Research progress toward hydrogen embrittlement microstructure mechanism in Fe–Mn–(Al)–C high-strength-and-toughness steel

-

摘要: 隨著汽車行業的快速發展,輕量化汽車用鋼的研發和應用越來越廣泛。抗拉強度超過1000 MPa的第二、三代汽車用鋼往往是復相組織,通過固溶、析出、變形、細晶強化等各種強化方式,在基體中形成大量缺陷,導致鋼材服役過程中對氫更加敏感,容易在很小的氫溶解條件下發生氫脆。Fe?Mn?C系、Fe?Mn?Al?C系等含Mn量高的汽車結構用鋼因層錯能較高,不僅直接決定了其強韌性機制,還對其服役性能有重要影響。在Fe?Mn?C系TWIP鋼的成分基礎上,添加少量Al元素,形成Fe?Mn?(Al)?C鋼,不僅能降低鋼材密度,提高鋼材的強韌性,也因Al元素改變了鋼材的微觀組織構成,一定程度上令氫脆得到緩解。但當Al含量較高時,形成低密度鋼,其組織構成更加復雜,析出物更多,導致氫脆敏感性更顯著。本文從Fe?Mn?(Al)?C高強韌性鋼的組織構成、第二相、晶體缺陷等特征出發,綜述了H在Fe?Mn?(Al)?C鋼中的滲透、溶解和擴散行為,H與基體組織、析出相、晶格缺陷的交互作用,H在鋼中的作用模型、氫脆機制、氫脆評價手段和方法等。并評述了Fe?Mn?(Al)?C高強韌性鋼氫脆問題開展的相關研究工作和最新發展動態,指出通過第一性原理計算、分子動力學模擬和借助氫原子微印技術、三維原子探針等物理實驗相結合的方法是從微觀層面揭示高強韌性鋼氫脆機制的未來發展方向。Abstract: With the rapid development of the automobile industry, the development and application of lightweight automobile steel are increasingly extensive. The second- and third-generation automobile steels with a tensile strength of over 1000 MPa are usually of duplex structure. Through solid solution strengthening, precipitation, deformation, fine grain strengthening, and other strengthening methods, a large number of defects are formed in the matrix, which makes the steel more sensitive to hydrogen in the service process and prone to hydrogen embrittlement under very small hydrogen dissolution conditions. The high-Mn content steels Fe?Mn?C and Fe?Mn?Al?C steels have high stacking fault energy, which not only influences their strength and toughness but also significantly affects their service performance. Based on the composition of twinning-induced plasticity (TWIP) steel of the Fe?Mn?C system, adding a small amount of Al element to form Fe?Mn?(Al)?C steel can not only reduce the steel density and improve the steel strength and toughness but also change the steel microstructure to a certain extent; the effect on the microstructure reduces the steel susceptibility to hydrogen embrittlement. However, when the Al content is high, low-density steel with a more complex structure is formed, and the precipitates are more, which leads to a more significant sensitivity to hydrogen embrittlement. In this paper, the permeation, dissolution, and diffusion behavior of H in Fe?Mn?(Al)?C high-strength-and-toughness-steel; the interaction between H and the matrix structure, the precipitated phase, and lattice defects; the model of H in steel; the hydrogen embrittlement mechanism; and the methods of hydrogen embrittlement evaluation were summarized based on the structure, second phase, and crystal defects of Fe?Mn?(Al)?C high-strength-and-toughness steel. The related research work and the latest developments of the hydrogen embrittlement of Fe?Mn?(Al)?C high-strength-and-toughness steel were reviewed. The development direction of the hydrogen embrittlement microstructure mechanism of high-strength-and-toughness steel was revealed by combining first-principle calculations, molecular dynamics simulation, and physical experiments such as hydrogen atom microprinting technology and three-dimensional atomic probe analysis.

-

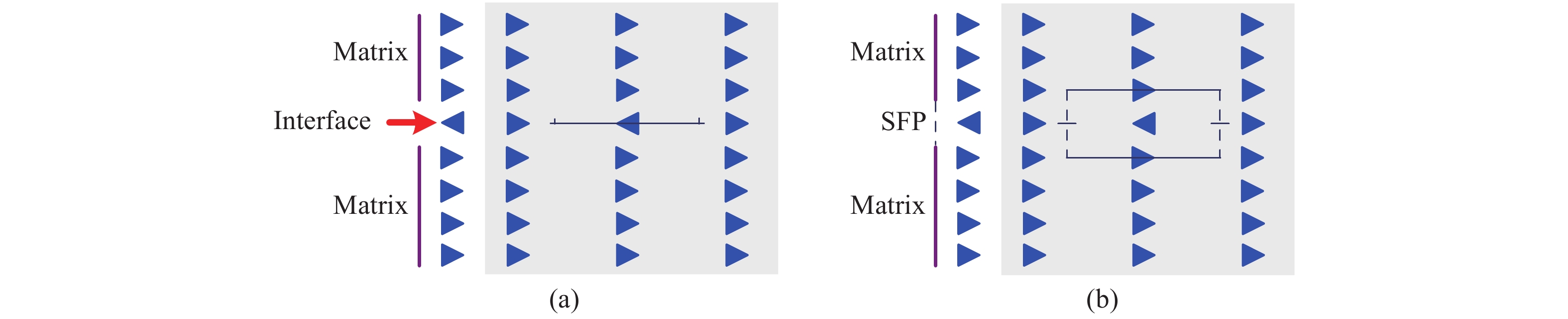

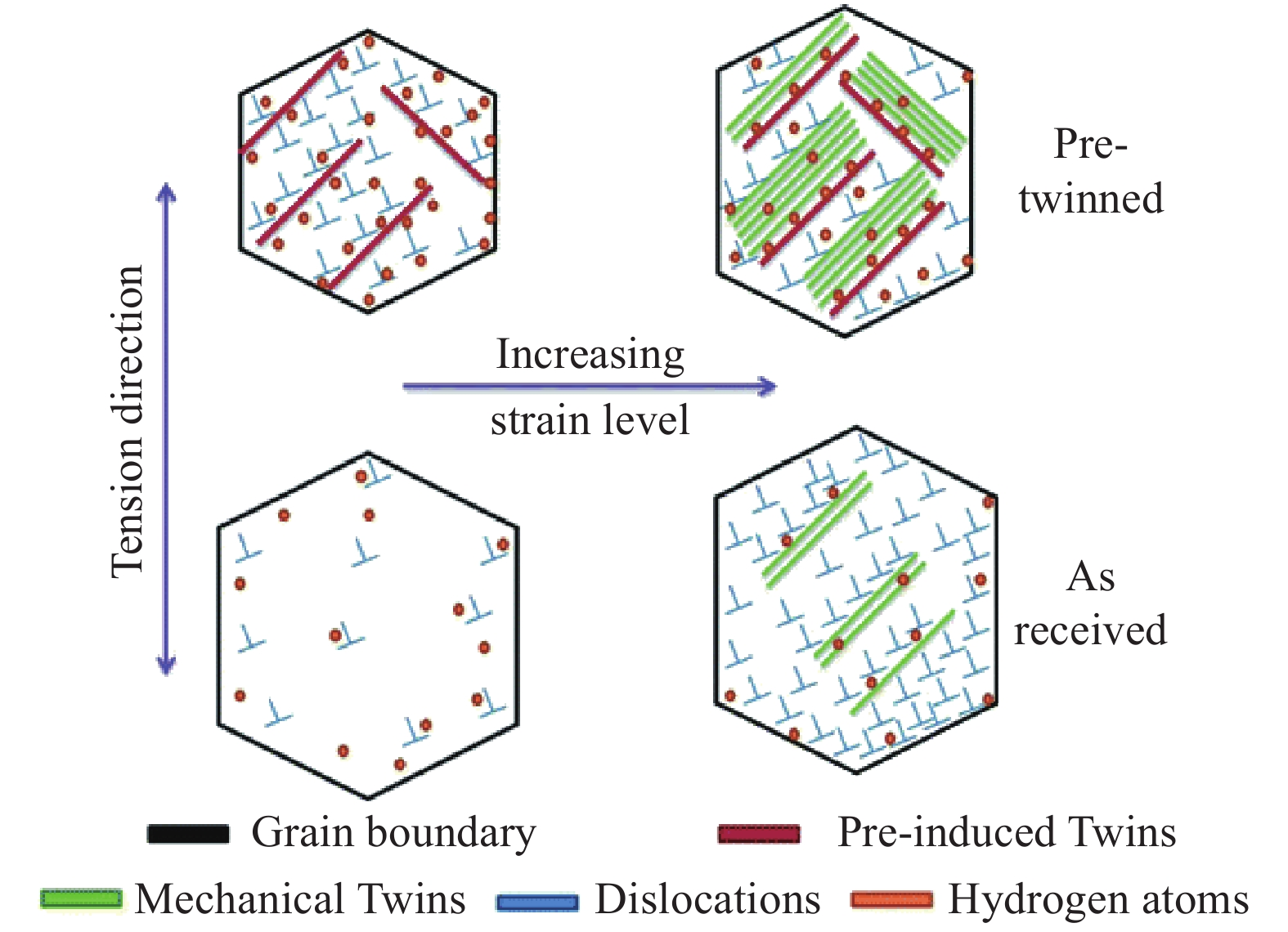

圖 5 變形孿晶界氫俘獲示意圖(TB:孿晶界)[38]。(a)變形孿晶尖端的應力集中;(b)位錯孿晶交叉形成的臺階處的應變場;(c)偽孿晶形成引起的晶格畸變;(d)變形孿晶的納米結構,包括位錯和納米孿晶帶

Figure 5. Schematics describing the factors affecting hydrogen trapping at the deformation twin boundaries (TB: twin boundary)[38]: (a) stress concentration at a tip of a deformation twin; (b) strain field at the steps formed by the dislocation–twin intersection; (c) lattice distortion due to pseudo-twin formation; (d) nanoscale structure of deformation twins, including dislocations and nanotwin plates

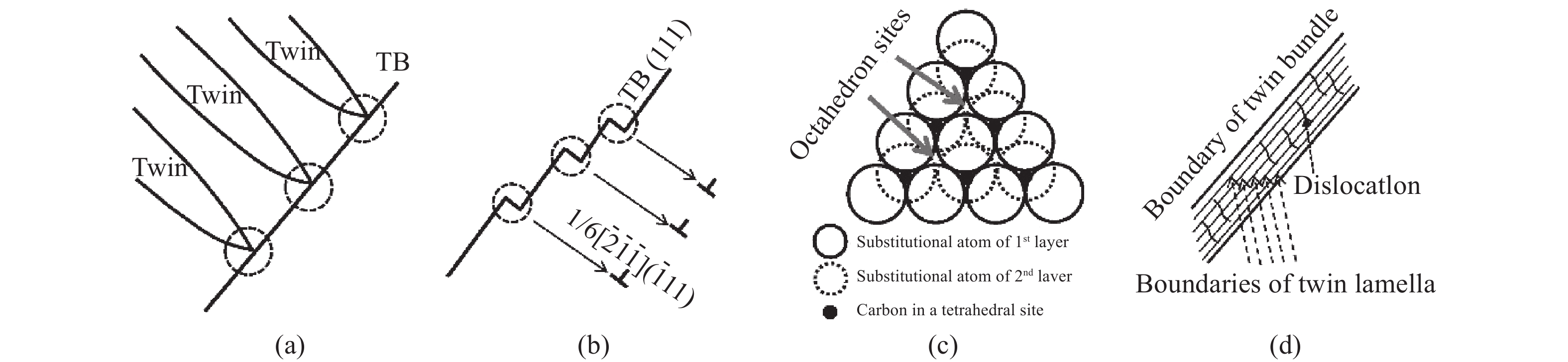

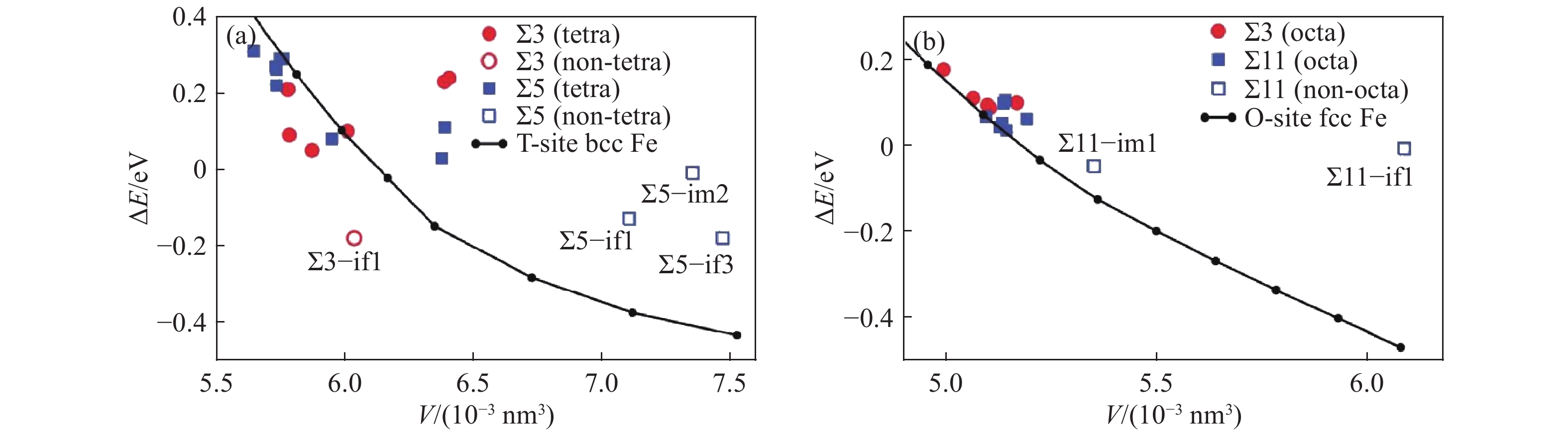

圖 6 氫在不同位置的溶解能[39]。(a)BCC鐵中的四面體位和BCC∑3, BCC∑5晶界內各種中間(im)和界面 (if)的間隙吸附位;(b)FCC鐵中的八面體位, FCC∑3和FCC∑11 Fe晶界內各種中間(im)和界面(if)的間隙吸附位

Figure 6. Solution energy of hydrogen as a function of the volume of the interstitial site[39]: (a) tetrahedral sites in BCC Fe and various intermediate (im) and interface (if) interstitial adsorption sites within BCC∑3 and BCC∑5 Fe grain boundaries; (b) octahedral sites in FCC Fe and various intermediate (im) and interface (if) interstitial adsorption sites within FCC∑3, and FCC∑11 Fe grain boundaries

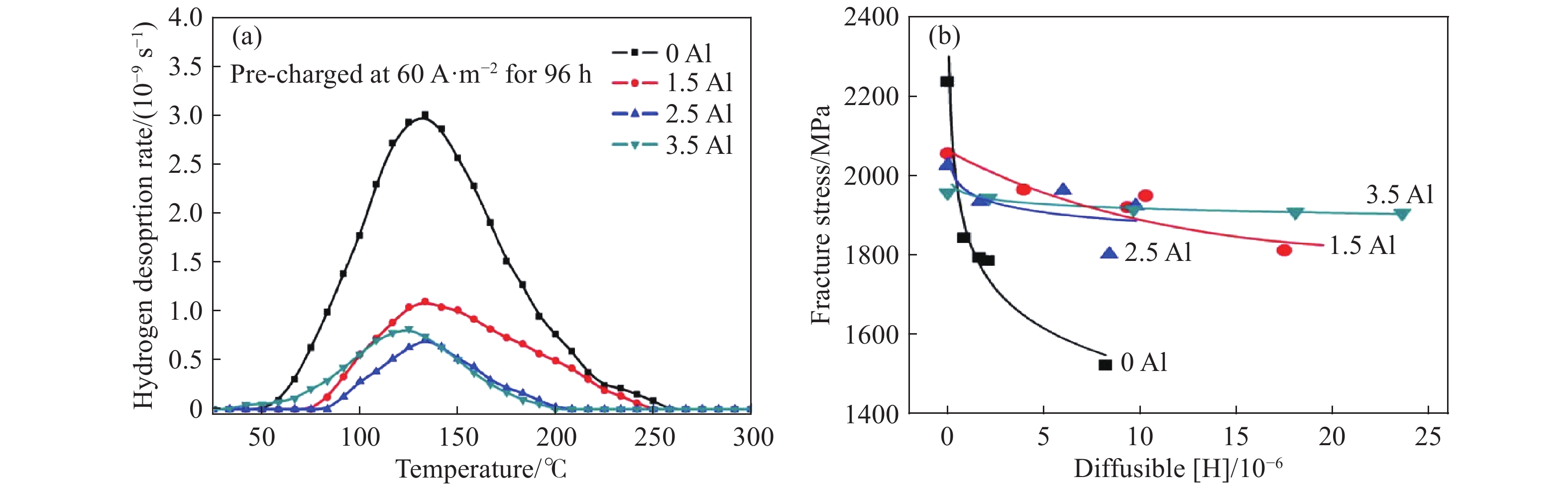

圖 11 Fe?18Mn?xAl鋼的熱解吸分析(TDA)曲線和斷裂應力[13, 42, 58]。(a)相同充氫條件下的TDA;(b)不同擴散氫條件下缺口試樣的斷裂應力

Figure 11. TDA profiles and fracture stress with different Al contents in Fe?18Mn?xAl steels[13, 42, 58]: (a) TDA profiles at an identical hydrogen charging condition; (b) plot of fracture stress of notched specimens against diffusible hydrogen content

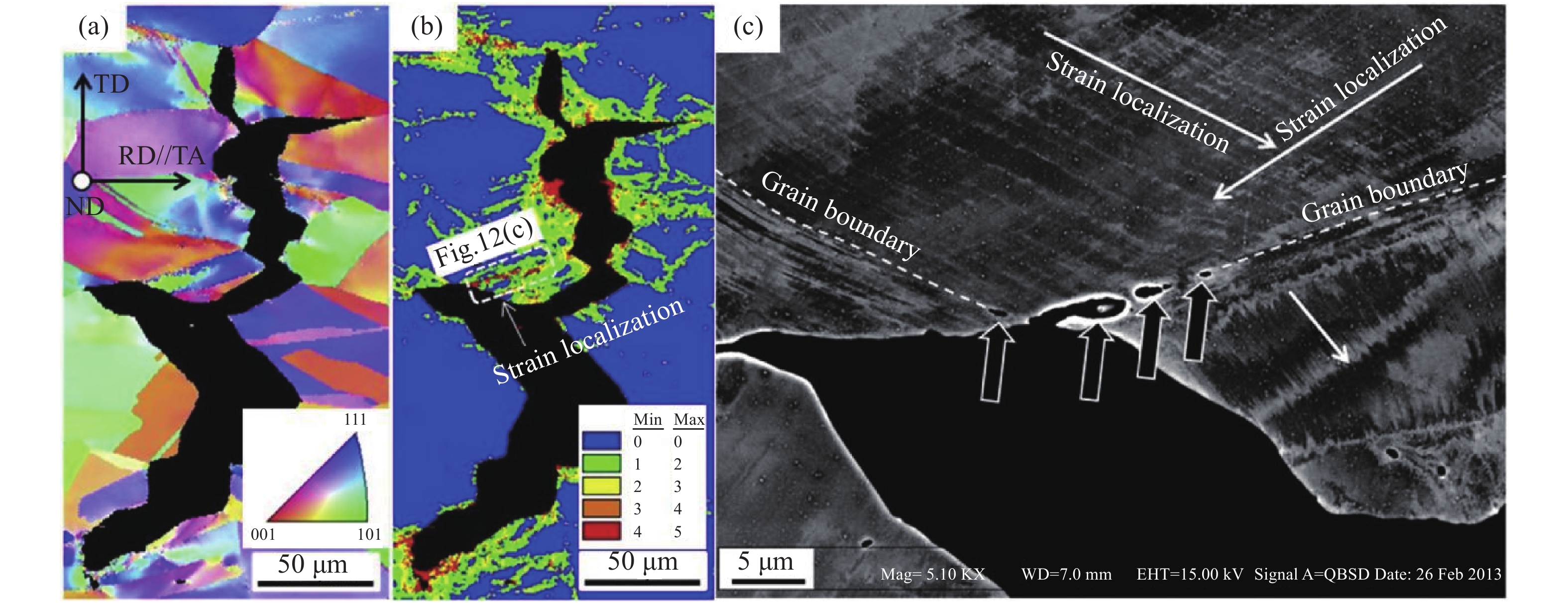

圖 12 含κappa碳化物Fe?26Mn?11Al?1.2C奧氏體鋼的氫致晶間裂紋[13, 51]。(a)反極圖(IPF);(b)充氫條件下的KAM圖;(c)晶間裂紋形成

Figure 12. Hydrogen-induced intergranular crack in Fe?26Mn?11Al?1.2C austenitic steel containing κ-carbides[13, 51]: (a) inverse pole figure (IPF); (b) kernel average misoritation(KAM)maps under hydrogen charging; (c) intergranular crack formation

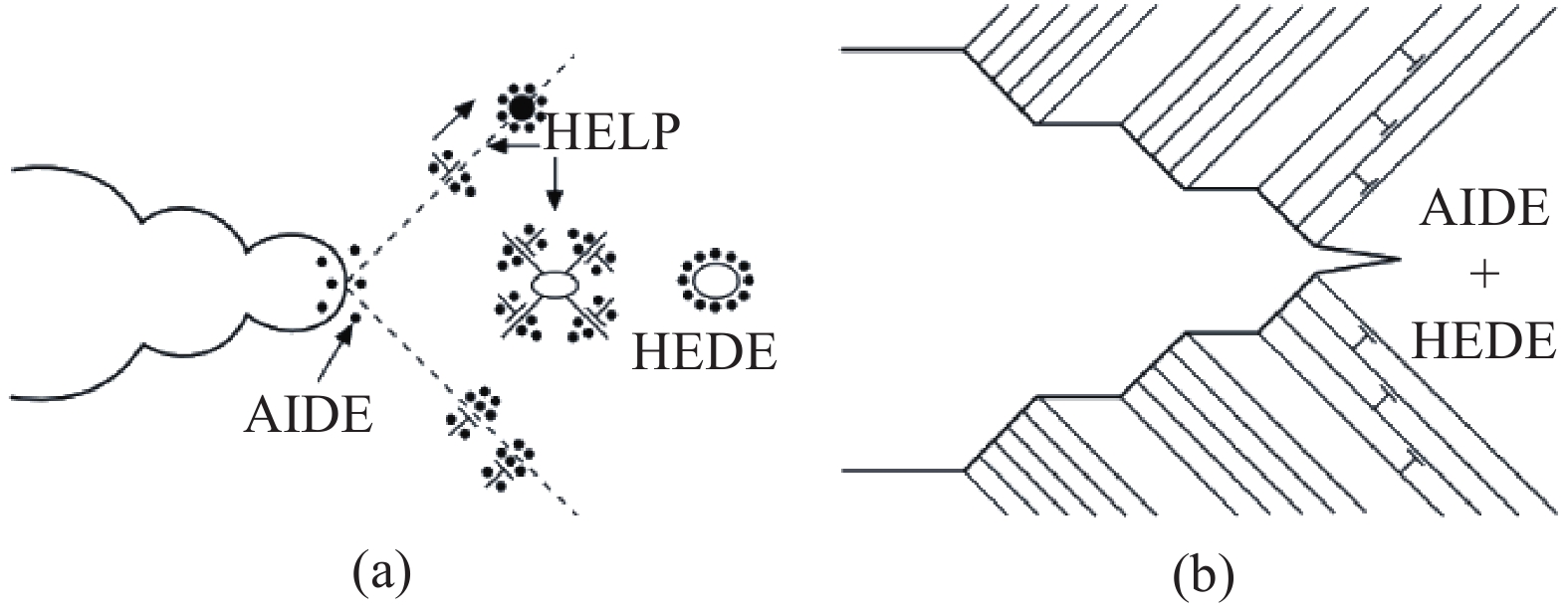

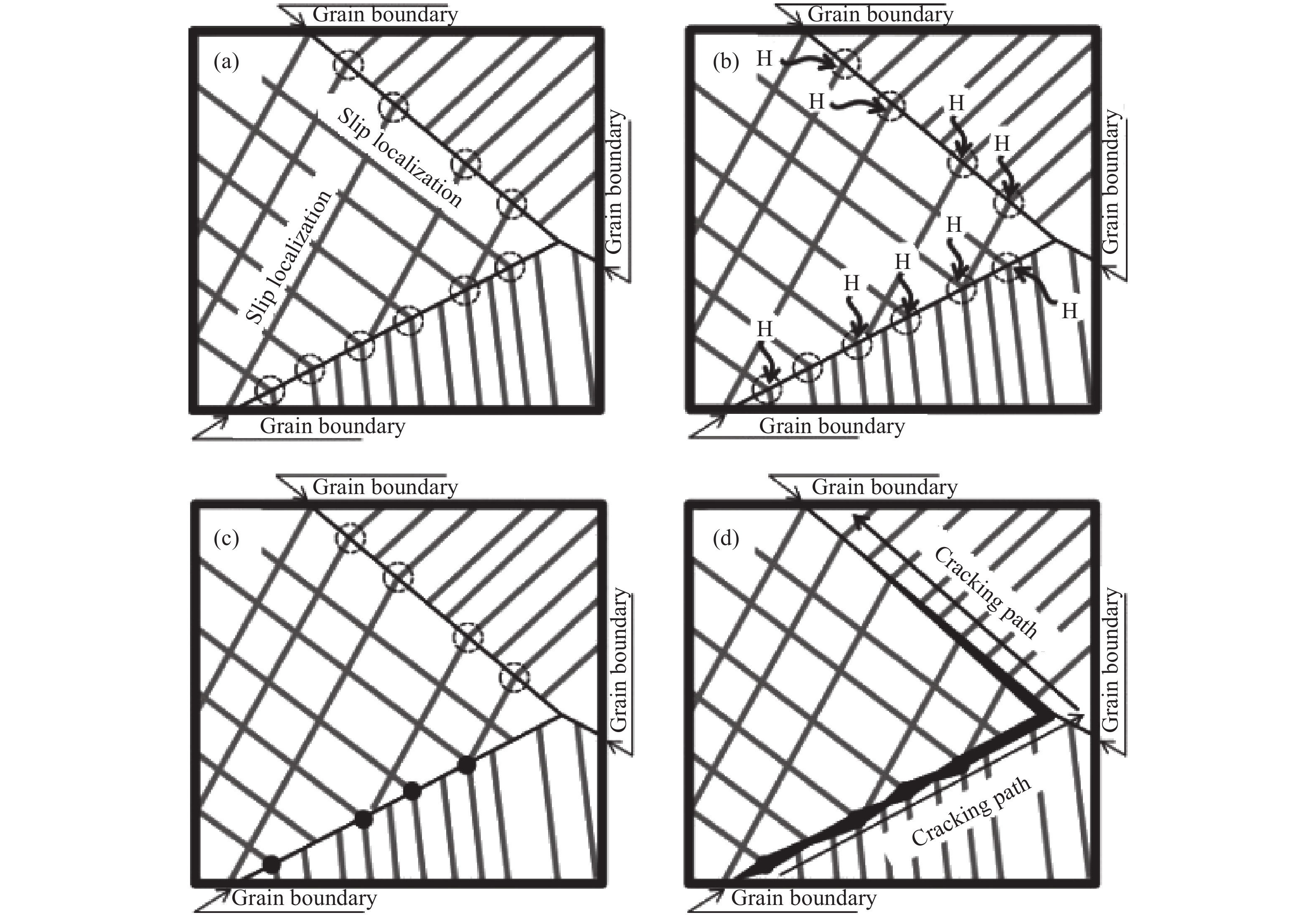

圖 14 鋼中氫輔助裂紋和裂紋擴展的示意圖[51]。(a)晶界處應變局部化;(b)擴散氫沿晶界向應變局部化區域遷移;(c)應變局部化帶晶界處形成的微空洞;(d)微空洞合并及沿晶界傳播

Figure 14. Schematic sketches showing hydrogen-assisted cracking and crack propagation in the steel[51]: (a) strain localization occurring particularly on grain boundaries; (b) diffusible hydrogen moving to the strain localization regions along the grain boundaries; (c) formation of micro-voids on the grain boundary intersecting strain localization bands; (d) micro-voids coalescence and subsequent propagation along grain boundaries

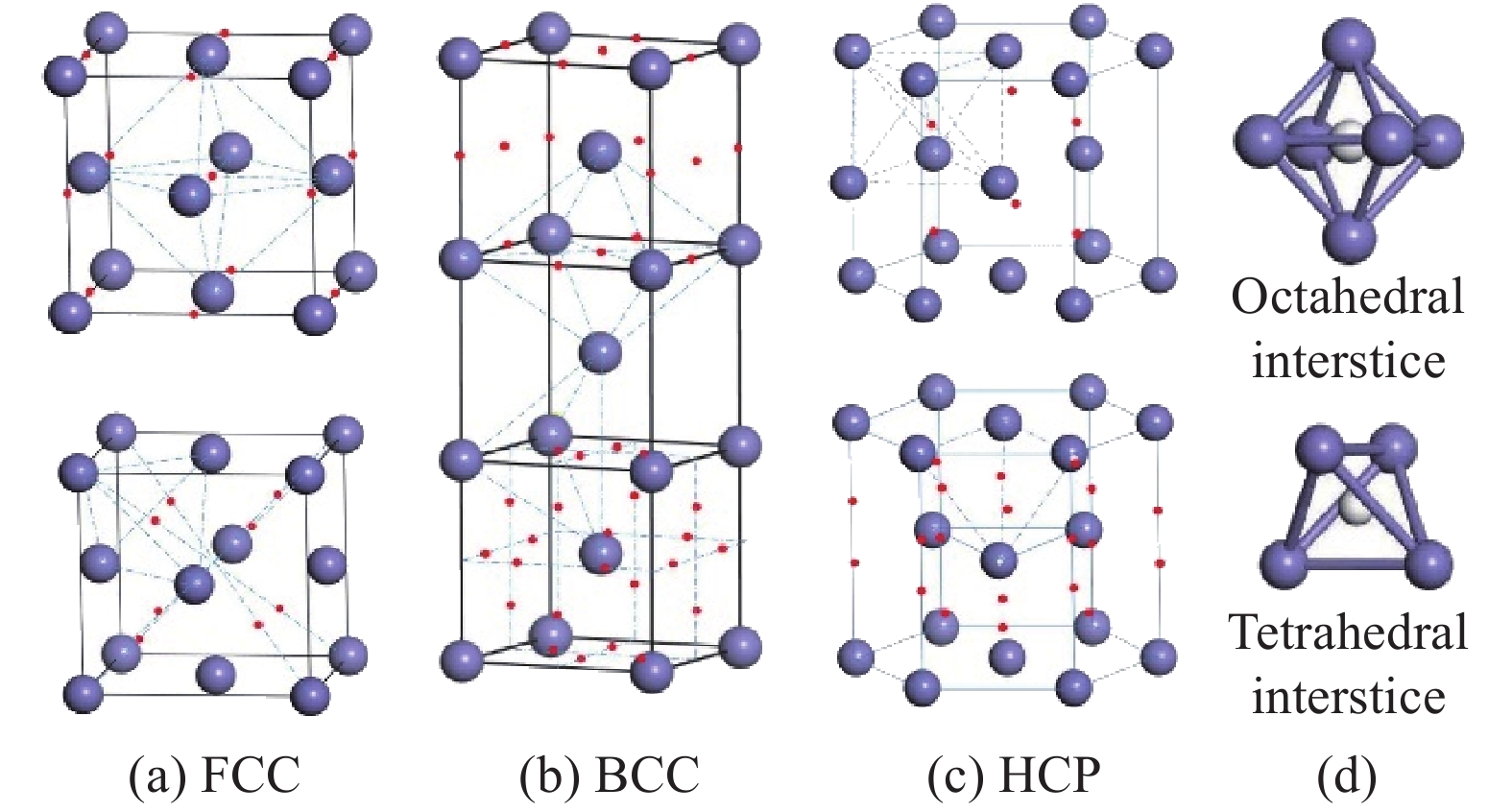

表 1 α-Fe、γ-Fe和ε-Fe的晶格特征

Table 1. Crystallographic characteristics of α-Fe,γ-Fe, and ε-Fe structures

Type of crystal structure Lattice constant/ nm Atomic radius, r/ nm Size of tetrahedral interstice/ nm Size of octahedral interstice/ nm Hydrogen atomic radius/ nm FCC a=b=c=0.344 $r = \sqrt 2 a/4 = {\rm{0}}{\rm{.}}1216$ 0.225r=0.0274 0.414r=0.0503 0.037 BCC a=b=c=0.286 $r = \sqrt 3 a/4 = {\rm{0}}{\rm{.}}1238$ 0.291r=0.0360 0.154r=0.0191 HCP a=b=0.245, c/a=0.1584 $r{\rm{ = }}a/2 = {\rm{0}}{\rm{.}}1225$ 0.225r=0.0275 0.414r=0.0507 表 2 氫在BCC、FCC、FCT和HCP中擴散的遷移能

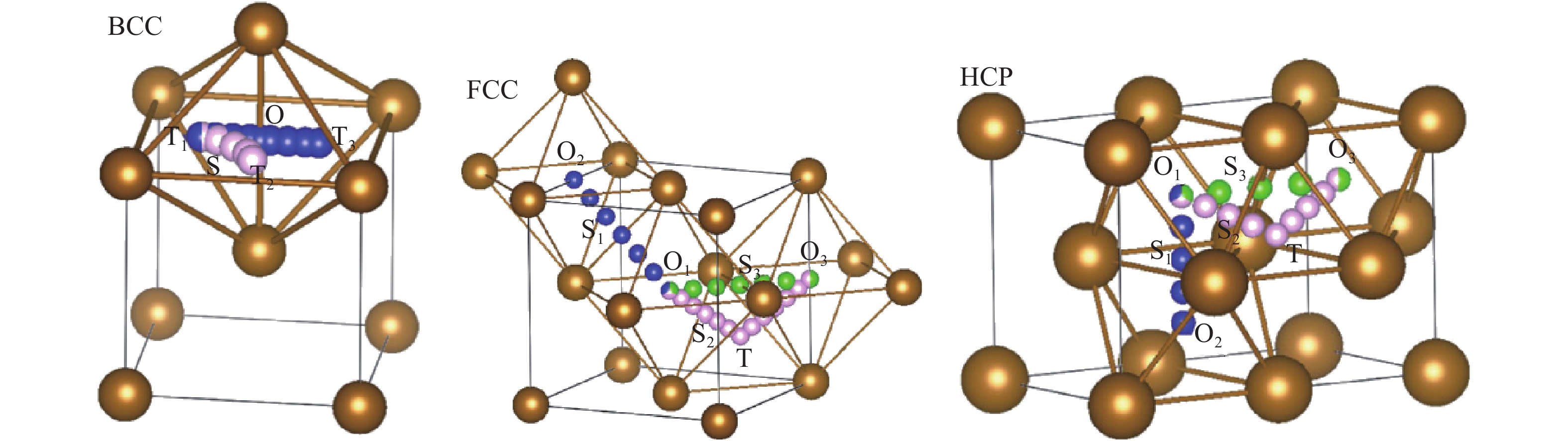

Table 2. Migration energy of hydrogen diffusion in BCC, nonmagnetic FCC, antiferromagnetic FCT, and HCP

Type of crystal structure Path Migration energy/eV 1# 2# 3# 1# 2# 3# BCC T1—T2 T1—O—T3 — 0.088 0.123 — FCC(Nonmagnetic) O1—T—O3 O1—O3 — 0.64 1.08 — FCC(Antiferromagnetic) O1—T—O3 O1—O3 — 0.44 0.84 — FCT O1—T—O3 O1—O2 O1—O3 0.44 0.72 1.07 HCP O1—O2 O1—T—O3 O1—O3 0.72 0.77 1.26 表 3 氫與鋼中元素、空位及陷阱位的結合能

Table 3. Elements and vacancy in steel and selected trap sites binding energy values of H in steel

Atom and vacancy

defect sitesBinding energy between H atom

and point defect/ eVTrap sites Binding energy between H atom

and line, surface, volume

defects/ (kJ·mol?1)References H with vacancy 0.57 Substitutional Ni in Fe 7.7?9.7 [25, 48] H with solid solution atom 0.57?0.60 Dislocation / Dislocation cores 19.2?26 / 58?(62.2±0.3) [25, 48-50] H with carbon atom 0.09 Grain boundaries 20?46 [25, 48-49] H with aluminium atom 0.04 α/γ interface ?52 [25, 48] H with copper atom 0.06 α/cementite interface 8.4?13.4 [25, 48] H with nickel atom 0.01 Incoherent carbides >97 [25, 48] H with manganese and

silicon atom— Incoherent particles in Fe 67.5?96.5 [25, 48] Inclusions 79 [49] Twin boundaries 62 [49] 表 4 鋼中H的激活能值

Table 4. Activation energy values of H in steel

Trap site Steel Activation energy/(kJ·mol?1) References Grain boundary Pure iron 17 [50-51] Elastic field of edge dislocation Pure iron Martensitic steel Austenitic steel 27–35 [50-52] Micro-void Pure iron 35 [50-51] Σ3 twin boundary Austenitic steel 62 [51-52] Dislocation core Martensitic steel 58 [51, 53] k-carbides Austenitic steel 76–80 [51] 表 5 BCC、FCC和HCP晶體中不同位置的氫形成能

Table 5. Formation energy of H in different sites of BCC, FCC, and HCP Fe crystal

Type of crystal structure T-site/

eVO-site/

eVFormation energy of substitutional /eV Formation energy of vacancy /eV T-site near a single vacancy /eV O-site near s single vacancy /eV BCC ?3.17 — 2.61 2.44 — ?3.24 FCC ?2.68 ?3.24 2.39 ?3.705 ?3.717 HCP ?2.79 ?3.30 表 6 晶界處氫擴散的計算數值

Table 6. Calculated values of hydrogen diffusion at grain boundaries

Grain size, d/μm Grain boundary area per unit volume, ${S_v}$/(m2·m?3) Content of diffusible hydrogen, $X_{\rm{H}}^{{\rm{all}}}$/10?6 Hydrogen mass per unit grain boundary area,

$Y_{\rm{H}}^{{\rm{GB}}}$ /(g·m?2)37 5.4×104 3.30 4.8×10?4 2.3 8.7×105 4.58 4.1×10?5 0.85 2.4×106 7.10 2.4×10?5 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Dwivedi S K, Vishwakarma M. Hydrogen embrittlement in different materials: a review. <italic>Int J Hydrogen Energy</italic>, 2018, 43(46): 21603 doi: 10.1016/j.ijhydene.2018.09.201 [2] Liu Q L, Zhou Q J, Venezuela J, et al. Hydrogen influence on some advanced high-strength steels. <italic>Corros Sci</italic>, 2017, 125: 114 doi: 10.1016/j.corsci.2017.06.012 [3] Loidl M, Kolk O, Veith S, et al. Characterization of hydrogen embrittlement in automotive advanced high strength steels. <italic>Materialwissenschaft Und Werkstofftechnik</italic>, 2011, 42(12): 1105 doi: 10.1002/mawe.201100917 [4] Shin S E, Lee S J, Nambu S, et al. Hydrogen embrittlement in multilayer steel consisting of martensitic and twinning induced plasticity steels. <italic>Mater Sci Eng A</italic>, 2019, 756: 508 doi: 10.1016/j.msea.2019.04.085 [5] Koyama M, Akiyama E, Tsuzaki K. Effect of hydrogen content on the embrittlement in a Fe?Mn?C twinning-induced plasticity steel. <italic>Corros Sci</italic>, 2012, 59: 277 doi: 10.1016/j.corsci.2012.03.009 [6] De Cooman B C, Estrin Y, Kim S K. Twinning-induced plasticity (TWIP) steels. <italic>Acta Mater</italic>, 2018, 142: 283 doi: 10.1016/j.actamat.2017.06.046 [7] Gutierrez-Urrutia I, Raabe D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe-Mn-Al-C steel. <italic>Acta Mater</italic>, 2012, 60(16): 5791 doi: 10.1016/j.actamat.2012.07.018 [8] Hong S, Lee J, Lee B J, et al. Effects of intergranular carbide precipitation on delayed fracture behavior in three twinning induced plasticity (TWIP) steels. <italic>Mater Sci Eng A</italic>, 2013, 587: 85 doi: 10.1016/j.msea.2013.08.063 [9] Bracke L, Kestens L, Penning J. Direct observation of the twinning mechanism in an austenitic Fe?Mn?C steel. <italic>Scripta Mater</italic>, 2009, 61(2): 220 doi: 10.1016/j.scriptamat.2009.03.045 [10] Chen S P, Rana R, Haldar A, et al. Current state of Fe?Mn?Al?C low density steels. <italic>Prog Mater Sci</italic>, 2017, 89: 345 doi: 10.1016/j.pmatsci.2017.05.002 [11] Scott C, Allain S, Faral M, et al. The development of a new Fe?Mn?C austenitic steel for automotive applications. <italic>Rev Met Paris</italic>, 2006, 103(6): 293 doi: 10.1051/metal:2006142 [12] Chen L, Lee S J, De Cooman B C. Mechanical properties of H-charged Fe?18Mn?1.5Al?0.6C TWIP steel. <italic>ISIJ Int</italic>, 2012, 52(9): 1670 doi: 10.2355/isijinternational.52.1670 [13] Koyama M, Akiyama E, Lee Y K, et al. Overview of hydrogen embrittlement in high-Mn steels. <italic>Int J Hydrogen Energy</italic>, 2017, 42(17): 12706 doi: 10.1016/j.ijhydene.2017.02.214 [14] Lynch S P. Hydrogen embrittlement (HE) phenomena and mechanisms // Stress Corrosion Cracking. Cambridge: Woodhead Publishing, 2011 [15] Nagumo M, Takai K. The predominant role of strain-induced vacancies in hydrogen embrittlement of steels: overview. <italic>Acta Mater</italic>, 2019, 165: 722 doi: 10.1016/j.actamat.2018.12.013 [16] Doshida T, Takai K. Dependence of hydrogen-induced lattice defects and hydrogen embrittlement of cold-drawn pearlitic steels on hydrogen trap state, temperature, strain rate and hydrogen content. <italic>Acta Mater</italic>, 2014, 79: 93 doi: 10.1016/j.actamat.2014.07.008 [17] Lovicu G, Bottazzi M, D'Aiuto F, et al. Hydrogen embrittlement of automotive advanced high-strength steels. <italic>Metall Mater Trans A</italic>, 2012, 43(11): 4075 doi: 10.1007/s11661-012-1280-8 [18] Tian X, Li H, Zhang Y S. Effect of Al content on stacking fault energy in austenitic Fe?Mn?Al?C alloys. <italic>J Mater Sci</italic>, 2008, 43(18): 6214 doi: 10.1007/s10853-008-2919-0 [19] Park K T, Jin K G, Han S H, et al. Stacking fault energy and plastic deformation of fully austenitic high manganese steels: effect of Al addition. <italic>Mater Sci Eng A</italic>, 2010, 527(16-17): 3651 doi: 10.1016/j.msea.2010.02.058 [20] Kim M S, Kang Y B. Development of thermodynamic database for high Mn–high Al steels: Phase equilibria in the Fe?Mn?Al?C system by experiment and thermodynamic modeling. <italic>Calphad</italic>, 2015, 51: 89 doi: 10.1016/j.calphad.2015.08.004 [21] Lu T, Niu G J, Xu Y P, et al. Molecular dynamics study of the diffusion properties of H in Fe with point defects. <italic>Fusion Eng Des</italic>, 2016, 113: 340 doi: 10.1016/j.fusengdes.2016.06.044 [22] He Y. First-Principle Study on Diffusion and Aggregation Behavior of Hydrogen Atoms in Austenite Steel [Dissertation]. Beijing: China University of Petroleum, 2017何洋. 奧氏體鋼中氫的擴散與聚集行為的計算研究[學位論文]. 北京: 中國石油大學, 2017 [23] Hirata K, Iikubo S, Koyama M, et al. First-principles study on hydrogen diffusivity in BCC, FCC, and HCP iron. <italic>Metall Mater Trans A</italic>, 2018, 49(10): 5015 doi: 10.1007/s11661-018-4815-9 [24] Counts W A, Wolverton C, Gibala R. First-principles energetics of hydrogen traps in α-Fe: Point defects. <italic>Acta Mater</italic>, 2010, 58(14): 4730 doi: 10.1016/j.actamat.2010.05.010 [25] He Y, Li Y J, Chen C F, et al. Diffusion coefficient of hydrogen interstitial atom in α-Fe, γ-Fe and ε-Fe crystals by first-principle calculations. <italic>Int J Hydrogen Energy</italic>, 2017, 42(44): 27438 doi: 10.1016/j.ijhydene.2017.08.212 [26] Jiang D E, Carter E A. Diffusion of interstitial hydrogen into and through bcc Fe from first principles. <italic>Phys Rev B</italic>, 2004, 70(6): 064102 doi: 10.1103/PhysRevB.70.064102 [27] Li X, Gao C, Xiong X L, et al. Hydrogen diffusion in α-Fe under an applied 3-axis strain: a quantum manifestation. <italic>Int J Hydrogen Energy</italic>, 2015, 40(32): 10340 doi: 10.1016/j.ijhydene.2015.06.089 [28] Koyama M, Abe Y, Tsuzaki K. Split and shift of ε-martensite peak in an X-ray diffraction profile during hydrogen desorption: a geometric effect of atomic sequence. <italic>ISIJ Int</italic>, 2018, 58(9): 1745 doi: 10.2355/isijinternational.ISIJINT-2018-260 [29] Ha M C, Koo J M, Lee J K, et al. Tensile deformation of a low density Fe?27Mn?12Al?0.8C duplex steel in association with ordered phases at ambient temperature. <italic>Mater Sci Eng A</italic>, 2013, 586: 276 doi: 10.1016/j.msea.2013.07.094 [30] Zhang X F, Li J X, Wan Y X, et al. Research progress of ordered precipitates in low-density steels. <italic>Mater Rev</italic>, 2019, 33(23): 3979 doi: 10.11896/cldb.18120211章小峰, 李家星, 萬亞雄, 等. 低密度鋼中有序析出相的研究進展. 材料導報, 2019, 33(23):3979 doi: 10.11896/cldb.18120211 [31] Zhang G K, Huang G Q, Hu M J, et al. Stability and clusterization of hydrogen-vacancy complexes in B2-FeAl: insight from hydrogen embrittlement. <italic>RSC Adv</italic>, 2017, 7(18): 11094 doi: 10.1039/C6RA27936H [32] Shu X L, Hu W Y, Xiao H N, et al. Vacancies and antisites in B2 FeAl and DO<sub>3</sub> Fe<sub>3</sub>Al with a modified analytic EAM model. <italic>J Mater Sci Technol</italic>, 2001, 17(6): 601 [33] Huang G Q, Zhang G K, Luo Z Y, et al. A review on hydrogen embrittlement of Fe?Al intermetallics. <italic>Mater Rev</italic>, 2018, 32(11): 1878 doi: 10.11896/j.issn.1005-023X.2018.11.015黃廣棋, 張桂凱, 羅朝以, 等. Fe?Al金屬間化合物氫脆效應研究現狀. 材料導報, 2018, 32(11):1878 doi: 10.11896/j.issn.1005-023X.2018.11.015 [34] González E A, Jasen P V, Brizuela G, et al. The effect of interstitial hydrogen on the electronic structure of the B2 FeAl alloy. <italic>Phys Status Solidi B</italic>, 2007, 244(10): 3684 doi: 10.1002/pssb.200743076 [35] Curtze S, Kuokkala V T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. <italic>Acta Mater</italic>, 2010, 58(15): 5129 doi: 10.1016/j.actamat.2010.05.049 [36] Ferreira P J, Mullner P. A thermodynamic model for the stacking-fault energy. <italic>Acta Mater</italic>, 1998, 46(13): 4479 doi: 10.1016/S1359-6454(98)00155-4 [37] Mahajan S, Chin G Y. Twin-slip, twin-twin and slip-twin interactions in Co-8wt.% Fe alloy single crystals. <italic>Acta Metall</italic>, 1973, 21(2): 173 doi: 10.1016/0001-6160(73)90059-X [38] Koyama M, Akiyama E, Tsuzaki K, et al. Hydrogen-assisted failure in a twinning-induced plasticity steel studied under in situ hydrogen charging by electron channeling contrast imaging. <italic>Acta Mater</italic>, 2013, 61(12): 4607 doi: 10.1016/j.actamat.2013.04.030 [39] Du Y A, Ismer L, Rogal J, et al. First-principles study on the interaction of H interstitials with grain boundaries in α- and γ-Fe. <italic>Phys Rev B</italic>, 2011, 84(14): 144121 doi: 10.1103/PhysRevB.84.144121 [40] Lee S M, Park I J, Jung J G, et al. The effect of Si on hydrogen embrittlement of Fe?18Mn?0.6C?<italic>x</italic>Si twinning-induced plasticity steels. <italic>Acta Mater</italic>, 2016, 103: 264 doi: 10.1016/j.actamat.2015.10.015 [41] Dieudonné T, Marchetti L, Wery M, et al. Role of copper and aluminum additions on the hydrogen embrittlement susceptibility of austenitic Fe?Mn?C TWIP steels. <italic>Corros Sci</italic>, 2014, 82: 218 doi: 10.1016/j.corsci.2014.01.022 [42] Malard B, Remy B, Scott C, et al. Hydrogen trapping by VC precipitates and structural defects in a high strength Fe?Mn?C steel studied by small-angle neutron scattering. <italic>Mater Sci Eng A</italic>, 2012, 536: 110 doi: 10.1016/j.msea.2011.12.080 [43] Kwon Y J, Lee T, Lee J, et al. Role of Cu on hydrogen embrittlement behavior in Fe?Mn?C?Cu TWIP steel. <italic>Int J Hydrogen Energy</italic>, 2015, 40(23): 7409 doi: 10.1016/j.ijhydene.2015.04.022 [44] Gangloff R P, Somerday B P. Gaseous Hydrogen Embrittlement of Materials in Energy Technologies. Cambridge: Woodhead Publishing, 2012 [45] Toribio J, Kharin V. Hydrogen transport to fracture sites in metals and alloys: multiphysics modelling. <italic>Procedia Struct Integrity</italic>, 2017, 5: 1291 doi: 10.1016/j.prostr.2017.07.112 [46] Oriani R A. The diffusion and trapping of hydrogen in steel. <italic>Acta Metall</italic>, 1970, 18(1): 147 doi: 10.1016/0001-6160(70)90078-7 [47] Krom A H M, Bakker A. Hydrogen trapping models in steel. <italic>Metall Mater Trans B</italic>, 2000, 31(6): 1475 doi: 10.1007/s11663-000-0032-0 [48] Maroef I, Olson D L, Eberhart M, et al. Hydrogen trapping in ferritic steel weld metal. <italic>Int Mater Rev</italic>, 2002, 47(4): 191 doi: 10.1179/095066002225006548 [49] Bai Y, Momotani Y, Chen M C, et al. Effect of grain refinement on hydrogen embrittlement behaviors of high-Mn TWIP steel. <italic>Mater Sci Eng A</italic>, 2016, 651: 935 doi: 10.1016/j.msea.2015.11.017 [50] Choo W Y, Lee J Y. Thermal analysis of trapped hydrogen in pure iron. <italic>Metall Trans A</italic>, 1982, 13(1): 135 doi: 10.1007/BF02642424 [51] Koyama M, Springer H, Merzlikin S V, et al. Hydrogen embrittlement associated with strain localization in a precipitation-hardened Fe?Mn?Al?C light weight austenitic steel. <italic>Int J Hydrogen Energy</italic>, 2014, 39(9): 4634 doi: 10.1016/j.ijhydene.2013.12.171 [52] So K H, Kim J S, Chun Y S, et al. Hydrogen delayed fracture properties and internal hydrogen behavior of a Fe?18Mn?1.5Al?0.6C TWIP steel. <italic>ISIJ Int</italic>, 2009, 49(12): 1952 doi: 10.2355/isijinternational.49.1952 [53] Thomas R L S, Li D M, Gangloff R P, et al. Trap-governed hydrogen diffusivity and uptake capacity in ultrahigh-strength AERMET 100 steel. <italic>Metall Mater Trans A</italic>, 2002, 33(7): 1991 doi: 10.1007/s11661-002-0032-6 [54] Bal B, Koyama M, Gerstein G, et al. Effect of strain rate on hydrogen embrittlement susceptibility of twinning-induced plasticity steel pre-charged with high-pressure hydrogen gas. <italic>Int J Hydrogen Energy</italic>, 2016, 41(34): 15362 doi: 10.1016/j.ijhydene.2016.06.259 [55] Casillas G, Gazder A A, Pereloma E V, et al. Evidencing extrinsic stacking faults in twinning-induced plasticity steel. <italic>Mater Charact</italic>, 2017, 123: 275 doi: 10.1016/j.matchar.2016.11.039 [56] Khedr M, Li W, Jin X J. Studying hydrogen embrittlement in nano-twinned polycrystalline Fe−12.5Mn−1.2C austenitic steel // TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. Phoenix, 2018: 113 [57] Koyama M, Akiyama E, Tsuzaki K. Hydrogen embrittlement in Al-added twinning-induced plasticity steels evaluated by tensile tests during hydrogen charging. <italic>ISIJ Int</italic>, 2012, 52(12): 2283 doi: 10.2355/isijinternational.52.2283 [58] Chun Y S, Park K T, Lee C S. Delayed static failure of twinning-induced plasticity steels. <italic>Scripta Mater</italic>, 2012, 66(12): 960 doi: 10.1016/j.scriptamat.2012.02.038 [59] Chin K G, Kang C Y, Shin S Y, et al. Effects of Al addition on deformation and fracture mechanisms in two high manganese TWIP steels. <italic>Mater Sci Eng A</italic>, 2011, 528(6): 2922 doi: 10.1016/j.msea.2010.12.085 [60] Gutierrez-Urrutia I, Raabe D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. <italic>Scripta Mater</italic>, 2013, 68(6): 343 doi: 10.1016/j.scriptamat.2012.08.038 [61] Rao V S. Some observations on the hydrogen embrittlement of Fe<sub>3</sub>Al?Fe<sub>3</sub>AlC intermetallic compounds. <italic>Mater Res Bull</italic>, 2004, 39(2): 169 doi: 10.1016/j.materresbull.2003.10.006 [62] Timmerscheidt T A, Dey P, Bogdanovski D, et al. The role of κ-carbides as hydrogen traps in high-Mn steels. <italic>Metals</italic>, 2017, 7(7): 264 doi: 10.3390/met7070264 [63] Turk A, Martín D S, Rivera-Díaz-del-Castillo P E J, et al. Correlation between vanadium carbide size and hydrogen trapping in ferritic steel. <italic>Scri Mater</italic>, 2018, 152: 112 [64] Counts W, Wolverton C, Gibala R. Binding of multiple H atoms to solute atoms in bcc Fe using first principles. <italic>Acta Mater</italic>, 2011, 59(14): 5812 doi: 10.1016/j.actamat.2011.05.058 [65] Marchi C S, Somerday B P, Robinson S L. Permeability, solubility and diffusivity of hydrogen isotopes in stainless steels at high gas pressures. <italic>Int J Hydrogen Energy</italic>, 2007, 32(1): 100 doi: 10.1016/j.ijhydene.2006.05.008 [66] Martin M L, Dadfarnia M, Nagao A, et al. Enumeration of the hydrogen-enhanced localized plasticity mechanism for hydrogen embrittlement in structural materials. <italic>Acta Mater</italic>, 2019, 165: 734 doi: 10.1016/j.actamat.2018.12.014 [67] Matsumoto R, Taketomi S, Matsumoto S, et al. Atomistic simulations of hydrogen embrittlement. <italic>Int J Hydrogen Energy</italic>, 2009, 34(23): 9576 doi: 10.1016/j.ijhydene.2009.09.052 [68] Song J, Curtin W A. Mechanisms of hydrogen-enhanced localized plasticity: an atomistic study using α-Fe as a model system. <italic>Acta Mater</italic>, 2014, 68: 61 doi: 10.1016/j.actamat.2014.01.008 [69] Xie D G, Li M, Shan Z W. Review on hydrogen-microstructure interaction in metals. <italic>Mater China</italic>, 2018, 37(3): 215解德剛, 李蒙, 單智偉. 氫與金屬的微觀交互作用研究進展. 中國材料進展, 2018, 37(3):215 [70] Chida T, Hagihara Y, Akiyama E, et al. Comparison of constant load, SSRT and CSRT methods for hydrogen embrittlement evaluation using round bar specimens of high strength steels. <italic>Tetsu-to-Hagane</italic>, 2014, 100(10): 1298 doi: 10.2355/tetsutohagane.100.1298 [71] Song S W, Kim J N, Seo H J, et al. Effects of carbon content on the tensile and fatigue properties in hydrogen-charged Fe?17Mn?<italic>x</italic>C steels: the opposing trends. <italic>Mater Sci Eng A</italic>, 2018, 724: 469 doi: 10.1016/j.msea.2018.03.117 [72] Li X C, Liu Y N, Yu Y, et al. Helium defects interactions and mechanism of helium bubble growth in tungsten: a molecular dynamics simulation. <italic>J Nucl Mater</italic>, 2014, 451(1-3): 356 [73] Ismer L, Hickel T, Neugebauer J. Ab initio study of the solubility and kinetics of hydrogen in austenitic high Mn steels. <italic>Phys Rev B</italic>, 2010, 81(9): 094111 doi: 10.1103/PhysRevB.81.094111 [74] Jiang Y F, Zhang B, Zhou Y, et al. Atom probe tomographic observation of hydrogen trapping at carbides/ferrite interfaces for a high strength steel. <italic>J Mater Sci Technol</italic>, 2018, 34(8): 1344 doi: 10.1016/j.jmst.2017.11.008 [75] Ishikawa N, Sueyoshi H, Nagao A. Hydrogen microprint analysis on the effect of dislocations on grain boundary hydrogen distribution in steels. <italic>ISIJ Int</italic>, 2016, 56(3): 413 doi: 10.2355/isijinternational.ISIJINT-2015-329 -

下載:

下載: