥相比,CPCM使充填體凝結時間縮短8 h左右,且固化28 d后強度未出現劣化,表明CPCM與含硫尾砂相容性好。X射線衍射、掃描電鏡和電子能譜分析表明,CPCM水化產物主要為Ca(OH)2和C?S?H。磷渣不斷水化,導致Ca(OH)2含量下降,逐漸形成致密的低Ca/Si摩爾比C?S?H,這不僅保證了CPCM后期強度增加,而且避免了充填體強度劣化。Abstract: Phosphorus slag (PS) is an industrial waste discharged during the refining of yellow phosphorus by a high-temperature electric furnace. The slag is generally deposited on the surface in situ, and this uses up considerable areas of land and causes environmental pollution problems. The glass phase content in electric furnace PS is over 90%, indicating that the PS has potential cementitious property. As a cement admixture, PS has a retarding effect on cement, thus, its application to cement has become less adopted. Based on the hydration characteristics of PS and the application conditions of mine filling, the feasibility of alkali-activated cement–PS used as cementitious material (CPCM) to cement sulfur tailings was studied. Quicklime, NaOH, and Na2SiO3 were used as the activators to investigate the CPCM curing performance in a laboratory, and the compatibility of CPCM with sulfur tailings was evaluated. The results show that when the PS-to-cement mole ratio is 1∶1, quicklime is 3% of PS, the final setting time of CPCM is 300 min, and the CPCM strength for 28 days is 40.6 MPa, indicating that the material can replace P.O 42.5 cement in the subsequent filling process. When the Na2SiO3 is 4% of PS, the final setting time of CPCM is 39.3% less than that of cement, and its strength for 7 days is 31.1% higher than that of cement. Compared with cement, CPCM shortens the setting time of backfill by 8 hours, and its strength does not deteriorate after curing for 28 days. Therefore, CPCM is suitable for cementing sulfur tailings. X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) analyses show that the CPCM hydration products are mainly Ca(OH)2 and C?S?H. Moreover, the PS hydration resulted in a decrease in the Ca(OH)2 content, and a compact C?S?H gel with a low Ca/Si mole ratio is formed. This not only improves the later strength of CPCM but also prevents the strength deterioration of the backfill.

-

Key words:

- phosphorus slag /

- alkali activators /

- early activity /

- sulfur tailings /

- mine filling

-

表 1 水泥、全尾砂和磷渣化學成分

Table 1. Chemical compositions of cement, tailings, and phosphorus slag

Raw materials Mass fraction/% CaO SiO2 Al2O3 P2O5 Fe2O3 MgO Cement 62.35 20.18 5.22 0.48 3.27 2.16 Tailings 6.95 17.26 10.03 — 16.34 0.18 Phosphorus slag (PS) 43.18 37.37 5.78 3.93 0.25 2.57 表 2 CPCM配合比設計

Table 2. Design of CPCM mix ratio

Name of mix ratio Mass fraction of phosphorus slag /% Mass fraction of activators /% Type of activators CPO 0 0 Pure cement paste CPA 25 0 CPB 50 CPC 75 CPD 100 DL3 100 3 Quicklime DL6 6 DL9 9 DH2 100 2 NaOH (by Na2O mass fraction) DH4 4 DH6 6 DN2 100 2 Na2SiO3 (by Na2O mass fraction) DN4 4 DN6 6 表 3 CPTB配合比設計

Table 3. Design of CPTB mix ratio

Name of filing body Type of binders Mass fraction of paste/% Binder sand ratio CPTB?1# CPO 76 1∶12 CPTB?2# DL3 76 1∶12 CPTB?3# DN4 76 1∶12 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Jiang M, Wang C H, Hang X F, et al. Secondary pollution prediction of recycling process of yellow phosphorus slag by moulding under thermal state. J Central S Univ Sci Technol, 2016, 47(3): 1078蔣明, 王重華, 黃小鳳, 等. 黃磷爐渣熱態成型資源化過程的二次污染預測. 中南大學學報: 自然科學版, 2016, 47(3):1078 [2] Chen J S, Zhao B, Wang X M, et al. Cemented backfilling performance of yellow phosphorus slag. Int J Miner Metall Mater, 2010, 17(1): 121 doi: 10.1007/s12613-010-0121-2 [3] Wu Y M, Zhang Q, Li L J. Effect of phosphorus slag on retarding properties of ordinary portland cement. Bull Chin Ceram Soc, 2019, 38(4): 1177吳一鳴, 張覃, 李龍江. 磷渣對普通硅酸鹽水泥緩凝特性影響的研究. 硅酸鹽通報, 2019, 38(4):1177 [4] Xu C W, Du Q S. Influence of phosphorus slag replacing sand on properties of cement-based grouting material. Concrete, 2018(10): 85 doi: 10.3969/j.issn.1002-3550.2018.10.021徐長偉, 杜秋實. 磷渣代砂對水泥基灌漿料性能的影響. 混凝土, 2018(10):85 doi: 10.3969/j.issn.1002-3550.2018.10.021 [5] Wang T, Song K P, Peng Z B, et al. Experiment study of low-clinker phosphorus slag based cement. Bull Chin Ceram Soc, 2019, 38(6): 1805王濤, 宋科鵬, 彭澤斌, 等. 少熟料磷渣基水泥的研究. 硅酸鹽通報, 2019, 38(6):1805 [6] Zhu L P. Experimental study on modified phosphorous slag based cementing material with lime. Non-Metallic Mines, 2019, 42(4): 28 doi: 10.3969/j.issn.1000-8098.2019.04.008朱麗蘋. 石灰改性磷渣基膠凝材料的試驗研究. 非金屬礦, 2019, 42(4):28 doi: 10.3969/j.issn.1000-8098.2019.04.008 [7] Peng Y Z, Zhang J, Xu G, et al. Preparation and microstructure of phosphorous slag-based cementitious materials with high early strength. J China Three Gorges Univ Nat Sci, 2015, 37(6): 15彭艷周, 張俊, 徐港, 等. 快硬早強磷渣基膠凝材料的制備及其微觀結構研究. 三峽大學學報: 自然科學版, 2015, 37(6):15 [8] Chen X, Yang H Q, Zhang J F, et al. Pozzolanic activation and analysis of phosphorus slag powder. Concrete, 2015(10): 82 doi: 10.3969/j.issn.1002-3550.2015.10.021陳霞, 楊華全, 張建峰, 等. 磷渣粉的火山灰活性激發及分析. 混凝土, 2015(10):82 doi: 10.3969/j.issn.1002-3550.2015.10.021 [9] Chen X, Yang H Q, Shi Y, et al. Hydration characteristics of cement-based materials with incorporation of phosphorus slag powder. J Build Mater, 2016, 19(4): 619 doi: 10.3969/j.issn.1007-9629.2016.04.002陳霞, 楊華全, 石妍, 等. 磷渣粉水泥基復合膠凝體系的水化特性. 建筑材料學報, 2016, 19(4):619 doi: 10.3969/j.issn.1007-9629.2016.04.002 [10] Cheng L, Zhu C G, Sheng G H. Mechanical properties and microstructures of alkali-activated phosphorous slag cement. J Chin Ceram Soc, 2006, 34(5): 604 doi: 10.3321/j.issn:0454-5648.2006.05.019程麟, 朱成桂, 盛廣宏. 堿磷渣水泥的力學性能及微觀結構. 硅酸鹽學報, 2006, 34(5):604 doi: 10.3321/j.issn:0454-5648.2006.05.019 [11] Hao J G, Guo C Z, Zhou W B, et al. Effect of CaO on hydration and hardening of phosphorous slag Portland cement. Cement, 2010(11): 6 doi: 10.3969/j.issn.1002-9877.2010.11.002郝晉高, 郭成洲, 周衛兵, 等. CaO對磷渣硅酸鹽水泥水化硬化影響的試驗研究. 水泥, 2010(11):6 doi: 10.3969/j.issn.1002-9877.2010.11.002 [12] Song J W, Fang K H, Liu D M, et al. Research on fractal characteristics of phosphate slag?cement paste pore with MIP. Eng J Wuhan Univ, 2008, 41(6): 41宋軍偉, 方坤河, 劉冬梅, 等. 壓汞測孔評價磷渣?水泥漿體材料孔隙分形特征的試驗. 武漢大學學報: 工學版, 2008, 41(6):41 [13] Zhang M, Ma Q M, Guo R X, et al. Utilization of phosphorous slag in cement concrete. Bull Chin Ceram Soc, 2019, 38(8): 2464張敏, 馬倩敏, 郭榮鑫, 等. 磷渣在水泥混凝土中的資源化利用. 硅酸鹽通報, 2019, 38(8):2464 [14] Xu Y H. Study on influence of sulphide in tailings on quality of backfill. Min Res Dev, 2009(5): 4許毓海. 尾砂中硫化物對充填體質量影響研究. 礦業研究與開發, 2009(5):4 [15] Kesimal A, Yilmaz E, Ercikdi B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem Concr Res, 2004, 34(10): 1817 doi: 10.1016/j.cemconres.2004.01.018 [16] Jiang G Z, Wu A X, Li H, et al. Long-term strength performance of sulfur tailings filling and its affecting factors. J Central S Univ Sci Technol, 2018, 49(6): 1504姜關照, 吳愛祥, 李紅, 等. 含硫尾砂充填體長期強度性能及其影響因素. 中南大學學報: 自然科學版, 2018, 49(6):1504 [17] Jiang G Z, Wu A X, Wang Y M, et al. Effect of compound activator on copper slag activity and preparation of filling materials. Chin J Eng, 2017, 39(9): 1305姜關照, 吳愛祥, 王貽明, 等. 復合激發劑對銅爐渣活性影響及充填材料制備. 工程科學學報, 2017, 39(9):1305 [18] Chen M, Sun Z P, Liu J S. State of the art review on activating techniques and mechanism of phosphorus slag. Mater Rev, 2013, 27(21): 112陳明, 孫振平, 劉建山. 磷渣活性激發方法及機理研究進展. 材料導報, 2013, 27(21):112 [19] Xu B, Pu X C. Study on sulfate-resistance property of solid alkaline as cement. China Build Mater Sci Technol, 1997(5): 11徐彬, 蒲心誠. 固態堿組分堿礦渣水泥抗硫酸鹽性能研究. 中國建材科技, 1997(5):11 [20] Zhang X J. The Microstructure Formation and Evolution of C−S−H Gel in Cement Paste under the Attack of Sulfate in Weak Alkaline[Dissertation]. Hefei: Anhui Jianzhu University, 2019張曉佳. 弱堿環境下硫酸鹽侵蝕水泥石中C−S−H凝膠結構的形成與演變[學位論文]. 合肥: 安徽建筑大學, 2019 [21] He X Y, Zheng Z Q, Su Y, et al. Study on the properties of phosphorous slag-blast furnace slag-cement composite cementitious materials activated by acetylene slag. Bull Chin Ceram Soc, 2019, 38(3): 889賀行洋, 鄭正旗, 蘇英, 等. 電石渣激發磷渣?礦渣?水泥復合膠凝材料的性能研究. 硅酸鹽通報, 2019, 38(3):889 [22] Liu J, He W, Wang D M. Long-term characteristics of the hydration product of cement-phosphorus slag composite binder under steam curing condition. J Chin Electron Microsc Soc, 2017, 36(6): 571 doi: 10.3969/j.issn.1000-6281.2017.06.009劉進, 何偉, 王棟民. 蒸養條件下水泥-磷渣復合膠凝材料的水化產物的長齡期特征. 電子顯微學報, 2017, 36(6):571 doi: 10.3969/j.issn.1000-6281.2017.06.009 [23] Song H, Chen J K, Jiang J Y. An internal expansive stress model of concrete under sulfate attack. Acta Mech Solida Sin, 2016, 29(6): 610 doi: 10.1016/S0894-9166(16)30331-7 [24] Liu L, Zhu C, Chen G L, et al. Erosion mechanism of sulfur-bearing tailings in micro-scale. J Xi’an Univ Sci Technol, 2018, 38(4): 553劉浪, 朱超, 陳國龍, 等. 微觀尺度下含硫尾砂膠結充填體侵蝕機理. 西安科技大學學報, 2018, 38(4):553 [25] Liu R G, Yan P Y. Hydration characteristics of slag in cement-slag complex binder. J Chin Ceram Soc, 2012, 40(8): 1112劉仍光, 閻培渝. 水泥?礦渣復合膠凝材料中礦渣的水化特性. 硅酸鹽學報, 2012, 40(8):1112 -

下載:

下載: