Uniaxial compression failure and energy dissipation of marble specimens with flaws at the end surface

-

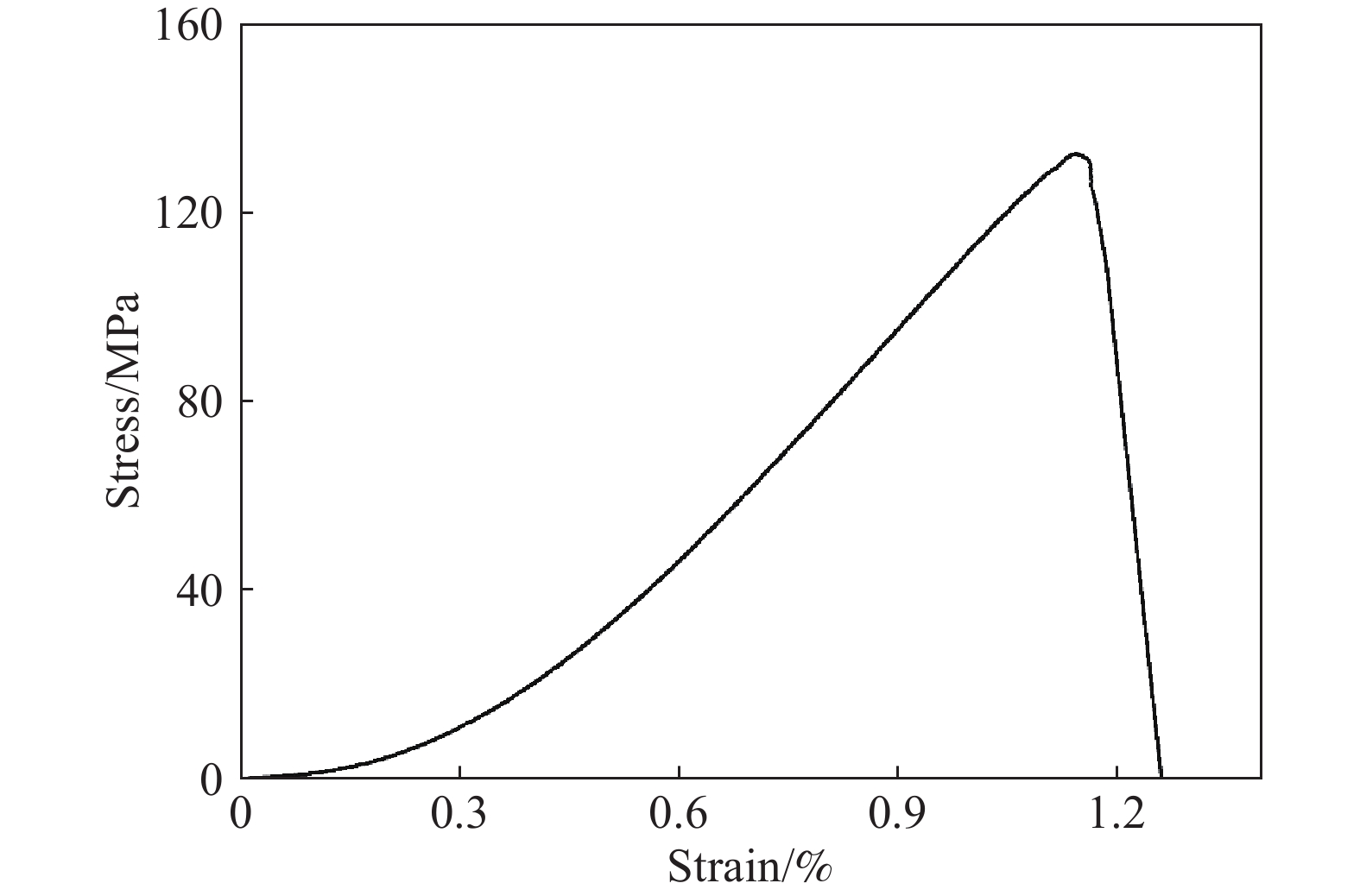

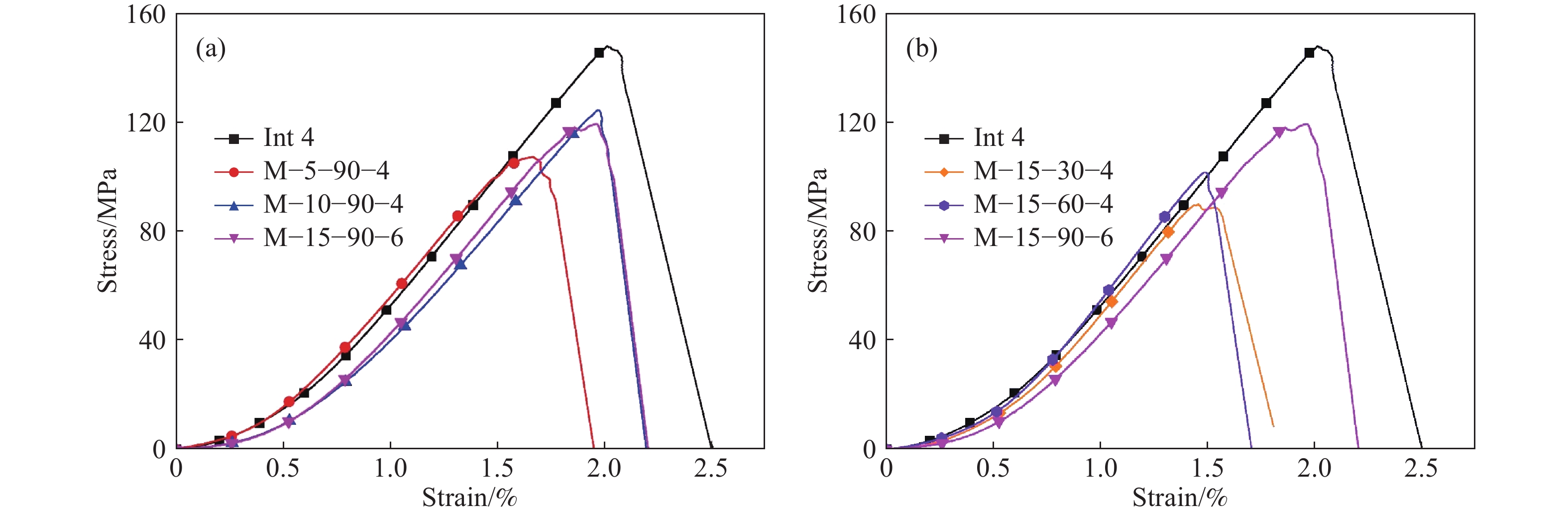

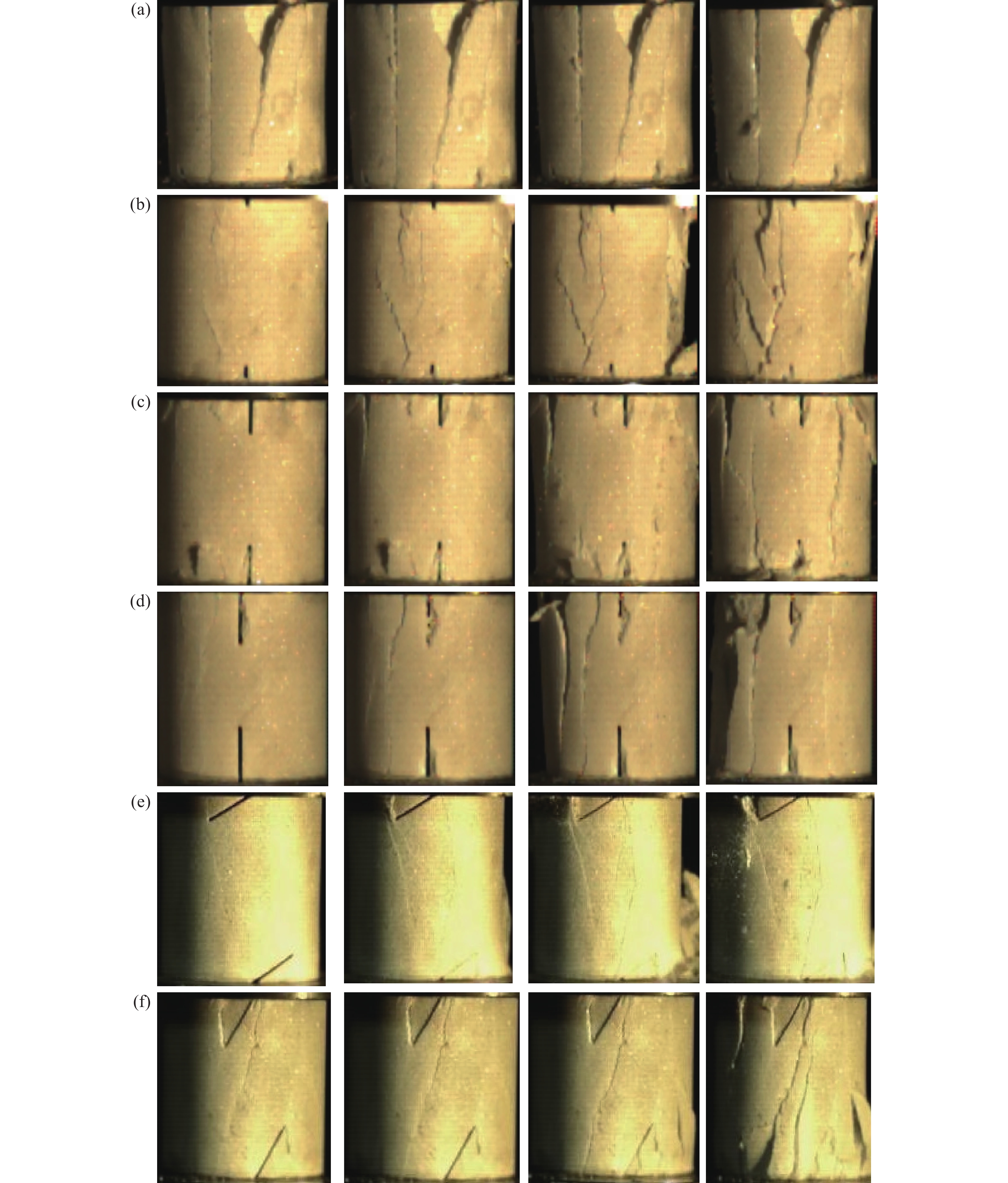

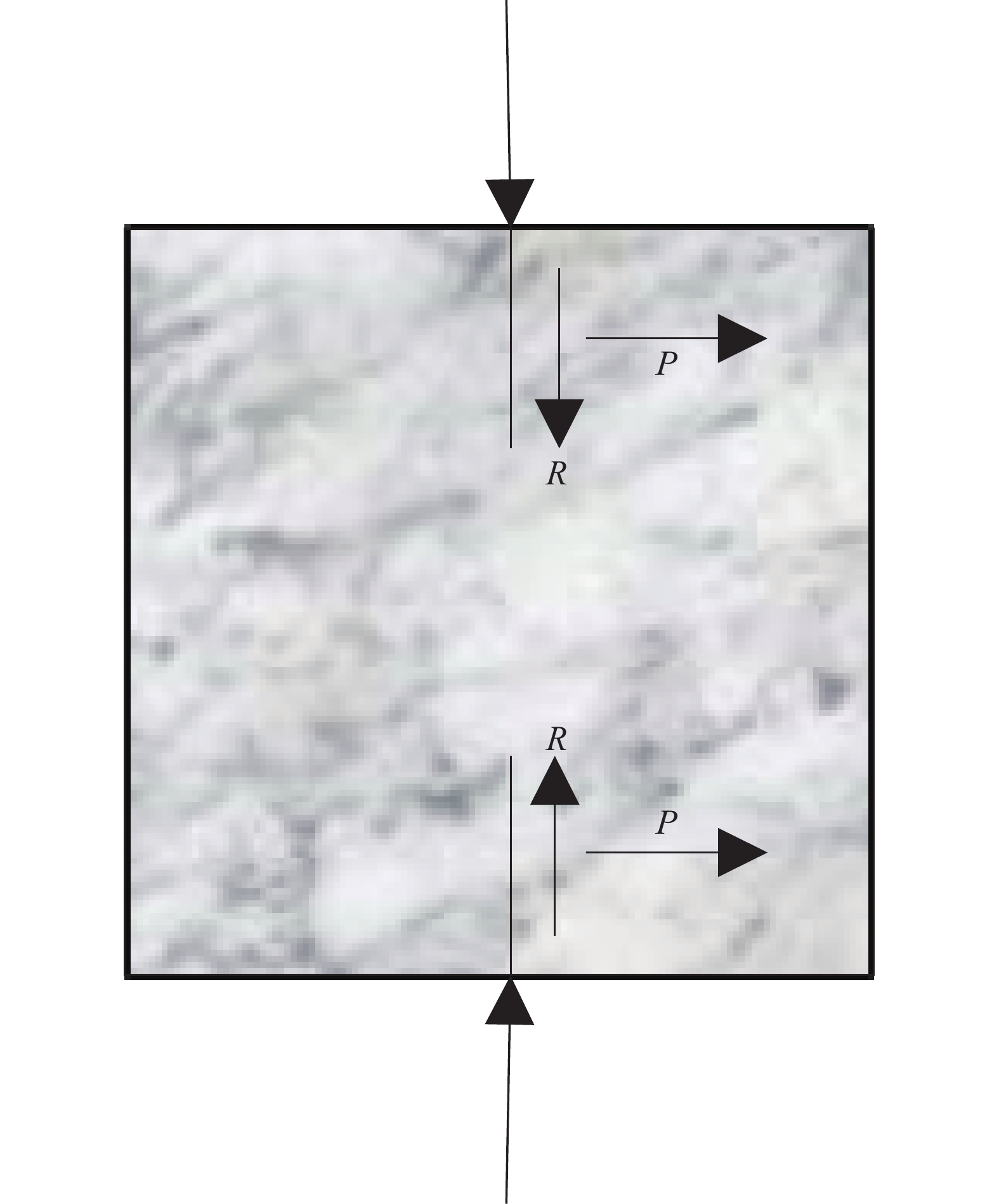

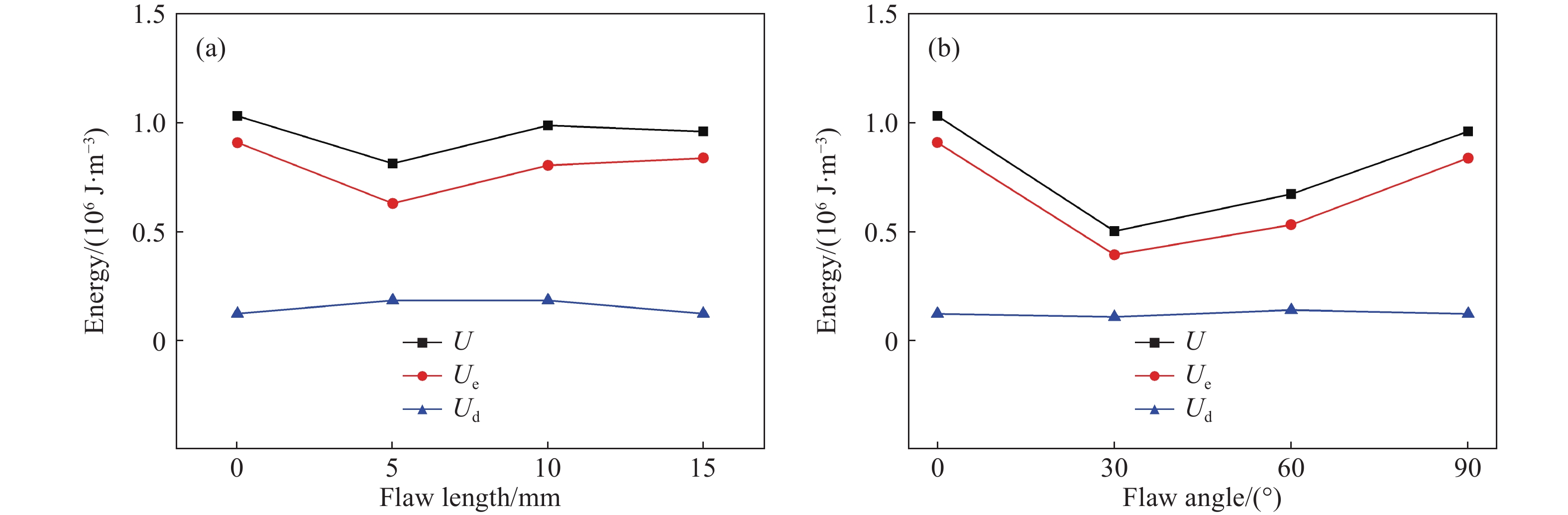

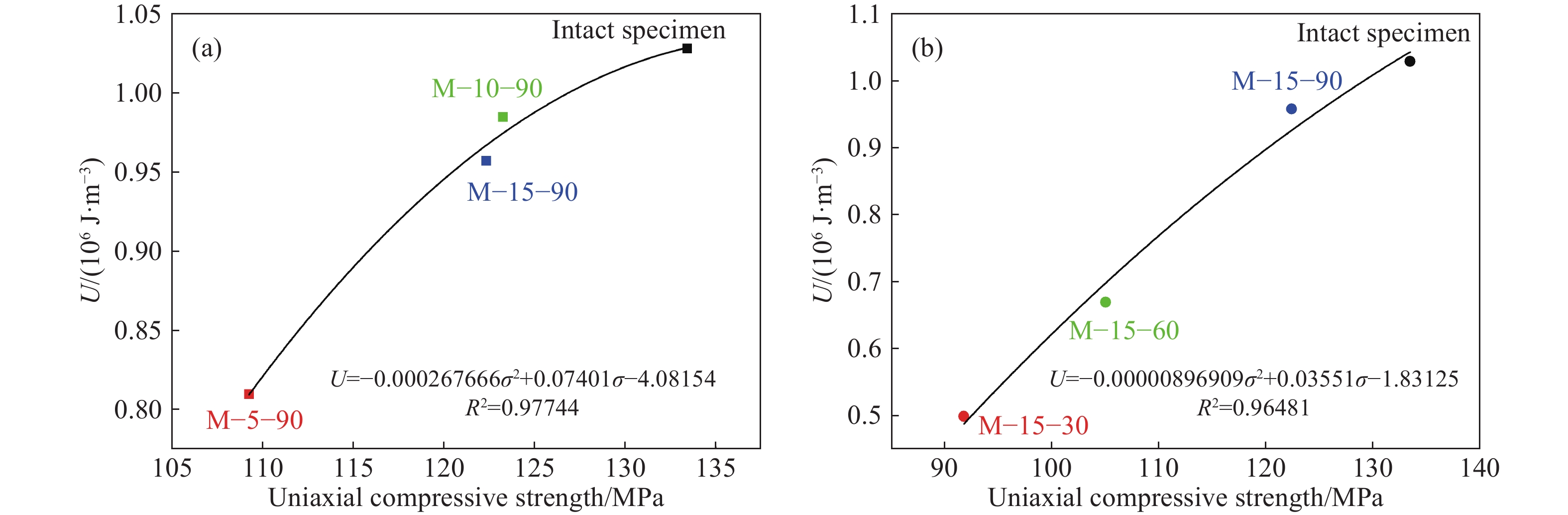

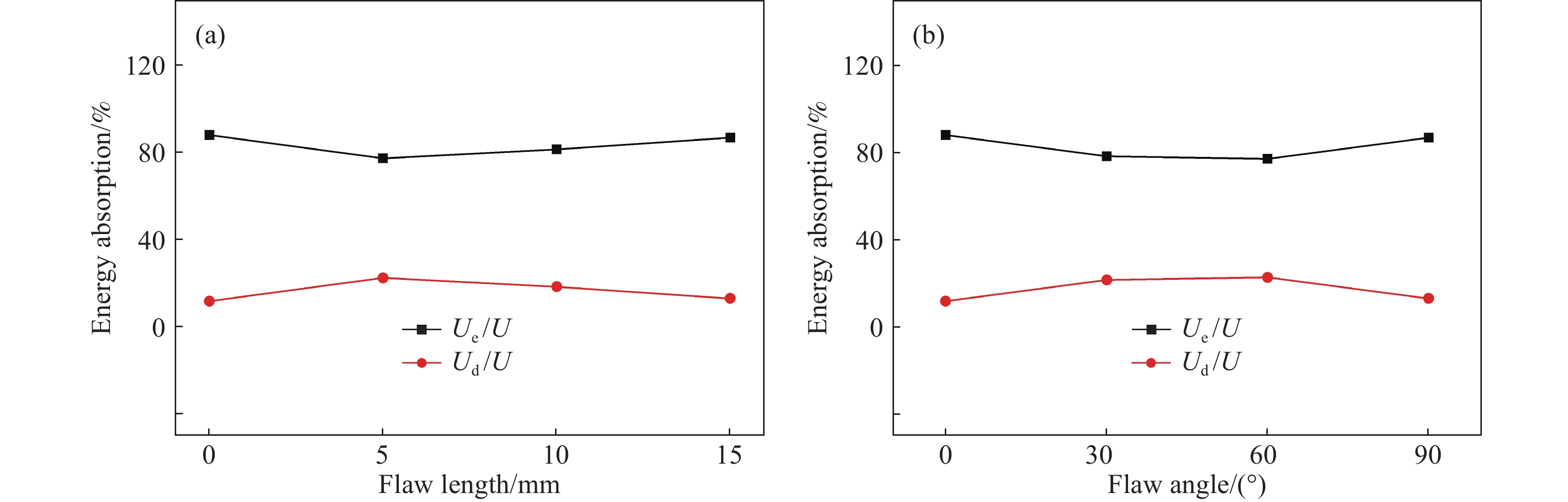

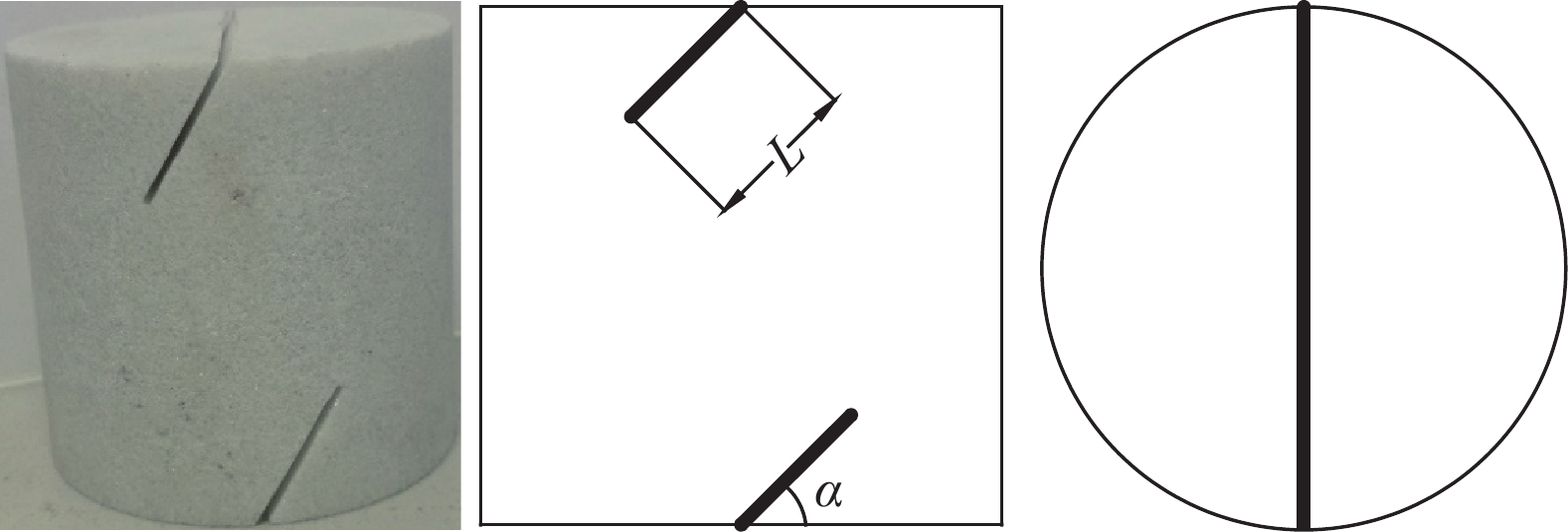

摘要: 對含端部雙裂隙?50 mm×50 mm的圓柱體大理巖試樣進行單軸壓縮試驗,并利用高速攝影儀實時記錄試樣破壞過程,研究了端部裂隙長度和傾角對大理巖力學特性及裂紋擴展規律的影響。研究表明,當裂隙長度達到門檻值前,試樣的單軸抗壓強度的弱化程度較低,彈性模量、峰值應變的變化較小。相對垂直裂隙,相同長度的傾斜裂隙對大理巖的影響更加顯著。試驗結果與理論分析均表明,裂紋一般不從端部垂直裂隙尖端起裂,試樣的起裂裂紋大多發展為主裂紋,擴展過程中較少產生分支與分叉,試樣表面會產生局部剝落,傾斜裂隙試樣宏觀上呈剪切或拉剪復合破壞,垂直裂隙試樣呈劈裂拉伸破壞。試樣能耗參數與單軸抗壓強度的變化趨勢一致,試樣總應變能和其單軸抗壓強度有較好的正相關關系。最后,比較了動、靜載荷作用下含端部裂隙大理巖力學響應與裂紋擴展過程的差異。Abstract: It is a fact that a large number of defects such as cracks, voids, inclusions, weak planes, and joint sets are generated within the rock mass during the process of rock formation because of geological-tectonic evolution. The existence of these preexisting natural defects poses potential threats to the stability and safety of structures built on the rock mass. Therefore, it is highly significant to better understand the effects of the preexisting defects on the rock mechanical and fracture behaviors for the stability and safety assessment of rock structures. Uniaxial compression tests were carried out by using ?50 mm × 50 mm cylindrical marble specimens with double parallel flaws at end surfaces. When tests were performed, a high speed camera was used to capture the failure processes of the marble specimens. The effects of the flaw length and inclination angle on the mechanical properties and crack propagation of marble specimens were investigated. Further, the experimental results indicate that the uniaxial compressive strength, elastic modulus, and peak strain of the specimen decrease slightly before the flaw length reaches the threshold value. Compared to flaws at vertical angle 90°, flaws at inclined angles (0°<α<90°) of the same length have larger effect on the mechanical properties of marble. It is found from both the experimental and theoretical analysis that cracks usually do not start from the tip of vertical end flaws and most of initiation cracks are developed into dominant cracks. In addition, there are few branches and bifurcations in the crack propagation process, and further, local spalling also occurs at the surface of the specimen. The specimens with inclined flaws exhibit shear failure or combined shear and tensile failure and the ones with vertical end flaws show axial splitting tensile failure. The variation trend of energy consumption parameters is consistent with that of uniaxial compressive strength. It is found that total strain energy of the specimen is positively correlated with its uniaxial compressive strength. Finally, the difference between mechanical and crack propagation processes of marble specimens with end flaws under dynamic and static loads were compared.

-

Key words:

- rock mechanics /

- marble /

- flaws at the end surfaces /

- strength /

- crack propagation /

- energy evolution

-

表 1 動、靜態加載下含裂隙大理巖的力學參數均值[3]

Table 1. Mechanical parameters of flawed marble specimens under dynamic and static loads

Loading type Specimen Peak strength/

MPaElastic modulus/

GPaPeak strain/

10?2Static uniaxial compression Intact 133.40 5.94 1.95 SM–5–90 109.29 5.87 1.83 SM–10–90 123.27 5.42 2.01 SM–15–30 91.82 5.93 1.41 SM–15–60 105.04 5.76 1.55 SM–15–90 122.36 5.88 1.84 Dynamic loading DM–15–30 97.0 32.8 0.40 DM–15–60 129.0 32.8 0.52 DM–15–90 204.0 45.7 0.46 Note:S represents the static uniaxial compression test,D represents the dynamic unconfined compression test,M represents marble,5/10/15 is the flaw length,and 30/60/90 is the flaw angle. 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Zou C J, Wong L N Y, Loo J J, et al. Different mechanical and cracking behaviors of single-flawed brittle gypsum specimens under dynamic and quasi-static loadings. Eng Geol, 2016, 201: 71 doi: 10.1016/j.enggeo.2015.12.014 [2] Li D Y, Han Z Y, Sun X L, et al. Dynamic mechanical properties and fracturing behavior of marble specimens containing single and double flaws in SHPB tests. Rock Mech Rock Eng, 2019, 52(6): 1623 doi: 10.1007/s00603-018-1652-5 [3] Li D Y, Han Z Y, Sun X L, et al. Characteristics of dynamic failure of marble with artificial flaws under split Hopkinson pressure bar tests. Chin J Rock Mech Eng, 2017, 36(12): 2872李地元, 韓震宇, 孫小磊, 等. 含預制裂隙大理巖SHPB動態力學破壞特性試驗研究. 巖石力學與工程學報, 2017, 36(12):2872 [4] Bobet A, Einstein H H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min Sci, 1998, 35(7): 863 doi: 10.1016/S0148-9062(98)00005-9 [5] Yang S Q, Dai Y H, Han L J, et al. Experimental study on mechanical behavior of brittle marble samples containing different flaws under uniaxial compression. Eng Fract Mech, 2009, 76(12): 1833 doi: 10.1016/j.engfracmech.2009.04.005 [6] Yang S Q. Study of strength failure and crack coalescence behavior of sandstone containing three pre-existing fissures. Rock Soil Mech, 2013, 34(1): 31楊圣奇. 斷續三裂隙砂巖強度破壞和裂紋擴展特征研究. 巖土力學, 2013, 34(1):31 [7] Yang S Q, Huang Y H. Failure behaviour of rock-like materials containing two pre-existing unparallel flaws: an insight from particle flow modeling. Eur J Environ Civil Eng, 2018, 22(Suppl 1): s57 [8] Huang Y H, Yang S Q, Zeng W. Experimental and numerical study on loading rate effects of rock-like material specimens containing two unparallel fissures. J Cent South Univ, 2016, 23(6): 1474 doi: 10.1007/s11771-016-3200-3 [9] Liu Y, Dai F, Dong L, et al. Experimental investigation on the fatigue mechanical properties of intermittently jointed rock models under cyclic uniaxial compression with different loading parameters. Rock Mech Rock Eng, 2018, 51(1): 47 doi: 10.1007/s00603-017-1327-7 [10] Liu Y, Dai F, Zhao T, et al. Numerical investigation of the dynamic properties of intermittent jointed rock models subjected to cyclic uniaxial compression. Rock Mech Rock Eng, 2017, 50(1): 89 doi: 10.1007/s00603-016-1085-y [11] Liu Y, Dai F, Fan P X, et al. Experimental investigation of the influence of joint geometric configurations on the mechanical properties of intermittent jointed rock models under cyclic uniaxial compression. Rock Mech Rock Eng, 2017, 50(6): 1453 doi: 10.1007/s00603-017-1190-6 [12] Li J C, Ma G W, Huang X. Analysis of wave propagation through a filled rock joint. Rock Mech Rock Eng, 2010, 43(6): 789 doi: 10.1007/s00603-009-0033-5 [13] Li J C, Ma G W, Zhao J. An equivalent viscoelastic model for rock mass with parallel joints. J Geophys Res Solid Earth, 2010, 115(B3): B03305 [14] Li J C, Ma G W, Zhao J. Analysis of stochastic seismic wave interaction with a slippery rock fault. Rock Mech Rock Eng, 2011, 44(1): 85 doi: 10.1007/s00603-010-0109-2 [15] Li J C, Li H B, Ma G W, et al. A time-domain recursive method to analyse transient wave propagation across rock joints. Geophys J Int, 2012, 188(2): 631 doi: 10.1111/j.1365-246X.2011.05286.x [16] Zhao J, Cai J G. Transmission of elastic P-waves across single fractures with a nonlinear normal deformational behavior. Rock Mech Rock Eng, 2001, 34(1): 3 doi: 10.1007/s006030170023 [17] Zhao J, Zhao X B, Cai J G. A further study of P-wave attenuation across parallel fractures with linear deformational behaviour. Int J Rock Mech Min Sci, 2006, 43(5): 776 doi: 10.1016/j.ijrmms.2005.12.007 [18] Yang S Q, Liu X R, Li Y S. Experimental analysis of mechanical behavior of sandstone containing hole and fissure under uniaxial compression. Chin J Rock Mech Eng, 2012, 31(Suppl 2): 3539楊圣奇, 劉相如, 李玉壽. 單軸壓縮下含孔洞裂隙砂巖力學特性試驗分析. 巖石力學與工程學報, 2012, 31(增刊2): 3539 [19] Yang S Q, Su C D, Xu W Y. Experimental and theoretical study of size effect of rock material. Eng Mech, 2005, 22(4): 112 doi: 10.3969/j.issn.1000-4750.2005.04.022楊圣奇, 蘇承東, 徐衛亞. 巖石材料尺寸效應的試驗和理論研究. 工程力學, 2005, 22(4):112 doi: 10.3969/j.issn.1000-4750.2005.04.022 [20] Liu B C, Zhang J S, Du Q Z, et al. A study of size effect for compression strength of rock. Chin J Rock Mech Eng, 1998, 17(6): 611 doi: 10.3321/j.issn:1000-6915.1998.06.001劉寶琛, 張家生, 杜奇中, 等. 巖石抗壓強度的尺寸效應. 巖石力學與工程學報, 1998, 17(6):611 doi: 10.3321/j.issn:1000-6915.1998.06.001 [21] Jing H W, Su H J, Yang D L, et al. Study of strength degradation law of damaged rock sample and its size effect. Chin J Rock Mech Eng, 2012, 31(3): 543 doi: 10.3969/j.issn.1000-6915.2012.03.012靖洪文, 蘇海健, 楊大林, 等. 損傷巖樣強度衰減規律及其尺寸效應研究. 巖石力學與工程學報, 2012, 31(3):543 doi: 10.3969/j.issn.1000-6915.2012.03.012 [22] Li D Y, Han Z Y, Zhu Q Q, et al. Stress wave propagation and dynamic behavior of red sandstone with single bonded planar joint at various angles. Int J Rock Mech Min Sci, 2019, 117: 162 doi: 10.1016/j.ijrmms.2019.03.011 [23] Xie H P, Ju Y, Li LY. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng, 2005, 24(17): 3003 doi: 10.3321/j.issn:1000-6915.2005.17.001謝和平, 鞠楊, 黎立云. 基于能量耗散與釋放原理的巖石強度與整體破壞準則. 巖石力學與工程學報, 2005, 24(17):3003 doi: 10.3321/j.issn:1000-6915.2005.17.001 [24] Xie H P, Peng R D, Ju Y, et al. On energy analysis of rock failure. Chin J Rock Mech Eng, 2005, 24(15): 2603 doi: 10.3321/j.issn:1000-6915.2005.15.001謝和平, 彭瑞東, 鞠楊, 等. 巖石破壞的能量分析初探. 巖石力學與工程學報, 2005, 24(15):2603 doi: 10.3321/j.issn:1000-6915.2005.15.001 [25] Xie H P, Peng R D, Ju Y. Energy dissipation of rock deformation and fracture. Chin J Rock Mech Eng, 2004, 23(21): 3565 doi: 10.3321/j.issn:1000-6915.2004.21.001謝和平, 彭瑞東, 鞠楊. 巖石變形破壞過程中的能量耗散分析. 巖石力學與工程學報, 2004, 23(21):3565 doi: 10.3321/j.issn:1000-6915.2004.21.001 [26] Zhang P, Yang C H, Wang H, et al. Stress-strain characteristics and anisotropy energy of shale under uniaxial compression. Rock Soil Mech, 2018, 39(6): 2106張萍, 楊春和, 汪虎, 等. 頁巖單軸壓縮應力–應變特征及能量各向異性. 巖土力學, 2018, 39(6):2106 [27] Li H. Rock Fracture Mechanics. Chongqing: Chongqing University Press, 1988李賀. 巖石斷裂力學. 重慶: 重慶大學出版社, 1988 [28] Chu F J, Liu D W, Tao M, et al. Dynamic damage laws of sandstone under different water bearing conditions based on nuclear magnetic resonance. Chin J Eng, 2018, 40(2): 144褚夫蛟, 劉敦文, 陶明, 等. 基于核磁共振的不同含水狀態砂巖動態損傷規律. 工程科學學報, 2018, 40(2):144 [29] Zhang Q B, Zhao J. Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads. Int J Rock Mech Min Sci, 2013, 60: 423 doi: 10.1016/j.ijrmms.2013.01.005 [30] Dai F, Huang S, Xia K W, et al. Some fundamental issues in dynamic compression and tension tests of rocks using split Hopkinson pressure bar. Rock Mech Rock Eng, 2010, 43(6): 65 -

下載:

下載: