-

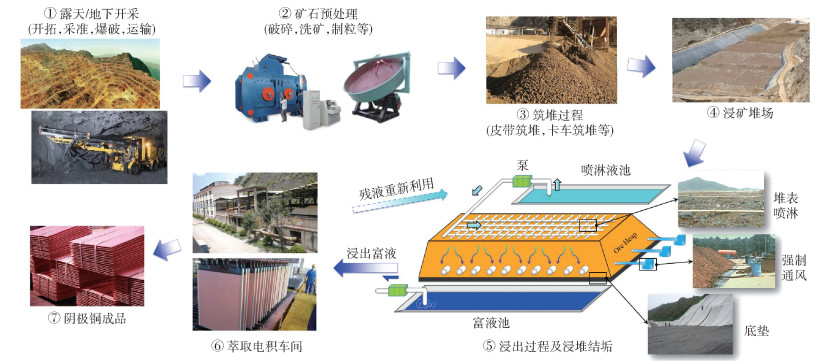

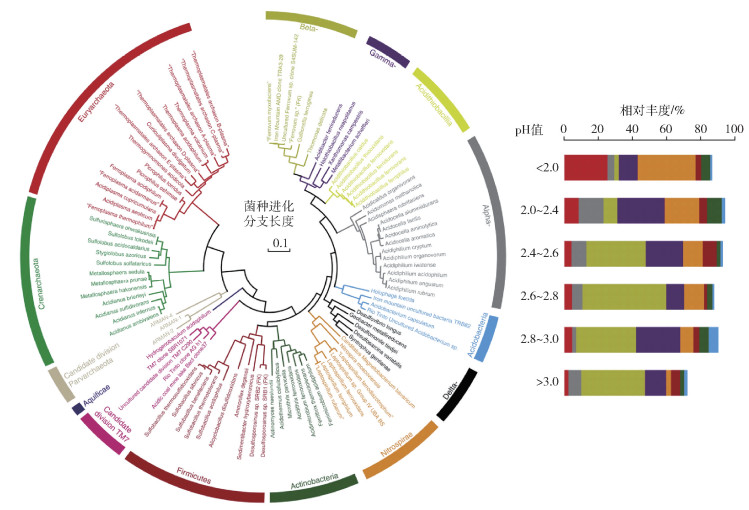

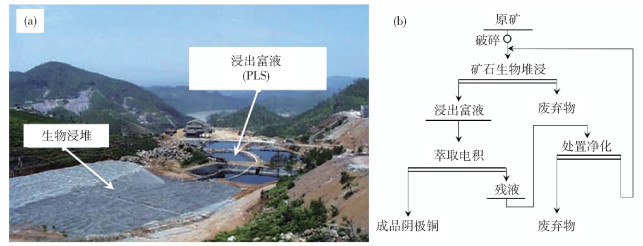

摘要: 回顧了我國微生物浸出技術發展的歷史進程, 總結了我國開展生物浸銅技術的探索與應用進程, 介紹了紫金山銅礦、德興銅礦兩個典型的生物浸銅案例; 探討了浸礦細菌分離、鑒定與富集, 生物浸出機理與界面反應, 浸出體系多級滲流行為, 孔隙結構重構與定量化, 浸出體系多場耦合與過程模擬, 電子廢棄物中的銅金屬回收領域的主要進展.最后, 結合生物浸銅技術的當前進展, 闡述了生物浸銅技術面臨的環保、安全等方面的挑戰與未來發展趨勢, 為今后該領域的研究提供良好借鑒.Abstract: Mineral resources are the mainstay industries supporting the development of the national economy. Due to its excellent ductility, electrical and thermal conductivity, copper is widely used in construction, power, transportation, and manufacturing as an important strategic metal resource. According to statistics, in terms of output and consumption of ten kinds of non-ferrous metals such as copper, aluminum, and zinc, China has ranked first in the world for more than ten consecutive years. China's copper resources are poorly endowed, being low grade, highly ore-deficient, and of poor ore floatability; the use of conventional separation methods has been costly and caused serious environmental pollution due to difficulties with residue disposal. Bioleaching is a special mining technology that leaches and yields valuable metal elements from inside ores using leaching bacteria. Copper metal resources inside low-grade ores, waste ores, and boundary ores are recycled efficiently using bioleaching technology, which is efficient, and both environmentally-friendly and economical. Currently, more than a quarter of the world's copper production depends on this technology. However, the microbial copper leaching process has always been regarded as a "black box", being difficult to effectively monitor and regulate. This paper reviews the history of bioleaching technology in China, reviews those copper mines that have carried out exploration into or application of bioleaching technology, and introduces two typical copper bioleaching industrial cases, the Zijinshan and Dexing Copper Mines. This paper explores (a) the main process of isolation, identification and enrichment of leaching bacteria, (b) the bioleaching mechanism and interface reaction, (c) the multistage seepage behavior of leaching systems, (d) the reconstruction and quantification of pore structures, (e) the multi-field coupling and process simulation of leaching systems, and (f) copper metal recycling from waste printed circuit boards. Finally, along with the current status of copper bioleaching, major challenges such as environmental protection, security, and future trends in copper bioleaching are discussed as a basis for further research.

-

Key words:

- solution mining /

- bioleaching /

- ore heap leaching /

- solution seepage /

- pore evolution

-

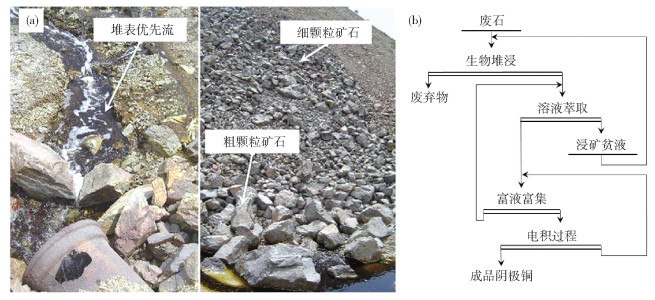

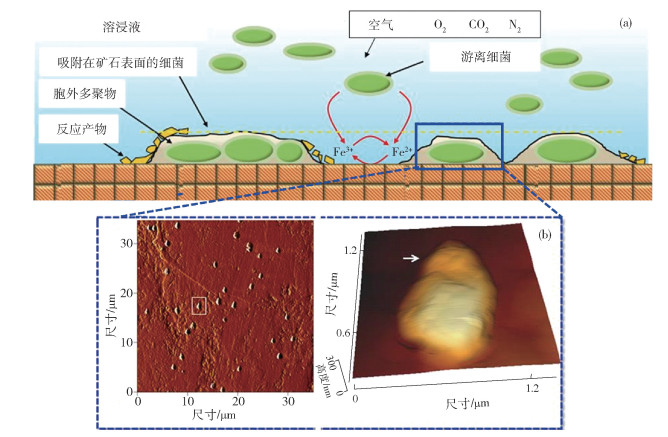

圖 5 浸礦過程中的界面反應與吸附菌的原子力顯微圖像[84-85]. (a) 浸礦系統中細菌-礦物相互作用; (b) 基于原子力顯微鏡的礦物與細菌微觀形貌

Figure 5. Interface reaction and AFM micro images of attached bacteria during leaching process[84-85]: (a) interaction effect of bacteria-mineral inside ore leaching system; (b) micro morphology of minerals and bacterial based on atomic force microscope

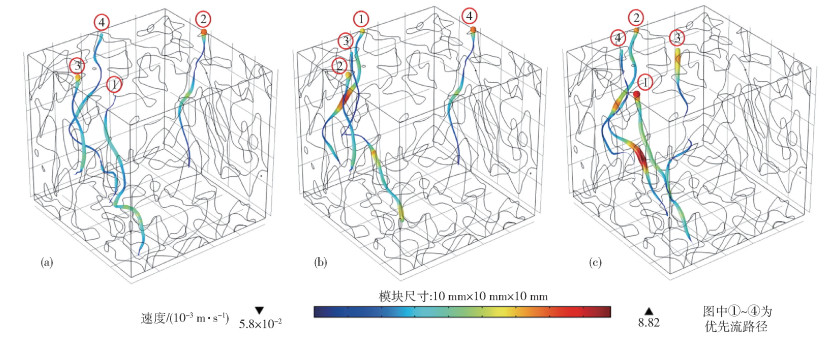

圖 8 基于COMSOL Multiphysics的雙重孔隙結構內優先流路徑模擬[108]. (a) 單孔隙度模型; (b) 微孔網絡滲透率5.18×10-11 mm2; (c) 微孔網絡滲透率8.54×10-10 mm2

Figure 8. Simulation of preferential flow pathways inside dual pore structures using COMSOL Multiphysics[108]: (a) single macro porosity model; (b) micro-pore network permeability is 5.18×10-11 mm2; (c) micro-pore network permeability is 8.54×10-10 mm2

表 1 我國低品位銅礦微生物浸出技術的主要探索與應用(不完全統計)

Table 1. Exploration and successful industrial cases of low-grade copper bioleaching in China (incomplete statistics)

礦山名稱 地點 礦物特征 主要特點 德興銅礦[34] 江西,德興 Cu 0.30%(質量分數,下同),原生硫化銅為主 始建于1965年,自1979年開始使用生物浸出技術,1997年建成生物廢石浸出廠,銅浸出率30%,年產陰極銅2000 t 羊拉銅礦[35] 云南,迪慶 Cu 1.01% (氧化銅為主,孔雀石0.36%, 硅孔雀石0.29%, 輝銅礦0.29%) 利用Providencia sp. JAT-1開展堿性細菌浸礦研究; 初始pH值8,初始溫度為30 ℃,浸礦156 h后銅浸出率達54.5% 紫金山銅礦[36-37] 福建,上杭 低品位硫化銅礦為主,Cu 0.38% 采用萃取-電積生物堆浸技術,2006年,建成年產銅礦20000 t堆浸廠 官房銅礦[38] 云南,臨滄 次生硫化銅礦為主,Cu 0.9% 2003年建成生物堆浸廠,處置原生及次生硫化銅礦 中條山銅礦[39] 山西,運城 次生硫化銅59.1%,自由氧化銅37.4%,Cu 0.65% 地下原位破碎浸出,生物浸出與酸浸結合,2000年年產銅500 t 銅官山銅礦[40] 安徽,銅陵 Cu 0.9% 自1965年實驗地下生物浸出,1980年銅回收率達95%,2003年停產 大寶山銅礦[41] 廣東,韶關 Cu 1.06% (原生及次生硫化銅占總質量90%),Fe 26.8%; 利用大寶山銅礦分離出的T.f菌,進行生物廢石堆浸 玉龍銅礦[42] 西藏,江達 Cu 2.75% (次生硫化銅礦28.95%, 原生硫化銅35%) 氧化銅礦及硫化礦的萃取-電積生物堆浸廠,地處西藏高海拔地區(4569~5118 m); 其中,硫化礦中的銅回收率超過80% 阿舍勒銅礦[43] 新疆,哈巴河 Cu 2.43% 2004年7月,生物堆浸廠建成并使用,銅浸出率達80% 永平銅礦[44] 江西,上饒 Cu 0.32% (原生硫化銅65.6%) 我國第二大露天礦,始建于1984年,自上世紀90年代,利用生物浸出回收低品位銅礦和廢石 賽什塘銅礦[45] 青海,興海 Cu 0.83% (硫化銅礦與氧化銅為主) 地處青藏高原的高海拔地區(3450 m); 開展高寒-低氧含量環境下的生物浸出實驗 東川銅礦[46] 云南,東川 Cu 0.9%~1.5% (硫化銅礦33%,氧化銅礦41%) 始建于上世紀60年代,順利開展了工業級的生物浸出實驗 冬瓜山銅礦[47] 安徽,銅陵 Cu 0.94%~1.06% (黃銅礦為主), 主要浸礦細菌為A.f (CUMT-1 & ZJJN-3) 利用Acidithiobacillus ferrooxidans和Acidithiobacillus thiooxidans開展黃銅礦浸出實驗 金川銅鎳礦[48] 甘肅,金川 Cu 0.44% (原生硫化銅69.8%, 自由氧化銅20.6%,次生硫化銅8% 生物浸出探索自2006至2009年運行,鎳銅鈷多金屬聯合浸出,40 d后銅浸出率達93.48% 東鄉銅礦[49] 江西,福州 Cu 1.34% (黃銅礦1.01%, 輝銅礦0.33%), 黃鐵礦11.48%, Fe 30.05% 采用原生硫化銅地下破碎原位浸出技術,高硫、高鐵礦石 云浮銅鎳礦[50] 江西,梅州 我國第一大FeS2礦山 多細菌聯合浸出探索,Betaproteobacteria 47.75%, Gammaproteobacteria 37.84%為主 薩熱克銅礦[51] 新疆,烏恰 Cu 1.34%,次生硫化銅礦(黃銅礦,輝銅礦等) 開展生物浸出工業級實驗,經155 d后,銅浸出率達93.77% 多寶山銅礦[52] 黑龍江,嫩江 Cu 0.51%,原生硫化銅(黃銅礦為主) 開展浸出實驗,經326 d后,銅浸出率僅為15.5%,大量CaSO4導致板結鈍化現象嚴重 大冶鐵礦[53] 湖北,大冶 Cu 0.35%,硫化銅32.3%,自由氧化銅26.3% 低品位廢石堆浸,高氧化性,高泥,經80 d浸出試驗,銅浸出率達83.97% 中衛銅礦[54] 寧夏,中衛 Cu 0.32%,次生硫化銅59.38%,原生硫化銅37.5% 開展工業試驗,經315 d后銅浸出率達83.03%,板結嚴重,產生大量CaSO4 哈密銅鎳礦[55] 新疆,哈密 Cu 3%, 硫化銅礦為主 含錳低品位硫化銅礦,開展銅鎳生物浸出實驗,銅浸出率達32.6% 表 2 世界范圍內已分離獲得的浸銅細菌(不完全統計)[59]

Table 2. Leaching bacteria after being isolated and identified around the world (incomplete statistics)[59]

細菌種類 NCBI編號 菌種采樣位置及國家 Acidithiobacillus ferrivorans CF27 CCCS000000000 某銅鈷礦的酸性礦坑水,美國 Acidiplasma sp.MBA-1 JYHS00000000 某銅礦浸出反應器,俄羅斯 Acidiplasma cupricumulans BH2 LKBH00000000 某硫化銅礦,緬甸 Ferrovum sp. JA12 LJWX00000000 某硫化銅礦礦坑水,德國 Ferrovum sp.Z-31 LRRD00000000 某銅礦酸性礦坑水,德國 Acidithiobacillus thiooxidans Licanantay JMEB00000000 某銅礦,智利 "Ferrovum myxofaciens" P3GT JPOQ00000000 某銅礦礦坑水,英國 "Acidibacillus ferrooxidans" DSM 5130T LPVJ00000000 某低品位黃銅礦礦坑水,巴西 Ferrimicrobium acidiphilum DSM 19497T JQKF00000000 某銅礦礦坑水,英國 Leptospirillum sp.Sp-Cl LGSH00000000 某銅礦,智利 Sulfobacillus thermosulfidooxidans Cutipay ALWJ00000000 某銅礦滲濾液,智利 Acidithiobacillus ferrooxidans (4664533.3)# 德興銅礦,中國 Sulfobacillus thermosulfidooxidans DSM 9293T (2506210005)* 某自熱礦床,哈薩克斯坦 Acidithiobacillus ferrooxidans ATCC 53993 NC_011206 某銅礦,亞美尼亞 Acidithiobacillus caldus SM-1 NC_015850 微生物資源前期開發國家重點實驗室,中國 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Watling H R. The bioleaching of sulphide minerals with emphasis on copper sulphides—a review. Hydrometallurgy, 2006, 84(1-2): 81 doi: 10.1016/j.hydromet.2006.05.001 [2] Rawlings D E, Johnson D B. The microbiology of biomining: development and optimization of mineral-oxidizing microbial consortia. Microbiol, 2007, 153: 315 doi: 10.1099/mic.0.2006/001206-0 [3] Panda S, Akcil A, Pradhan N, et al. Current scenario of chalcopyrite bioleaching: a review on the recent advances to its heap-leach technology. Bioresour Technol, 2015, 196: 694 doi: 10.1016/j.biortech.2015.08.064 [4] Fang X, Shen Y, Zhao J, et al. Status and prospect of lignocellulosic bioethanol production in China. Bioresour Technol, 2010, 101(13): 4814 doi: 10.1016/j.biortech.2009.11.050 [5] Yin S H, Wang L M, Pan C Y, et al. Secondary copper sulfide bioleaching experiments. Chin J Eng, 2017, 39(10): 1498 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201710006.htm尹升華, 王雷鳴, 潘晨陽, 等. 次生硫化銅礦微生物浸出實驗. 工程科學學報, 2017, 39(10): 1498 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201710006.htm [6] Wu A X, Wang H J, Yang B H, et al. Progress and prospect of solution mining. Min Technol, 2006, 6(3): 39 doi: 10.3969/j.issn.1671-2900.2006.03.009吳愛祥, 王洪江, 楊保華, 等. 溶浸采礦技術的進展與展望. 采礦技術, 2006, 6(3): 39 doi: 10.3969/j.issn.1671-2900.2006.03.009 [7] Petersen J. Heap leaching as a key technology for recovery of values from low-grade ores——a brief overview. Hydrometallurgy, 2016, 165: 206 doi: 10.1016/j.hydromet.2015.09.001 [8] Johnson D B. Biomining goes underground. Nat Geosci, 2015, 8: 165 doi: 10.1038/ngeo2384 [9] Shiers D W, Collinson D M, Watling H R. Life in heaps: a review of microbial responses to variable acidity in sulfide mineral bioleaching heaps for metal extraction. Res Microbiol, 2016, 167(7): 576 doi: 10.1016/j.resmic.2016.05.007 [10] Rawlings D E, Silver S. Mining with microbes. Nat Biotechnol, 1995, 13: 773 doi: 10.1038/nbt0895-773 [11] Yin S H, Wu A X, Wang H J, et al. Current status and present situation and development trend of low-grade ore bioleaching technology. Min Res Dev, 2010, 30(1): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK201001017.htm尹升華, 吳愛祥, 王洪江, 等. 微生物浸出低品位礦石技術現狀與發展趨勢. 礦業研究與開發, 2010, 30(1): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK201001017.htm [12] Johnson D B. Biodiversity and ecology of acidophilic microorganisms. FEMS Microbiol Ecol, 1998, 27(4): 307 doi: 10.1111/j.1574-6941.1998.tb00547.x [13] Johnson D B. Biomining-biotechnologies for extracting and recovering metals from ores and waste materials. Curr Opin Biotechnol, 2014, 30: 24 doi: 10.1016/j.copbio.2014.04.008 [14] Videla A R, Lin C L, Miller J D. 3D characterization of individual multiphase particles in packed particle beds by X-ray microtomography (XMT). Int J Miner Process, 2007, 84(1-4): 321 doi: 10.1016/j.minpro.2006.07.009 [15] Miller J D, Lin C L, Hupka L, et al. Liberation-limited grade/recovery curves from X-ray micro CT analysis of feed material for the evaluation of separation efficiency. Int J Miner Process, 2009, 93(1): 48 doi: 10.1016/j.minpro.2009.05.009 [16] Yin S H, Wang L M, Pan C Y, et al. Fluid flowing characteristics in ore granular with fine interlayers existed. Chin J Nonferrous Met, 2017, 27(3): 574 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201703016.htm尹升華, 王雷鳴, 潘晨陽, 等. 細粒層存在條件下礦巖散體內的溶液流動特性. 中國有色金屬學報, 2017, 27(3): 574 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201703016.htm [17] Nosrati A, Quast K, Xu D F, et al. Agglomeration and column leaching behaviour of nickel laterite ores: effect of ore mineralogy and particle size distribution. Hydrometallurgy, 2014, 146: 29 doi: 10.1016/j.hydromet.2014.03.004 [18] Kodali P, Dhawan N, Depci T, et al. Particle damage and exposure analysis in HPGR crushing of selected copper ores for column leaching. Miner Eng, 2011, 24(13): 1478 doi: 10.1016/j.mineng.2011.07.010 [19] Ilankoon I M S K, Neethling S J. Liquid spread mechanisms in packed beds and heaps. The separation of length and time scales due to particle porosity. Miner Eng, 2016, 86: 130 doi: 10.1016/j.mineng.2015.12.010 [20] Luo Y, Wen J K, Wu B, et al. Acid agglomeration and mechanism analysis of a low-grade oxide-sulfide mixed copper ore. Chin J Eng, 2017, 39(9): 1321 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201709004.htm羅毅, 溫建康, 武彪, 等. 低品位氧硫混合銅礦的酸性制粒及機理. 工程科學學報, 2017, 39(9): 1321 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201709004.htm [21] Zhang S, Liu W Y. Application of aerial image analysis for assessing particle size segregation in dump leaching. Hydrometallurgy, 2017, 171: 99 doi: 10.1016/j.hydromet.2017.05.001 [22] Chen J P, Zhang Y, Wang J X, et al. On present situlation and potential analysis of copper resources in China. J Geol, 2013, 37(3): 358 doi: 10.3969/j.issn.1674-3636.2013.03.358陳建平, 張瑩, 王江霞, 等. 中國銅礦現狀及潛力分析. 地質學刊, 2013, 37(3): 358 doi: 10.3969/j.issn.1674-3636.2013.03.358 [23] Huang C K, Bai Y, Zhu Y S, et al. 1st ed. Copper Deposit of China. Beijing: Geological Publishing House, 2001黃崇軻, 白冶, 朱裕生, 等. 1版. 中國銅礦床. 北京: 地質出版社, 2001 [24] Ruan R M. A Case Study on Bio-heapleaching Practice of Zijinshan Copper Sulphide: Kinetics and Process Optimization [Dissertation]. Changsha: Central South University, 2011阮仁滿. 紫金山銅礦生物堆浸工業案例分析——相關動力學研究與多因素匹配[學位論文]. 長沙: 中南大學, 2011 [25] Ruan R M, Wen J K, Chen J H. Bacterial heap-leaching: practice in Zijinshan copper mine. Hydrometallurgy, 2006, 83(1-4): 77 doi: 10.1016/j.hydromet.2006.03.048 [26] Ruan R M, Liu X Y, Zou G, et al. Industrial practice of a distinct bioleaching system operated at low pH, high ferric concentration, elevated temperature and low redox potential for secondary copper sulfide. Hydrometallurgy, 2011, 108(1-2): 130 doi: 10.1016/j.hydromet.2011.03.008 [27] Liu X Y, Chen B W, Chen J H, et al. Spatial variation of microbial community structure in the Zijinshan commercial copper heap bioleaching plant. Miner Eng, 2016, 94: 76 doi: 10.1016/j.mineng.2016.05.008 [28] Ruan R M, Zou G, Zhong S P, et al. Why Zijinshan copper bioheapleaching plant works efficiently at low microbial activity——study on leaching kinetics of copper sulfides and its implications. Miner Eng, 2013, 48: 36 doi: 10.1016/j.mineng.2013.01.002 [29] Wan C F. Discussion on the discharge of waste stone and stack for heap leaching in Dexing Copper Mine. Nonferrous Mines, 2000, 29(2): 15 doi: 10.3969/j.issn.1672-609X.2000.02.005萬長峰. 德興銅礦廢石排放與堆浸筑堆相結合的探討. 有色礦山, 2000, 29(2): 15 doi: 10.3969/j.issn.1672-609X.2000.02.005 [30] Wang H J, Wu A X, Zhang J, et al. Characters of anisotropy seepage in homogenous ore material. J Univ Sci Technol Beijing, 2009, 31(4): 405 doi: 10.3321/j.issn:1001-053X.2009.04.001王洪江, 吳愛祥, 張杰, 等. 礦巖均質體各向異性滲流特性. 北京科技大學學報, 2009, 31(4): 405 doi: 10.3321/j.issn:1001-053X.2009.04.001 [31] Li Z K, Gui B W, Duan X X. Production practice and technical study in heap leaching mill of Dexing copper mine. Min Metall Eng, 2002, 22(1): 46 doi: 10.3969/j.issn.0253-6099.2002.01.015李壯闊, 桂斌旺, 段希祥. 德興銅礦堆浸廠的生產實踐及技術研究. 礦冶工程, 2002, 22(1): 46 doi: 10.3969/j.issn.0253-6099.2002.01.015 [32] Yang S R, Xie J Y, Qiu G Z, et al. Research and application of bioleaching and biooxidation technologies in China. Miner Eng, 2002, 15(5): 361 doi: 10.1016/S0892-6875(02)00019-5 [33] Li X R, Song B S. Production of electrolytic copper from waste ore with dump leaching at Dexing copper mine. Min Metall, 1999, 8(2): 44 doi: 10.3969/j.issn.1005-7854.1999.02.011李樣人, 宋炳申. 德興銅礦堆浸廢礦石生產電銅. 礦冶, 1999, 8(2): 44 doi: 10.3969/j.issn.1005-7854.1999.02.011 [34] Wu A X, Yin S H, Wang H J, et al. Technological assessment of a mining-waste dump at the Dexing copper mine, China, for possible conversion to an in situ bioleaching operation. Bioresour Technol, 2009, 100(6): 1931 doi: 10.1016/j.biortech.2008.10.021 [35] Yin S H, Wang L M, Wu A X, et al. Enhancement of copper recovery by acid leaching of high-mud copper oxides: a case study at Yangla Copper Mine, China. J Cleaner Pro, 2018, 202: 321 doi: 10.1016/j.jclepro.2018.08.122 [36] Ruan R M, Wen J K, Chen J H. Bacterial heap-leaching: practice in Zijinshan copper mine. Hydrometallurgy, 2006, 83(1-4): 77 doi: 10.1016/j.hydromet.2006.03.048 [37] Ruan R M, Liu X Y, Zou G, et al. Industrial practice of a distinct bioleaching system operated at low pH, high ferric concentration, elevated temperature and low redox potential for secondary copper sulfide. Hydrometallurgy, 2011, 108(1-2): 130 doi: 10.1016/j.hydromet.2011.03.008 [38] Wang B Y, Cong Z F, Dai S J. Current developments and prospects in bioleaching of copper ores. Non-Ferrous Min Metall, 2008, 24(4): 28 doi: 10.3969/j.issn.1007-967X.2008.04.010王本英, 叢自范, 代淑娟. 生物浸出提銅技術的研究現狀及前景. 有色礦冶. 2008, 24(4): 28 doi: 10.3969/j.issn.1007-967X.2008.04.010 [39] He Z G, Xie X H, Xiao S M, et al. Microbial diversity of mine water at Zhong Tiaoshan copper mine, China. J Basic Microbiol, 2007, 47(6): 485 doi: 10.1002/jobm.200700219 [40] Zhan J, Sun Q Y. Development of microbial properties and enzyme activities in copper mine wasteland during natural restoration. Catena, 2014, 116: 86 doi: 10.1016/j.catena.2013.12.012 [41] Qiu G Z, Wan M X, Qian L, et al. Archaeal diversity in acid mine drainage from Dabaoshan Mine, China. J Basic Microbiol, 2008, 48(5): 401 doi: 10.1002/jobm.200800002 [42] Hao X D, Liang Y L, Yin H Q, et al. The effect of potential heap construction methods on column bioleaching of copper flotation tailings containing high levels of fines by mixed cultures. Miner Eng, 2016, 98: 279 doi: 10.1016/j.mineng.2016.07.015 [43] Yang H X, Zhou A D, Xu J Z. Application of biohydrometallurgy in copper industry. Non-Ferrous Min Metall, 2003, 19(5): 15 doi: 10.3969/j.issn.1007-967X.2003.05.006楊紅曉, 周愛東, 徐家振. 生物浸出技術在銅工業中的應用. 有色礦冶, 2003, 19(5): 15 doi: 10.3969/j.issn.1007-967X.2003.05.006 [44] Wu Y H. Study on Bioleaching of Yongping Low Grade Copper Sulfide Ore in Jiangxi by Mixed Cultures [Dissertation]. Changsha: Central South University, 2011吳永宏. 江西永平低品位硫化銅礦石的混合菌浸出研究[學位論文]. 長沙: 中南大學, 2011 [45] Li L J. Study on Bacteria Bioleaching and Adsorbent for Low Grade Copper Mine in Qinghai Saishitang [Dissertation]. Mianyang: Southwest University of Science and Technology, 2012李靚潔. 青海賽什塘低品位銅礦微生物浸出和吸附研究[學位論文]. 綿陽: 西南科技大學, 2012 [46] Dai Z M, Yin H Q, Zeng X X, et al. Comparison of microbial community of acid mine drainage from Dongchuan copper pyrite. Prog Mod Biomed, 2007, 7(11): 1608 https://www.cnki.com.cn/Article/CJFDTOTAL-SWCX200711005.htm戴志敏, 尹華群, 曾曉希, 等. 云南東川黃銅礦酸性浸礦廢水中微生物群落分析. 現代生物醫學進展, 2007, 7(11): 1608 https://www.cnki.com.cn/Article/CJFDTOTAL-SWCX200711005.htm [47] Feng S S, Yang H L, Wang W. Improved chalcopyrite bioleaching by Acidithiobacillus sp. via direct step-wise regulation of microbial community structure. Bioresour Technol, 2015, 192: 75 doi: 10.1016/j.biortech.2015.05.055 [48] Banerjee I, Burrell B, Reed C, et al. Metals and minerals as a biotechnology feedstock: engineering biomining microbiology for bioenergy applications. Curr Opin Biotechnol, 2017, 45: 144 doi: 10.1016/j.copbio.2017.03.009 [49] Li J L, Li D C. The practice of low grade primary chalcopyrite bacteria leaching technology. Copper Eng, 2006(2): 7 doi: 10.3969/j.issn.1009-3842.2006.02.003李金龍, 李得春. 低品位原生黃銅礦生物浸出技術的應用實踐. 銅業工程, 2006(2): 7 doi: 10.3969/j.issn.1009-3842.2006.02.003 [50] He Z G, Zhao J C, Gao F L, et al. Monitoring bacterial community shifts in bioleaching of Ni-Cu sulfide. Bioresour Technol, 2010, 101(21): 8287 doi: 10.1016/j.biortech.2010.05.047 [51] Wang J. Research and Practice on Bioleaching of Low-Grade Complex Copper Sulphide [Dissertation]. Changsha: Central South University, 2011王軍. 低品位復雜硫化銅礦生物浸出的研究與應用[學位論文]. 長沙: 中南大學, 2011 [52] Wang J, Qin W Q, Qiu G Z. Theory and Practice of Bioleaching of Low Grade Complex Copper Sulphide Minerals. Changsha: Central South University Press, 2015王軍, 覃文慶, 邱冠周. 低品位復雜硫化銅礦生物浸出理論與實踐. 長沙: 中南大學出版社, 2015 [53] Zhen S J, Yan Z Q, Zhang Y S, et al. Column bioleaching of a low grade nickel-bearing sulfide ore containing high magnesium as olivine, chlorite and antigorite. Hydrometallurgy, 2009, 96(4): 337 doi: 10.1016/j.hydromet.2008.11.007 [54] Zhuang W Q, Fitts J P, Ajo-Franklin C M, et al. Recovery of critical metals using biometallurgy. Curr Opin Biotechnol, 2015, 33: 327 doi: 10.1016/j.copbio.2015.03.019 [55] Tuovinen O H, Fry I J. Bioleaching and mineral biotechnology. Curr Opin Biotechnol, 1993, 4(3): 344 doi: 10.1016/0958-1669(93)90106-7 [56] Johnson D B. Biodiversity and interactions of acidophiles: key to understanding and optimizing microbial processing of ores and concentrates. Trans Nonferrous Met Soc China, 2008, 18(6): 1367 doi: 10.1016/S1003-6326(09)60010-8 [57] Temple K L, Colmer A R. The autotrophic oxidation of iron by a new bacterium: Thiobacillus ferrooxidans. J Bacteriol. , 1951, 62(5): 605 doi: 10.1128/jb.62.5.605-611.1951 [58] Zhu T. Current Copper Hydrometallurgy. Beijing: Metallurgical Industry Press, 2002朱屯. 現代銅濕法冶金. 北京: 冶金工業出版社, 2002 [59] Cárdenas J P, Quatrini R, Holmes D S. Genomic and metagenomic challenges and opportunities for bioleaching: a mini-review. Res Microbiol, 2016, 167(7): 529 doi: 10.1016/j.resmic.2016.06.007 [60] Qiu G Z, Wang J, Zhong K N, et al. Cultivation and industrial application of bacteria. Met Ore Dress Abroad, 1998(6): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK199806011.htm邱冠周, 王軍, 鐘康年, 等. 浸礦細菌的育種及工業應用. 國外金屬礦選礦, 1998(6): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK199806011.htm [61] Gao J, Zhang C G, Wu X L, et al. Isolation and identification of a strain of Leptospirillum ferriphilum from an extreme acid mine drainage site. Ann Microbiol, 2007, 57(2): 171 doi: 10.1007/BF03175203 [62] Xie X, Xiao S, He Z, et al. Microbial populations in acid mineral bioleaching systems of Tong Shankou Copper Mine, China. J Appl Microbiol, 2007, 103(4): 1227 doi: 10.1111/j.1365-2672.2007.03382.x [63] Yin H Q, Cao L H, Qiu G Z, et al. Development and evaluation of 50-mer oligonucleotide arrays for detecting microbial populations in Acid Mine Drainages and bioleaching systems. J Microbiol Methods, 2007, 70(1): 165 doi: 10.1016/j.mimet.2007.04.011 [64] Yin H Q. Development and Application of the Microarray Technology during the Research on the Structure and Function of Microbial Communities for Acid Drainages from the Copper Mines [Dissertation]. Changsha: Central South University, 2007尹華群. 在銅礦礦坑水微生物群落結構與功能研究中基因芯片技術的發展和應用[學位論文]. 長沙: 中南大學, 2007 [65] Dong Y B, Lin H, Wang H, et al. Effects of ultraviolet irradiation on bacteria mutation and bioleaching of low-grade copper tailings. Miner Eng, 2011, 24(8): 870 doi: 10.1016/j.mineng.2011.03.020 [66] Zhang Y S. The Bioleaching of Low Grade Copper Sulphide Ore [Dissertation]. Changsha: Central South University, 2007張雁生. 低品位原生硫化銅礦的細菌浸出研究[學位論文]. 長沙: 中南大學, 2007 [67] Yin S H, Wang L M, Chen X. Effects of ore particle sizes on leaching regularities of secondary copper sulphide. J Central S Univ Sci Technol, 2015, 46(8): 2771 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201508001.htm尹升華, 王雷鳴, 陳勛. 礦石粒徑對次生硫化銅礦浸出規律的影響. 中南大學學報(自然科學版), 2015, 46(8): 2771 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201508001.htm [68] Hu K J, Wu A X, Wang H J, et al. A new heterotrophic strain for bioleaching of low grade complex copper ore. Minerals, 2016, 6(1): 12 doi: 10.3390/min6010012 [69] Wang H J, Xu C S, Wu A X, et al. Inhibition of spontaneous combustion of sulfide ores by thermopile sulfide oxidation. Miner Eng, 2013, 49: 61 doi: 10.1016/j.mineng.2013.05.011 [70] Qiu G Z, Liu X D, Zhou H B. Microbial community structure and function in sulfide ore bioleaching systems. Trans Nonferrous Met Soc China, 2008, 18(6): 1295 doi: 10.1016/S1003-6326(09)60001-7 [71] Qin W Q, Yang C R, Lai S S, et al. Bioleaching of chalcopyrite by moderately thermophilic microorganisms. Bioresour Technol, 2013, 129: 200 doi: 10.1016/j.biortech.2012.11.050 [72] Li H X, Dong Q H, Cang D Q, et al. Thermophilic microorganism sulfolobus growth and leaching chalcopyrite properties. J Univ Sci Technol Beijing, 2007, 29(1): 20 doi: 10.3321/j.issn:1001-053X.2007.01.005李宏煦, 董清海, 蒼大強, 等. 高溫浸礦菌sulfolobus的生長及浸礦性能. 北京科技大學學報, 2007, 29(1): 20 doi: 10.3321/j.issn:1001-053X.2007.01.005 [73] Liang C L. The Study of Thermo-bioleaching Mechanism of Chalcopyrite and Therein Sulphur Speciation Transformation [Dissertation]. Changsha: Central South University, 2011梁長利. 黃銅礦高溫生物浸出機理和硫形態轉化研究[學位論文]. 長沙: 中南大學, 2011 [74] Ding J N. Isolation, Identification of Thermophilic Leaching Microorganisms and Basic Studies on Their Application and Bioleaching Potential [Dissertation]. Changsha: Central South University, 2007丁建南. 幾種高溫浸礦菌的分離鑒定及其應用基礎與浸礦潛力研究[學位論文]. 長沙: 中南大學, 2007 [75] Chen L X, Huang L N, Mendez-Garcia C, et al. Microbial communities, processes and functions in acid mine drainage ecosystems. Curr Opin Biotechnol, 2016, 38: 150 doi: 10.1016/j.copbio.2016.01.013 [76] Wu B. A Study on Fundamentals of Selective Inhibit Pyrite Bioleaching of Chalcocite and Covellite [Dissertation]. Beijing: General Research Institute for Nonferrous Metals, 2017武飚. 黃鐵礦與輝銅礦、銅藍選擇性生物浸出機理研究[學位論文]. 北京: 北京有色金屬研究總院, 2017 [77] Ma L Y, Wang X J, Feng X, et al. Co-culture microorganisms with different initial proportions reveal the mechanism of chalcopyrite bioleaching coupling with microbial community succession. Bioresour Technol, 2017, 223: 121 doi: 10.1016/j.biortech.2016.10.056 [78] Flemming H C, Wingender J. The biofilm matrix. Nat Rev Microbiol, 2010, 8(9): 623 doi: 10.1038/nrmicro2415 [79] Zeng W M. The Formation Mechanism of Passivation Layer and Its Elimination Way during Bioleaching of Chalcopyrite [Dissertation]. Changsha: Central South University, 2011曾偉民. 黃銅礦生物浸出過程中鈍化膜的形成機制及其消除方法探討[學位論文]. 長沙: 中南大學, 2011 [80] Yu R L, Liu A J, Liu Y N, et al. The research progress of the functions and mechanism of extracellular proteins in bioleaching. Biotechnol Bull, 2017, 33(7): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-SWJT201707009.htm余潤蘭, 劉阿娟, 劉亞楠, 等. 微生物浸出過程中胞外蛋白的作用及其機理研究進展. 生物技術通報, 2017, 33(7): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-SWJT201707009.htm [81] Yu R L, Shi L J, Zhou D, et al. Research development of microorganism synergy mechanisms during bioleaching. Chin J Nonferrous Met, 2013, 23(10): 3006 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201310036.htm余潤蘭, 石麗娟, 周丹, 等. 生物浸出過程中微生物協同作用機制的研究進展. 中國有色金屬學報, 2013, 23(10): 3006 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201310036.htm [82] Qiu G Z, Liu J S, Wang D Z, et al. Iron behaviour in growth of thiobacillus ferrooxidans. J Central S Univ Technol, 1998, 29(3): 226 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD803.005.htm邱冠周, 柳建設, 王淀佐, 等. 氧化亞鐵硫桿菌生長過程鐵的行為. 中南工業大學學報, 1998, 29(3): 226 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD803.005.htm [83] Zhao H B, Wang J, Qiu J Q, et al. Surface physicochemical properties of bornite in presence of bacteria. J Central S Univ Sci Technol, 2015, 46(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201501001.htm趙紅波, 王軍, 邱建強, 等. 細菌作用下斑銅礦表面物理化學性質變化. 中南大學學報(自然科學版), 2015, 46(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201501001.htm [84] Diao M X, Taran E, Mahler S, et al. A concise review of nanoscopic aspects of bioleaching bacteria-mineral interactions. Adv Colloid Interface Sci, 2014, 212: 45 doi: 10.1016/j.cis.2014.08.005 [85] Zhang R Y, Bellenberg S, Castro L, et al. Colonization and biofilm formation of the extremely acidophilic archaeon Ferroplasma acidiphilum. Hydrometallurgy, 2014, 150: 245 doi: 10.1016/j.hydromet.2014.07.001 [86] Wu A X, Yin S H, Yang B H, et al. Study on preferential flow in dump leaching of low-grade ores. Hydrometallurgy, 2007, 87(3-4): 124 doi: 10.1016/j.hydromet.2007.03.001 [87] Yin S H, Wu A X, Hu K J, et al. Visualization of flow behavior during bioleaching of waste rock dumps under saturated and unsaturated conditions. Hydrometallurgy, 2013, 133: 1 doi: 10.1016/j.hydromet.2012.11.009 [88] Yin S H, Wang L M, Chen X, et al. Effect of ore size and heap porosity on capillary process inside a leaching heap. Trans Nonferrous Met Soc China, 2016, 26(3): 835 doi: 10.1016/S1003-6326(16)64174-2 [89] Wu A X, Li X W, Yin S H, et al. Interface effects of unsaturated seepage in dump leaching. J Univ Sci Technol Beijing, 2013, 35(7): 844 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201307001.htm吳愛祥, 李希雯, 尹升華, 等. 礦堆非飽和滲流中的界面作用. 北京科技大學學報, 2013, 35(7): 844 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201307001.htm [90] Yin S H, Wu A X. Study on the seepage law of solution in dump leaching. Min Res Dev, 2006, 26(1): 31 doi: 10.3969/j.issn.1005-2763.2006.01.012尹升華, 吳愛祥. 堆浸礦堆溶液滲流規律初探. 礦業研究與開發, 2006, 26(1): 31 doi: 10.3969/j.issn.1005-2763.2006.01.012 [91] Liu C. Evolution of the Pore Structure and Flow in Granular Ore Heaps for Copper Oxides Acid Leaching [Dissertation]. Beijing: University of Science and Technology Beijing, 2017劉超. 酸浸條件下氧化銅礦巖散體孔隙結構及滲流演化規律[學位論文]. 北京: 北京科技大學, 2017 [92] Yin S H, Wu A X, Su Y D, et al. Experimental study on preferential solution flow during dump leaching of low-grade ores. J Central S Univ Technol, 2007, 14(4): 584 doi: 10.1007/s11771-007-0112-2 [93] Dhawan N, Safarzadeh M S, Miller J D, et al. Crushed ore agglomeration and its control for heap leach operations. Miner Eng, 2013, 41: 53 doi: 10.1016/j.mineng.2012.08.013 [94] Wang S Y, Wu A X, Wang H J, et al. Crash of wash-classification of heap leaching used in high-clay copper oxide ore. Chin J Nonferrous Met, 2013, 23(1): 229 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201301032.htm王少勇, 吳愛祥, 王洪江, 等. 高含泥氧化銅礦水洗-分級堆浸工藝. 中國有色金屬學報, 2013, 23(1): 229 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201301032.htm [95] Yin S H, Chen X, Wu A X, et al. Undisturbed test on mesoscopic solution seepage field in ore heap based on PIV. J Central S Univ Sci Technol, 2015, 46(7): 2597 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201507029.htm尹升華, 陳勛, 吳愛祥, 等. 基于PIV技術的細觀礦堆溶液滲流場無擾動測試. 中南大學學報(自然科學版), 2015, 46(7): 2597 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201507029.htm [96] Yin S H, Wang L M, Xie F F, et al. Effect of heap structure on column leaching of secondary copper sulphide. Chin J Nonferrous Met, 2017, 27(11): 2340 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201711020.htm尹升華, 王雷鳴, 謝芳芳, 等. 堆體結構對次生硫化銅礦柱浸的影響. 中國有色金屬學報, 2017, 27(11): 2340 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201711020.htm [97] Wang Y M, Wu A X, Zuo H, et al. Effect of particles sedimentation during leaching on seepage characteristic of copper dumps. Chin J Nonferrous Met, 2007, 17(12): 2074 doi: 10.3321/j.issn:1004-0609.2007.12.027王貽明, 吳愛祥, 左恒, 等. 微粒滲濾沉積作用對銅礦排土場滲流特性的影響. 中國有色金屬學報, 2007, 17(12): 2074 doi: 10.3321/j.issn:1004-0609.2007.12.027 [98] Dhawan N, Safarzadeh M S, Miller J D, et al. Recent advances in the application of X-ray computed tomography in the analysis of heap leaching systems. Miner Eng, 2012, 35: 75 doi: 10.1016/j.mineng.2012.03.033 [99] Wu A X, Xue Z L, Yin S H, et al. Study of the granular medium structure of mine rock and solution distribution based on MRI technology. J China Univ Min Technol, 2014, 43(4): 582 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201404004.htm吳愛祥, 薛振林, 尹升華, 等. 基于核磁共振技術的礦巖散體結構及溶液分布研究. 中國礦業大學學報, 2014, 43(4): 582 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201404004.htm [100] Lin C L, Videla A R, Miller J D. Advanced three-dimensional multiphase flow simulation in porous media reconstructed from X-ray Microtomography using the He-Chen-Zhang Lattice Boltzmann Model. Flow Meas Instrum, 2010, 21(3): 255 doi: 10.1016/j.flowmeasinst.2010.02.008 [101] Wen J K. Research and Application on Selective Bioleaching of High Sulphur Low Copper Secondary Copper Sulphide Ore[Dissertation]. Beijing: General Research Institute for Nonferrous Metals, 2016溫建康. 高硫低銅次生硫化銅礦選擇性生物浸出研究與應用[學位論文]. 北京: 北京有色金屬研究總院, 2016 [102] Xue Z L, Wu A X, Yin S H, et al. Evolution rules of dual medium fractal seepage in copper oxide ore heap leaching. Chin J Nonferrous Met, 2014, 24(9): 2373 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409025.htm薛振林, 吳愛祥, 尹升華, 等. 氧化銅礦堆浸雙重介質分形滲流演化規律. 中國有色金屬學報, 2014, 24(9): 2373 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409025.htm [103] Yang B H, Wu A X, Miao X X. 3D micropore structure evolution of ore particles based on image processing. Chin J Eng, 2016, 38(3): 328 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201603005.htm楊保華, 吳愛祥, 繆秀秀. 基于圖像處理的礦石顆粒三維微觀孔隙結構演化. 工程科學學報, 2016, 38(3): 328 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201603005.htm [104] Lin Q Y, Barker D J, Dobson K J, et al. Modelling particle scale leach kinetics based on X-ray computed micro-tomography images. Hydrometallurgy, 2016, 162: 25 doi: 10.1016/j.hydromet.2016.02.008 [105] Chen X S, Liang X C, Xun Z Y. The infiltration models of leach solution in heap leaching process. Gold, 1999, 20(4): 30 https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ904.009.htm陳喜山, 梁曉春, 荀志遠. 堆浸工藝中溶浸液的滲透模型. 黃金, 1999, 20(4): 30 https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ904.009.htm [106] Pan W. Study on Chaos Characteristics and Control Theory of Heap Immersed Surface [Dissertation]. Changsha: Central South University, 2005潘偉. 堆浸浸潤面混沌特性與控制理論研究[學位論文]. 長沙: 中南大學, 2005 [107] Liu J Z. Numerical Simulation Analysis and Grey Prediction Research of Heap Leaching Process [Dissertation]. Changsha: Central South University, 2007劉金枝. 堆浸浸出過程數值模擬分析及灰色預測研究[學位論文]. 長沙: 中南大學, 2007 [108] Miao X X, Narsilio G A, Wu A X, et al. A 3D dual pore-system leaching model. Part 1: Study on fluid flow. Hydrometallurgy, 2017, 167: 173 doi: 10.1016/j.hydromet.2016.11.015 [109] Zeng W M, Zhu H Z, Ye Z J, et al. Review on recovering precious metals from wasted circuit board by bio-hydrometallurgy technology. Nonferrous Met Sci Eng, 2013, 4(1): 26 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201301007.htm曾偉民, 朱海珍, 葉子婕, 等. 生物濕法冶金技術回收廢棄線路板中有價金屬的研究進展. 有色金屬科學與工程, 2013, 4(1): 26 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201301007.htm [110] Zhang Y H, Liu S L, Xie H H, et al. Current status on leaching precious metals from waste printed circuit boards. Procedia Environ Sci, 2012, 16: 560 doi: 10.1016/j.proenv.2012.10.077 [111] Lu Y, Xu Z M. Precious metals recovery from waste printed circuit boards: A review for current status and perspective. Resour Conserv Recycl, 2016, 113: 28 doi: 10.1016/j.resconrec.2016.05.007 [112] Liang G B, Tang J H, Liu W P, et al. Optimizing mixed culture of two acidophiles to improve copper recovery from printed circuit boards (PCBs). J Hazard Mater, 2013, 250-251: 238 doi: 10.1016/j.jhazmat.2013.01.077 [113] Wang F F, Zhao Y M, Zhang T, et al. Metals recovery from dust derived from recycling line of waste printed circuit boards. J Cleaner Prod, 2017, 165: 452 doi: 10.1016/j.jclepro.2017.07.112 [114] Gu W H, Bai J F, Dong B, et al. Enhanced bioleaching efficiency of copper from waste printed circuit board driven by nitrogen-doped carbon nanotubes modified electrode. Chem Eng J, 2017, 324: 122 doi: 10.1016/j.cej.2017.05.024 [115] Awasthi A K, Zeng X L, Li J H. Integrated bioleaching of copper metal from waste printed circuit board—a comprehensive review of approaches and challenges. Environ Sci Pollut Res, 2016, 23(21): 21141 doi: 10.1007/s11356-016-7529-9 [116] Tripathi V, Edrisi S A, Chen B, et al. Biotechnological advances for restoring degraded land for sustainable development. Trends Biotechnol, 2017, 35(9): 847 doi: 10.1016/j.tibtech.2017.05.001 [117] Yin S H, Wang L M, Kabwe E, et al. Copper bioleaching in China: review and prospect. Miner, 2018, 8(2): 32 doi: 10.3390/min8020032 [118] Brierley C L, Brierley J A. Progress in bioleaching: part b: application of microbial processes by the minerals industries. Appl Microbiol Biotechnol, 2013, 97(17): 7543 doi: 10.1007/s00253-013-5095-3 [119] Rawlings D E, Dew D, du Plessis C. Biomineralization of metal-containing ores and concentrates. Trends Biotechnol, 2003, 21(1): 38 doi: 10.1016/S0167-7799(02)00004-5 [120] Zechendorf B. Sustainable development: how can biotechnology contribute? Trends Biotechnol, 1999, 17(6): 219 doi: 10.1016/S0167-7799(98)01297-9 [121] Chen L X, Huang L N, Méndez-García C, et al. Microbial communities, processes and functions in acid mine drainage ecosystems. Curr Opin Biotechnol, 2016, 38: 150 doi: 10.1016/j.copbio.2016.01.013 [122] Herbert R A. A perspective on the biotechnological potential of extremophiles. Trends Biotechnol, 1992, 10: 395 doi: 10.1016/0167-7799(92)90282-Z [123] Haque N, Norgate T. The greenhouse gas footprint of in-situ leaching of uranium, gold and copper in Australia. J Cleaner Prod, 2014, 84: 382 doi: 10.1016/j.jclepro.2013.09.033 [124] Pathak A, Morrison L, Healy M G. Catalytic potential of selected metal ions for bioleaching, and potential techno-economic and environmental issues: a critical review. Bioresour Technol, 2017, 229: 211 doi: 10.1016/j.biortech.2017.01.001 [125] Zhang L G, Xu Z M. A review of current progress of recycling technologies for metals from waste electrical and electronic equipment. J Cleaner Prod, 2016, 127: 19 doi: 10.1016/j.jclepro.2016.04.004 [126] Gadd G M, White C. Microbial treatment of metal pollution—a working biotechnology? Trends Biotechnol, 1993, 11(8): 353 doi: 10.1016/0167-7799(93)90158-6 [127] Murray C, Platzer W, Petersen J. Potential for solar thermal energy in the heap bioleaching of chalcopyrite in Chilean copper mining. Miner Eng, 2017, 100: 75 doi: 10.1016/j.mineng.2016.09.022 [128] Wu A X, Yang B H, Liu J Z, et al. Analysis of pore structure evolution of ore granular media during leaching based on X-ray computed tomography. Chin J Process Eng, 2007, 7(5): 960 doi: 10.3321/j.issn:1009-606x.2007.05.020吳愛祥, 楊保華, 劉金枝, 等. 基于X光CT技術的礦巖散體浸出過程中孔隙演化規律分析. 過程工程學報, 2007, 7(5): 960 doi: 10.3321/j.issn:1009-606x.2007.05.020 -

下載:

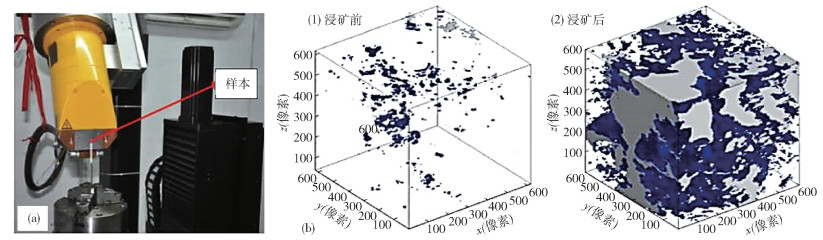

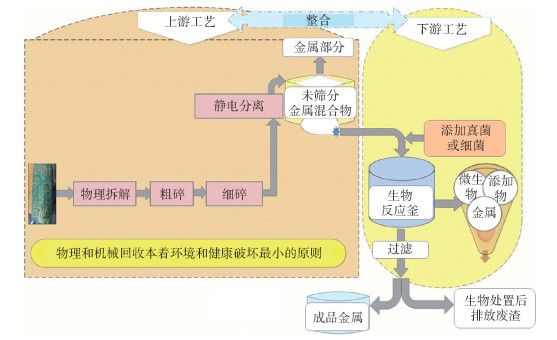

下載: