Modified exponential model for carbon prediction in the end blowing stage of basic oxygen furnace converter

-

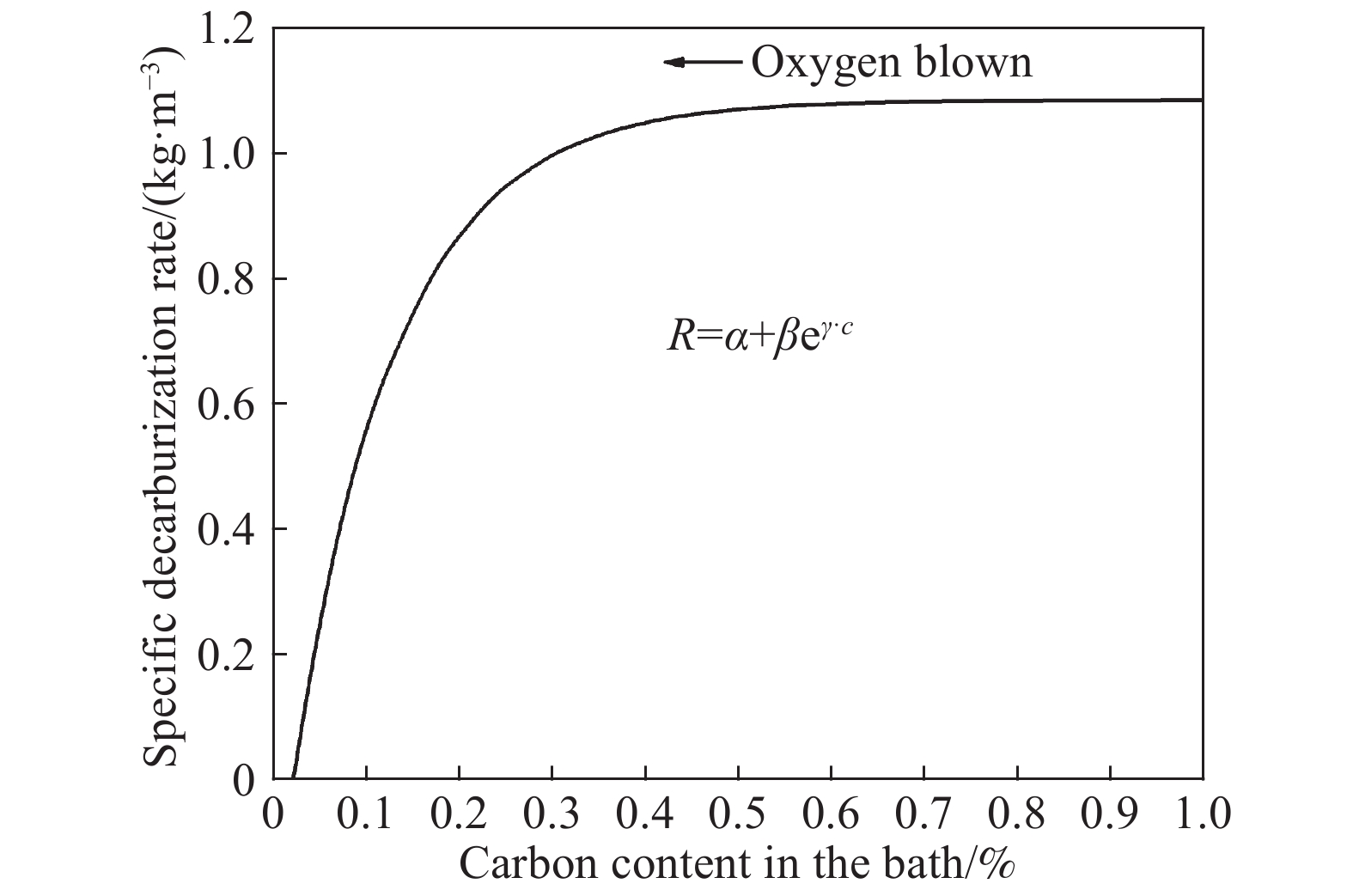

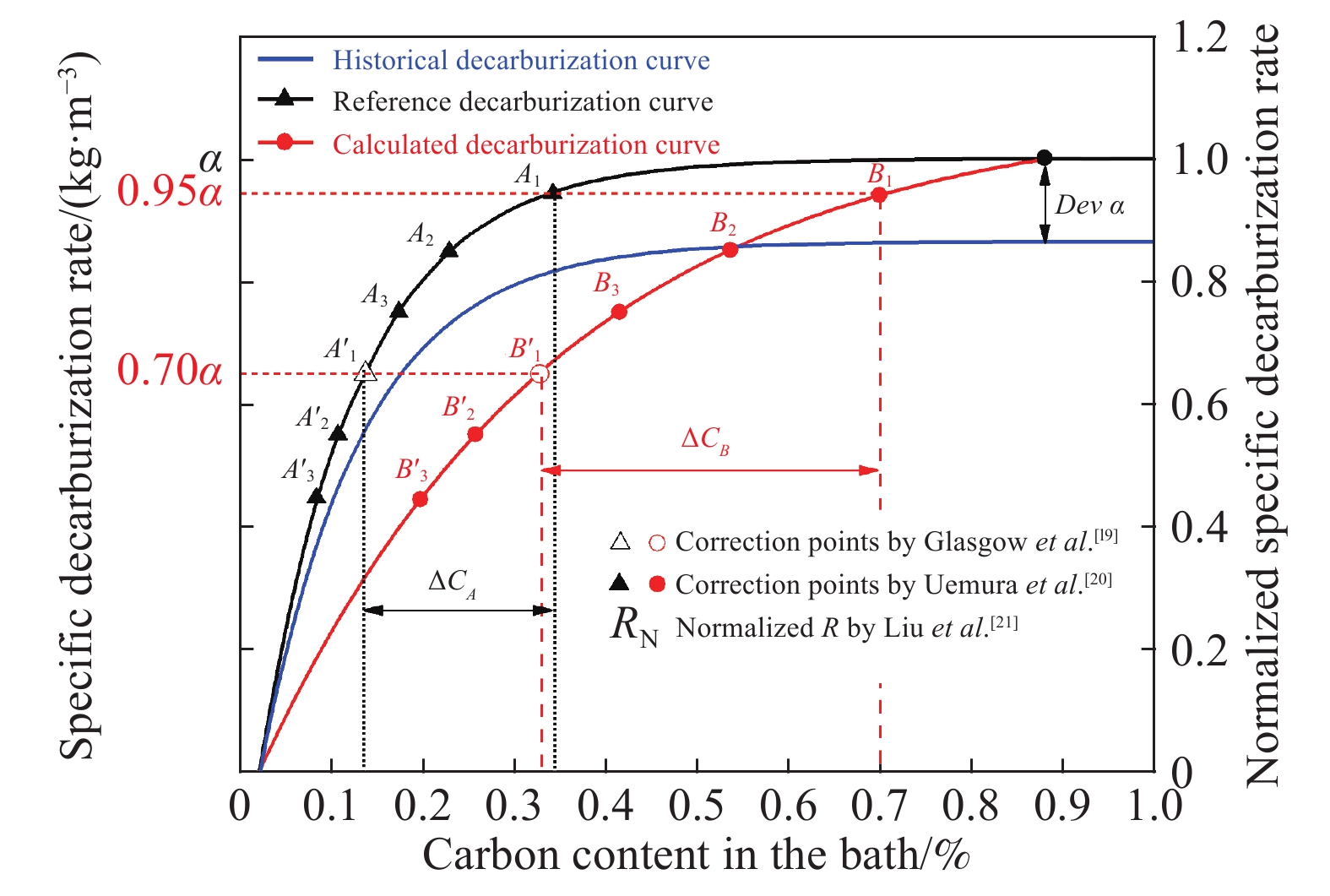

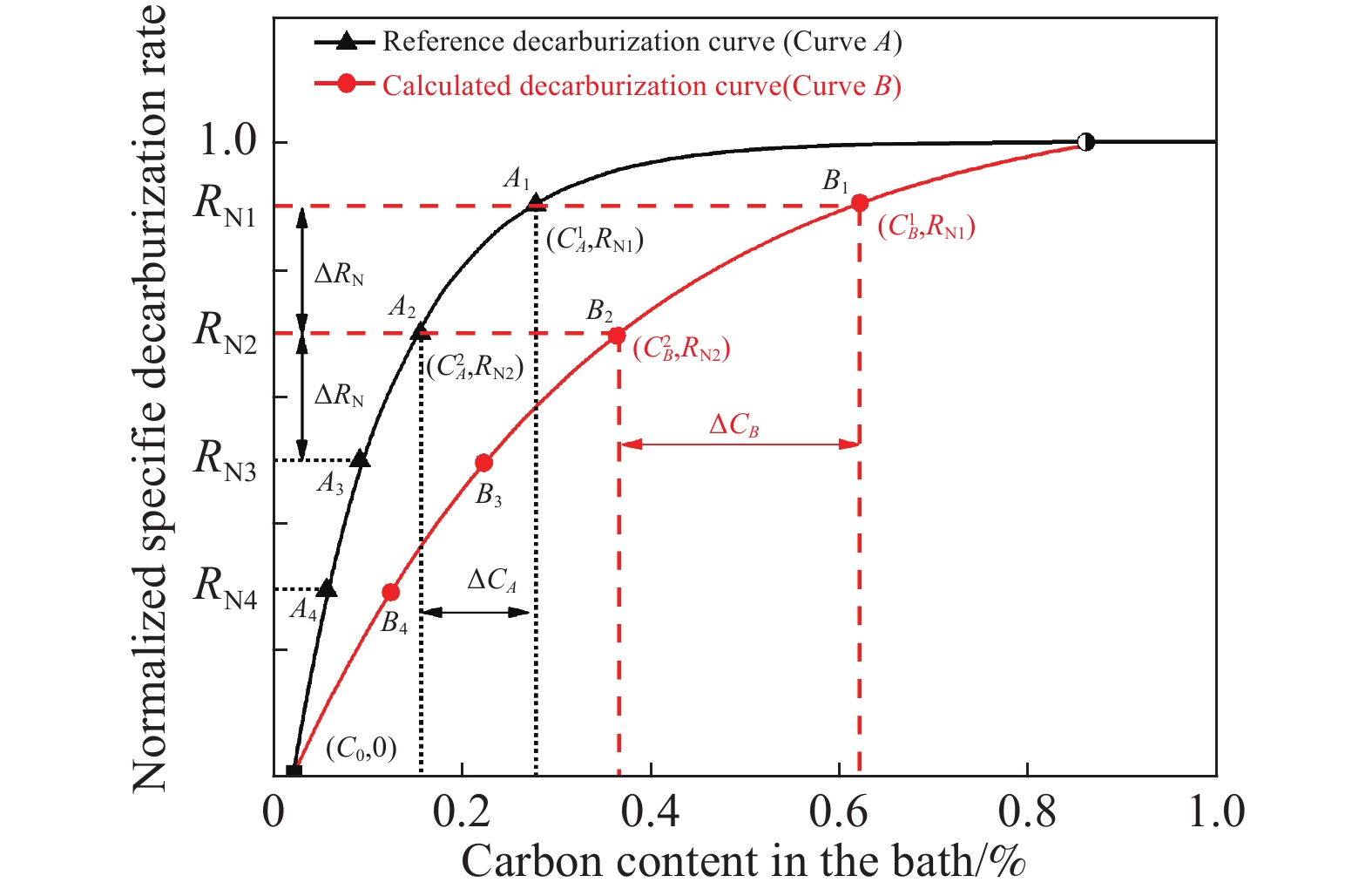

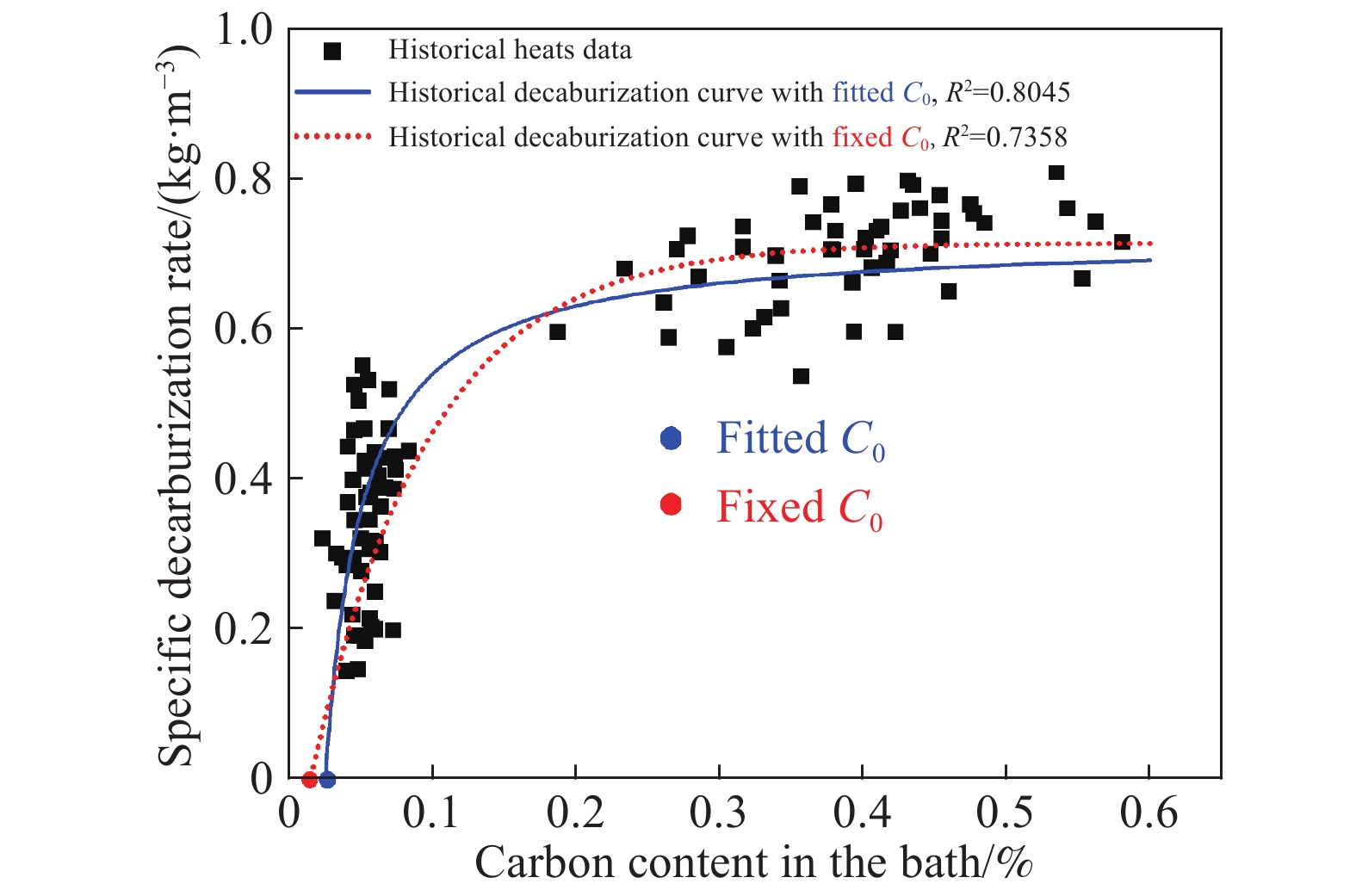

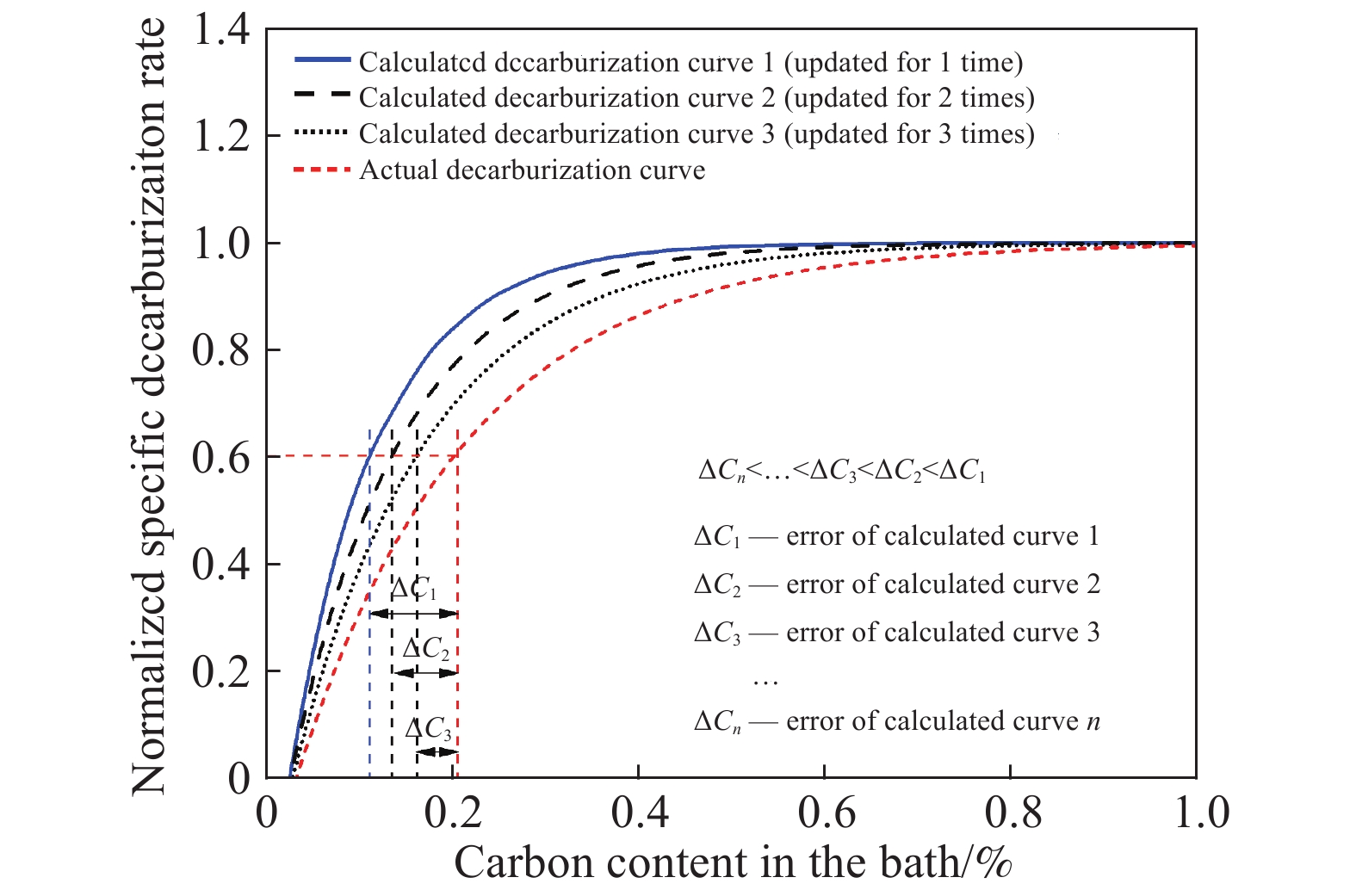

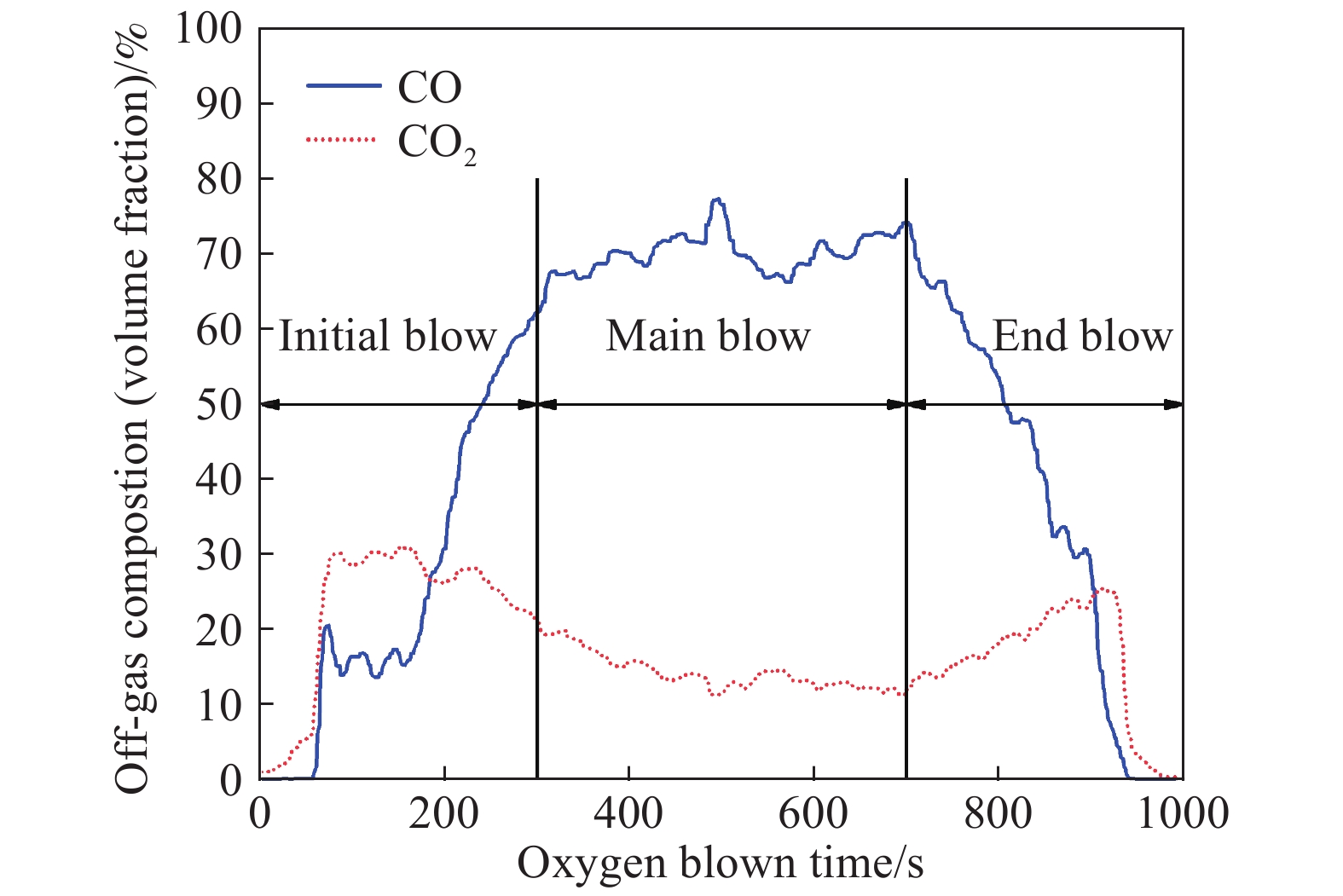

摘要: 介紹了幾種主要的轉爐煙氣分析碳含量預報模型,并分析了其中的指數衰減模型及其三種改進算法的基本原理和優缺點。在綜合三種模型優點的基礎上,提出了基于“極限碳含量擬合+曲線同步更新”算法的改進指數模型。首先,利用歷史爐次吹煉后期的脫碳氧效率和碳含量數據,通過指數擬合得到“歷史脫碳曲線”和極限碳含量參數;其次,使用當前爐次吹煉中期的最大脫碳氧效率值對“歷史脫碳曲線”的特征參數進行替換,得到當前爐次吹煉后期的“參考脫碳曲線”,再對其進行歸一化處理,得到歸一化的“參考脫碳曲線”;然后,采用多點校正的方法,計算當前爐次吹煉至各等距離校正點時“參考脫碳曲線”的脫碳量,并根據計算脫碳量與轉爐實際脫碳量的偏差,對熔池碳含量及脫碳曲線參數進行計算與校正,得到“計算脫碳曲線”;最后,通過逐次迭代計算對“參考脫碳曲線”和“計算脫碳曲線”進行同步更新,進而實現對轉爐吹煉后期熔池碳含量的精準預報。研究表明,改進的指數模型具有較高的準確率,終點碳含量預報誤差在±0.02%范圍內的命中率達到90%。Abstract: Several common models for carbon prediction were discussed based on an off-gas analysis of the basic oxygen furnace (BOF) process, and the basic principles, advantages and disadvantages of three exponential decay models with different correction algorithm were analyzed respectively. An improved exponential model of “critical carbon content fitting + update curves simultaneously” algorithm was established by combining the advantages of previous algorithms. Firstly, the historical decarburization curve in the end blowing stage and the critical carbon content in the bath were obtained by exponentially fitting the decarburization data of historical heats. Secondly, the reference decarburization curve was obtained by replacing the corresponding parameter of the historical decarburization curve with the maximum specific decarburization rate in the middle blowing stage of the real-time heat. Subsequently, the specific decarburization rates of the historical decarburization curve and the reference decarburization curve were converted to dimensionless values within the range of 0 to 1 by normalizing. Then, a multi-point correction method was used to correct the calculation results of the carbon content in the bath and repeatedly modify the key parameters of the calculated decarburization curve, according to the deviation of the removed carbon amount between the normalized reference curve and the actual process. The key parameters of the calculated and the reference decarburization curves were updated simultaneously after each calculation step, and the calculation error of the carbon content prediction decreased gradually through iterative calculation. Finally, the carbon content in the bath were precisely predicted in the end blowing stage of the BOF process. Plant trials were carried out in a BOF converter to demonstrate the performance of the proposed models. The results show that the new model exhibits better adaptability and higher accuracy than the other ones. The hit ratio of the new model to predict the end-point carbon content reaches 90% within a tolerance of ±0.02%.

-

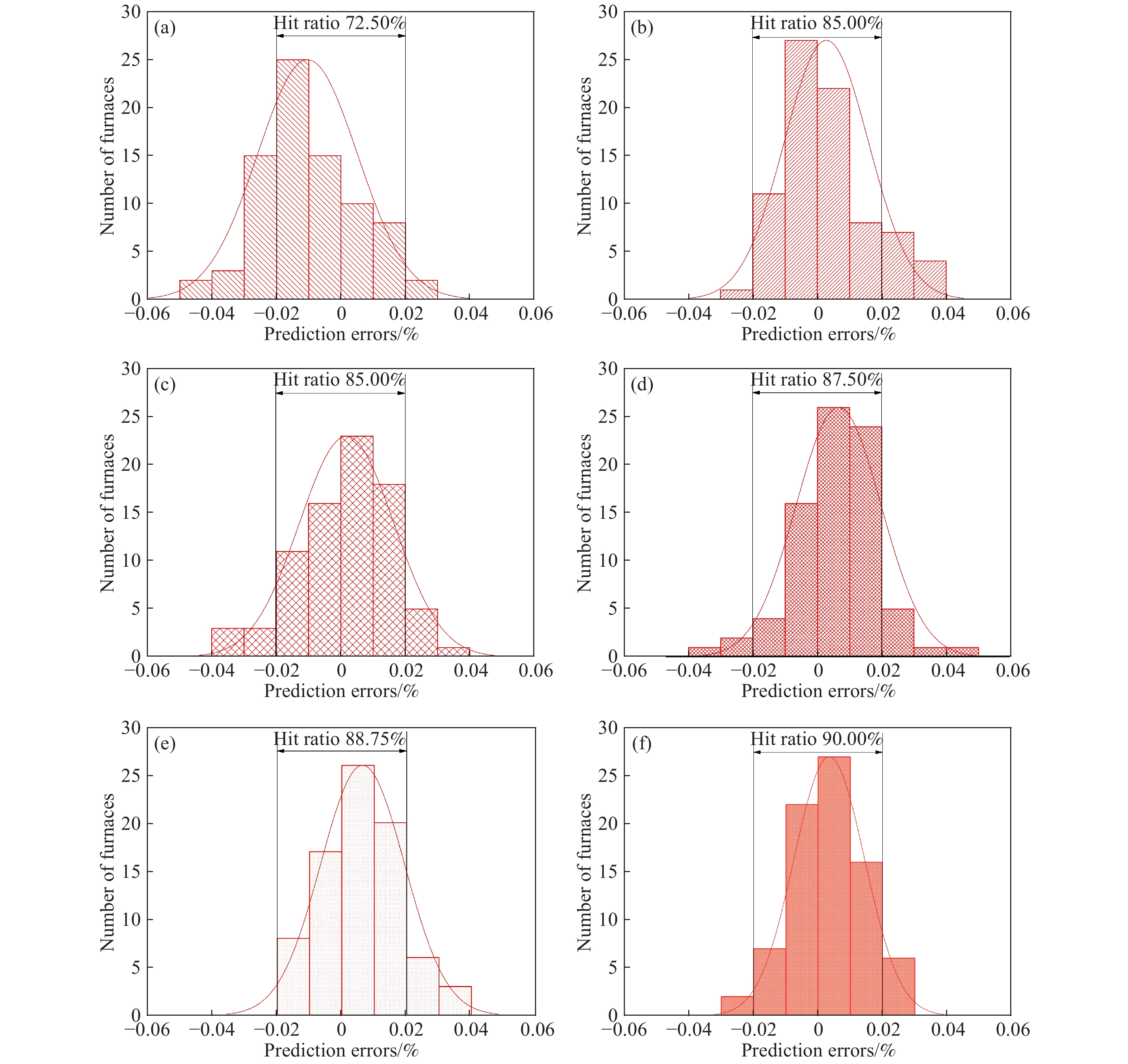

圖 7 不同模型預測誤差分布。(a)積分模型;(b)三次方模型;(c)固定C0且曲線不更新的指數模型;(d)固定C0且曲線更新的指數模型;(e)擬合C0且曲線不更新的指數模型;(f)擬合C0且曲線更新的指數模型

Figure 7. Prediction error distribution of the different models: (a) integral model; (b) cubic model; (c) exponential model with fixed C0 but without updated curve; (d) exponential model with fixed C0 and updated curve; (e) exponential model with fitted C0 but without updated curve; (f) exponential model with fitted C0 and updated curve

表 1 “極限碳含量擬合+曲線同步更新”算法改進模型驗證數據

Table 1. Validation of proposed model based on improved algorithm

% Heat No. Predicted end-point carbon content Actual end-point

carbon contentCurve updated for 1 time Curve updated for 2 times Curve updated for 3 times … Curve updated for n times H-1 0.0463 0.0519 0.0538 … 0.0558 0.0609 H-2 0.0412 0.0424 0.0462 … 0.0550 0.0501 H-3 0.0491 0.0529 0.0536 … 0.0559 0.0530 H-4 0.0450 0.0487 0.0510 … 0.0556 0.0591 H-5 0.0543 0.0619 0.0553 … 0.0567 0.0615 H-6 0.0502 0.0470 0.0614 … 0.0554 0.0625 H-7 0.0589 0.0571 0.0540 … 0.0563 0.0612 H-8 0.0686 0.0568 0.0565 … 0.0563 0.0485 H-9 0.0414 0.0452 0.0520 … 0.0582 0.0865 H-10 0.0434 0.0447 0.0505 … 0.0552 0.0673 表 2 幾種模型終點碳含量預測命中率

Table 2. Hit ratios of the different models

Model Hit ratio of end-point carbon prediction/%(ΔC≤±0.02%) Notes Integral model 72.50 Fig.7(a) Cubic model 85.00 Fig.7(b) Exponential model 85.00 Fig.7(c), fixed ${C_0}$, without updated curve 87.50 Fig.7(d), fitted ${C_0}$, without updated curve Modified exponential model proposed in current study 88.75 Fig.7(e), fixed ${C_0}$, with updated curve 90.00 Fig.7(f), fitted ${C_0}$, with updated curve 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Gutte H, Schulz T, Neuhof G, et al. Process control in the oxygen steel production. Acta Metall Sin Engl Lett, 2000, 13(6): 1101 [2] Li G H, Liu Q. Present status and prospect of BOF steelmaking process control. J Iron Steel Res, 2013, 25(1): 1李光輝, 劉青. 轉爐煉鋼過程工藝控制的發展與展望. 鋼鐵研究學報, 2013, 25(1):1 [3] Klingelhofer H, Schramm R, Lohndorf W, et al. Improving the converter process by use of a sublance. Steel Times, 1994, 222(4): 138 [4] Apeldoorn G J, Hubbeling P D, Gootjes P. Performance of Danieli Corus sublance systems. Iron Steel, 2004, 39(11): 29 doi: 10.3321/j.issn:0449-749X.2004.11.007Apeldoorn G J, Hubbeling P D, Gootjes P. 達涅利康力斯副槍系統的應用. 鋼鐵, 2004, 39(11):29 doi: 10.3321/j.issn:0449-749X.2004.11.007 [5] Zuo K L, Zou J S, Sun X H, et al. Sub-lance measuration and composition prediction in BOF steelmaking. Steelmaking, 2009, 25(2): 59左康林, 鄒俊蘇, 孫曉輝, 等. 轉爐副槍測量與成分預報技術. 煉鋼, 2009, 25(2):59 [6] Wu M, Li Y J. Practical analysis of dynamic control steelmaking technique of off gas analysis and assistant lance. Iron Steel, 2009, 44(4): 28 doi: 10.3321/j.issn:0449-749X.2009.04.007吳明, 李應江. 煙氣分析與副槍動態控制煉鋼技術的實踐分析. 鋼鐵, 2009, 44(4):28 doi: 10.3321/j.issn:0449-749X.2009.04.007 [7] Fukumi J, Taki C, Hatanaka T, et al. Development of refining control system in combined blowing converter based on exhaust gas information. Tetsu-to-Hagane, 1990, 76(11): 192福味純一, 滝千尋, 畑中聡男, 等. 排ガス情報を利用した転爐吹錬の計算機制御技術の開発. 鉄と鋼, 1990, 76(11):192 [8] Hu Z G, He P, Tan M X, et al. Continuous determination of bath carbon content on 150 t BOF by off-gas analyzer. J Univ Sci Technol Beijing, 2003, 10(6): 22 [9] Sun S, Liao D S, Pyke N, et al. Development of an offgas/model technology to replace sublance operation for KOBM endpoint carbon control at ArcelorMittal Dofasco. Iron Steel Technol, 2008, 5(11): 36 [10] Bruckner C, Rodhammer H, Wohlfart K, et al. Implementation of BOF level 2 with DYNACON model and LOMAS offgas analysis at Tangshan ISCO // Proceedings of Asia Steel International Conference (Asia Steel 2012). Beijing, 2012: 130 [11] Wang X H, Li J Z, Liu F G. Technological progress of BOF steelmaking in period of development mode transition. Steelmaking, 2017, 33(1): 1王新華, 李金柱, 劉鳳剛. 轉型發展形勢下的轉爐煉鋼科技進步. 煉鋼, 2017, 33(1):1 [12] Ceriani A, Aprile G. Dynamic modeling of the BOF for endpoint prediction using EFSOP? technology results and implementation at Riva Taranto // AISTech Proceedings. Pittsburg, 2010: 997 [13] Liao D S, Sun S, Waterfall S, et al. Integrated KOBM steelmaking process control // Proceeding of the 6th International Congress on the Science and Technology of Steelmaking. Beijing, 2015: 107 [14] Wang X, Zhou H, Li P. Application of automatic steelmaking system based on LOMAS flue gas analysis in 100 t converter. Hebei Metall, 2018(9): 58王肖, 周航, 李朋. 基于LOMAS煙氣分析的自動化煉鋼系統在100 t轉爐的應用. 河北冶金, 2018(9):58 [15] IRSID. Method and Arrangement for Measuring Continuously the Change of the Carbon Content of a Bath of Molten Metal: French Patent, 1309212. 1962-10-8IRSID. Procédé et Dispositif Pour la Mesure Continue de la Teneur en Carbone d'un Bain Métallique en Cours D'affinage: Brevet d'invention fran?ais, 1309212. 1962-10-8 [16] Dumont-Fillon J, Vayssiere P, Trentini B. Continuous carbon determination in the basic oxygen processes. JOM, 1964, 16(6): 508 doi: 10.1007/BF03378283 [17] Meyer H W, Dukelow D A, Fischer M M. Static and dynamic control of the basic oxygen process. JOM, 1964, 16(6): 501 doi: 10.1007/BF03378282 [18] Zhang G Y, Wan X F, Lin D, et al. Carbon content prediction at blowing end-point of converter with off-gas analysis. J Mater Metall, 2007, 6(1): 3 doi: 10.3969/j.issn.1671-6620.2007.01.001張貴玉, 萬雪峰, 林東, 等. 應用爐氣分析預測轉爐吹煉終點碳含量. 材料與冶金學報, 2007, 6(1):3 doi: 10.3969/j.issn.1671-6620.2007.01.001 [19] Glasgow J A, Porter W F, Morrill J. Development and operation of BOF dynamic control. JOM, 1967, 19(8): 81 doi: 10.1007/BF03378624 [20] Uemura T, Yamamoto T, Kitagawa Y, et al. Process computer system at the No. 3 BOF shop in Wakayama Steel Works. Sumitomo Metal, 1973, 25(1): 71植村卓郎, 山本哲也, 北川美教, 等. 和歌山製鉄所第三製鋼工場計算機制御. 住友金屬, 1973, 25(1):71 [21] Liu K, Liu L, He P, et al. A new algorithm of endpoint carbon content of BOF based on of off-gas analysis. Steelmaking, 2009, 25(1): 33劉錕, 劉瀏, 何平, 等. 基于煙氣分析轉爐終點碳含量控制的新算法. 煉鋼, 2009, 25(1):33 [22] Tu H. Study on Converter Dynamic Process Model Based on Flue Gas Detection[Dissertation]. Shanghai: Shanghai University, 2002屠海. 基于爐氣檢測的轉爐動態過程模型研究[學位論文]. 上海: 上海大學, 2002 [23] Li N, Lin W H, Cao L L, et al. Carbon prediction model for basic oxygen furnace off-gas analysis based on bath mixing degree. Chin J Eng, 2018, 40(10): 1244李南, 林文輝, 曹玲玲, 等. 基于熔池混勻度的轉爐煙氣分析定碳模型. 工程科學學報, 2018, 40(10):1244 [24] Li G H, Wang B, Liu Q, et al. A process model for BOF process based on bath mixing degree. Int J Miner Metall Mater, 2010, 17(6): 715 doi: 10.1007/s12613-010-0379-4 [25] Rout B K, Brooks G, Akbar Rhamdhani M, et al. Dynamic model of basic oxygen steelmaking process based on multizone reaction kinetics: modeling of decarburization. Metall Mater Trans B, 2018, 49(3): 1022 doi: 10.1007/s11663-018-1244-5 [26] Shukla A K, Deo B, Millman S, et al. An insight into the mechanism and kinetics of reactions in BOF steelmaking: theory vs practice. Steel Res Int, 2010, 81(11): 940 doi: 10.1002/srin.201000123 -

下載:

下載: