Overview of advances in emission control technologies for nitric oxides from biomass boilers

-

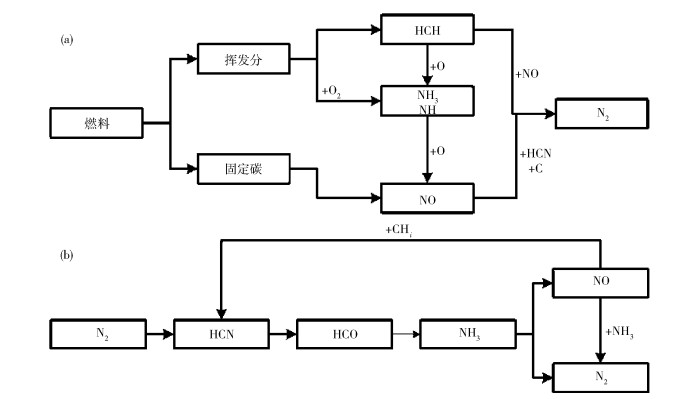

摘要: 生物質燃料中含有的燃料氮含量較低, 但是大約70%~100%(質量分數)的氮最終會轉化為NOx, 并且秸稈等生物質燃料燃燒排放的NOx含量較木質燃料等更高.此外, 近年來, 我國空氣質量面臨嚴峻態勢, NOx是常見的大氣污染物, 對居民身體健康、生產和生活有很大影響.因此, 本文對目前國內外的NOx燃燒控制技術進行綜述, 總結了各類技術的優缺點, 及我國目前對于生物質鍋爐NOx控制技術遇到的瓶頸, 并對該研究領域的未來趨勢做出展望.Abstract: Currently, fossil fuels such as oil, coal, and natural gas are the world's primary energy sources. However, it is anticipated that these energy sources will be depleted in less than 100 years. As such, the development of new energy technologies is urgently needed. Biomass is one of the earliest sources of energy, and is used especially in rural areas where it is often the only one that is accessible and affordable. With the depletion of fossil fuels and increasing environmental degradation, biomass energy is attracting increasing attention around the world. Compared with fossil fuel, biomass is carbon neutral and sustainable, and has a smaller greenhouse gas footprint and lower SO2 emission levels. In addition, biomass energy remains the only renewable green energy that can be stored and transported. A number of countries have developed mature and proven combustion technologies, but these technologies are mainly based on wood biomass fuels. Unlike these developed countries, China is a large agricultural country with a limited amount of available firewood. As such, foreign experience cannot be fully applied in China. Although biomass fuels typically have relatively low fuel-N contents, this fuel-N between 70%-100% mass fraction is converted to NOx during combustion. In addition, the combustion of straw and other biomass fuels emits more NOx than wood fuels. In recent years, the air quality in China has become a serious public health concern, and NOx is a widespread atmospheric pollutant with significant impacts on human health and the economy. In this paper, an overview of biomass combustion technologies and NOx control systems in China and around the world was presented, and their advantages and disadvantages were summarized. The main bottleneck was identified in NOx control technologies with respect to biomass boilers in China and the development of new technologies in this field was predicted.

-

Key words:

- biomass fuel /

- combustion /

- nitric oxides /

- control technology /

- de-NOx

-

表 1 不同來源生物質燃料工業分析、元素組成和熱值

Table 1. Statistics regarding industrial analysis index, elemental composition, and calorific value of different biomass fuels

生物質燃料 工業分析/% 熱值/(MJ·kg-1) 元素質量分數/% 參考文獻 灰分 揮發分 固定碳 C H S N 木質 原料 云杉木 1.50 70.20 29.30 20.50 51.40 6.10 0 0.30 [8-10] 白楊木 2.70 84.81 12.49 19.38 48.45 5.85 0.01 0.47 [11-12] 櫸木 0.50 82.50 17.00 19.60 49.50 6.20 0.01 0.40 [8, 13-14] 成型燃料 0.40 81.52 13.20 18.52 44.66 7.64 0.10 0.32 [15] 玉米秸稈 原料 2.80 82.20 15.00 10.73 49.40 5.60 0.10 0.60 [9, 11, 13] 成型燃料 8.96 69.18 17.62 15.29 43.76 5.60 0.18 1.09 [16] 稻草 原料 18.67 65.47 15.86 14.00 38.45 5.28 — 0.88 [8, 12, 17] 成型燃料 13.86 65.11 16.06 13.98 38.32 5.06 0.11 0.63 [18] 小麥秸稈 原料 7.02 75.27 17.71 19.30 49.40 6.10 0.17 0.70 [8, 12, 14] 成型燃料 8.90 67.36 19.35 15.37 41.28 5.31 0.18 0.65 [18] 核桃殼 原料 2.80 59.30 37.90 — 53.60 6.60 0.10 1.50 [9, 13] 成型燃料 0.68 80.88 18.44 17.60 51.11 5.80 0.05 0.20 [19] 鋸末 原料 2.80 82.20 15.00 18.02 55.34 5.83 0.00 0.09 [13, 20-21] 成型燃料 0.96 80.30 18.70 18.64 52.15 5.37 0.01 0.10 [20-21] 榛子殼 原料 1.40 69.30 28.30 19.50 50.80 5.60 0.00 1.00 [8-10] 成型燃料 2.28 20.61 77.11 19.85 53.50 6.10 — — [22] 煙煤 20.64 21.05 50.01 23.38 61.33 3.20 0.49 0.85 [18] 無煙煤 16.80 8.00 67.20 20.97 67.70 3.10 0.70 1.00 [18] 表 2 不同生物質成型燃料NOx排放情況

Table 2. NOx emission concentration of different biomass briquettes

259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

[1] Shafiee S, Topal E. When will fossil fuel reserves be diminished? Energy Policy, 2009, 37(1): 181 doi: 10.1016/j.enpol.2008.08.016 [2] Mu X Z, Yu S S, Xu P. Review on utilizing rural biomass as energy. Mod Chem Ind, 2018, 38(3): 9 https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201803003.htm穆獻中, 余漱石, 徐鵬. 農村生物質能源化利用研究綜述. 現代化工, 2018, 38(3): 9 https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201803003.htm [3] Gonzalez-Salazar M A, Morini M, Pinelli M, et al. Methodology for estimating biomass energy potential and its application to Colombia. Appl Energy, 2014, 136: 781 doi: 10.1016/j.apenergy.2014.07.004 [4] Zhang B, Jin P F, Qiao H, et al. Exergy analysis of Chinese agriculture. Ecol Indic, 2017, https://doi.org/10.1016/j.ecolind.2017.08.054 [5] World Bioenergy Association. WBA global bioenergy statistics[J/OL]. World Bioenergy Association(2018-12-18)[2018-03-14]. https://worldbioenergy.org/uploads/WBA%20GBS%202017_lq.pdf [6] Zeng X Y, Ma Y T, Ma L R. Utilization of straw in biomass energy in China. Renewable Sustainable Energy Rev, 2007, 11(5): 976 doi: 10.1016/j.rser.2005.10.003 [7] Li Q. Research on the Compression of Straw of Baler[Dissertation]. Wuxi: Jiangnan University, 2008李倩. 秸稈打包機的分層疊壓技術研究[學位論文]. 無錫: 江南大學, 2008 [8] Demirbas A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog Energy Combust Sci, 2005, 31(2): 171 doi: 10.1016/j.pecs.2005.02.002 [9] Haykiri-Acma H. Combustion characteristics of different biomass materials. Energy Convers Manage, 2003, 44(1): 155 doi: 10.1016/S0196-8904(01)00200-X [10] Shen J F, Zhu S G, Liu X Z, et al. The prediction of elemental composition of biomass based on proximate analysis. Energy Convers Manage, 2010, 51(5): 983 doi: 10.1016/j.enconman.2009.11.039 [11] Sami M, Annamalai K, Wooldridge M. Co-firing of coal and biomass fuel blends. Prog Energy Combust Sci, 2001, 27(2): 171 doi: 10.1016/S0360-1285(00)00020-4 [12] Jenkins B M, Baxter L L, Miles T R. Combustion properties of biomass. Fuel Process Technol, 1998, 54(1-3): 17 doi: 10.1016/S0378-3820(97)00059-3 [13] Demirbas A. Combustion characteristics of different biomass fuels. Prog Energy Combust Sci, 2004, 30(2): 219 doi: 10.1016/j.pecs.2003.10.004 [14] Vassilev S V, Baxter D, Andersen L K, et al. An overview of the chemical composition of biomass. Fuel, 2010, 89(5): 913 doi: 10.1016/j.fuel.2009.10.022 [15] Jiang S J, Wei L X, Ai Y F, et al. Experimental research on emission behavior of pellet stove during ignition and shutting process. J Therm Sci Technol, 2010, 9(3): 256 https://www.cnki.com.cn/Article/CJFDTOTAL-RKXS201003013.htm蔣紹堅, 魏烈旭, 艾元方, 等. 生物質成型燃料爐點火和熄火過程中排放行為的實驗研究. 熱科學與技術, 2010, 9(3): 256 https://www.cnki.com.cn/Article/CJFDTOTAL-RKXS201003013.htm [16] Sun K, Chen C, Xu Y, et al. Design and experiments study on combustion engine of straw briquettes fuel. Chem Ind Forest Prod, 2014, 34(6): 93 https://www.cnki.com.cn/Article/CJFDTOTAL-LCHX201406018.htm孫康, 陳超, 許玉, 等. 秸稈成型燃料鍋爐燃燒機設計及試驗研究. 林產化學與工業, 2014, 34(6): 93 https://www.cnki.com.cn/Article/CJFDTOTAL-LCHX201406018.htm [17] Huang C, Han L, Yang Z, et al. Ultimate analysis and heating value prediction of straw by near infrared spectroscopy. Waste Manage, 2009, 29(6): 1793 doi: 10.1016/j.wasman.2008.11.027 [18] Zuo P L, Han B J, Yue T, et al. Tests of air pollutants emissions from biofuels-fired boilers and analysis on abatement potential//2014 Annual Meeting of Chinese Society for Environment Science. Chengdu, 2014: 1左朋萊, 韓斌杰, 岳濤, 等. 生物質成型燃料鍋爐主要大氣污染物排放測試及減排潛力分析//2014中國環境科學學會學術年會. 成都, 2014: 1 [19] Yang L. Study on the Properties of Biomass Charcoal Produced by Pyrolysis and Its By-Products[Dissertation]. Kunming: Kunming University of Science and Technology, 2013楊麗. 熱解法生產成型生物質炭及其副產物特性研究[學位論文]. 昆明: 昆明理工大學, 2013 [20] Jiang E C, He G S. Experimental research on low temperature pyrolysis of biomass extrusion bar of rice husk and sawdust. Trans Chin Soc Agric Eng, 2007, 23(1): 188 doi: 10.3321/j.issn:1002-6819.2007.01.036蔣恩臣, 何光設. 稻殼、鋸末成型燃料低溫熱解特性試驗研究. 農業工程學報, 2007, 23(1): 188 doi: 10.3321/j.issn:1002-6819.2007.01.036 [21] Stolarski M J, Szczukowski S, Tworkowski J, et al. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renewable Energy, 2013, 57: 20 doi: 10.1016/j.renene.2013.01.005 [22] Demirbas A. Properties of charcoal derived from hazelnut shell and the production of briquettes using pyrolytic oil. Energy, 1999, 24(2): 141 doi: 10.1016/S0360-5442(98)00077-2 [23] Faborode M O, O'Callaghan J R. Theoretical analysis of the compression of fibrous agricultural materials. J Agric Eng Res, 1986, 35(3): 175 doi: 10.1016/S0021-8634(86)80055-5 [24] Demirba? A, ?ahin A. Evaluation of biomass residue: 1. briquetting waste paper and wheat straw mixtures. Fuel Process Technol, 1998, 55(2): 175 doi: 10.1016/S0378-3820(98)00041-1 [25] Su J L, Wang Z K, Jiao Z W. The exploitation and application on biomass boiler by high efficiency and clean combustion. J Agric Mechn Res, 2009, 31(8): 202 doi: 10.3969/j.issn.1003-188X.2009.08.057蘇俊林, 王震坤, 矯振偉. 高效潔凈生物質鍋爐的開發及應用. 農機化研究, 2009, 31(8): 202 doi: 10.3969/j.issn.1003-188X.2009.08.057 [26] Luo Z Y, Zhou J S, Wang S R, et al. Technological evaluation of China biomass energy utilization. Energy China, 2004, 26(9): 39 doi: 10.3969/j.issn.1003-2355.2004.09.009駱仲泱, 周勁松, 王樹榮, 等. 中國生物質能利用技術評價. 中國能源, 2004, 26(9): 39 doi: 10.3969/j.issn.1003-2355.2004.09.009 [27] Zhang B L. Energy Engineering in Rural Area. Beijing: China Agriculture Press, 1999張百良. 農村能源工程學. 北京: 中國農業出版社, 1999 [28] Saidur R, Abdelaziz E A, Demirbas A, et al. A review on biomass as a fuel for boilers. Renewable Sustainable Energy Rev, 2011, 15(5): 2262 doi: 10.1016/j.rser.2011.02.015 [29] Xu Z G, Wang X H, Bai H J. Dynamic response analysis on water-cooled vibrating stoker of straw boiler. Boiler Manuf, 2008(1): 21 doi: 10.3969/j.issn.1674-1005.2008.01.006許志貴, 王新華, 白紅俊. 秸稈鍋爐水冷振動爐排動態特性分析. 鍋爐制造, 2008(1): 21 doi: 10.3969/j.issn.1674-1005.2008.01.006 [30] Li G F, Zhao X, Han Z S. Application of biomass fuel firing technology on combined grates. Mod Manuf Technol Equip, 2009(4): 52 doi: 10.3969/j.issn.1673-5587.2009.04.025李廣風, 趙旭, 韓增頌. 聯合爐排在生物質燃料鍋爐中的應用. 現代制造技術與裝備, 2009(4): 52 doi: 10.3969/j.issn.1673-5587.2009.04.025 [31] Chen G Y, Fang M X, Luo Z Y, et al. Experimental studies of rice husk-fired fluidized bed and design of a 35 t/h boiler. Power Eng, 1997, 17(6): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-DONG706.008.htm陳冠益, 方夢祥, 駱仲泱, 等. 燃用稻殼流化床鍋爐的試驗研究及35 t/h鍋爐的設計. 動力工程, 1997, 17(6): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-DONG706.008.htm [32] Zhang Z D, Bie R S, Yang L D, et al. Development of SZF4-1.25-D type fluidized bed boiler for rice husk. Energy Conserv Technol, 1995(5): 8 https://www.cnki.com.cn/Article/CJFDTOTAL-JNJS505.003.htm張子棟, 別如山, 楊勵丹, 等. SZF4-1.25-D型稻殼流化床鍋爐的研制. 節能技術, 1995(5): 8 https://www.cnki.com.cn/Article/CJFDTOTAL-JNJS505.003.htm [33] Xiu T C. Development and Experimental Study on Biomass Brequette Stoves[Dissertation]. Haerbin: Harbin Institute of Technology, 2009修太春. 生物質成型燃料爐具的研制及實驗研究[學位論文]. 哈爾濱: 哈爾濱工業大學, 2009 [34] Yu G S, Hou M. Development status and trend of biomass briquettes processing equipment. Forestry Mach Woodwork Equip, 2009, 37(2): 4 doi: 10.3969/j.issn.2095-2953.2009.02.001俞國勝, 侯孟. 生物質成型燃料加工裝備發展現狀及趨勢. 林業機械與木工設備, 2009, 37(2): 4 doi: 10.3969/j.issn.2095-2953.2009.02.001 [35] Zhang M, Chen J. Control and development situation of nitrogen oxide at domestic coal-fired power plant. Sichuan Chem Ind, 2009, 12(5): 44 doi: 10.3969/j.issn.1672-4887.2009.05.013張敏, 陳軍. 國內燃煤電廠氮氧化物的控制現狀及其發展. 四川化工, 2009, 12(5): 44 doi: 10.3969/j.issn.1672-4887.2009.05.013 [36] Sartor K, Restivo Y, Ngendakumana P, et al. Prediction of SOx and NOx emissions from a medium size biomass boiler. Biomass Bioenergy, 2014, 65: 91 doi: 10.1016/j.biombioe.2014.04.013 [37] Gao P. Experiments and Mechanism Study of Advanced Reburning and Selective Non-catalytic Reduction on NO Removal[Dissertation]. Jinan: Shandong University, 2008高攀. 先進再燃及選擇性非催化脫硝優化實驗與機理研究[學位論文]. 濟南: 山東大學, 2008 [38] Hao J T. High Level Reburning Denitrification Test of Biomass and Chemical Kinetics Simulation of NO Reduction[Dissertation]. Nanjing: Nanjing Normal University, 2014郝江濤. 生物質高級再燃脫硝試驗及NO還原化學動力學模擬[學位論文]. 南京: 南京師范大學, 2014 [39] Gao J, Wang Y, Zhang B. Countermeasure of atmospheric nitrogen oxide pollution in China. Environ Prot Sci, 2004, 30(5): 1 doi: 10.3969/j.issn.1004-6216.2004.05.001高婕, 王禹, 張蓓. 我國大氣氮氧化物污染控制對策. 環境保護科學, 2004, 30(5): 1 doi: 10.3969/j.issn.1004-6216.2004.05.001 [40] Yang N, Wang X. Nitrogen oxide pollution and its prevention and control. Environmental Protection Circular Economy, 2010, 30(11): 63 doi: 10.3969/j.issn.1674-1021.2010.11.022楊楠, 王雪. 氮氧化物污染及防治. 環境保護與循環經濟, 2010, 30(11): 63 doi: 10.3969/j.issn.1674-1021.2010.11.022 [41] Committee of Desulfurization and Dust Removal of Boiler and Kiln. China development report on desulfurization&denitration industry of power plant in 2009. China Environ Prot Ind, 2010(6): 17 doi: 10.3969/j.issn.1006-5377.2010.06.005中國環境保護產業協會鍋爐爐窯脫硫除塵委員會. 我國火電廠脫硫脫硝行業2009年發展綜述. 中國環保產業, 2010(6): 17 doi: 10.3969/j.issn.1006-5377.2010.06.005 [42] Hao J M, Ma G D, Wang S X. Air Pollution Control Engineering. Beijing: Higher Education Press, 2010郝吉明, 馬廣大, 王書肖. 大氣污染控制工程. 北京: 高等教育出版社, 2010 [43] Ministry of Environmental Protection, People's Republic of China. GB13271-2014 Emission Standard of Air Pollutants for Boiler. Beijing: China Environmental Science Press, 2014中華人民共和國環境保護部. GB13271-2014鍋爐大氣污染物排放標準. 北京: 中國環境科學出版社, 2014 [44] Guan Q Y, Liao F L, Luo D S. Review on the development of bioenergy in China and the World. J Agric Mech Res, 2007(11): 20 doi: 10.3969/j.issn.1003-188X.2007.11.005官巧燕, 廖福霖, 羅棟燊. 國內外生物質能發展綜述. 農機化研究, 2007(11): 20 doi: 10.3969/j.issn.1003-188X.2007.11.005 [45] Xie Z H. China Circular Economy Yearbook. Beijing: Chinese Financial&Economic Publishing House, 2008解振華. 中國循環經濟年鑒. 北京: 中國財政經濟出版社, 2008 [46] Liu Z X, He X L. Analysis and comparison of biomass energy development under the Low-carbon economy in China. Ecol Econ, 2012(1): 117 https://www.cnki.com.cn/Article/CJFDTOTAL-STJJ201201026.htm劉志雄, 何曉嵐. 低碳經濟背景下我國生物質能發展分析及比較. 生態經濟(中文版), 2012(1): 117 https://www.cnki.com.cn/Article/CJFDTOTAL-STJJ201201026.htm [47] Yang Y. Study on Environmental Performance and Adaptability in China of Biomass Power Generation[Dissertation]. Nanjing: Nanjing University of Information Science & Technology, 2011楊艷. 生物質發電環保性能及在我國的適應性研究[學位論文]. 南京: 南京信息工程大學, 2011 [48] Yang S. Low nitrogen combustion technical renovation of biomass boiler and NOx emission monitoring. Chem Eng Equip, 2015(7): 258 https://www.cnki.com.cn/Article/CJFDTOTAL-FJHG201507084.htm楊松. 生物質顆粒工業鍋爐低氮燃燒技術改造及NOx排放監測. 化學工程與裝備, 2015(7): 258 https://www.cnki.com.cn/Article/CJFDTOTAL-FJHG201507084.htm [49] Wang Q C. Experimental Study on Pyrolysis and Carbonization of Biomass at Low Temperature and Its Reburning Denitrification[Dissertation]. Nanjing: Nanjing Normal University, 2012王秦超. 生物質低溫熱解炭化及其再燃脫硝特性的試驗研究[學位論文]. 南京: 南京師范大學, 2012 [50] Adams B R, Harding N S. Reburning using biomass for NOx control. Fuel Process Technol, 1998, 54(1-3): 249 doi: 10.1016/S0378-3820(97)00072-6 [51] Liu H, Hampartsoumian E, Gibbs B M. Evaluation of the optimal fuel characteristics for efficient NO reduction by coal reburning. Fuel, 1997, 76(11): 985 doi: 10.1016/S0016-2361(97)00114-2 [52] Shi B G, Li Y L, Wang Y J. Study on automotive emission control technology. Urban Vehicles, 2005(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-CSCL200502013.htm石本改, 李岳林, 王藝娟. 汽車排放控制技術的研究. 城市車輛, 2005(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-CSCL200502013.htm [53] Guo F Q, Dong Y P, Dong L, et al. Design and low NOx emission effect of biomass briquette boiler with third air distribution type. Trans Chin Soc Agric Eng, 2012, 28(14): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201214009.htm郭飛強, 董玉平, 董磊, 等. 生物質成型燃料三次配風鍋爐的設計及低NOx排放效果. 農業工程學報, 2012, 28(14): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201214009.htm [54] Zhou H, Jensen A D, Glarborg P, et al. Formation and reduction of nitric oxide in fixed-bed combustion of straw. Fuel, 2006, 85(5-6): 705 doi: 10.1016/j.fuel.2005.08.038 [55] Luan J Y. Experimental Studies and Numerical Simulation on Reburning Process of Biomasses [Dissertation]. Haerbin: Harbin Institute of Technology, 2009欒積毅. 生物質再燃過程的試驗研究及數值模擬[學位論文]. 哈爾濱: 哈爾濱工業大學, 2009 [56] Ministry of Environmental Protection, People's Republic of China. Technical policy for the prevention and control of nitrogen oxides in thermal power plants[R/OL]. Ministry of Environmental Protection, People's Republic of China(2009-06-25)[2018-03-14]. http://www.mee.gov.cn/gkml/hbb/bgth/200910/t20091022_175013.htm中華人民共和國環境保護部. 火電廠氮氧化物防治技術政策(征求意見稿)編制說明[R/OL]. 中華人民共和國環境保護部(2009-06-25)[2018-03-14]. http://www.mee.gov.cn/gkml/hbb/bgth/200910/t20091022_175013.htm [57] Yao L Y, Zhang D G, Wang W, et al. Technology route on coal-fired industrial boilers NOx pollution prevention. North Environ, 2012, 24(4): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-NMHB201204037.htm姚立英, 張東國, 王偉, 等. 燃煤工業鍋爐氮氧化物污染防治技術路線. 北方環境, 2012, 24(4): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-NMHB201204037.htm [58] Niu S L, Han K H, Lu C M. Experimental study on the effect of urea and additive injection for controlling nitrogen oxides emissions. Environ Eng Sci, 2010, 27(1): 47 doi: 10.1089/ees.2008.0181 [59] Wang Y F. Experimental Study and Chemical Kinetics Modeling of Advanced Natrual Gas Reburning Nitrogen Oxides Reduction Mechanism[Dissertation]. Shanghai: Shanghai Jiao Tong University, 2008王亞飛. 天然氣高級再燃脫硝機理的實驗研究和化學動力學模擬[學位論文]. 上海: 上海交通大學, 2008 [60] Harding N S, Adams B R. Biomass as a reburning fuel: a specialized cofiring application. Biomass Bioenergy, 2000, 19(6): 429 doi: 10.1016/S0961-9534(00)00054-4 [61] Han K H, Niu S L, Lu C M. Experimental study on biomass advanced reburning for nitrogen oxides reduction. Process Saf Environ Prot, 2010, 88(6): 425 doi: 10.1016/j.psep.2010.07.002 [62] Gao J H, Zhang Y A, Gao Y. Choice of technical options about biomass boiler flue gas desulphurization and denitrification. Sulphur Acid Ind, 2017(8): 52 doi: 10.3969/j.issn.1002-1507.2017.08.013高勁豪, 張幼安, 高原. 生物質鍋爐煙氣脫硫脫硝技術方案選擇. 硫酸工業, 2017(8): 52 doi: 10.3969/j.issn.1002-1507.2017.08.013 [63] Xue J, Weng W G, Yu Y, et al. Study and analysis of denitrification technologies on 130 t/h full-biomass-fired boiler. Boiler Manuf, 2017(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-GLZZ201702008.htm薛軍, 翁衛國, 俞燕, 等. 130 t/h全燒生物質鍋爐脫硝技術研究及應用. 鍋爐制造, 2017(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-GLZZ201702008.htm [64] Li L M, Li Q P, Yu Y, et al. Research and application of denitration technology of flue gas from biomass CFB boiler. Energy Conserv, 2017(3): 47 doi: 10.3969/j.issn.2095-0802.2017.03.023李廉明, 李秋萍, 俞燕, 等. 生物質循環流化床鍋爐煙氣脫硝技術研究與應用. 節能, 2017(3): 47 doi: 10.3969/j.issn.2095-0802.2017.03.023 -

下載:

下載: