Research progress on solar energy storage water tanks based on phase-change materials

-

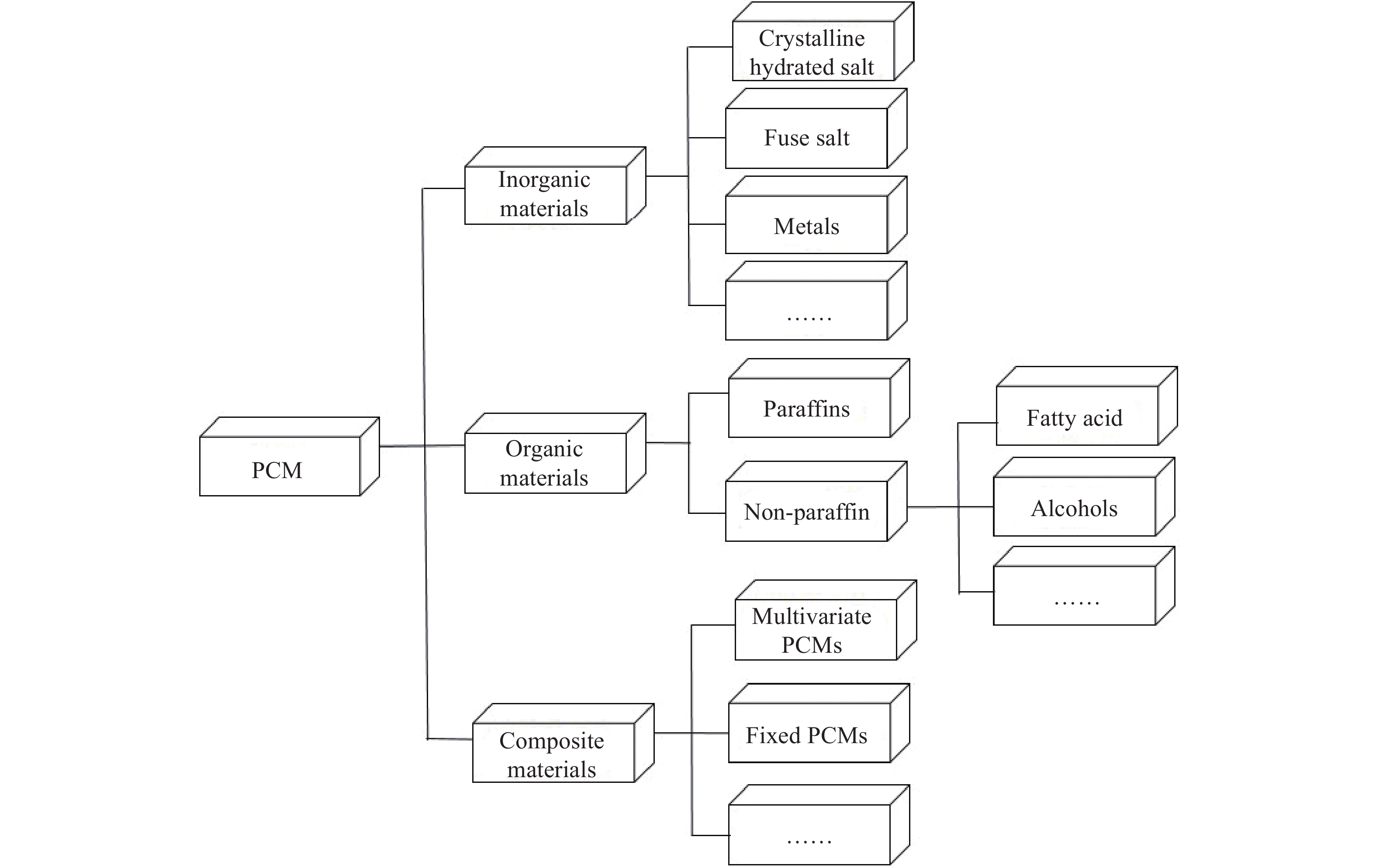

摘要: 在建筑節能領域,太陽能是一種備受青睞的清潔能源。然而,太陽能本身的不穩定性及不連續性極大的影響了其應用效果。相變儲能技術以其巨大的相變潛熱、相變過程溫度恒定等優點受到廣泛關注,是太陽能存儲技術中應用較為廣泛的一種技術。為總結相變儲能技術在太陽能存儲領域的應用效果及研究現狀,本文綜述了國內外基于相變儲能材料(PCM)的太陽能儲能水箱的研究進展。通過對太陽能相變儲能水箱中PCM的性能改進、相變儲能水箱結構優化設計、相變儲能水箱性能提升等問題的現有研究進行總結分析,歸納出目前基于PCM儲能的太陽能儲能水箱在應用中的優勢與不足。最后,提出改善太陽能相變儲能水箱性能的研究思路,分別對PCM的融化率、強化傳熱方法、技術經濟性、儲能水箱應用場景、多能耦合供熱性能匹配等問題進行了展望,旨在為太陽能相變儲能水箱的深入研究與應用提供幫助和借鑒。Abstract: In the field of building energy conservation, solar energy is a highly favored clean energy source. However, the instability and discontinuity of solar energy greatly affect its application. Phase-change energy storage technology is widely used for solar energy storage because of its huge latent heat and constant temperature during phase change. To summarize the application effect and research status of phase-change energy storage technology in the field of solar energy storage, this paper reviews the research progress on solar energy storage tanks based on phase-change energy storage materials at home and abroad. This paper focuses on the research progress on phase-change material (PCM) packaging technology from the aspects of geometry packaging and microcapsule encapsulation. The improvements in material thermal conductivity, supercooling and phase separation problems, and material cycle durability are summarized and analyzed. Moreover, this paper summarizes and analyzes the existing research on the structural optimization design of solar thermal storage tanks, stratification of solar phase-change energy storage tanks, storage performance of solar phase-change energy storage tanks, operation strategy of solar phase-change energy storage systems, and performance improvement of the solar heating system by a phase-change energy storage tank. The advantages and disadvantages of solar energy storage tanks based on PCM energy storage in applications are summarized. Finally, the research idea of improving the performance of solar phase-change energy storage tanks is proposed. First, it is suggested that further research should be conducted on the encapsulation technology and heat transfer enhancement technology of composite PCMs, and the economic problems of PCM preparation should be fully considered. Second, the problem that PCM cannot completely melt or solidify during heat storage and release should be comprehensively studied to further improve the energy release performance of the heat storage tank. Third, the structural design and operation strategy of solar phase-change energy storage tanks should be optimized. Finally, to further explore the application potential of solar phase-change energy storage tanks, it is necessary to develop a multi-energy coupled heating system based on a solar phase-change energy storage tank, study the cascade utilization of various energy sources such as photothermal, photoelectric, and electromagnetic heat, and improve the stability and energy conversion efficiency of the multi-energy coupled heating system. This study aims to provide a reference for further research on and application of solar phase-change energy storage tanks.

-

Key words:

- solar energy /

- energy storage /

- PCM /

- energy storage water tank /

- the research progress

-

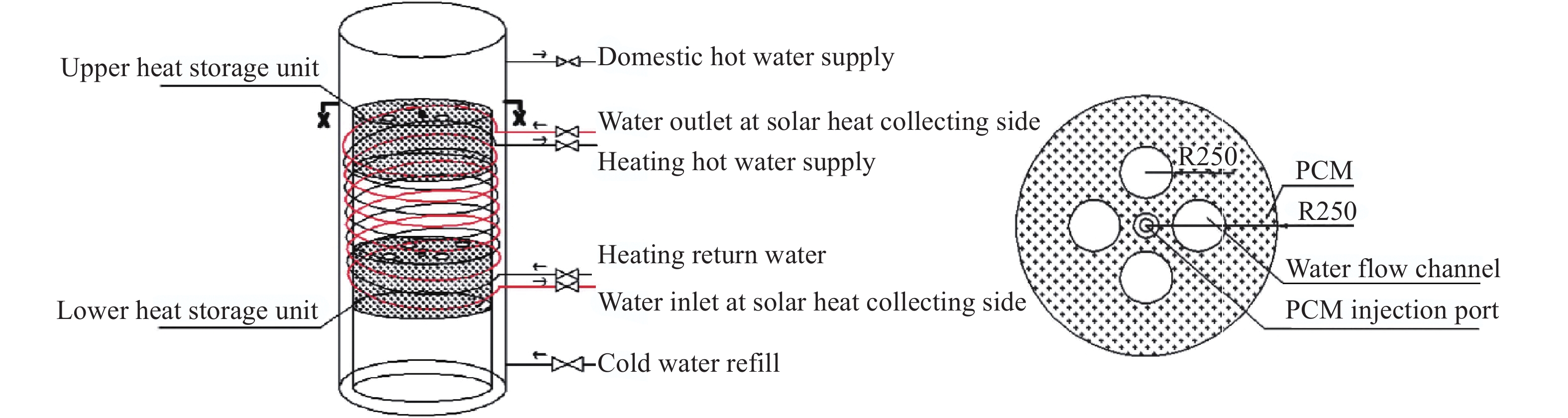

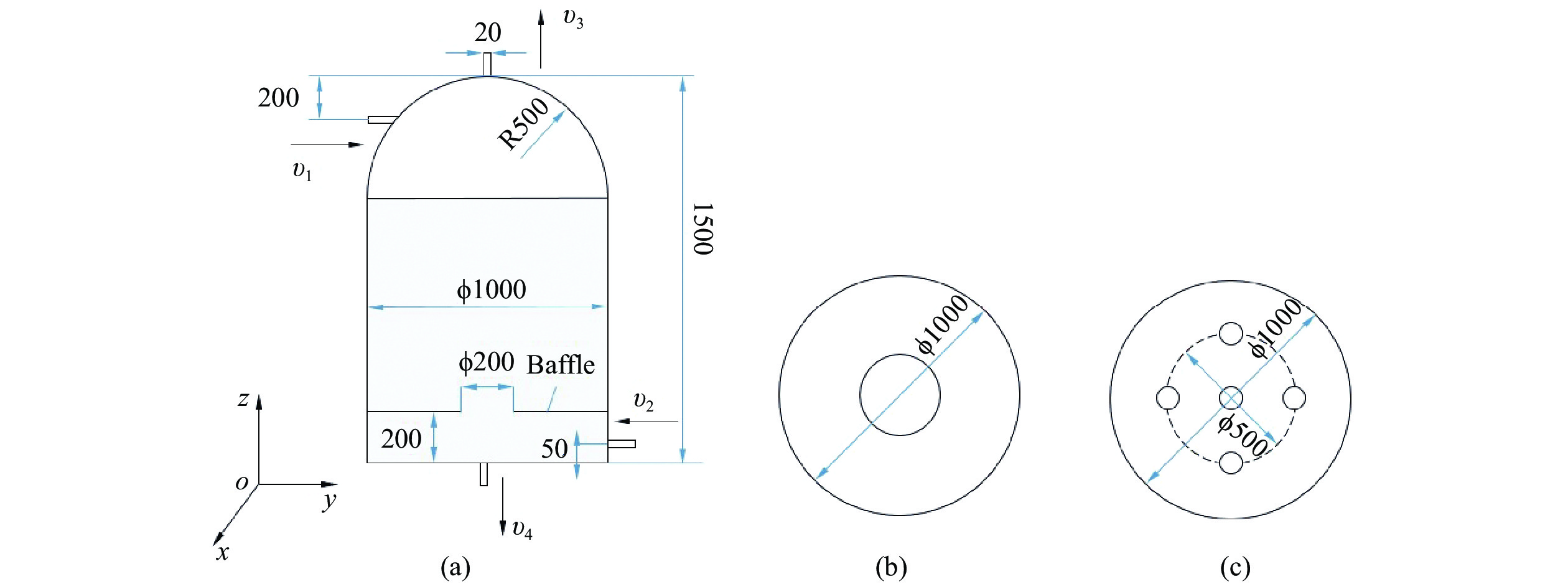

圖 5 蓄熱水箱、內置隔板物理模型及冷熱水流向示意圖[47]

Figure 5. Physical model of a thermal storage tank and built-in partition and schematic of the cold and hot water flow directions[47]

v1 and v3 are the hot water inlet and outlet flow velocities, respectively. v2 and v4 are the inlet and outlet flow velocities of cold water, respectively. The dimension unit is mm. 1 # tank has a conical top and a single round hole with a built-in partition structure, 2 # tank has a conical top and a multi-round hole with a built-in partition structure, and 3 # tank has a hemispherical top and a single round hole with built-in partition structure, R is the radius of the hemispherical top.(a) 3# Water tank shape structure; (b) 1# and 3# Water tank baffle structure; (c) 2# Water tank baffle structure.

表 1 相變儲能材料封裝方式分類及優缺點

Table 1. Classification and advantages and disadvantages of phase-change energy storage materials

Encapsulation

methodSpecific encapsulation

methodAdvantages Disadvantages Classification Application scope Geometry packaging A certain mass of the phase-change material (PCM) is encapsulated in a tubular or spherical plate or closed geometric containers of other shapes made of metal, plastic, or films that do not react with the PCM. The preparation process is simple and easy to transport Leakage and corrosion of metal materials may occur Plate type, shell type, cylindrical type, ball type, and irregular geometry Widely used in most organic and inorganic PCMs Microencapsulation The PCM is a solid or liquid coated with film-forming microparticles to form a core–shell structure. Stable structure and good thermal conductivity The preparation process is complex, and the cost is high In situ polymerization, interface polymerization, suspension polymerization, emulsion polymerization, and sol–gel method Paraffin, fatty acids, and other organic composite PCM 表 2 PCM封裝形式示意圖

Table 2. Schematics of phase-change material encapsulation form

Encapsulation method Name of PCM Schematic diagram of encapsulation

method and SEM diagramDevice name Source of reference Geometry packaging Unknown PCM

Regenerative sphere [3] Lauric acid

Inverted conical structure PCM package [5] Decylic acid

Concentric tube bundle-type air phase-change accumulator [7] Paraffin

Condenser heat accumulator unit [8] Microencapsulation N-octadecane

N-octadecane - melamine formaldehyde resin microcapsule PCM [9, 10] Lauric acid - myristic acid

Lauric acid - myristic acid - expanded graphite microcapsule PCM [11] N-decane

N-decane + calcium carbonate microcapsule PCM [12] Decylic acid

Melamine - urea-formaldehyde [13] 表 3 部分關于相變儲能材料性能提升的研究成果

Table 3. Research on the performance improvement of phase-change energy storage materials

Phase-change material substrate Additive Thermal conductivity/

(W·m?1·K?1)Phase-change temperature/℃ Latent heat of phase change/ (J·g?1) Complex method Source of reference Paraffin Expanded graphite (EG) 2%–10%(mass fraction) Before adding 0.22 40.2 178.3 Impregnation method [14] After adding 0.40, 0.52, 0.68, 0.82 Polyethylene glycol (PEG) SWNT Before adding 0.267 51–52 90–103 Vacuum vapor deposition method [15] After adding 0.312 Palmitic acid - stearic acid (PA-SA) Carbon nanotube (CNT) 5%–8%(mass fraction) Before adding 0.263 53–54 165–179 Melt blending method [16] After adding 0.316, 0.332, 0.332, 0.341 Stearic acid (SA) Graphene Before adding 0.205 71–72 181–195 Emulsion technique [17] After adding 0.245–0.335 Pentacylglyceride (PG) Expanded graphite (EG) Before adding 0.232 76–82 163.8

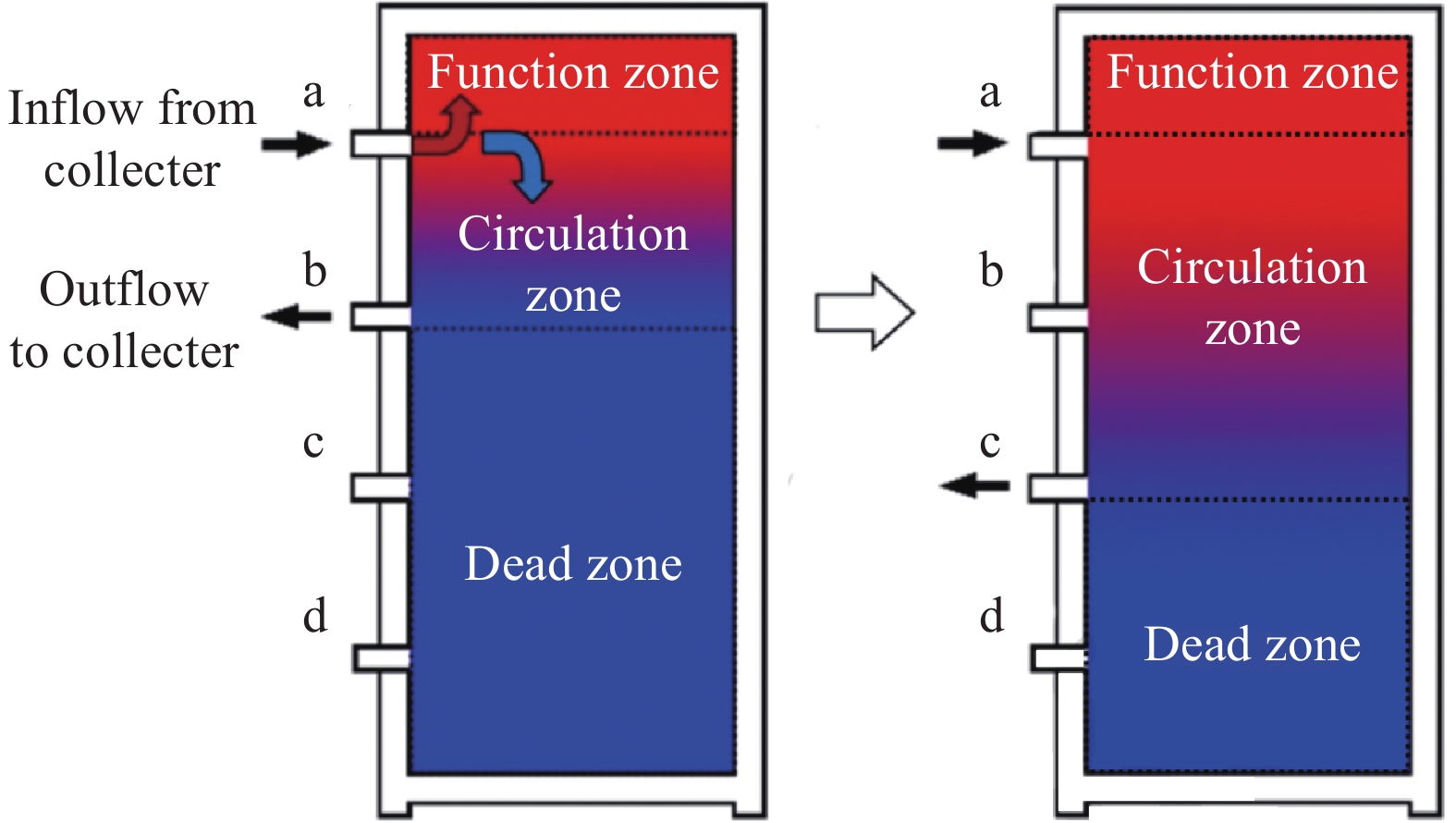

161.6

160.1Melt blending method [18] After adding 0.647, 0.863, 0.944 Stearic acid/n-octadecane (SA-ODE) — — 27.4 227 Blending method [19] N-undecane/calcium carbonate Emulator Before adding 0.152 22 and 32.19 134.83 Microenc apsulation [12] After adding 1.283 Sodium acetate trihydrate (SAT) Starch — 54.7 180–189 Melt blending method [20] Bentonite — 56.4 153–161 Methyl hydroxyethyl cellulose — 55.1 165 Sodium sulfate decahydrate Sodium carboxymethyl cellulose, vapor white carbon black, borax, and sodium chloride — 27–31 134–157 Melt blending method [21] Sodium acetate trihydrate (SAT) Nanoalumina, nanocopper, and carbon nanotubes Before adding 0.6 58 243–252 [22] After adding 0.4453–0.6698 Myristic acid Silicon dioxide, sodium dodecyl benzene sulfonate (SDBS) Before adding 0.18 48–56 190 Bending method [23] After adding 0.26–0.38 259luxu-164<th id="5nh9l"></th> <strike id="5nh9l"></strike> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <strike id="5nh9l"></strike> <progress id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"><noframes id="5nh9l"> <th id="5nh9l"></th> <strike id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <progress id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"><span id="5nh9l"></span> <strike id="5nh9l"><noframes id="5nh9l"><strike id="5nh9l"></strike> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"><noframes id="5nh9l"> <span id="5nh9l"></span> <span id="5nh9l"><video id="5nh9l"></video></span> <th id="5nh9l"><noframes id="5nh9l"><th id="5nh9l"></th> <progress id="5nh9l"><noframes id="5nh9l"> -

參考文獻

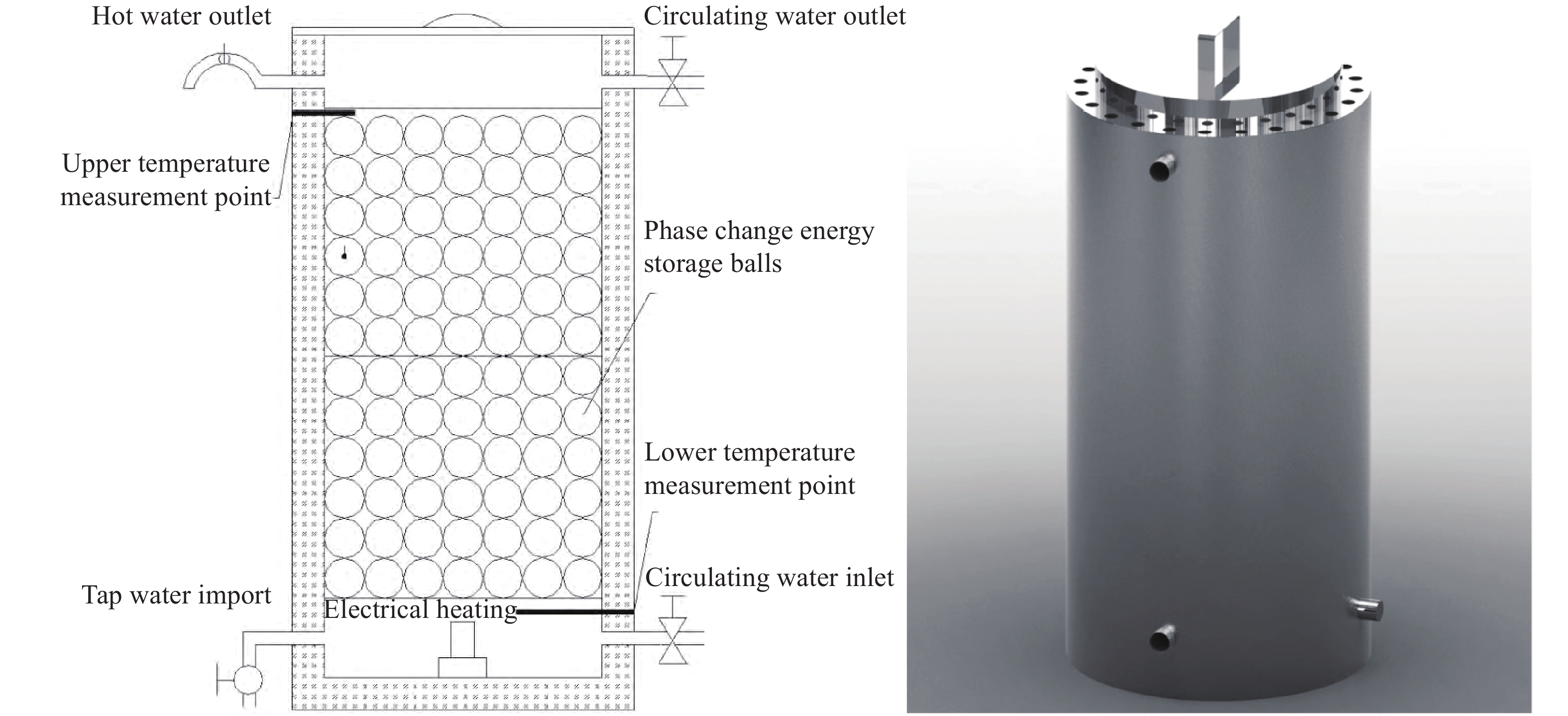

[1] Seddegh S, Wang X L, Henderson A D, et al. Solar domestic hot water systems using latent heat energy storage medium: A review. Renew Sustain Energy Rev, 2015, 49: 517 doi: 10.1016/j.rser.2015.04.147 [2] Telkes M, Raymond E. Storing solar heat in chemicals. Heat Vent, 1949, 46: 80 [3] Cui H T, Wang Z H, Guo Y S, et al. Experimental study on heat performance of new phase change thermal energy storagy unit. Acta Energiae Solaris Sin, 2009, 30(10): 1188崔海亭, 王振輝, 郭彥書, 等. 圓柱形相變蓄熱器蓄/放熱性能實驗研究. 太陽能學報, 2009, 30(10):1188 [4] Fang G H, Zhang W, Liu D H, et al. Experimental study on heat storage and exothermic of phase change heat storage device based on spherical package. Build Sci, 2020, 36(10): 134方桂花, 張偉, 劉殿賀, 等. 基于球形封裝的相變儲熱裝置的蓄放熱實驗研究. 建筑科學, 2020, 36(10):134 [5] Yu Z, Wang J, Yan Z J, et al. Study on improvement and melting performance of phase change material encapsulated structure in domestic hot water tank. J Hunan Univ(Nat Sci), 2021, 48(11): 215俞準, 王姜, 嚴中俊, 等. 生活水箱內相變材料封裝結構改進及熔化性能研究. 湖南大學學報(自然科學版), 2021, 48(11):215 [6] Carmona M, Rincón A, Gulfo L. Energy and energy model with parametric study of a hot water storage tank with PCM for domestic applications and experimental validation for multiple operational scenarios. Energy Convers Manage, 2020, 222: 113189 doi: 10.1016/j.enconman.2020.113189 [7] Yan T, Gao J J, Xu X H. Study on quasi-steady-state heat transfer model for casing pipe-encapsulated PCM. Build Sci, 2017, 33(10): 143嚴天, 高佳佳, 徐新華. 套管封裝相變材料準穩態傳熱模型研究. 建筑科學, 2017, 33(10):143 [8] Huang K L, Chang Q P, Song J S, et al. Analysis of influence factors to heat transfer of concentric tube air type phase change heat accumulator. Fluid Mach, 2018, 46(11): 74黃凱良, 萇群鵬, 宋嘉森, 等. 同心管束式空氣型相變蓄熱器換熱影響因素分析. 流體機械, 2018, 46(11):74 [9] Pan L, Tao Q H, Zhang S D, et al. Preparation, characterization and thermal properties of micro-encapsulated phase change materials. Sol Energy Mater Sol Cells, 2012, 98: 66 doi: 10.1016/j.solmat.2011.09.020 [10] Wang Y, Liu Z M, Niu X F, et al. Preparation, characterization, and thermal properties of microencapsulated phase change material for low-temperature thermal energy storage. Energy Fuels, 2019, 33(2): 1631 doi: 10.1021/acs.energyfuels.8b02504 [11] Li L, Li D X, Liu Y, et al. Preparation and characterization of lauric acid-myristic acid/expanded graphite composite encapsulated phase change energy storage material. Acta Energiae Solaris Sin, 2016, 37(10): 2627李琳, 李東旭, 劉洋, 等. 月桂酸?肉豆蔻酸/膨脹石墨封裝復合相變儲能材料的制備及表征. 太陽能學報, 2016, 37(10):2627 [12] Zhang Q W, Liu C Z, Rao Z H. Preparation and characterization of n-nonadecane/CaCO3 microencapsulated phase change material for thermal energy storage. ChemistrySelect, 2019, 4(29): 8482 doi: 10.1002/slct.201901436 [13] Konuklu Y, Paksoy H O, Unal M, et al. Microencapsulation of a fatty acid with Poly(melamine–urea–formaldehyde). Energy Convers Manag, 2014, 80: 382 doi: 10.1016/j.enconman.2014.01.042 [14] Sar? A, Karaipekli A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl Therm Eng, 2007, 27(8-9): 1271 doi: 10.1016/j.applthermaleng.2006.11.004 [15] Wang Y M, Tang B T, Zhang S F. Single-walled carbon nanotube/phase change material composites: Sunlight-driven, reversible, form-stable phase transitions for solar thermal energy storage. Adv Funct Mater, 2013, 23(35): 4354 doi: 10.1002/adfm.201203728 [16] Zhang N, Yuan Y P, Yuan Y G, et al. Effect of carbon nanotubes on the thermal behavior of palmitic-stearic acid eutectic mixtures as phase change materials for energy storage. Sol Energy, 2014, 110: 64 doi: 10.1016/j.solener.2014.09.003 [17] Dao T D, Jeong H M. Novel stearic acid/graphene core-shell composite microcapsule as a phase change material exhibiting high shape stability and performance. Sol Energy Mater Sol Cells, 2015, 137: 227 doi: 10.1016/j.solmat.2015.02.009 [18] Zhang N, Song Y L, Du Y X, et al. A novel solid-solid phase change material: Pentaglycerine/expanded graphite composite PCMs. Adv Eng Mater, 2018, 20(10): 1800237 doi: 10.1002/adem.201800237 [19] Shen J F, Hu Z J, Wang C M, et al. Preparation and thermal properties of stearic acid/n-octadecane binary eutectic mixture as phase change materials for energy storage. ChemistrySelect, 2019, 4(14): 4125 doi: 10.1002/slct.201900415 [20] Cabeza L F, Svensson G, Hiebler S, et al. Thermal performance of sodium acetate trihydrate thickened with different materials as phase change energy storage material. Appl Therm Eng, 2003, 23(13): 1697 doi: 10.1016/S1359-4311(03)00107-8 [21] Li H X, He N, Chen Q Z, et al. The preparation of Na2SO4·10H2O phase change energy storage system. J Shenyang Jianzhu Univ(Nat Sci), 2013, 29(3): 513李慧星, 赫娜, 陳其針, 等. 新型Na2SO4·10H2O相變儲能體系的制備. 沈陽建筑大學學報(自然科學版), 2013, 29(3):513 [22] Du X D, Zhang X L, Ding J H, et al. Effects of nanoparticles nucleating agents on the performance of sodium acetate trihydrate. Build Energy Effic, 2017, 45(9): 25杜曉冬, 章學來, 丁錦宏, 等. 納米成核劑對三水醋酸鈉蓄熱性能的影響. 建筑節能, 2017, 45(9):25 [23] Harikrishnan S, Devaraju A, Sivasamy P, et al. Experimental investigation of improved thermal characteristics of SiO2/myristic acid nanofluid as phase change material (PCM). Mater Today Proc 2019, 9: 397 [24] Hu Z P. Melting Characteristic-Based Study on Melting Heat Transfer Enhancement of the Traditional Thermal Storage Units [Dissertation]. Xi’an: Xi’an University of Architecture and Technology, 2015胡志培. 基于相變材料熔化特性的蓄熱裝置強化傳熱研究[學位論文]. 西安: 西安建筑科技大學, 2015 [25] Li A G, Shi B J, Zhang W Q, et al. Structure optimization of phase change thermal storage water tank based on solar energy utilization. Acta Energiae Solaris Sin, 2020, 41(2): 217李安桂, 史丙金, 張婉卿, 等. 基于太陽能利用的相變蓄熱水箱結構優化. 太陽能學報, 2020, 41(2):217 [26] Xia L. Preparation of Composite Phase Change Material and Study on the Thermo-physical Phenomena in the Latent Thermal Energy Storage [Dissertation]. Shanghai: Shanghai Jiao Tong University, 2011夏莉. 復合相變儲能材料的研制與潛熱儲能中熱物理現象的研究[學位論文]. 上海: 上海交通大學, 2011 [27] Bouzaher M T, Bouchahm N, Guerira B, et al. On the thermal stratification inside a spherical water storage tank during dynamic mode. Appl Therm Eng, 2019, 159: 113821 doi: 10.1016/j.applthermaleng.2019.113821 [28] Wang Y, Lin H X, Hu Y, et al. Optimization of structure and operation parameters in solar energy storage water tank with hemispherical top and internal staggered obstacle. Energy Storage Sci Technol, 2020, 9(3): 942王燁, 藺虎相, 胡悅, 等. 半球形頂太陽能蓄熱水箱內置錯層隔板結構及運行參數優化. 儲能科學與技術, 2020, 9(3):942 [29] Liu K, Cai Y L. A new type of phase change heat storage tank in solar energy combination system. Energy Storage Sci Technol, 2019, 8(6): 1230劉凱, 蔡穎玲. 一種新型相變蓄熱水箱應用于太陽能組合系統的實驗研究. 儲能科學與技術, 2019, 8(6):1230 [30] He M M, Huang Z W, Xuan Y M. Research and development trends of temperature stratified storage tank in solar water heating systems. Contam Control Air Cond Technol, 2014(4): 16賀淼淼, 黃志偉, 宣永梅. 太陽能熱水系統中蓄熱水箱溫度分層研究及發展趨勢. 潔凈與空調技術, 2014(4):16 [31] Huang Z, Wang Z L, Zhang H, et al. Experimental analysis on stratification characteristics of different structure tanks. Chem Ind Eng Prog, 2018, 37(1): 44黃震, 王子龍, 張華, 等. 不同結構儲熱水箱分層特性的實驗研究. 化工進展, 2018, 37(1):44 [32] Huang H J, Wang Z L, Zhang H, et al. CFD simulation and exeperiment research on thermal stratification of hot water storage tank with eaualizer. Acta Energiae Solaris Sin, 2020, 41(6): 348黃華杰, 王子龍, 張華, 等. 均流結構蓄熱水箱熱特性的模擬與實驗研究. 太陽能學報, 2020, 41(6):348 [33] Li J R, Li X D, Du R Q, et al. A new design concept of thermal storage tank for adaptive heat charging in solar heating system. Appl Therm Eng, 2020, 165: 114617 doi: 10.1016/j.applthermaleng.2019.114617 [34] Wang D J, Liu Y F. Temperature stratification studying of heat storage tank. Build Energy Environ, 2010, 29(1): 16王登甲, 劉艷峰. 太陽能熱水采暖蓄熱水箱溫度分層分析. 建筑熱能通風空調, 2010, 29(1):16 [35] Cheng Y L, Wang J S, Liu M, et al. Numerical simulation optimization analysis of solar thermal storage layered water tank. Renew Energy Resour, 2019, 37(10): 1448程友良, 王敬雙, 劉萌, 等. 太陽能蓄熱分層水箱數值模擬優化分析. 可再生能源, 2019, 37(10):1448 [36] Zhang Q D, Zhang H, Wang Z L, et al. Experimental study on the effect of phase change thermal storage ball on thermal stratification of water tank. J Refrig, 2020, 41(2): 144張喬丹, 張華, 王子龍, 等. 相變蓄熱球對水箱熱分層特性影響的實驗研究. 制冷學報, 2020, 41(2):144 [37] Zhang Y X, Li S H, Cao K, et al. Numerical analysis of the discharging performance of a solar energy storage tank containing PCM modules. Energy Storage Sci Technol, 2013, 2(4): 377張永信, 李舒宏, 操愷, 等. 太陽能相變儲能水箱釋能性能的數值模擬. 儲能科學與技術, 2013, 2(4):377 [38] Jadhav I B, Bose M, Bandyopadhyay S. Optimization of solar thermal systems with a thermocline storage tank. Clean Technol Environ Policy, 2020, 22: 1069 doi: 10.1007/s10098-020-01849-4 [39] Samet A, Ben Souf M A, Fakhfakh T, et al. Numerical investigation of the baffle plates effect on the solar water storage tank efficiency. Energy Sources A, 2020, 42(16): 2034 doi: 10.1080/15567036.2019.1607925 [40] Feng G H, Zhu Y H, Huang K L, et al. Heat storage and release performance simulation and multiple factors analysis in phase change energy storage tank. J Shenyang Jianzhu Univ(Nat Sci), 2016, 32(4): 675馮國會, 朱玉華, 黃凱良, 等. 相變儲能水箱蓄放熱性能多因素模擬分析. 沈陽建筑大學學報(自然科學版), 2016, 32(4):675 [41] Touati B, Kerroumi N, Virgone J. Solar thermal energy discharging from a multiple phase change materials storage tank. Appl Sol Energy, 2017, 53(2): 185 doi: 10.3103/S0003701X17020141 [42] Lu S L, Zhang T S, Chen Y F. Study on the performance of heat storage and heat release of water storage tank with PCMs. Energy Build, 2018, 158: 1770 doi: 10.1016/j.enbuild.2017.10.059 [43] Chen Y F. Study on the Performance of A Novle Phase Change Thermal Storage Water Tank [Dissertation]. Tianjin: Tianjin University, 2017陳亞飛. 新型相變蓄熱型熱水箱性能研究[學位論文]. 天津: 天津大學, 2017 [44] Hua W S, Zhang X L, Ding J H, et al. Design and thermal performance study on water/PCM compound heat storage water tank. Build Energy Effic, 2016, 44(11): 108華維三, 章學來, 丁錦宏, 等. 復合蓄熱式水箱的設計及蓄放熱研究. 建筑節能, 2016, 44(11):108 [45] Wolfson R L T, Harvey H S. Experimental comparison of control strategies for solar energy systems incorporating dual storage tanks. J Sol Energy Eng, 1981, 103(1): 47 doi: 10.1115/1.3266207 [46] Li X X. Research on Dynamic Characteristic and Control Strategy of Solar Heating System with Seasonal Thermal Energy Storage [Dissertation]. Lanzhou: Lanzhou University of Technology, 2021李曉霞. 太陽能跨季節儲/供熱系統動態特性及運行策略研究[學位論文]. 蘭州: 蘭州理工大學, 2021 [47] Wang Y, Sun Z D, He T, et al. Combined operation mode of the solar hot water storage tank. J Chongqing Univ, 2021, 44(6): 109王燁, 孫振東, 何騰, 等. 太陽能蓄熱水箱聯合運行模式研究. 重慶大學學報, 2021, 44(6):109 [48] Qu S L, Sun Z F, Ji Y B, et al. Influence analysis and experimental study of heat storage water tank on performance characteristics of solar energy-water source heat. Acta Energiae Solaris Sin, 2012, 33(8): 1405曲世琳, 孫峙峰, 吉玉保, 等. 蓄熱水箱對太陽能?水源熱泵系統性能特性的影響分析及實驗研究. 太陽能學報, 2012, 33(8):1405 [49] Wang Y B, Quan Z H, Xu Z H, et al. Heating performance of a novel solar-air complementary building energy system with an energy storage feature. Sol Energy, 2022, 236: 75 doi: 10.1016/j.solener.2022.02.054 [50] Lin R S, Tian B S, Shao J X, et al. Application research on PCM thermal storage in solar heating. Energy Conserv Technol, 2018, 36(5): 447藺瑞山, 田斌守, 邵繼新, 等. 相變儲熱在太陽能采暖中的應用研究. 節能技術, 2018, 36(5):447 [51] Ko?elj R, Mlakar U, Zavrl E, et al. An experimental and numerical analysis of an improved thermal storage tank with encapsulated PCM for use in retrofitted buildings for heating. Energy Build, 2021, 248: 111196 doi: 10.1016/j.enbuild.2021.111196 [52] Prasanth N, Sharma M, Yadav R N, et al. Designing of latent heat thermal energy storage systems using metal porous structures for storing solar energy. J Energy Storage, 2020, 32: 101990 doi: 10.1016/j.est.2020.101990 [53] Qin D, Yu Z, Yang T T, et al. Thermal performance evaluation of a new structure hot water tank integrated with phase change materials. Energy Procedia, 2019, 158: 5034 doi: 10.1016/j.egypro.2019.01.659 [54] Mazman M, Cabeza L F, Mehling H, et al. Utilization of phase change materials in solar domestic hot water systems. Renew Energy, 2009, 34(6): 1639 doi: 10.1016/j.renene.2008.10.016 -

下載:

下載: