-

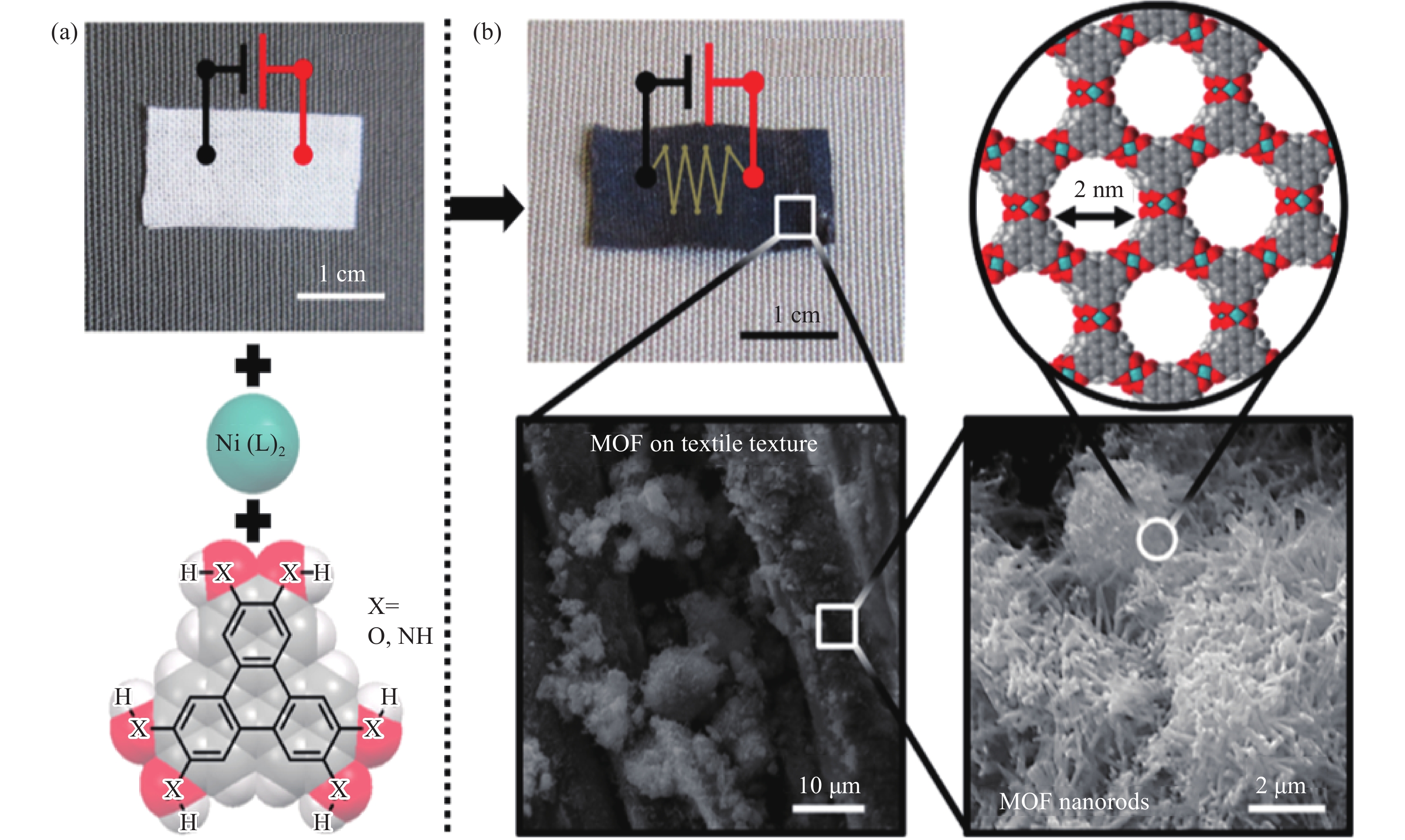

摘要: 總結了將MOFs材料與金屬氧化物、紡織品以及碳基導電纖維材料相結合,并在電阻式氣體傳感器領域的研究與應用。其中金屬氧化物結合MOFs過程中,MOFs主要有兩個作用:一是作為分散劑提高金屬氧化物的分散性;二是利用MOFs本身具有較大的比表面積和大量的活性位點,來提高材料對于氣體分子的吸附量和選擇性。當紡織品與MOFs結合的過程中,由于紡織品的導電性相對較差,所以需要結合一些導電性及氣體選擇性較好的MOFs來作為傳感器。碳基導電纖維一般具有較好的機械性能和導電性能,因此將其與MOFs材料復合后用于柔性電阻氣體傳感器具有一定的優勢。Abstract: Metal-organic frameworks (MOFs) are a new class of organic–inorganic hybrid materials that show great potential for gas adsorption and storage. However, the powder form of these materials limits the range of their applications. Integration of MOFs on polymer fiber scaffolds to increase the contact area between these frameworks and target molecules and improve the performance of the resulting material is expected to provide new application prospects in gas adsorption, membrane separation, catalysis, and toxic gas sensing. Electrochemical sensors with good flexibility and high sensitivity and selectivity are needed in environmental detection, disease diagnosis, food safety, and other fields. Flexible resistance sensors are sensitive, low cost, and can be produced on a large scale; thus, these sensors have received extensive attention from researchers. Preparing flexible resistance sensors with high sensitivity, high stability, and good wearing comfort is a current and popular area of research. In this paper, we summarized the research and application of MOFs materials combined with metal oxides, textiles and carbon-based conductive fiber materials in the field of resistance gas sensors. Metal oxides act as a conductive material in resistance sensors bearing a metal oxide-and-MOF design. In this design, MOFs play two roles. First, MOFs can wrap precious metals and form nanoparticles encasing these precious metals when calcined. Here, the precious metal functions as a catalyst while the MOF is used as a dispersant to distribute the metal evenly on the surface of the sensing material. Second, the MOFs are combined with the metal oxide by in situ growth or doping on the metal oxide surface. The MOF surface has a large specific surface area and numerous active sites that can bind with the target gas. Resistance sensing is achieved by changing the electronic distribution within the sensing material. When textiles and MOFs are combined, the resulting resistive sensing materials must have a certain electrical conductivity. However, common MOF materials have poor electrical conductivity. Therefore, developing a conductive MOF material in which 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP) and 2,3,6,7,10,11-hexaaminotriphenylene (HATP) show strong sensing performance for NO, H2S, and H2O is necessary. Carbon nanotube fibers and MOF materials can also be combined to obtain resistive sensor materials. Carbon nanotube materials are characterized by cross contact at the nanoscale and have good mechanical and electrical conductive properties. Thus, they feature certain advantages over other materials when applied to flexible resistive sensors.

-

Key words:

- metal-organic frameworks /

- fiber /

- flexible /

- gas sensor /

- resistance

-

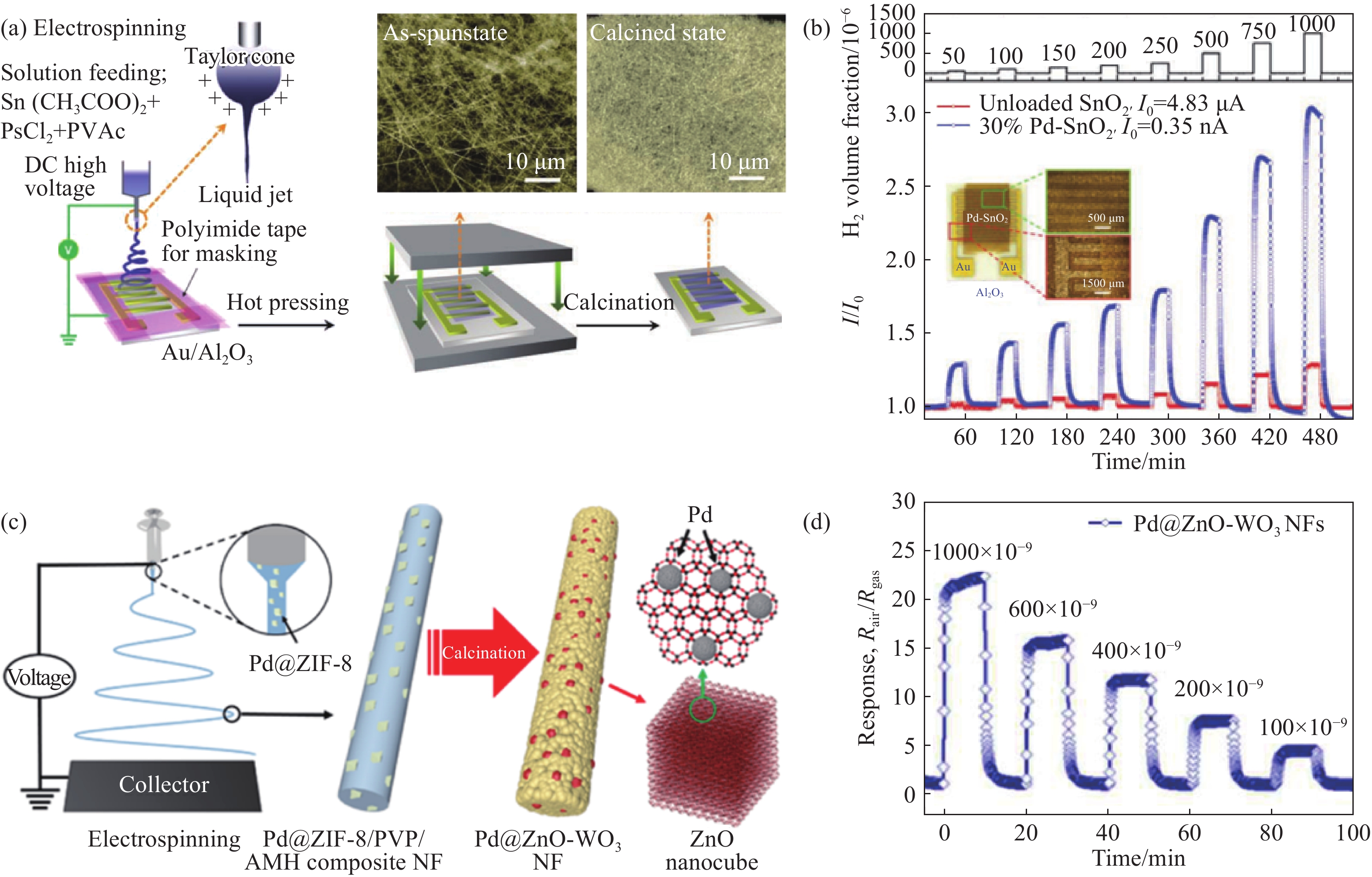

圖 1 (a)SnO2傳感器的制備流程圖,插圖為煅燒前后的掃描電子顯微鏡圖像對比;(b)比較未負載和負載30% Pd–SnO2對于H2的響應值;(c) PdO@ZnO?WO2纖維的合成工藝圖;(d) 350 ℃時PdO@ZnO?WO2對甲苯的傳感性能[8, 12]

Figure 1. (a) Schematic diagram illustrating the fabrication process of our SnO2 sensor prototypes, the inset shows images of the materials in the as-spun state and after hot-pressing and calcination obtained by confocal microscopy; (b) electrical responses of unloaded and 30% Pd-loaded SnO2 sensors to H2; (c) schematic illustration of the synthetic process of PdO@ZnO?WO2 nanoparticles; (d) sensitivity of PdO@ZnO?WO2 nanoparticles to toluene at 350 ℃[8, 12]

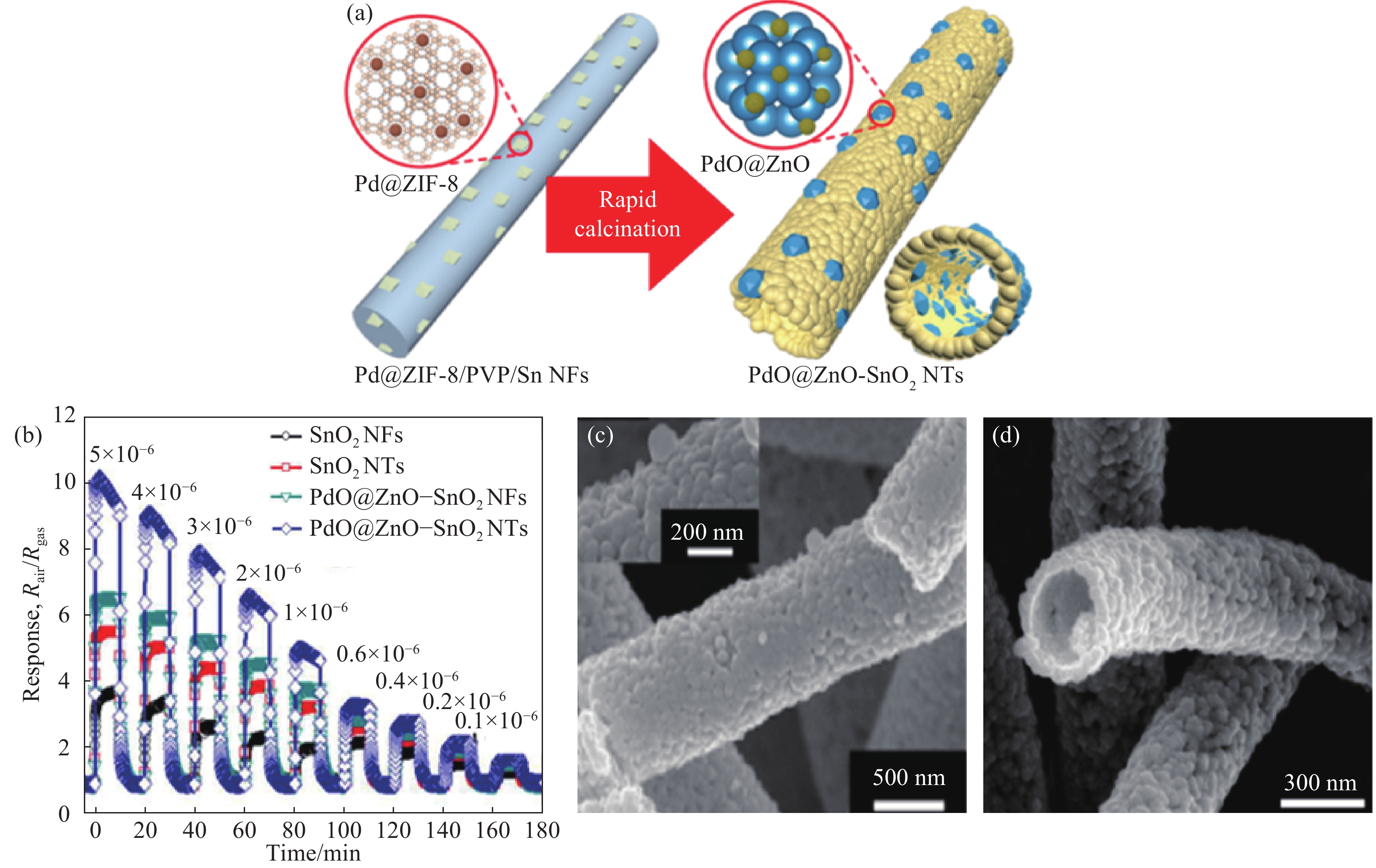

圖 2 (a) PdO@ZnO–SnO2納米纖維合成工藝示意圖;(b) 400 ℃下不同材料對0.1×10?6~5×10?6體積分數丙酮的響應值;(c) Pd@ZnO–WO3納米纖維的掃描電鏡圖像,插圖為表面放大圖像;(d) PdO@ZnO-SnO2的掃描電鏡圖像[13]。

Figure 2. (a) Schematic illustration of the synthetic process of PdO@ZnO-SnO2 nanoparticles; (b) Transition of dynamic responses to acetone in the volume fraction range of 0.1×10?6?5.0×10?6 at 400 ℃; (c) SEM images of Pd@ZnO–WO3 nanofibers and magnified image of the material surface; (d) SEM image of PdO@ZnO–SnO2 nanotubes[13]

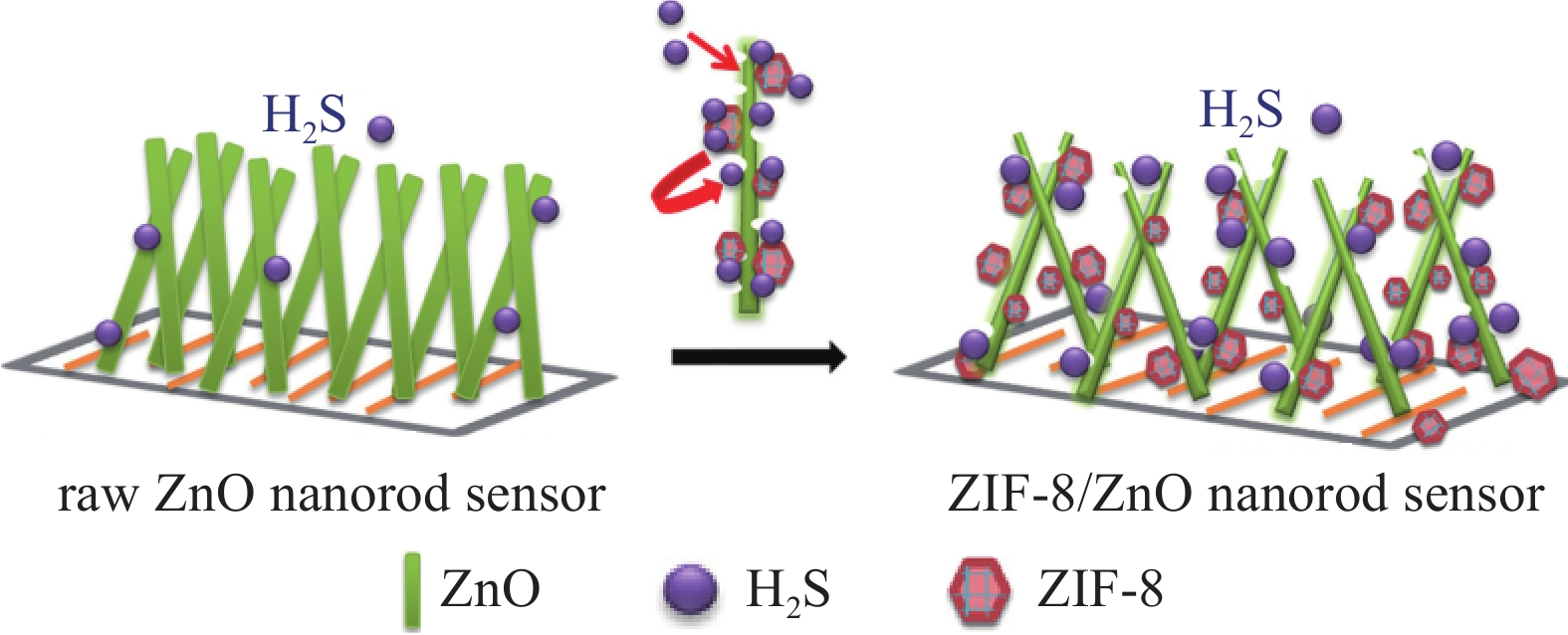

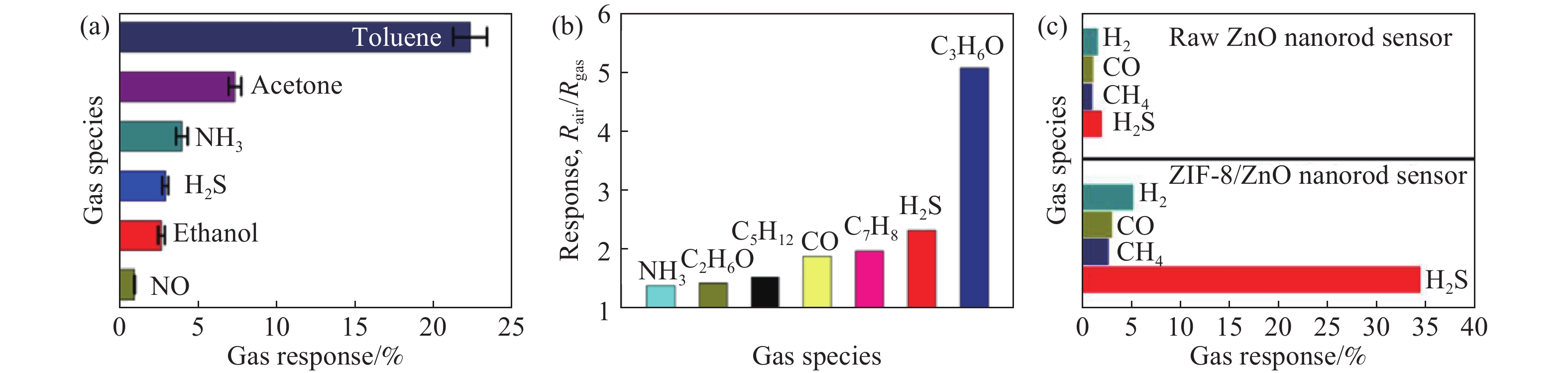

圖 4 (a) Pd@ZnO–WO3納米纖維在350 ℃下對于不同氣體的選擇性;(b) PdO@ZnO–SnO2納米纖維在400 ℃下對于不同氣體的選擇性;(c) ZnO和ZIF-8/ZnO對于不同氣體的選擇性[12-14]

Figure 4. (a) Selective detection characteristics of Pd@ZnO-WO3 nanofibers toward toluene in the presence of multiple interfering analytes at 350 °C; (b) selective sensing characteristics of PdO@ZnO–SnO2 nanoparticles at 400 ℃; (c) selective of ZnO and ZIF-8/ZnO for different gases[12-14]

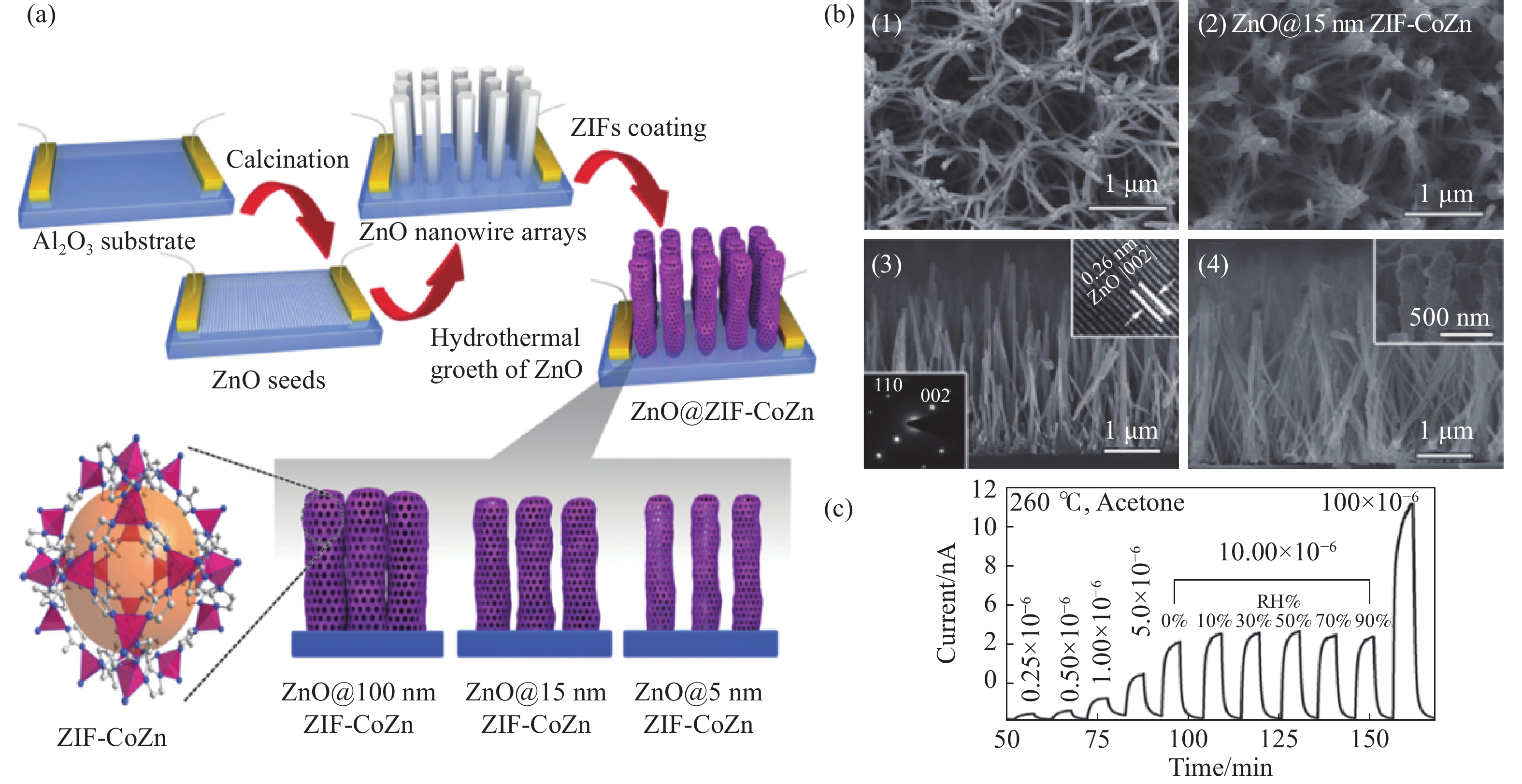

圖 5 (a) ZnO@ZIF–CoZn氣體傳感器的制備原理圖;(b) ZnO and ZnO@ ZIF–CoZn的平面圖和截面圖;(c) ZnO@5 nm ZIF–CoZn對不同體積分數丙酮的響應值,并且在10×10?6體積分數下測試對于不同濕度的響應值[4]

Figure 5. (a) Schematic illustration of the preparation of ZnO@ZIF–CoZn gas sensors; (b) plan and cross-sectional views of ZnO and ZnO@ ZIF–CoZn nanowire arrays: (1,3) HRTEM image of pure ZnO and SAED patterns of a single ZnO nanowire (in inset), (2,4) ZnO@15 nm ZIF–CoZn;(c) response–recovery curves of ZnO@5 nm ZIF–CoZn toward acetone of different volume fraction in dry air and 10×10?6 acetone at different relative humidities[4]

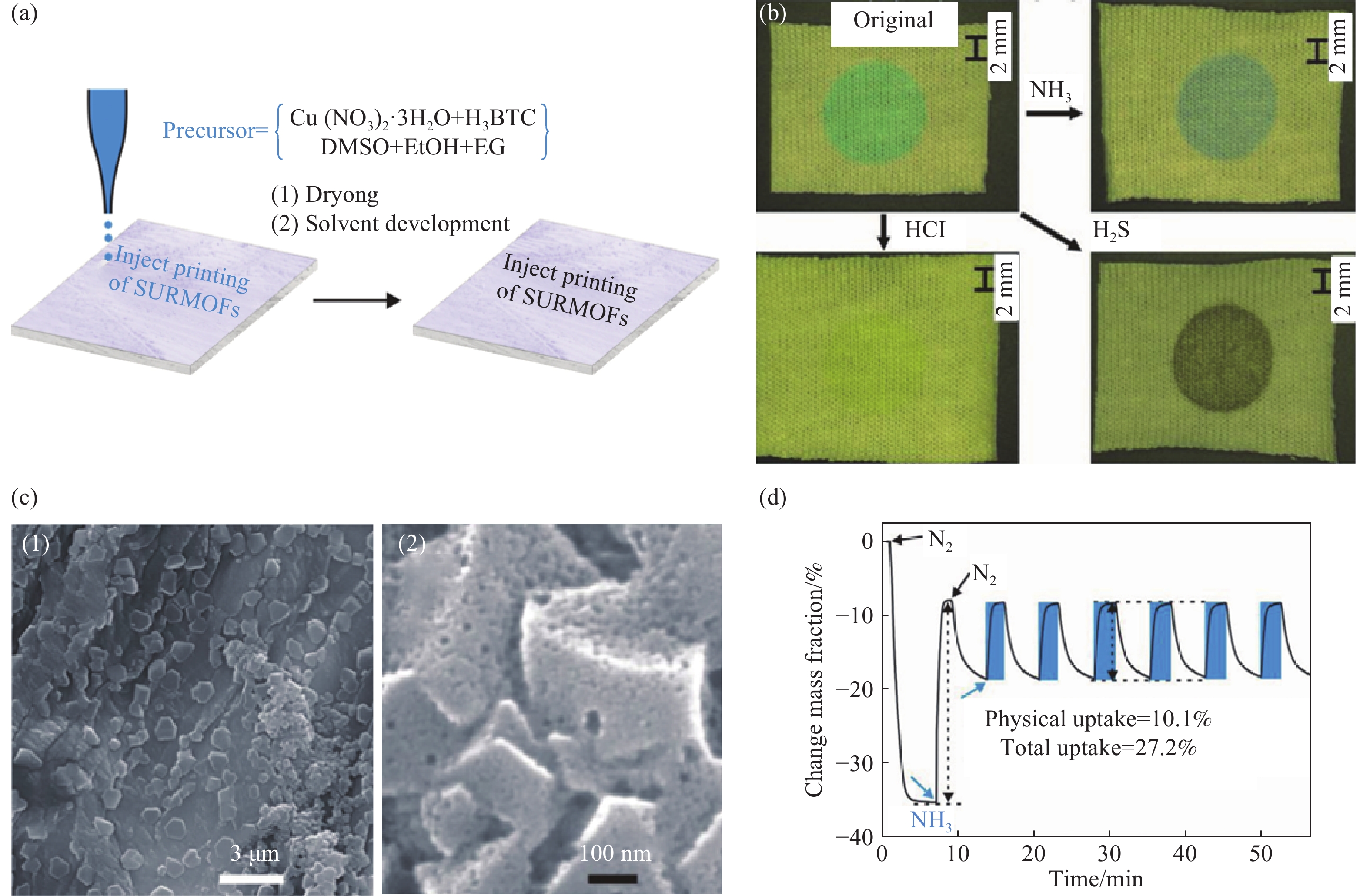

圖 6 (a)通過噴墨印刷技術,將HKUST-1合成在柔性基材上;(b) HKUST-1暴露在不同氣體前后的對比照片;(c) HKUST-1的掃描電鏡圖像;(d) HKUST-1對于NH3的傳感響應曲線[24]。

Figure 6. (a) Inkjet printing of SURMOFs onto flexible substrates using a HKUST-1 precursor solution as “ink”; (b) photographs of a dot of HKUST-1 printed onto textiles before and after exposure to different gases; (c) SEM images of a HKUST-1 printed paper fiber; (d) partial reversible adsorption/desorption of NH3 on HKUST-1 film[24]

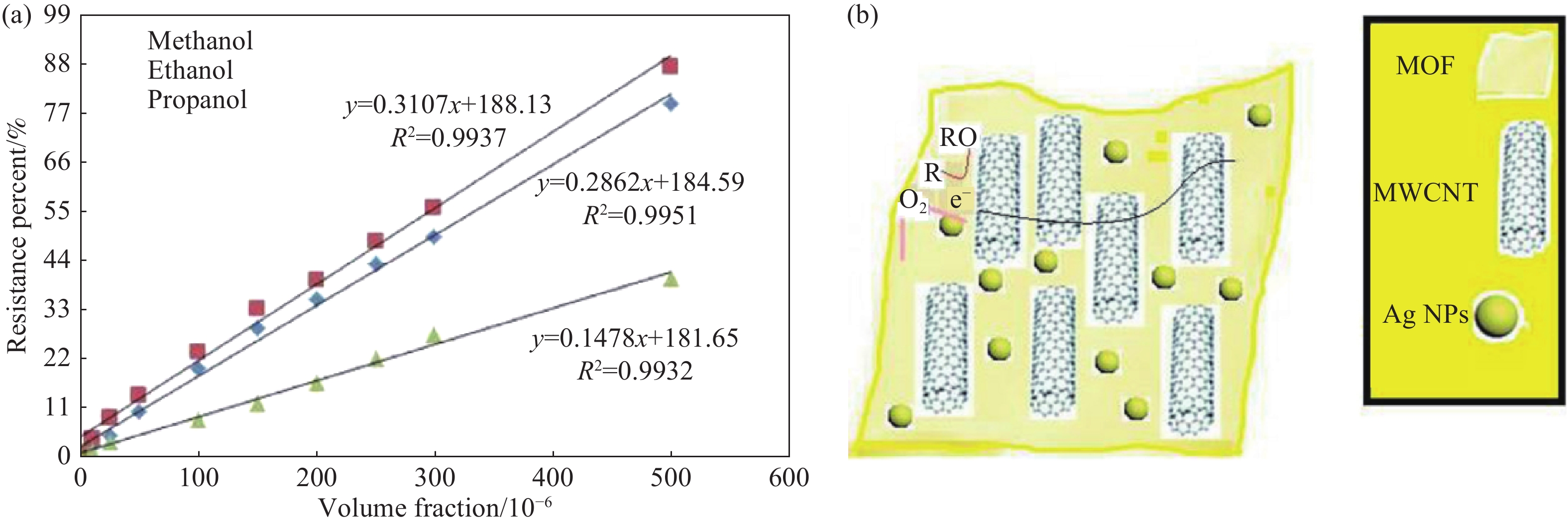

圖 8 (a)校準曲線在體積分數范圍為(10~500)×10?6時用于分析物(甲醇,乙醇和異丙醇)的傳感器;(b)MIL-53(Cr-Fe)/Ag/CNT三元納米復合材料的傳感機理[29]

Figure 8. (a) Calibration curves of the sensors for different analytes (methanol, ethanol, and iso-propanol) in the volume fraction range of (10–500)×10?6; (b) sensing mechanism of the MIL-53(Cr-Fe)/Ag/CNT ternary nanocomposite[29]

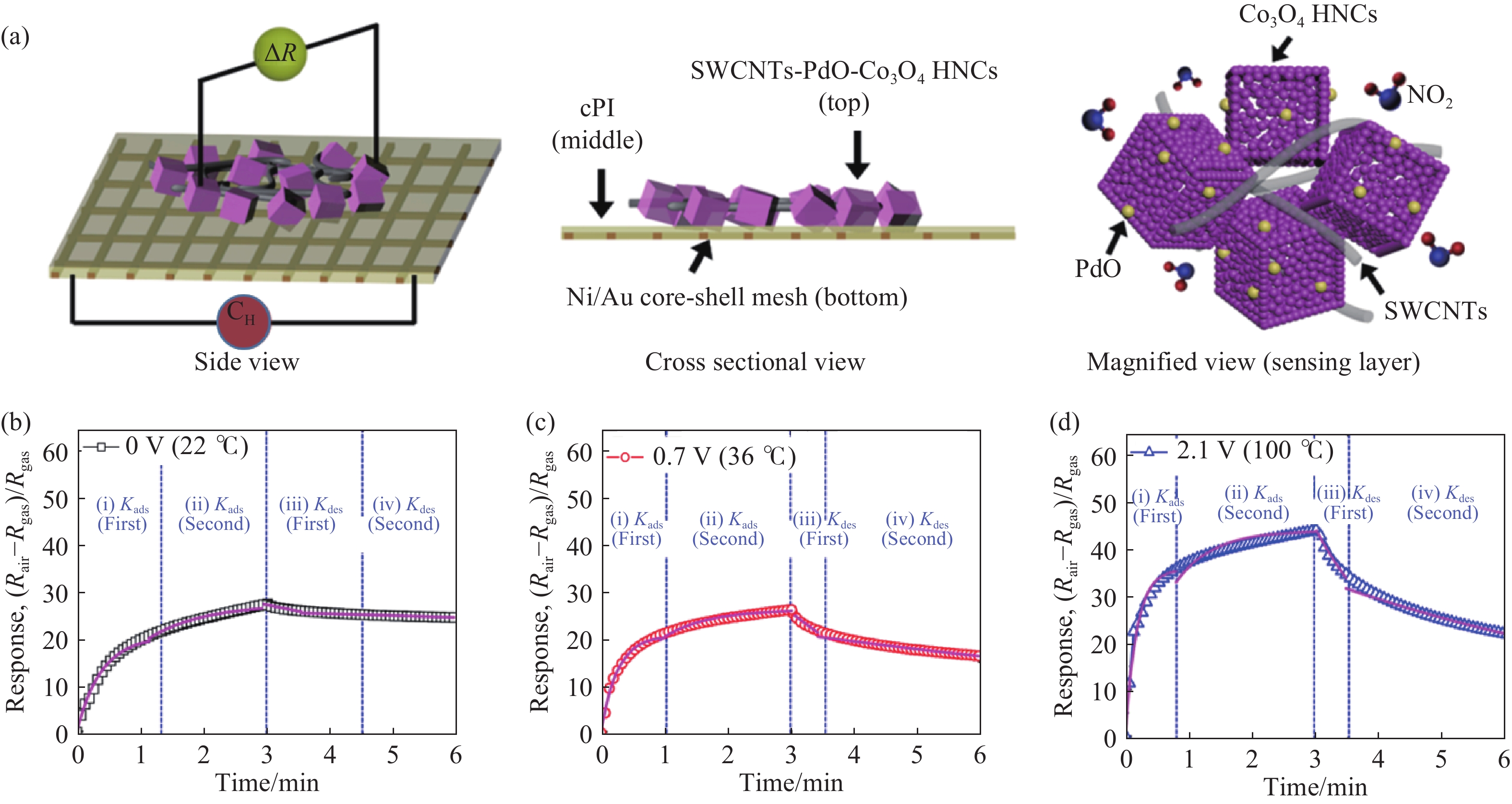

圖 9 (a)傳感器示意圖;0 V (22 ℃)(b),0.7 V (36 ℃) (c)和2.1 V (100 ℃) (d)下傳感器的響應和恢復動力學曲線[30]

Figure 9. (a) Schematic illustrations of the overall sensing platform; response and recovery kinetics of SWCNT-loaded PdO–Co3O4 HNCs on cPI film toward the Ni/Au-cPI heater at 0 V (22 °C) (b), 0.7 V (36 °C) (c), and 2.1 V (100 °C) (d)[30]

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Zhao J J, Losego M D, Lemaire P C, et al. Highly adsorptive, MOF-functionalized nonwoven fiber mats for hazardous gas capture enabled by atomic layer deposition. <italic>Adv Mater Interfaces</italic>, 2014, 1(4): 1400040 doi: 10.1002/admi.201400040 [2] Koo W T, Jang J S, Kim I D. Metal-organic frameworks for chemiresistive sensors. <italic>Chem</italic>, 2019, 5(8): 1938 doi: 10.1016/j.chempr.2019.04.013 [3] Alrammouz R, Podlecki J, Abboud P, et al. A review on flexible gas sensors: from materials to devices. <italic>Sensors Actuat A-Phys</italic>, 2018, 284: 209 doi: 10.1016/j.sna.2018.10.036 [4] Yao M S, Tang W X, Wang G E, et al. MOF thin film-coated metal oxide nanowire array: significantly improved chemiresistor sensor performance. <italic>Adv Mater</italic>, 2016, 28(26): 5229 doi: 10.1002/adma.201506457 [5] Zhan S, Li D M, Liang S F, et al. A novel flexible room temperature ethanol gas sensor based on SnO<sub>2</sub> doped poly-diallyldimethylammonium chloride. <italic>Sensors</italic>, 2013, 13(4): 4378 doi: 10.3390/s130404378 [6] Tonezzer M, Lacerda R G. Zinc oxide nanowires on carbon microfiber as flexible gas sensor. <italic>Physica E</italic>, 2012, 44(6): 1098 doi: 10.1016/j.physe.2010.11.029 [7] Lin J, Liang F, Lu X Y, et al. Modeling and designing fault-tolerance mechanisms for MPI-based mapreduce data computing framework // 2015 IEEE First International Conference on Big Data Computing Service and Applications. Redwood City, 2015: 176 [8] Yang D J, Kamienchick I, Youn D Y, et al. Ultrasensitive and highly selective gas sensors based on electrospun SnO<sub>2</sub> nanofibers modified by Pd loading. <italic>Adv Funct Mater</italic>, 2010, 20(24): 4258 doi: 10.1002/adfm.201001251 [9] Zhang X L, Fan W, Li H, et al. Extending cycling life of lithium–oxygen batteries based on novel catalytic nanofiber membrane and controllable screen-printed method. <italic>J Mater Chem A</italic>, 2018, 6(43): 21458 doi: 10.1039/C8TA07884J [10] Zhang X L, Fan W, Zhao S Y, et al. An efficient, bifunctional catalyst for lithium–oxygen batteries obtained through tuning the exterior Co<sup>2+</sup>/Co<sup>3+</sup> ratio of CoO<sub><italic>x</italic></sub> on N-doped carbon nanofibers. <italic>Catal Sci Technol</italic>, 2019, 9(8): 1998 doi: 10.1039/C9CY00477G [11] Yang W, Li N W, Zhao S Y, et al. A breathable and screen-printed pressure sensor based on nanofiber membranes for electronic skins. <italic>Adv Mater Technol</italic>, 2018, 3(2): 1700241 doi: 10.1002/admt.201700241 [12] Koo W T, Choi S J, Kim S J, et al. Heterogeneous sensitization of metal-organic framework driven metal@metal oxide complex catalysts on oxide nanofiber scaffold toward superior gas sensors. <italic>J Am Chem Soc</italic>, 2016, 138(40): 13431 doi: 10.1021/jacs.6b09167 [13] Koo W T, Jang J S, Choi S J, et al. Metal-organic framework templated catalysts: dual sensitization of PdO–ZnO composite on hollow SnO<sub>2</sub> nanotubes for selective acetone sensors. <italic>ACS Appl Mater Interfaces</italic>, 2017, 9(21): 18069 doi: 10.1021/acsami.7b04657 [14] Wu X N, Xiong S S, Gong Y, et al. MOF–SMO hybrids as a H<sub>2</sub>S sensor with superior sensitivity and selectivity. <italic>Sensors Actuat B</italic>:<italic>Chem</italic>, 2019, 292: 32 doi: 10.1016/j.snb.2019.04.076 [15] Talin A A, Centrone A, Ford A C, et al. Tunable electrical conductivity in metal-organic framework thin film devices. <italic>Science</italic>, 2014, 343(6166): 66 doi: 10.1126/science.1246738 [16] Shi J D, Liu S, Zhang L S, et al. Smart textile-integrated microelectronic systems for wearable applications. <italic>Adv Mater</italic>, 2020, 32(5): 1901958 doi: 10.1002/adma.201901958 [17] Zhang Y Y, Yuan S, Feng X, et al. Preparation of nanofibrous metal-organic framework filters for efficient air pollution control. <italic>J Am Chem Soc</italic>, 2016, 138(18): 5785 doi: 10.1021/jacs.6b02553 [18] Bradshaw D, Garai A, Huo J. Metal-organic framework growth at functional interfaces: thin films and composites for diverse applications. <italic>Chem Soc Rev</italic>, 2012, 41(6): 2344 doi: 10.1039/C1CS15276A [19] Denny Jr M S, Moreton J C, Benz L, et al. Metal–organic frameworks for membrane-based separations. <italic>Nat Rev Mater</italic>, 2016, 1(12): 16078 doi: 10.1038/natrevmats.2016.78 [20] López-Maya E, Montoro C, Rodríguez-Albelo L M, et al. Textile/metal-organic-framework composites as self-detoxifying filters for chemical-warfare agents. <italic>Angew Chem Int Ed</italic>, 2015, 54(23): 6790 doi: 10.1002/anie.201502094 [21] Liu J X, W?ll C. Surface-supported metal–organic framework thin films: fabrication methods, applications, and challenges. <italic>Chem Soc Rev</italic>, 2017, 46(19): 5730 doi: 10.1039/C7CS00315C [22] Li M Y, Dinc? M. Reductive electrosynthesis of crystalline metal-organic frameworks. <italic>J Am Chem Soc</italic>, 2011, 133(33): 12926 doi: 10.1021/ja2041546 [23] Ozer R R, Hinestroza J P. One-step growth of isoreticular luminescent metal–organic frameworks on cotton fibers. <italic>RSC Adv</italic>, 2015, 5(25): 19400 doi: 10.1039/C5RA90014J [24] Zhang J L, Ar D, Yu X J, et al. Patterned deposition of metal-organic frameworks onto plastic, paper, and textile substrates by inkjet printing of a precursor solution. <italic>Adv Mater</italic>, 2013, 25(33): 4631 doi: 10.1002/adma.201301626 [25] Smith M K, Mirica K A. Self-organized frameworks on textiles (SOFT): conductive fabrics for simultaneous sensing, capture, and filtration of gases. <italic>J Am Chem Soc</italic>, 2017, 139(46): 16759 doi: 10.1021/jacs.7b08840 [26] Hmadeh M, Lu Z, Liu Z, et al. New porous crystals of extended metal-catecholates. <italic>Chem Mater</italic>, 2012, 24(18): 3511 doi: 10.1021/cm301194a [27] Sheberla D, Sun L, Blood-Forsythe M A, et al. High electrical conductivity in Ni-3(2, 3, 6, 7, 10, 11-hexaiminotriphenyl-ene)(2), a semiconducting metal-organic graphene analogue. <italic>J Am Chem Soc</italic>, 2014, 136(25): 8859 doi: 10.1021/ja502765n [28] Rui K, Wang X S, Du M, et al. Dual-function metal–organic framework-based wearable fibers for gas probing and energy storage. <italic>ACS Appl Mater Interfaces</italic>, 2018, 10(3): 2837 doi: 10.1021/acsami.7b16761 [29] Ghanbarian M, Zeinali S, Mostafavi A. A novel MIL-53(Cr-Fe)/Ag/CNT nanocomposite based resistive sensor for sensing of volatile organic compounds. <italic>Sensors Actuat B-Chem</italic>, 2018, 267: 381 doi: 10.1016/j.snb.2018.02.138 [30] Choi S J, Choi H J, Koo W T, et al. Metal-organic framework-templated PdO-Co<sub>3</sub>O<sub>4</sub> nanocubes functionalized by SWCNTs: improved NO<sub>2</sub> reaction kinetics on flexible heating film. <italic>ACS Appl Mater Interfaces</italic>, 2017, 9(46): 40593 doi: 10.1021/acsami.7b11317 -

下載:

下載: