-

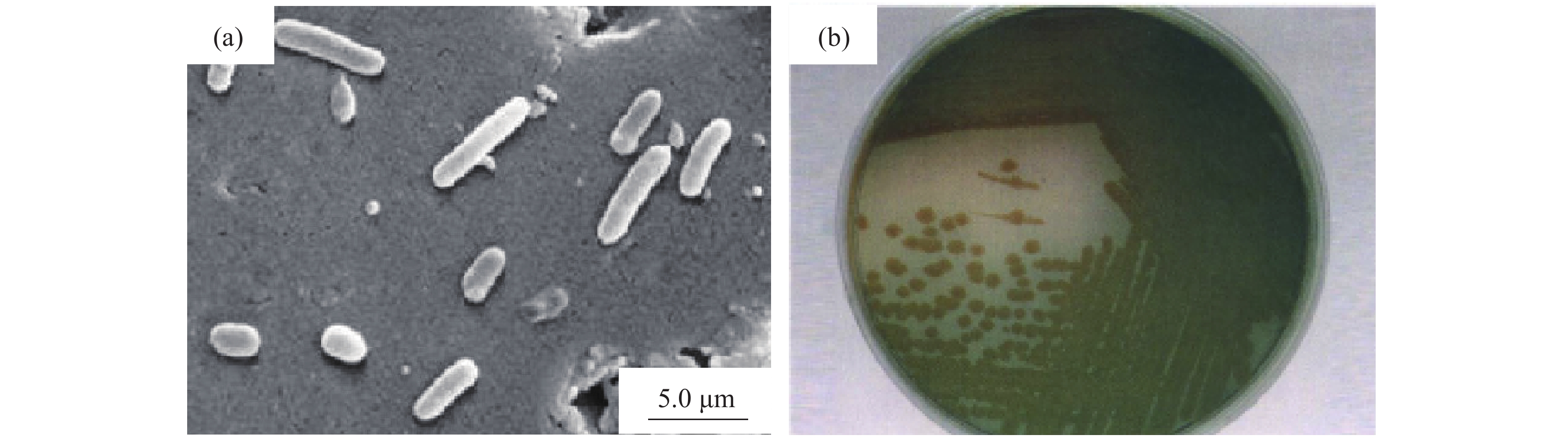

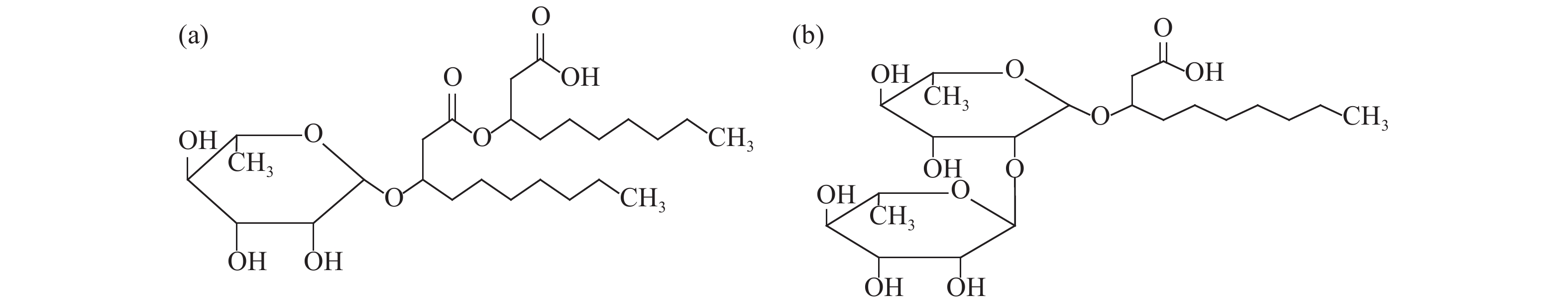

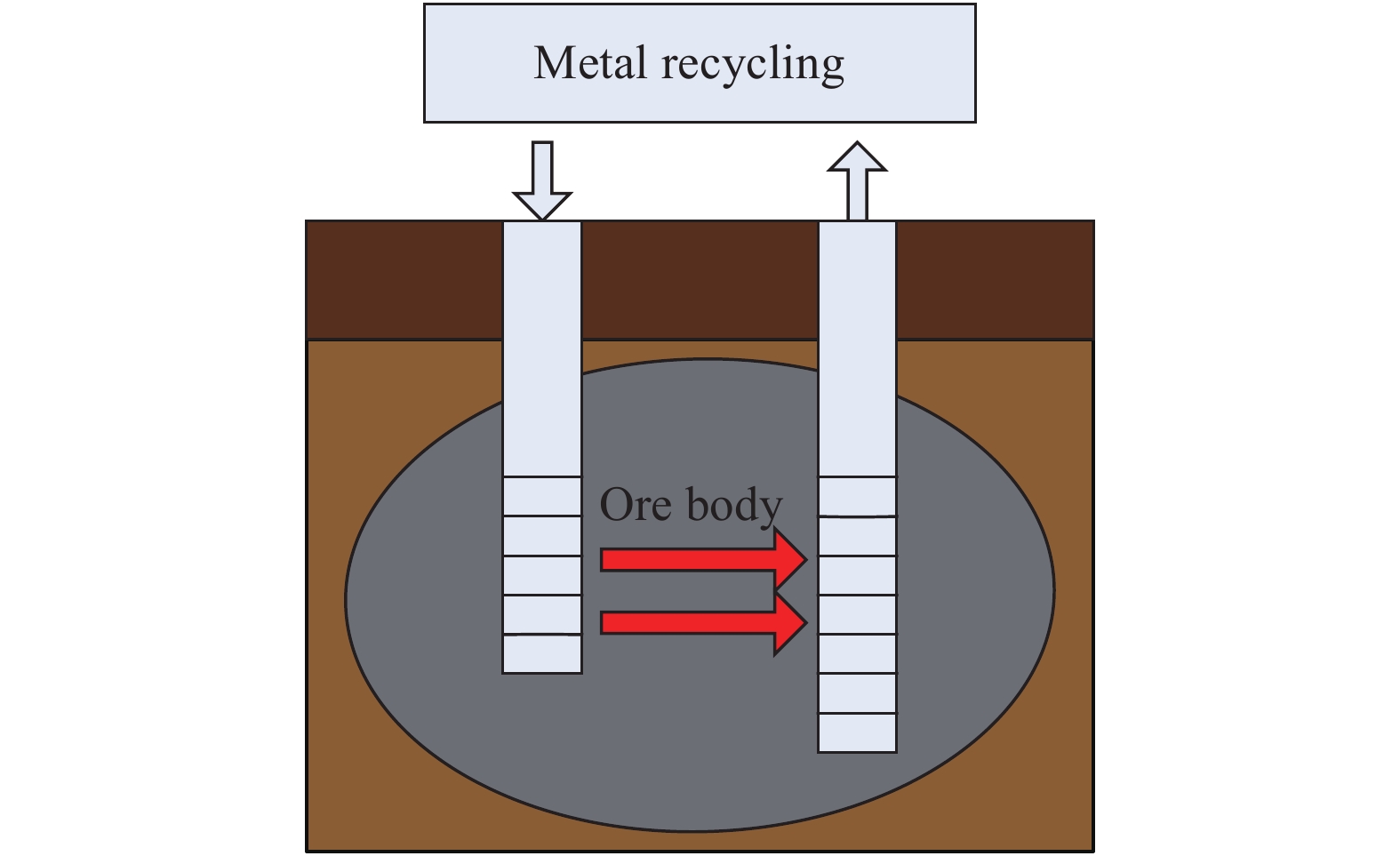

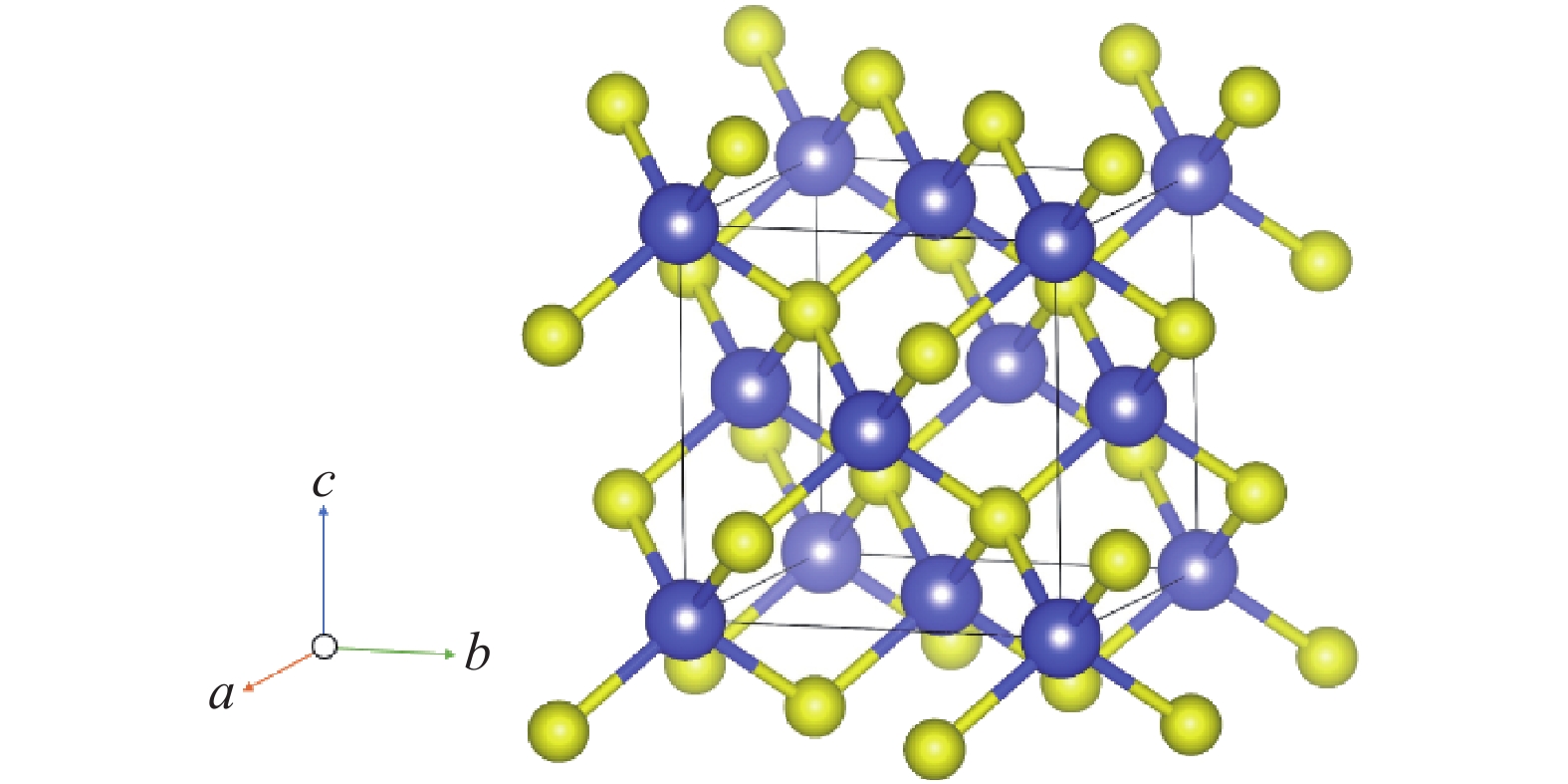

摘要: 鋅是現代工業所必需的有色金屬,屬于很重要的戰略資源,其在世界所有金屬產量中排名第四,僅次于鐵、鋁和銅。隨著低品位難處理鋅資源的種類和產量的不斷增加,以及濕法冶金技術的不斷發展,鋅的生物浸出技術得到了研究人員的廣泛關注,并展示出了良好的潛在應用前景。本文首先較為詳細的介紹了含鋅資源的礦物特征,并對其生物可浸性進行了分析。其次,對目前鋅的生物浸出體系,所用浸礦菌種,浸出過程所涉及的電化學、熱力學、動力學以及浸出機理進行了歸納總結;接著,對鋅的生物浸出技術現狀和工藝新進展進行了闡述。最后,展望了鋅的生物浸出工藝的發展趨勢及后續的研究熱點。研究表明高效浸鋅菌種的選育馴化、與之相匹配的工藝及裝備研發,是鋅的生物浸出當今研究熱點及未來發展方向。Abstract: Zinc is a nonferrous metal necessary for modern industry and an important strategic resource. It ranks fourth among all metals in terms of world production after iron, aluminum, and copper. Zinc sulfide ore is the most important zinc-producing mineral in the world, followed by associated zinc oxide ore and zinc-containing secondary resources. China is rich in zinc resources. Most of China’s lead–zinc and copper–zinc deposits are mainly lead–zinc integrated deposits, lead–zinc sulfide deposits, and other associated components. These types of mineral resources lead to wastage of resources in the development and utilization processes and affect the subsequent smelting process, which places considerable pressure on the production efficiency and ecological environment. The current mining and metallurgical industry vigorously promotes industrial development and has shifted in the favor of recycling, low-carbon, and green technologies. The biological leaching technology, as a green and low-carbon wet metallurgy technology, meets the current environmental protection policy requirements. This technology uses microorganisms and their metabolites to soak valuable metals in ores and has many advantages such as simple process, environmental protection, and capability to process low-grade ores. With the development of hydrometallurgical technology, the biological leaching technology of zinc from various types of low-grade zinc resources has attracted researchers’ attention and shown considerable application potential. First, this study introduced the mineral characteristics of zinc resources and analyzed their bioleachability. Then, the bioleaching process of zinc was summarized, and the leaching bacteria, electrochemistry, thermodynamics, kinetics, and leaching mechanism were systemically introduced. Furthermore, the current situation and/or progress of zinc bioleaching technology were generalized. Finally, the development trend of zinc bioleaching process and future research hotspots were considered. This study shows that the breeding of highly efficient bioleaching bacteria and the corresponding technology and equipment inventions are the current research hotspots and can also be the development directions for zinc bioleaching in the future. This will help ensure rapid and effective development of the zinc bioleaching technology.

-

Key words:

- zinc /

- bioleaching /

- bacteria /

- reaction mechanism /

- extraction

-

表 1 鋅的生物浸出特點

Table 1. Bioleaching characteristics of zinc

Types Zinc resources Bacterial species Extractant Characteristic Sulfide ore Sphalerite, marmatite, wurtzite Inorganic acidophilic bacteria Fe3+,H2SO4 Short leaching cycle and high efficiency Zinc-containing polymetallic

sulfide oreInorganic acidophilic bacteria Fe3+,H2SO4 Selective priority leaching Smithsonite, zincite, sillizonite, heteropolar Heterotrophic alkaline bacteria Organic acid Need external energy substrate Non-sulfide ore Electronic waste such as zinc-manganese batteries Inorganic acidophilic bacteria, heterotrophic alkaline bacteria Fe3+,H2SO4, Organic acid Need external energy substrate and low efficiency Lead-zinc smelting slag Inorganic acidophilic bacteria, heterotrophic alkaline bacteria Fe3+,H2SO4, Organic acid High acid consumption and high leaching rate Zinc-containing sludge and wastewater Inorganic acidophilic bacteria, heterotrophic alkaline bacteria Fe3+,H2SO4, Organic acid Direct decomposition of organic matter and sulfide 表 2 部分常用浸礦細菌特征

Table 2. Some frequently used bioleaching bacteria characteristics

Types Bioleaching bacteria Growth environment Optimum growth pH value Energy substance Oxidation products Inorganic acidophilic bacteria Acidithiobacillus ferrooxidans Acidic 2.5 Fe2+,${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,S0,Sulfide ore Fe3+,${\rm{SO}}_4^{2 - }$ Leptospirillum ferrooxidans Acidic 1.5?3.0 Fe2+ Fe3+- Acidimirobium ferrooxidans Acidic 2.0 Fe2+ Fe3+ Sulfobacillus thermosul fidooxidans Acidic 2.0 Fe2+,${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,S0,Sulfide ore Fe3+,${\rm{SO}}_4^{2 - }$ Acidithiobacillus thiooxidans Acidic 1.5?3 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,S0,Sulfide ore Thioalklimicrobium Alkaline 9.5?10.0 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$, S0,Sulfide ore ${\rm{SO}}_4^{2 - }$ Thiobacillus novellus Alkaline 7.8?9.0 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,S0,Sulfide ore ${\rm{SO}}_4^{2 - }$ Thioalkalivibrio Alkaline 10.0?10.2 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,Sulfide ore S0 Thiobacillus versutus Alkaline 8.0?9.0 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,Sulfide ore ${\rm{SO}}_4^{2 - }$ Alpha proteobacterium Alkaline 8.5?8.8 ${{\rm{S}}_2}{\rm{O}}_3^{2 - }$,Sulfide ore S0 Pseudomonas stutzeri Alkaline 7.5?8.0 Sulfide ore ${\rm{SO}}_4^{2 - }$ Heterotrophic alkaline bacteria Pseudomonas aeruginosa Alkaline — C6H12O6,Sulfide ore C2H4O2、${\rm{SO}}_4^{2 - }$ Arthrobacter oxydans Alkaline — Organic compound C2H2O4、C3H6O3 Microbacterium sp. Alkaline — Organic compound C2H2O4、C6H12O7 Bacillus megaterium Alkaline 4.0?7.5 Organic compound C6H8O7 Promicromonospora sp. Alkaline — Organic compound C6H12O7 Number Model Types 1 ${K_{\rm{t}}} = 1 - {(1 - X)^{\frac{2}{3}}}$ Hybrid control model of shrin-king core model (diffusion control; chemical reaction control) 2 ${K_{\rm{t}}} = {[1 - {(1 - X)^{1/3}}]^2}$ Product layer diffusion model 3 ${K_{\rm{t}}} = - \ln (1 - X)$ Hybrid control model (surface reaction control, sulfur layer diffusion control) 4 ${K_{\rm{t}}} = 1 - \dfrac{2}{3}X - {\left( {1 - X} \right)^{{\frac{1}{3}}}}$ Diffusion of porous product layer based on shrinking core model 5 ${K_{\rm{t}}} = \dfrac{1}{3}\ln (1 - X) + [{(1 - X)^{ - \frac{1}{3}}} - 1]$ Interface transfer and product layer diffusion 6 ${K_{\rm{t}}} = 1 - 3{\left( {1 - X} \right)^{\frac{2}{3}}} + 2\left( {1 - X} \right)$ Diffusion of H+ in the product layer of the shrinking core model 7 ${K_{\rm{t}}} = 1 - {(1 - 0.45X)^{1/3}}$ Surface chemical reaction diffusion of shrinking core model 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Shi S Y, Zhang G J, Zhao Y F, et al. Bioleaching of zinc sulfide ore. Metallic Ore Dressing Abroad, 2002(02): 12石紹淵, 張廣積, 趙月峰, 等. 硫化鋅礦的生物浸出. 國外金屬礦選礦, 2002(02):12 [2] Luo R. Experimental study of W-1 inhibitor on zinc flotation of a flotation lead concentrate in Inner Mongolia. Hunan Nonferrous Met, 2018, 34(2): 15駱任. W-1抑制劑對內蒙古某浮選鉛精礦降鋅選礦試驗研究. 湖南有色金屬, 2018, 34(2):15 [3] Sun Z J. Processing research refractory lead-zinc ore in Qinghai. Nonferrous Met (Miner Process Sect) , 2016(5): 22孫志健. 青海某難選鉛鋅礦選礦試驗研究. 有色金屬(選礦部分), 2016(5):22 [4] Liu X, Zhang Y, Wang N, et al. Pb?Zn metal resources situation and suggestion for Pb?Zn metals industry development in China. China Min Mag, 2015, 24(Suppl 1): 6劉曉, 張宇, 王楠, 等. 我國鉛鋅礦資源現狀及其發展對策研究. 中國礦業, 2015, 24(增刊1): 6 [5] Wen J K. Current status and development of biometallurgy. China Nonferrous Met, 2008(10): 74溫建康. 生物冶金的現狀與發展. 中國有色金屬, 2008(10):74 [6] Li G Z, Wang H J, Wu A X, et al. Research status on bioleaching of ores. Hydrometallurgy China, 2014, 33(02): 82李廣澤, 王洪江, 吳愛祥, 等. 生物浸礦技術研究現狀. 濕法冶金, 2014, 33(02):82 [7] Wang J X, Luo Y M, Shen L J. Craft mineralogy research of lead-zinc ore somewhere. Hunan Nonferrous Met, 2003, 19(5): 4王建雄, 羅印敏, 沈立俊. 某鉛鋅礦石工藝礦物學研究. 湖南有色金屬, 2003, 19(5):4 [8] Tong X, He J, Rao F, et al. Experimental study on activation of high iron-bearing marmatite. Min Metall Eng, 2006, 26(4): 19童雄, 何劍, 饒峰, 等. 云南都龍高鐵閃鋅礦的活化試驗研究. 礦冶工程, 2006, 26(4):19 [9] Shan L J. Mineralogical study on the refractory factor of one Pb?Zn ore originated from Inner Mongolia Aobaotu and discussion on the refractory factors. Non-ferrous Min Metall, 2018, 34(5): 19單連軍. 內蒙古敖包吐鉛鋅礦礦石工藝礦物學研究及礦石難選因素分析. 有色礦冶, 2018, 34(5):19 [10] Saririchi T, Azad R R, Arabian D, et al. On the optimization of sphalerite bioleaching; the inspection of intermittent irrigation, type of agglomeration, feed formulation and their interactions on the bioleaching of low-grade zinc sulfide ores. Chem Eng J, 2012, 187: 217 doi: 10.1016/j.cej.2010.10.013 [11] Wang L, Xia J L, Zhu H R, et al. Progress on research of microbe?mineral interaction and interfacial micro-analysis. Microbiol China, 2017, 44(3): 716王蕾, 夏金蘭, 朱泓睿, 等. 微生物?礦物相互作用及界面顯微分析研究進展. 微生物學通報, 2017, 44(3):716 [12] Brierley C L. Biohydrometallurgical prospects. Hydrometallurgy, 2010, 104(3-4): 324 doi: 10.1016/j.hydromet.2010.03.021 [13] Mehrabani J V, Shafaei S Z, Noaparast M, et al. Bioleaching of sphalerite sample from Kooshk lead–zinc tailing dam. Trans Nonferrous Met Soc China, 2013, 23(12): 3763 doi: 10.1016/S1003-6326(13)62927-1 [14] Wu B, Wen J K, Liu X, et al. A Selective Bioleaching Process for Leaching Bacteria and Low-grade Zinc Sulfide Ore: China Patent, 200810227389.8. 2008-11-27武彪, 溫建康, 劉學, 等. 一種浸礦菌及低品位硫化鋅礦的選擇性生物浸出工藝: 中國專利, 200810227389.8. 2008-11-27 [15] Li S S. Study on the Resources and Utilization of Smelting Waste of Zinc[Dissertation]. Changsha: Central South University, 2012李珊珊. 鋅冶煉廢渣資源化利用的研究[學位論文]. 長沙: 中南大學, 2012 [16] Sorokin D Y, Kuenen J G. Haloalkaliphilic sulfur-oxidizing bacteria in soda lakes. FEMS Microbiol Rev, 2005, 29(4): 685 doi: 10.1016/j.femsre.2004.10.005 [17] Sorokin D Y, Cherepanov A, De Vries S, et al. Identification of cytochrome c oxidase in the alkaliphilic, obligately chemolithoautotrophic, sulfur-oxidizing bacterium ‘Thioalcalomicrobium aerophilum’ strain AL 3. FEMS Microbiol Lett, 1999, 179(1): 91 doi: 10.1111/j.1574-6968.1999.tb08713.x [18] Willscher S, Bosecker K. Studies on the leaching behaviour of heterotrophic microorganisms isolated from an alkaline slag dump. Hydrometallurgy, 2003, 71(1-2): 257 doi: 10.1016/S0304-386X(03)00164-6 [19] Xiong Y W, Wang H J, Wu A X, et al. Research status and development trend on bioleaching with alkaline microbes. Hydrometallurgy, 2012, 31(4): 199熊有為, 王洪江, 吳愛祥, 等. 堿性微生物浸礦研究現狀及發展趨勢. 濕法冶金, 2012, 31(4):199 [20] Shabani M A, Irannajad M, Meshkini M, et al. Investigations on bioleaching of copper and zinc oxide ores. Trans Indian Inst Met, 2019, 72(3): 609 doi: 10.1007/s12666-018-1509-3 [21] Cocini Y, Zhou T X, Li C G. Leaching of zinc sulfide concentrate by thermophilic acidophilic A.b. acid bacteria. Metallic Ore Dress Abroad, 2000(9): 31Y·科西尼, 周廷熙, 李長根. 嗜熱嗜酸A.b.酸桿菌浸出硫化鋅精礦. 國外金屬礦選礦, 2000(9):31 [22] Li A L, Huang S T, Wen J K, et al. Research on the bioleaching of chalcopyrite from Dexing copper mine by moderate thermophiles. Met Mine, 2011(11): 78李啊林, 黃松濤, 溫建康, 等. 中等嗜熱菌浸出德興黃銅礦的試驗研究. 金屬礦山, 2011(11):78 [23] Liu W F, Wang H J, Zhang X, et al. Experimental study on bioleaching of copper sulfide tailings under alkaline conditions. Min Metall Eng, 2011, 31(3): 89劉偉芳, 王洪江, 張旭, 等. 某硫化銅礦尾礦堿性細菌浸出試驗研究. 礦冶工程, 2011, 31(3):89 [24] Willscher S, Bosecker K. Studies on the leaching behaviour of heterotrophic microorganisms isolated from an alkaline slag dump. Hydrometallurgy, 2003, 71(1): 257 [25] Shabani M A, Irannajad M, Meshkini M, et al. Investigations on bioleaching of copper and zinc oxide ores. Trans Indian Inst Met, 2019, 72(3): 609 doi: 10.1007/s12666-018-1509-3 [26] Richter C, Kalka H, Myers E, et al. Constraints of bioleaching in in-situ recovery applications. Hydrometallurgy, 2018, 178: 209 doi: 10.1016/j.hydromet.2018.04.008 [27] Schippers A, Hedrich S, Vasters J, et al. Biomining: metal recovery from ores with microorganisms//Geobiotechnology I. Heidelberg: Springer, 2013 [28] Fomchenko N V, Muravyov M I. Selective leaching of zinc from copper-zinc concentrate. Appl Biochem Microbiol, 2017, 53(1): 73 doi: 10.1134/S0003683817010197 [29] Lizama H M, Fairweather M J, Dai Z, et al. How does bioleaching start? Hydrometallurgy, 2003, 69(1-3): 109 doi: 10.1016/S0304-386X(03)00028-8 [30] Fowler T A, Crundwell F K. The role of Thiobacillus ferrooxidans, in the bacterial leaching of zinc sulphide. Process Metall, 1999, 9: 273 doi: 10.1016/S1572-4409(99)80027-3 [31] Vera M, Schippers A, Sand W. Progress in bioleaching: fundamentals and mechanisms of bacterial metal sulfide oxidation—part A. Appl Microbiol Biotechnol, 2013, 97(17): 7529 doi: 10.1007/s00253-013-4954-2 [32] Schippers A, Sand W. Bacterial leaching of metal sulfides proceeds by two indirect mechanisms via thiosulfate or via polysulfides and sulfur. Appl Environ Microbiol, 1999, 65(1): 319 doi: 10.1128/AEM.65.1.319-321.1999 [33] Zhao L, Wang Y, Jin L, et al. Decomposition of hydrogen sulfide in non-thermal plasma aided by supported CdS and ZnS semiconductors. Green Chem, 2013, 15(6): 1509 doi: 10.1039/c3gc00092c [34] Chen S, Qiu G Z, Qin W Q, et al. Bioleaching of sphalerite by Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans cultured in 9K medium modified with pyrrhotite. J Cent South Univ Technol, 2008, 15(04): 79 [35] Schippers A. Biogeochemistry of metal sulfide oxidation in mining environments, sediments, and soils. Spe Paper Geolog Soc Am, 2004, 379: 49 [36] Rohwerder T, Sand W. The sulfane sulfur of persulfides is the actual substrate of the sulfur-oxidizing enzymes from Acidithiobacillus and Acidiphilium spp. Microbiology, 2003, 149(7): 1699 doi: 10.1099/mic.0.26212-0 [37] Balci N, Mayer B, Shanks Ⅲ W C, et al. Oxygen and sulfur isotope systematics of sulfate produced during abiotic and bacterial oxidation of sphalerite and elemental sulfur. Geochim Cosmochim Acta, 2012, 77: 335 doi: 10.1016/j.gca.2011.10.022 [38] Gu G H, Sun X J, Hu K T, et al. Electrochemical oxidation behavior of pyrite bioleaching by Acidthiobacillus ferrooxidans. Trans Nonferrous Met Soc China, 2012, 22(5): 1250 doi: 10.1016/S1003-6326(11)61312-5 [39] Jyothi N, Sudha K N, Natarajan K A. Electrochemical aspects of selective bioleaching of sphalerite and chalcopyrite from mixed sulphides. Int J Miner Process, 1989, 27(3-4): 189 doi: 10.1016/0301-7516(89)90064-1 [40] Ahonen L, Tuovinen O H. Silver catalysis of the bacterial leaching of chalcopyrite-containing ore material in column reactors. Miner Eng, 1990, 3(5): 437 doi: 10.1016/0892-6875(90)90037-C [41] Lantrajin K A, Wang J. Bioleaching electrochemistry of sulfide ores. Metallic Ore Dress Abroad, 1997(2): 44K·A·蘭特拉金, 王軍. 硫化礦生物浸出電化學. 國外金屬礦選礦, 1997(2):44 [42] Zhang Y J, Yang X W. Thermodynamics during bioleaching processes of sulfide-ores. Precious Met, 1998, 19(3): 26張英杰, 楊顯萬. 硫化礦生物浸出過程的熱力學. 貴金屬, 1998, 19(3):26 [43] Ghassa S, Noaparast M, Shafaei S Z, et al. A study on the zinc sulfide dissolution kinetics with biological and chemical ferric reagents. Hydrometallurgy, 2017, 171: 362 doi: 10.1016/j.hydromet.2017.06.012 [44] Coni? V T, Vujasinovi? M M R, Truji? V K, et al. Copper, zinc, and iron bioleaching from polymetallic sulphide concentrate. Trans Nonferrous Met Soc China, 2014, 24(11): 3688 doi: 10.1016/S1003-6326(14)63516-0 [45] Zhou X L, Zheng Y, Wang S H, et al. Mechanisms of bioleaching electrochemstry-enhanced of electronic wastes. Environmentally Chemistry, 2017, 36(10): 15周秀麗, 鄭越, 王淑華, 等. 電子垃圾生物浸出的電化學強化機制. 環境化學, 2017, 36(10):15 [46] Sajjad W, Zheng G D, Din G, et al. Metals extraction from sulfide ores with microorganisms: the bioleaching technology and recent developments. Trans Indian Inst Met, 2019, 72(3): 559 doi: 10.1007/s12666-018-1516-4 [47] Kumar C G, Mamidyala S K, Sujitha P, et al. Evaluation of critical nutritional parameters and their significance in the production of rhamnolipid biosurfactants from Pseudomonas aeruginosa BS-161R. Biotechnol Prog, 2012, 28(6): 1507 doi: 10.1002/btpr.1634 [48] Pir?llo M P S, Mariano A P, Lovaglio R B, et al. Biosurfactant synthesis by Pseudomonas aeruginosa LBI isolated from a hydrocarbon-contaminated site. J Appl Microbiol, 2008, 105(5): 1484 doi: 10.1111/j.1365-2672.2008.03893.x [49] Diaz M A, De Ranson I U, Dorta B, et al. Metal removal from contaminated soils through bioleaching with oxidizing bacteria and rhamnolipid biosurfactants. Soil Sediment Contamin Int J, 2015, 24(1): 16 doi: 10.1080/15320383.2014.907239 [50] Yang Z H, Zhang Z, Chai L Y, et al. Bioleaching remediation of heavy metal-contaminated soils using Burkholderia sp. Z-90. J Hazard Mater, 2016, 301: 145 doi: 10.1016/j.jhazmat.2015.08.047 [51] Zhu Y, Zeng G M, Zhang P Y, et al. Feasibility of bioleaching combined with Fenton-like reaction to remove heavy metals from sewage sludge. Bioresour Technol, 2013, 142: 530 doi: 10.1016/j.biortech.2013.05.070 [52] Charikinya E, Bradshaw S, Becker M. Characterising and quantifying microwave induced damage in coarse sphalerite ore particles. Miner Eng, 2015, 82: 14 doi: 10.1016/j.mineng.2015.07.020 [53] Natarajan G, Ting Y P. Gold biorecovery from e-waste: an improved strategy through spent medium leaching with pH modification. Chemosphere, 2015, 136: 232 doi: 10.1016/j.chemosphere.2015.05.046 [54] Niu Z R, Li T, Su C, et al. Preparation of Mn-Zn ferrite from spent Zn?Mn batteries using bioleaching liquor as precursor. Acta Sci Circum, 2017, 37(9): 3356牛志睿, 李彤, 蘇沉, 等. 廢舊鋅錳電池生物淋濾-水熱法制備納米錳鋅鐵氧體. 環境科學學報, 2017, 37(9):3356 [55] Kaksonen A H, Perrot F, Morris C, et al. Evaluation of submerged bio-oxidation concept for refractory gold ores. Hydrometallurgy, 2014, 141: 117 doi: 10.1016/j.hydromet.2013.10.012 [56] Haschke M, Ahmadian J, Zeidler L, et al. In-situ recovery of critical technology elements. Procedia Eng, 2016, 138: 248 doi: 10.1016/j.proeng.2016.02.082 [57] Pakostova E, Grail B M, Johnson D B. Indirect oxidative bioleaching of a polymetallic black schist sulfide ore. Miner Eng, 2017, 106: 102 doi: 10.1016/j.mineng.2016.08.028 [58] Sun J Z, Chen B W, Wen J K, et al. Application and research progresses of hydrometallurgy technology for nickel ore. Chin J Nonferrous Met, 2018, 28(2): 356 doi: 10.1016/S1003-6326(18)64669-2孫建之, 陳勃偉, 溫建康, 等. 鎳礦濕法冶金技術應用進展及研究展望. 中國有色金屬學報, 2018, 28(2):356 doi: 10.1016/S1003-6326(18)64669-2 [59] Riekkola-Vanhanen M. Talvivaara Sotkamo mine—bioleaching of a polymetallic nickel ore in subarctic climate. Nova Biotechnol, 2010, 10(1): 7 [60] Fu K B, Ning Y, Wang J M, et al. Recovering copper and zinc from bioleaching lixivium of Liwu Copper Mine tailings by process of solvent extraction-precipitation. J Southwest Univ Sci Technol, 2017, 32(1): 10傅開彬, 寧燕, 王進明, 等. 四川里伍銅礦尾礦生物浸出液中回收銅、鋅的研究. 西南科技大學學報, 2017, 32(1):10 [61] Sun C Y, Zhou J W, Jia M X, et al. Research on genetic mineral processing engineering. Nonferrous Met (Miner Process Sect) , 2018(1): 1孫傳堯,周俊武,賈木欣,等. 基因礦物加工工程研究. 有色金屬(選礦部分), 2018(1):1 -

下載:

下載: