| [1] |

Wang X H, Chen B, Jiang M, et al. Effect of slag-metal reaction on formation of non-metallic inclusions of lower melting temperature in high strength alloyed structural steel. Iron Steel, 2008, 43(12): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-GANT200812007.htm王新華, 陳斌, 姜敏, 等. 渣-鋼反應對高強度合金結構鋼中生成較低熔點非金屬夾雜物的影響. 鋼鐵, 2008, 43(12): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-GANT200812007.htm

|

| [2] |

Xu K D, Xiao L J. Deoxidation andinclusion control in special steel refining. Iron Steel, 2012, 47(10): 1徐匡迪, 肖麗俊. 特殊鋼精煉中的脫氧及夾雜物控制. 鋼鐵, 2012, 47(10): 1

|

| [3] |

Wang X H, Jiang M, Yu H X, et al. Investigation on non-metallic inclusions in ultra-low oxygen special steels. Steelmaking, 2015, 31(6): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201506001.htm王新華, 姜敏, 于會香, 等. 超低氧特殊鋼中非金屬夾雜物研究. 煉鋼, 2015, 31(6): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201506001.htm

|

| [4] |

Li J Z, Jiang M, He X F, et al. Investigation on nonmetallic inclusions in ultra-low-oxygen special steels. Metall Mater Trans B, 2016, 47(4): 2386 doi: 10.1007/s11663-016-0687-9

|

| [5] |

Yang H L, He P, Zhai Y C. Progress on control of ultra-low-oxygen content and non-metallic inclusions in high quality bearing steel. Spec Steel, 2013, 34(2): 16 doi: 10.3969/j.issn.1003-8620.2013.02.005楊虎林, 何平, 翟玉春. 高品質軸承鋼超低氧含量和非金屬夾雜物控制的進展. 特殊鋼, 2013, 34(2): 16 doi: 10.3969/j.issn.1003-8620.2013.02.005

|

| [6] |

Park J S, Park J H. Effect of slag composition on the concentration of Al2O3 in the inclusions in Si-Mn-killed steel. Metall Mater Trans B, 2014, 45(3): 953 doi: 10.1007/s11663-013-9998-2

|

| [7] |

Liu J Z. Experimental Study on the Effect of Refractory on Oxygen Content in Molten Steel[Dissertation]. Shenyang: Northeastern University, 2011劉家占. 耐火材料對鋼中氧含量影響的實驗研究[學位論文]. 沈陽: 東北大學, 2011

|

| [8] |

Guo J, Fang K M, Guo H J, et al. Determination of three-dimensional morphology and inner structure of second-phase inclusions in metals by non-aqueous solution electrolytic and room temperature organic methods. Metals, 2018, 8(1): 68 doi: 10.3390/met8010068

|

| [9] |

Zhang X W, Zhang L F, Yang W, et al. Comparison of 2D and 3D morphology of non-metallic inclusions in steel using different methods. Metall Res Technol, 2017, 114(1): 113 doi: 10.1051/metal/2016056

|

| [10] |

Jiang G L, Li J S, Sun K M, et al. Study on macro inclusions in 30CrMo gas cylinder steel. Steelmaking, 2009, 25(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ200904018.htm姜桂連, 李京社, 孫開明, 等. 30CrMo氣瓶鋼中大型夾雜物的研究. 煉鋼, 2009, 25(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ200904018.htm

|

| [11] |

Janis D, Inoue A, Karasev P G, et al. Application of different extraction methods for investigation of nonmetallic inclusions and clusters in steels and alloys. Adv Mater Sci Eng, 2014, 2014: 210486 http://www.oalib.com/paper/3066102

|

| [12] |

Li J G, Zeng Y N, Wang S H, et al. Research on the non-metallic inclusion in 20CrMnTi steel during the process of refining and casting. Iron Steel Van Tit, 2010, 31(1): 56 https://www.cnki.com.cn/Article/CJFDTOTAL-GTFT201001011.htm李俊國, 曾亞南, 王樹華, 等. 20CrMnTi冶煉過程中夾雜物行為研究. 鋼鐵釩鈦, 2010, 31(1): 56 https://www.cnki.com.cn/Article/CJFDTOTAL-GTFT201001011.htm

|

| [13] |

Stampa E, Cipparrone M. Detection of harmful inclusions in steels for tire cord. Wire J Int, 1987, 20(3): 44 http://www.researchgate.net/publication/294523280_DETECTION_OF_HARMFUL_INCLUSIONS_IN_STEELS_FOR_TIRE_CORD

|

| [14] |

Sawai T, Wakoh M, Ueshima Y, et al. Analysis of oxide dispersion during solidification in Ti, Zr-deoxidized steels. ISIJ Int, 1992, 32(1): 169 doi: 10.2355/isijinternational.32.169

|

| [15] |

Yaguchi H, Tsuchida T, Shindou Y, et al. Non-lead-added free machining steel by sulfide inclusion morphology modification. Kobe Res Develop Jpn, 2002, 52(3): 62 http://www.researchgate.net/publication/289302749_Non-lead-added_free_machining_steel_by_sulfide_inclusion_morphology_modification

|

| [16] |

Matsui N, Watari K. Wear reduction of carbide tools observed in cutting Ca-added steels for machine structural use. ISIJ Int, 2006, 46(11): 1720 doi: 10.2355/isijinternational.46.1720

|

| [17] |

Runner D L, Maeda S, Gale J P, et al. Start-up of tire cord though USS/KOBE's billet caster//1998 Steelmaking Conference Proceeding. Toronto, 1998: 129

|

| [18] |

Yang X W. General understanding and deep understanding of bearing steel. Bearing, 2012(9): 54 https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201209020.htm楊曉蔚. 對軸承鋼的一般認識和深入認識. 軸承, 2012(9): 54 https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201209020.htm

|

| [19] |

Chan C F, Ko Y C. Effect of CaO content on the hot strength of alumina-spine castables in the temperature range of 1000℃ to 1500℃. J Am Ceram Soc, 1998, 81(11): 2957 http://www.ams.org/mathscinet-getitem?mr=2349

|

| [20] |

Shen S Y. Study on erosion mechanism of grade Ⅰ alumina bricks as ladle lining in Taigang. Bull Chin Ceram Soc, 1992(4): 45 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT199204010.htm沈上越. 太鋼一等高鋁磚用于盛鋼桶襯磚的侵蝕機理研究. 硅酸鹽通報, 1992(4): 45 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT199204010.htm

|

| [21] |

Li N D, Xie Y C, Yan S X, et al. Effect of additives on the structure and properties of high alumina bricks. Refractories, 1999, 33(3): 158 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL903.011.htm李乃動, 謝宜才, 燕宿祥, 等. 添加物對高鋁磚結構和性能的影響. 耐火材料, 1999, 33(3): 158 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL903.011.htm

|

| [22] |

Resende W S, Stoll R M, Justus S M, et al. Key features of alumina/magnesia/graphite refractories for steel ladle lining. J Eur Ceram Soc, 2000, 20(9): 1419 doi: 10.1016/S0955-2219(00)00004-2

|

| [23] |

Akkurt S, Leigh H D. Corrosion of MgO-C ladle refractories. Am Ceram Soc Bull, 2003, 82(5): 32 http://www.researchgate.net/publication/292543930_Corrosion_of_MgO-C_ladle_refractories

|

| [24] |

Li S F. Aluminum-magnesium carbon brick and its application on ladle. Steelmaking, 1990(2): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ199002002.htm李遂方. 鋁鎂碳磚及其在鋼包上的應用. 煉鋼, 1990(2): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ199002002.htm

|

| [25] |

Yao H B, Yao S Z, Luo C, et al. Current research and developing trend of MgO-C bricks. Chin J Eng, 2018, 40(3): 253 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201803001.htm姚華柏, 姚蘇哲, 駱昶, 等. 鎂碳磚的研究現狀與發展趨勢. 工程科學學報, 2018, 40(3): 253 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201803001.htm

|

| [26] |

Lee W E, Zhang S. Melt corrosion of oxide and oxide-carbon refractories. Int Mater Rev, 1999, 44(3): 77 doi: 10.1179/095066099101528234

|

| [27] |

Zhu B Q, Zhang W J. Research of low-carbon magnesia carbon bricks: present situation and development. J Wuhan Univ Sci Technol Nat Sci Ed, 2008, 31(3): 233 doi: 10.3969/j.issn.1674-3644.2008.03.003朱伯銓, 張文杰. 低碳鎂碳磚的研究現狀與發展. 武漢科技大學學報(自然科學版), 2008, 31(3): 233 doi: 10.3969/j.issn.1674-3644.2008.03.003

|

| [28] |

Shi Y W, Jia X J, Wei P C. Development and applications of low-carbon magnesia carbon bricks. Sci Technol Baotou Steel, 2012, 38(1): 17 doi: 10.3969/j.issn.1009-5438.2012.01.007石永午, 賈新軍, 魏鵬程. 低碳鎂碳磚的研制和應用. 包鋼科技, 2012, 38(1): 17 doi: 10.3969/j.issn.1009-5438.2012.01.007

|

| [29] |

Zhang S, Marriott N J, Lee W E. Thermochemistry and microstructures of MgO-C refractories containing various antioxidants. J Eur Ceram Soc, 2001, 21(8): 1037 doi: 10.1016/S0955-2219(00)00308-3

|

| [30] |

Gokce A S, Gurcan C, Ozgen S, et al. The effect of antioxidants on the oxidation behaviour of magnesia-carbon refractory bricks. Ceram Int, 2008, 34(2): 323 doi: 10.1016/j.ceramint.2006.10.004

|

| [31] |

He Z Y, Peng X Y, Li L, et al. Effect of ZrB2 on oxidation resistance of low-carbon MgO-C materials. Refactories, 2006, 40(4): 280 doi: 10.3969/j.issn.1001-1935.2006.04.010賀智勇, 彭小艷, 李林, 等. ZrB2對低碳鎂碳材料抗氧化性能的影響. 耐火材料, 2006, 40(4): 280 doi: 10.3969/j.issn.1001-1935.2006.04.010

|

| [32] |

Xu N, Li Z J, Wu F, et al. Research on mechanism of improving of slag corrosion-resistance of MgO-C brick with TiN. Bull Chin Ceram Soc, 2008, 27(5): 1044 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT200805033.htm徐娜, 李志堅, 吳鋒, 等. TiN提高鎂碳磚抗渣侵蝕機理的研究. 硅酸鹽通報, 2008, 27(5): 1044 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT200805033.htm

|

| [33] |

Yamaguchi A, Zhang S W. Synthesis and some properties of Al4 SiC4. J Ceram Soc Jpn, 1995, 103(1193): 20 doi: 10.2109/jcersj.103.20

|

| [34] |

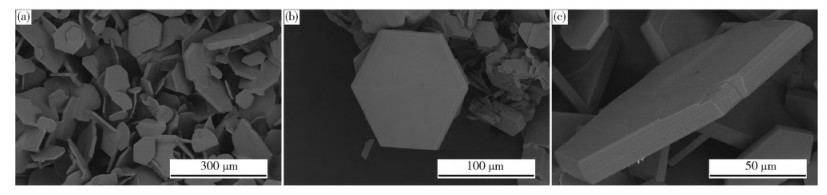

Xing X M, Li B, Chen J H, et al. Formation mechanism of large size plate-like Al4 SiC4 grains by a carbothermal reduction method. CrystEngComm, 2018, 20: 1399 doi: 10.1039/C7CE02193C

|

| [35] |

Xing X M, Chen J H, Bei G P, et al. Synthesis of Al4 SiC4 powders via carbothermic reduction: reaction and grain growth mechanisms. J Adv Ceram, 2017, 6(4): 351 doi: 10.1007/s40145-017-0247-z

|

| [36] |

Wang Z F, Zhang Y C, Li R C, et al. Experimental study on anti-oxidation of graphite crucible impregnation. Non-Metallic Mines, 2004, 27(3): 3 https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK200403001.htm王志發, 張永春, 李如春, 等. 石墨坩堝浸漬法抗氧化試驗研究. 非金屬礦, 2004, 27(3): 3 https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK200403001.htm

|

| [37] |

Ouyang D G. Present status and development of anti-oxidation coatings for carbon-containing refractory. Ind Heat, 2005, 34(4): 51 doi: 10.3969/j.issn.1002-1639.2005.04.015歐陽德剛. 含碳耐火材料抗氧化涂料的現狀與發展趨勢. 工業加熱, 2005, 34(4): 51 doi: 10.3969/j.issn.1002-1639.2005.04.015

|

| [38] |

Tamura T, Tsynemi O, Shigeyuki T, Nano-tech refractories-1: the development of the nano structural matrix//Proceedings of Unified International Technical Conference on Refractories. Osaka, 2003: 517

|

| [39] |

Zhu T B, Li Y W, Sang S B, et al. Effect of nanocarbon sources on microstructure and mechanical properties of MgO-C refractories. Ceram Int, 2014, 40(3): 4333 doi: 10.1016/j.ceramint.2013.08.101

|

| [40] |

Shi X Q, Li L, Peng X Y. Effects of nanometer carbon black on mechanical properties and thermal shock resistance of MgO-C bricks. China Metall, 2015, 25(6): 17 doi: 10.3969/j.issn.1007-0958.2015.06.010史曉強, 李林, 彭小艷. 納米炭黑對鎂碳磚力學性能和熱震性的影響. 中國冶金, 2015, 25(6): 17 doi: 10.3969/j.issn.1007-0958.2015.06.010

|

| [41] |

Yan Z G, Chen W, Yu J K. Synthesis of B4C-C composite powder and its application in low carbon MgO-C bricks. Chin J Process Eng, 2009, 9(5): 1011 doi: 10.3321/j.issn:1009-606X.2009.05.030顏正國, 陳偉, 于景坤. B4C-C復合粉體的合成及其在低碳鎂碳磚中的應用. 過程工程學報, 2009, 9(5): 1011 doi: 10.3321/j.issn:1009-606X.2009.05.030

|

| [42] |

Hua X J, Zhu B Q, Li X D, et al. TiC-C compound powder: synthesis and its influence on oxidation resistance of low-carbon MgO-C bricks. J Wuhan Univ Sci Technol Nat Sci Ed, 2007, 30(2): 145 doi: 10.3969/j.issn.1674-3644.2007.02.010華旭軍, 朱伯銓, 李雪冬, 等. TiC-C復合粉體的制備及其對低碳鎂碳磚抗氧化性能的影響. 武漢科技大學學報(自然科學版), 2007, 30(2): 145 doi: 10.3969/j.issn.1674-3644.2007.02.010

|

| [43] |

Li L, Tang G S, He Z Y, et al. Influences of black carbon addition on mechanical performance of low-carbon MgO-C composite. J Iron Steel Res Int, 2010, 17(12): 75 doi: 10.1016/S1006-706X(10)60201-4

|

| [44] |

Luo M, Li Y W, Jin S L, et al. Research and outlook of carbon nanotubes reinforced ceramic matrix composites. Mater Rev, 2010, 24(Spec): 155 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2010S1050.htm羅明, 李亞偉, 金勝利, 等. 碳納米管增強陶瓷基復合材料的研究與展望. 材料導報, 2010, 24(專輯): 155 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2010S1050.htm

|

| [45] |

Aneziris C G, Hubalkova J, Barabas R. Microstructure evaluation of MgO-C refractories with TiO2-and Al-additions. J Eur Ceram Soc, 2007, 27(1): 73 doi: 10.1016/j.jeurceramsoc.2006.03.001

|

| [46] |

Cao Y P, Yan W, Li N. Effect of Si-SiC composite powder addition on properties of low-carbon MgO-C refractories. Refractories, 2016, 50(3): 170 doi: 10.3969/j.issn.1001-1935.2016.03.004曹亞平, 鄢文, 李楠. Si-SiC復合粉添加量對低碳鎂碳耐火材料性能的影響. 耐火材料, 2016, 50(3): 170 doi: 10.3969/j.issn.1001-1935.2016.03.004

|

| [47] |

Wang Z Q, Zhu B Q, Fang B X, et al. Effects of B4C and Si antioxidant on oxidation resistance of low-carbon MgO-C bricks. Refractories, 2008, 42(3): 161 doi: 10.3969/j.issn.1001-1935.2008.03.001王志強, 朱伯銓, 方斌祥, 等. B4C和Si組合抗氧化劑對低碳MgO-C磚抗氧化性能的影響. 耐火材料, 2008, 42(3): 161 doi: 10.3969/j.issn.1001-1935.2008.03.001

|

| [48] |

Zhang LF. Several important scientific research points of non-metallic inclusions in steel. Steelmaking, 2016, 32(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201604002.htm張立峰. 鋼中非金屬夾雜物幾個需要深入研究的課題. 煉鋼, 2016, 32(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201604002.htm

|

| [49] |

Gao M, Li Z Y, Wang T S, et al. Influence of sintered spinel fines on properties of corundum-spinel castables. Refractories, 2018, 52(1): 56 doi: 10.3969/j.issn.1001-1935.2018.01.014高梅, 李朝云, 王團收, 等. 燒結尖晶石細粉加入量對剛玉-尖晶石澆注料性能的影響. 耐火材料, 2018, 52(1): 56 doi: 10.3969/j.issn.1001-1935.2018.01.014

|

| [50] |

Wu Y S, Ren L, Wang T S, et al. Effect of silica micro-powder on thermal shock resistance of cement-free corundum-spinel castables//Proceedings of the 13th National Conference on Unshaped Refractory Materials and the 2015 Academic Conference on Refractory Materials. Qingda, 2015: 22吳永生, 任林, 王團收, 等. 二氧化硅微粉對無水泥剛玉-尖晶石澆注料抗熱震性能的影響//第十三屆全國不定形耐火材料學術會議和2015耐火原料學術交流會. 青島, 2015: 22

|

| [51] |

Yao J F, Zhang E F, Tian S X. Influence of ultrafine α-Al2O3 on properties of corundum spinel castables. Refractories, 2008, 42(3): 209 doi: 10.3969/j.issn.1001-1935.2008.03.012姚金甫, 張恩甫, 田守信. α-Al2O3微粉對剛玉-尖晶石澆注料性能的影響. 耐火材料, 2008, 42(3): 209 doi: 10.3969/j.issn.1001-1935.2008.03.012

|

| [52] |

Lian W K, Tang B J, Wei J C, et al. Effects of ZrO2 micropowder addition on performances of corundum spinel castables. Refractories, 2018, 52(4): 250 doi: 10.3969/j.issn.1001-1935.2018.04.003連偉康, 唐冰杰, 魏軍從, 等. ZrO2微粉加入量對剛玉-尖晶石澆注料性能的影響. 耐火材料, 2018, 52(4): 250 doi: 10.3969/j.issn.1001-1935.2018.04.003

|

| [53] |

Li Z G, Ye F B. Effect of nano calcium carbonate on properties of corundum-spinel castables. Refractories, 2012, 46(6): 406 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL201206003.htm李志剛, 葉方保. 加入納米碳酸鈣對剛玉-尖晶石質澆注料性能的影響. 耐火材料, 2012, 46(6): 406 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL201206003.htm

|

| [54] |

Jia Q L, Ye F B, Zhong X C. Effect of TiO2 addition on properties of corundum spinel castables. Refractories, 2009, 43(6): 417 doi: 10.3969/j.issn.1001-1935.2009.06.005賈全利, 葉方保, 鐘香崇. TiO2加入量對剛玉-尖晶石澆注料性能的影響. 耐火材料, 2009, 43(6): 417 doi: 10.3969/j.issn.1001-1935.2009.06.005

|

| [55] |

Zhang D J, Wang H X. Corrosion behavior of refining slags with different basicities to corundum-spinel castable. Refractories, 2002, 36(4): 215 doi: 10.3969/j.issn.1001-1935.2002.04.010張殿軍, 王會先. 不同堿度的精煉渣對剛玉-尖晶石澆注料的侵蝕行為. 耐火材料, 2002, 36(4): 215 doi: 10.3969/j.issn.1001-1935.2002.04.010

|

| [56] |

Jia Q L, Ye F B, Zhong X C. Effects of cement addition on the slag resistance of alumina-spinel castables. J Zhengzhou Univ Eng Sci, 2011, 32(1): 43 doi: 10.3969/j.issn.1671-6833.2011.01.011賈全利, 葉方保, 鐘香崇. 水泥對剛玉-尖晶石澆注料抗侵蝕性影響研究. 鄭州大學學報(工學版), 2011, 32(1): 43 doi: 10.3969/j.issn.1671-6833.2011.01.011

|

| [57] |

Gao J Y, Zhou B Y, Bruno T, et al. Effect of CMA72 addition on the properties of corundum-spinel castables//Proceedings of the 15th National Refractory Youth Academic Conference. Yangzhou, 2016: 231郜劍英, 周寶余, Bruno Touzo, 等. CMA72加入量對剛玉-尖晶石澆注料性能的影響//第十五屆全國耐火材料青年學術報告會論文集. 揚州, 2016: 231

|

| [58] |

Ke C M, Li N, Mo J N. Contribution of lime based tundish working lining to clean steel making//Proceedings of 38th Annual Conference of Metallurgists of CIM-Advances in Refractories for the Metallurgical Industries. Quebec, 1999: 177

|

| [59] |

Wei Y W, Li N. Refractories for clean steel making. Am Ceram Soc Bull, 2002, 81(5): 32 http://www.researchgate.net/publication/291878532_Refractories_for_clean_steel_making

|

| [60] |

北村. タアグネツアの水化特性. Taikabutsu, 1996, 48(3): 112

|

| [61] |

Shi H S, Zhao Y J, Li W W. Effects of temperature on the hydration characteristics of free lime. Cem Concr Res, 2002, 32(5): 789 doi: 10.1016/S0008-8846(02)00714-7

|

| [62] |

Hou D Z, Zhang W J, Gu H Z, et al. Hydration resistance of MgO-CaO clinker treated by polyphosphate. Refractories, 2002, 36(1): 16 doi: 10.3969/j.issn.1001-1935.2002.01.005侯冬枝, 張文杰, 顧華志, 等. 聚磷酸鹽表面處理鎂鈣砂的抗水化性能. 耐火材料, 2002, 36(1): 16 doi: 10.3969/j.issn.1001-1935.2002.01.005

|

| [63] |

Ghosh A, Tripathi H S. Sintering behaviour and hydration resistance of reactive dolomite. Ceram Int, 2012, 38(2): 1315 doi: 10.1016/j.ceramint.2011.09.005

|

| [64] |

Lin B Y, Wu Q S. Refractory Mineral Material. Beijing: Metallurgical Industry Press, 1989林彬蔭, 吳清順. 耐火礦物原料. 北京: 冶金工業出版社, 1989

|

| [65] |

Chen M, Lu C Y, Yu J K. Improvement in performance of MgO-CaO refractories by addition of nano-sized ZrO2. J Eur CeramSoc, 2007, 27(16): 4633 doi: 10.1016/j.jeurceramsoc.2007.04.001

|

| [66] |

Chen K X, Chen Z Y. Effects of mixed rare earth oxides and Fe 2 O3 on the sintering properties and anti-hydration properties of dolomite. Refractories, 1992, 26(4): 187陳開獻, 陳肇友. 混合稀土氧化物與Fe2O3對白云石燒結性能和抗水化性能的影響. 耐火材料, 1992, 26(4): 187

|

| [67] |

Zhong X C. Looking ahead a new generation of high performance refractory ceramics. Refractories, 2003, 37(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL200301000.htm鐘香崇. 展望新一代優質高效耐火材料. 耐火材料, 2003, 37(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL200301000.htm

|

| [68] |

Chen Z Y, Tian S X. Relationship between clean steel and refractories. Refractories, 2004, 38(4): 219 doi: 10.3969/j.issn.1001-1935.2004.04.001陳肇友, 田守信. 耐火材料與潔凈鋼的關系. 耐火材料, 2004, 38(4): 219 doi: 10.3969/j.issn.1001-1935.2004.04.001

|

| [69] |

Bannenberg N. Demands on refractory material for clean steel production//Proceedings of Unified International Technical Conference on Refractories. Kyoto, 1995

|

| [70] |

Xu Y. The improvement of anti-erosion performance of magnesium-chrome refractories via adding nanoparticles. Refract Lime, 2015, 40(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-GWLH201504018.htm徐勇. 添加納米顆粒對鎂鉻耐火材料抗侵蝕性能的改善. 耐火與石灰, 2015, 40(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-GWLH201504018.htm

|

| [71] |

Zhu H X, Deng C J, Bai C, et al. Grain close packing model of refractory with continuous particle size distribution. J Wuhan Univ Sci Technol Nat Sci Ed, 2008, 31(2): 159 doi: 10.3969/j.issn.1674-3644.2008.02.012祝洪喜, 鄧承繼, 白晨, 等. 耐火材料連續顆粒分布的緊密堆積模型. 武漢科技大學學報(自然科學版), 2008, 31(2): 159 doi: 10.3969/j.issn.1674-3644.2008.02.012

|

| [72] |

Ye C. Investigation on Interaction between MgO-Al2O3 Refractory and Molten Steel in Refining Process[Dissertation]. Beijing: University of Science and Technology Beijing, 2008葉超. 鎂鋁質鋼包精煉用耐火材料與鋼液相互作用的基礎研究[學位論文]. 北京: 北京科技大學, 2008

|

| [73] |

Chen J H, Chen H Y, Mi W J, et al. Substitution of Ba for Ca in the structure of CaAl12O19. J Am Ceram Soc, 2017, 100(1): 413 doi: 10.1111/jace.14482

|

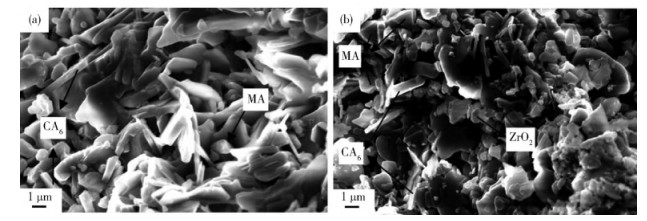

| [74] |

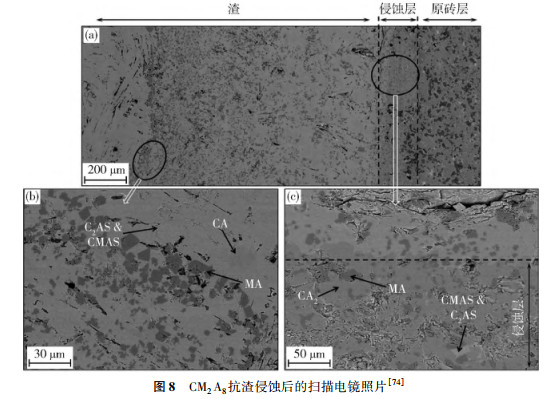

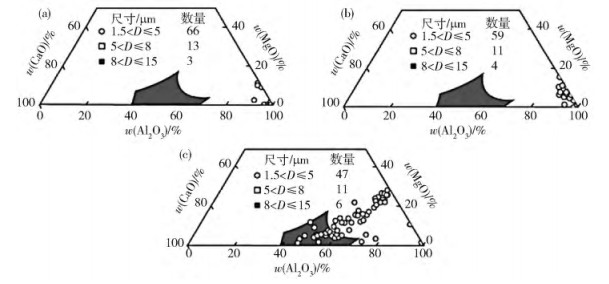

Chen J H, Chen H Y, Mi W J, et al. Synthesis of CaO·2MgO·8Al2O3(CM2A8) and its slag resistance mechanism. J Eur Ceram Soc, 2017, 37(4): 1799 doi: 10.1016/j.jeurceramsoc.2016.11.018

|

下載:

下載: